What is a chimney draft regulator?

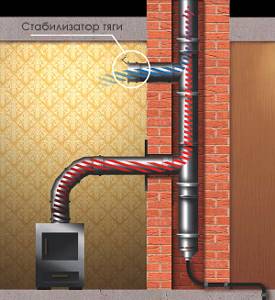

The concept of a stabilizer refers to a special mechanism, the main function of which is to supply air to the chimney in equal portions. This is how good traction is ensured, which is an integral part of the normal operation of the heating device. Thanks to a special safety valve, your equipment will be protected from excessive pressure; this part will control it and keep it normal.

Regulators, which are made of stainless steel, are universal; they are successfully used for any heat-generating device. They are easy to install and have proven themselves to be reliable and durable devices.

Purpose and scope of application

The functionality of the chimney determines such parameters as the quality of room heating, the level of correct energy consumption, and the safety of operation of heat-generating equipment. It is necessary to constantly monitor the draft force in the smoke exhaust duct, since:

- in the absence of draft or weak flow, it is problematic to light a fire,

- backflow of combustion products is fraught with consequences hazardous to health,

- When the intensity of outgoing flows is critical, the level of heat loss increases significantly.

The main reasons for thrust variability are determined by the following factors:

- Fluctuations in atmospheric temperatures. In hot weather, the stream in the chimney overturns and the flows move in the opposite direction. When the outside air is cold, the outflow of gases increases.

- Changes in air pressure. Changing atmospheric pressure parameters affects the intensity of the jet in the gas outlet channel.

- Chimney height parameters. The amount of vacuum at the top point of the smoke exhaust duct depends on the height of the pipe. The more significant this parameter, the stronger the thrust.

- Features of the smoke exhaust duct device. The length, the presence of bends, the roughness of the inner surface, the presence of foreign objects and deposits on the walls cause deterioration in traction.

Equipping the exhaust duct with an automatic regulator allows you to neutralize all the above-mentioned risks and improve the potential of a heat-generating device of any model, including condensing-type devices. Draft stabilizers are widely used in individual heating systems in Moscow and other regions.

Industrial traction stabilizer

Purpose and principle of operation

The uninterrupted operation of the chimney and draft are directly dependent on the weather and time of year. In case of sudden changes in temperature conditions during the winter season, in windy weather, the draft increases greatly. In order to maintain the optimal temperature in the room, you will have to spend more fuel, which will negatively affect the functioning of the entire smoke exhaust system.

Using a stabilizer, you will be able to maintain suitable values and not allow them to exceed the norm, which means that the operation of your heating device will be as productive as possible.

In addition to weather conditions, the quality of traction also depends on atmospheric air pressure, which can change at any moment due to the weather, time of day, year, and the place in which the house is located.

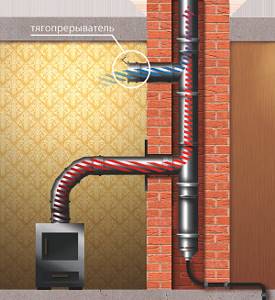

The operating principle of a chimney draft stabilizer is quite simple. Suppose the force or level reaches above normal, the device automatically begins to turn the valve, thereby reducing the pressure level. In such a situation, the incoming air is mixed with gases. The regulator will hold the limiter stopper in this position until the temperature reaches normal. Then it will automatically close in the pipe with a draft breaker and the system will begin to operate in the previous mode.

When traction is not enough

Methods for determining thrust

If you doubt that the chimney draft of a stove, fireplace or boiler is sufficient, you need to check it. The easiest way is to check it yourself using an anemometer. If the device shows a thrust of 10-20 PA, then this is considered normal. The problem with this method is the low measurement accuracy of cheap anemometers; when the draft is up to 1 PA, the device will show its complete absence, which is not entirely true. Professional appliances are not cheap; they are used by stove makers.

If you do not have an anemometer, use one of the popular methods for determining chimney draft:

. The most obvious sign of a lack of draft is the presence of a small amount of smoke indoors; a large amount of smoke indicates a high risk of fire and the risk of food poisoning.

Smoke- Flame color . By the color of the flame, you can understand the level of draft. If the flame inside the stove has a white tint and cracks when burning, then the draft is very powerful. An orange-red color indicates a lack of traction. If the chimney is made correctly, the flame should have an even golden color fading to yellow.

- With a match . You need to bring a lit match to the heater. If the flame deviates towards the stove, then there is draft. If it remains level, then you can be sure that there is traction, but of average magnitude. When the flame deviates in the opposite direction from the stove, a backdraft occurs in the chimney.

- With a mirror . Another way to check the draft force in the chimney is to place a small mirror against the stove. The occurrence of condensation on the surface of the mirror indicates that smoke removal is difficult.

Attention!

The difference in pressure outside and indoors is the basis for creating draft inside the chimney duct. The temperature in a heated room is higher than outside, and, consequently, the pressure it creates inside the room is greater. Hot air, supported by colder air from below, is squeezed into a zone with lower pressure, that is, into the atmosphere. When measurements are taken in summer, the temperature difference is least striking, therefore the draft will be worse and the measurement results may be low relative to the winter period.

Causes of malfunctions

Once you are sure that there is not enough draft inside the chimney, it is necessary to identify and correct the possible cause. Professionals say the most common causes of smoke duct failures are.

Error in design

To make a choice of chimney pipe, you need to focus on the volume of the firebox. If the size is smaller than the calculated parameter, then a weak chimney will not allow smoke to escape from the room.

Short pipe length

A pipe length of less than 5 m does not make a significant difference between indoor and outdoor pressure, which creates weak draft.

Incorrect placement of the chimney pipe

A master stove maker advises laying the chimney vertically, as tight corners keep smoke inside the chimney, reducing draft.

Long horizontal sections

If when laying the chimney it is not possible to avoid horizontal sections, make sure that their length does not exceed 100 cm, otherwise an amplifier will be needed for this.

Incorrect position relative to the skate

The pipes are at the same level or above the roof. The comb in the windward position sharply reduces the draft force in the chimney.

Getting into the wind support zone

If there is a tall building near the house, it blocks the chimney from the wind, preventing the normal functioning of the chimney system.

Weather conditions

Often, a decrease in draft occurs due to a decrease in atmospheric pressure, moisture entering the chimney due to rain, fog or snow. But this is not critical, because all these are temporary phenomena.

The first step in identifying problems in your chimney is to eliminate the most obvious causes of lack of draft. During the inspection, you must be sure that the tightness of the connections of all pipe elements is at a high level and there is no accumulation of soot. Make sure there is no moisture in the chimneys and that the atmospheric pressure is normal.

Advantages

The automatic chimney draft regulator has a number of positive properties. With this device you will provide your heating system with:

- Safe operation of the boiler and the entire chimney system.

- Long service life.

- Much less harmful substances will be released into the atmosphere.

- When the valve is held half-open, air masses circulate unhindered.

- The stabilizer will function regardless of the method of traction - natural or forced.

- Fuel combustion occurs evenly, so there is no need to worry that the chimney may overheat.

- In weather accompanied by strong winds, there will be no pressure drops.

- There will be no unpleasant burning odors, because... the regulator will not allow them to enter the room.

- Loss of thermal energy is eliminated.

- You can install such a device even in low-temperature boilers.

Chimney draft stabilizer SWAG with tee

Operating principle

If draft increases in the chimney system, pressure rises. As soon as it reaches a certain level, the valve is activated. It opens the damper and draws more air from the room. It lowers the temperature inside the chimney, thereby reducing the pressure. As soon as the temperature and pressure drop to the required minimum, the valve closes and the air intake stops. This process allows the flame temperature to be kept within the required range so that the fuel burns at the required rate. There are several positive points that speak in favor of installing a traction stabilizer:

- greater system security;

- increase in service life;

- reduction of harmful emissions;

- less soot settling in the chimney;

- no sudden pressure changes.

Thanks to the traction stabilizer, there is better air circulation. This means that less combustion waste will settle on the walls of the chimney, which will reduce waste on cleaning it. With a stabilizer, you don’t have to worry that in windy weather there may be a sharp drop that will cause the flame to go in the opposite direction. There will no longer be a burning smell in the room where the heating boiler is installed. The temperature inside the chimney will be maintained within acceptable limits. This is important to prevent soot from igniting, which leads to severe fires. That is, the traction stabilizer guarantees additional safety of the entire system.

DIY chimney draft stabilizer

In order to build a draft regulator for a chimney with your own hands, you first need to acquire all the tools that will be useful during work.

You will need:

- a cylinder with a gaseous substance in the form of compressed argon;

- stainless steel sheets, which are made in the form of petals;

- stainless steel sheet, thickness 1.2 mm;

- welding machine;

- reinforcement or rod for an axle with a diameter of 8-10 mm;

- bolts, nuts, cogs;

- keys, screwdrivers, hammer, metal scissors.

In order to construct a stabilizer yourself, you need to use exclusively stainless steel. Zinc coating is not suitable at all in such a situation.

In order for the stabilizer to have a universal meaning, i.e. so that he can adjust and close the chimney, you need to perform the following sequence of actions:

- It is necessary to roll the pipe so that its length is approximately 300 mm.

- Next, you need to weld the joint with an overlap of up to 10 mm, and it is important that the length of the internal diameter is 115 mm or higher.

- At the next stage, the seams are thoroughly cleaned on both sides.

- You should then make a cutout on the valve that is equal to 15% of the cross-sectional area of the pipe.

- The next thing to do is to screw on the screw clamp, which will perform the function of rotating the petal 180°.

- In order for the valve to be easily turned, it must be equipped with a handle.

- Build a lip in the middle of the pipe.

You can read about a chimney made from sandwich pipes here.

Installing a stabilizer to increase chimney draft is a simple process. You need to equip special “legs” and a bottom where the chimney stabilizer itself rests.

If you do not have proper experience in such work, it is better to use the services of specialists. If you still decide to build such a device yourself, then carefully study the installation diagrams and drawings.

Many users ask the question: how to calculate the draft of a chimney? It is worth noting that this procedure is carried out mainly for industrial chimney structures. For private houses, this indicator does not play a significant role.

Possible problems during installation and ways to eliminate them

- The pipe is not located vertically. Deviations are allowed up to 10 cm per 1 m of product. Ideally, the slope should not exceed 1 cm per 1 m of rolled metal element.

- The pipe does not fit into the smoke duct due to gaps. All gaps must be sealed with a clay-sand mortar or sealant that can withstand heating of the pipe up to 1000 degrees. To fill existing leaky areas, you can use soaked asbestos, heat-resistant sealant or asbestos cord.

Ways to increase chimney draft

There are several ways to increase draft in a pipe:

- The first thing to do is clean the pipe. To do this, you can resort to the services of a chimney sweep or remove soot deposits from the inner surface of the chimney with your own hands using a metal stove brush.

- Everyone knows about the dependence of thrust on the height and diameter of the pipe. In this regard, the power of the chimney can be increased by increasing the height of the chimney above the roof surface, adding several additional segments to it. In the same way, the chimney is removed from the area of wind support from the ridge and a higher building.

- Exhaust pipe attachment to improve draft. This is a special device designed for automatic traction control. It is made in the form of an umbrella with a temperature sensor, which is mounted on the chimney pipe. The temperature sensor monitors the temperature of the exhaust gases and operates independently. The nozzle on the pipe to increase draft is responsible for maintaining the pressure in the chimney within 10-35 Pa, thereby optimizing the functioning of the heating device and the amount of fuel consumed.

- Use of a special deflector. Models of deflectors are produced that are made in a special aerodynamic shape. Due to the ability of air to reduce pressure, during the fall effect while passing an obstacle, a rarefaction area is formed in the deflector, which stimulates smoke to exit the pipe. However, such devices are effective only in windy weather.

Ready-made options

In cases where there is no time or opportunity to tinker with making a traction stabilizer yourself, you can purchase ready-made options. One of the good solutions that is on the market is Darco products. Its RCO model stabilizers are designed for round chimney pipes. They are attached to them using clamps. This draft stabilizer is mounted on the very edge of the chimney. Anyone can cope with this task. RCR series models will require installation during installation of the entire system or some modification. Such stabilizers are also attached with clamps, but directly at the boiler outlet.

Solutions have also been developed for chimneys with rectangular or square cross-sections. These are RCP series models. They will require making an additional hole in the chimney and sealing the stabilizer. If necessary, it automatically opens the air intake valve. Adjustment is allowed within the range from 10 to 35 Pa. Another representative for surface mounting are models of the RCW series. They are also suitable for brick or other rectangular chimneys.

Setup and calibration

The device built into the case needs to be configured. This is done as follows:

- the ash pan door opens almost completely;

- the locking screw on the regulator handle is loosened;

- the required temperature regime is set on the handle (60° is suitable for a start);

- the chain is attached to the lever;

- the boiler heats up to the set temperature (the boiler thermometer will indicate when it is reached);

- the door is closed, it is necessary to leave a gap of 2 mm;

- the end of the chain is attached to the door handle so that the free play is about 1 mm;

- The fixing screw on the regulator handle is tightened.

You can make sure that the draft regulator is adjusted correctly by changing the temperature conditions. To do this, the thermostat is turned to 80°. If the previously described steps are performed correctly, the damper will open, air will flow in, and combustion will intensify. Having reached the set temperature, the regulator will close the door again, leaving a gap of 2-3 mm.

It is advisable to adjust and calibrate the traction control more often. All devices have an error - this one is 5%. This is a non-critical deviation, but it is still worth checking the correct operation of the device from time to time.

Types of regulators and features of choice

If the solid fuel heater is not equipped with a draft regulator as standard, you will have to install the device yourself.

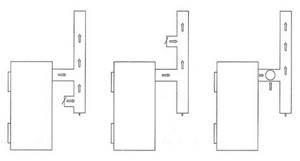

A prerequisite for this is

- the presence of a special sleeve mounted in the water jacket (the sleeve can be located on the top, front or side of the body);

- ash pan door opening upwards.

The type of device depends on the location of the sleeve - models are available that work only in a vertical position (mounted on top of the body), only in a horizontal position (mounted on the front or side panel) and universal.

On the left is a boiler with the ability to install a regulator, on the right is with manual control

When choosing a model, pay attention to the following parameters

- the force that the drive develops (the value is indicated in the passport, it should be sufficient to lift the ash pan door);

- temperature range for heating the coolant (60-90°C);

- the operating stroke of the drive (it should be sufficient to fully open and close the damper);

- type of threaded connection on the body - it must match the thread in the boiler unit sleeve (usually 3/4″).

The design of the draft regulator may provide for the repair or replacement of the actuator without dismantling the device itself and draining the coolant from the water jacket of the boiler. For such models, the immersion sleeve is removable.

Article on the topic: Mounting for heating radiators made of cast iron, steel, aluminum and bimetallic batteries

How to install and configure the regulator

To install the draft thermostat, it is necessary to free the boiler jacket from the coolant; for this purpose, as a rule, special taps are provided in the unit piping that cut off the circuit with the heating element. Otherwise, you will have to drain the entire volume of the system.

The next step is to remove the plug from the sleeve on the boiler, and install the prepared device in its place. After this, the system is filled with water again. To set up the draft regulator, you need to start the boiler for heat and perform a series of sequential actions.

- Open the damper to fully supply air to the firebox. In this case, the chain should not be connected yet.

- It is necessary to loosen the fixing screw on the adjustment handle.

- Select the position corresponding to the required temperature, for example, 70°.

- Noting the heating with a thermometer, connect the chain to the damper when the coolant reaches a temperature of 70°. The damper, in this position, should leave the hole open by only 2 mm.

- Finally, the fixing screw is tightened again.

After the structure is assembled, the draft regulator is checked in different operating modes from maximum to minimum. You should pause for the difference between reaching the set temperature and the moment the lever is activated, because firewood is not a gas and extinguishes smoothly. For this reason, you should not rush to set up the device again without pausing. After passing all checks, the installation of the draft regulator is considered completed.

A heterogeneous and complex concept that includes several factors is traction force. This parameter must be at the highest level in order for the device to operate stably. The way energy is generated and fuel is burned is influenced by the standard deviation of traction force indicators. Most often, owners of solid fuel boilers encounter this problem if there are irregularities in installation work. Prudent people purchase a draft regulator along with the equipment in order not to encounter such a problem.

The best known manufacturers and models: characteristics and prices

The market for solid fuel boilers is saturated with a large number of increasingly complex systems for automatically controlling the processes of heat production and hot water supply. They are more accurate and do not require user participation in most operations. However, such systems are becoming increasingly dependent on electricity and increasingly expensive to purchase and maintain. Autonomy, simplicity, quality of modern thermostats and low price make them quite popular and competitive.

ESBE ATA 212

One of the best draft regulators for a solid fuel boiler from a well-known Swedish manufacturer. Operates reliably in the range of 35˚-95˚С, operating temperatures from –20°C to +150°C. Can be used with various antifreezes, allows replacement of the thermostatic element. When used in low temperature environments, it requires heating. Can be installed in any position and does not require service. Inserts into a sleeve with 3/4" pipe thread. Weight 0.38 kg.

Cost: from 2800 rubles.

Regulus RT4

The most popular mechanical draft regulator for boilers burning solid fuel, due to its extreme unpretentiousness, ultra-reliability and low price. The body is made of die-cast brass, which guarantees a long service life. The device can be mounted in a vertical or horizontal position; the temperature level scale allows this. Coolant temperature control range 30–90°C, maximum operating temperature +120°C. Coupling for connection with internal thread G3/4”. Device weight 0.42 kg, manufacturer – Czech Republic.

Cost: from 1500 rubles.

Honeywell FR 124

High-quality mechanical thermostat from Germany, compatible with many boilers of domestic and foreign production. Water temperature control range is from +30 to +90°C, maximum operating temperature is +115°C. Chain load from 100 to 600 grams, lift stroke up to 60 mm. Standard installation in a bushing with a G 3/4″ thread. A special feature of this regulator is the presence of a removable immersion sleeve, to replace which it is not necessary to drain water from the boiler. Device weight 0.47 kg,

Cost: from 1900 rubles.

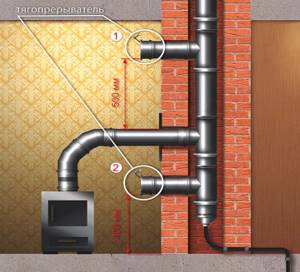

Regulator location

The chimney draft regulator must be located in the room where its heat source is located. The location directly on the pipe itself can be of two types:

- Installation at a distance of approximately 600 mm. from the final joining point of the chimney channel and the firebox or boiler furnace.

- The second installation method involves placing it directly flush with the stove, the distance must be at least 400 mm. from the base of the boiler. In simple terms, in this case, the stabilizer is installed directly on the first section of the pipe in the boiler room of the gas boiler.

Traction stabilizer location

For correct, and most importantly safe regulation, it is imperative to fill all voids and openings with heat-resistant sealant. By the way, it is allowed to use asbestos cement, which must be soaked with water before work.