What is it and what is it for?

Damper (from the German Schieber - damper) is a device for completely or partially blocking the movement of gases in the chimney. It has been used since the appearance of the first Russian stoves. Made from cast iron or steel. In modern engineering it has found application both in smoke exhaust structures and in ventilation systems.

Damper functions:

- Regulating draft and maintaining heat in the room.

The chimney is closed after use to prevent warm air from being drawn from the room into the chimney. Using a damper, you can reduce or increase the working cross-section of the chimney.

- Saving fuel consumption.

The valve can be used to regulate the intensity of oxygen flow to the flame, and accordingly increase or decrease the efficiency of the heater.

This statement is true only for furnaces and boilers without blowers and forced air supply devices.

Functions, purpose and characteristics

Being the main draft regulator inside the chimney, the damper regulates the combustion of fuel. To reduce the draft and reduce the intensity of the flame in the firebox, it is enough to close the slide valve. To increase traction, on the contrary, it is necessary to open it.

In fact, a gate is an ordinary metal plate that allows you to regulate traction.

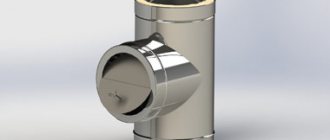

It can be installed both in single-wall and double-wall boiler systems.

If the fireplace and stove are not in use, then during this period the gate valve must be in the closed position.

But on the contrary, it is not recommended to install a valve on a section of a well-insulated chimney pipe. Especially when it comes to double-circuit pipes. When the metal of the inner and outer pipe expands, the gate valve may jam.

So, the main tasks of a gate valve are:

- Function of the draft regulator in the chimney.

- Partial blocking of the chimney channel section.

- Regulator of flame burning intensity in the firebox.

The gate valve is a thin metal plate that is manually adjusted using a special handle. The latter is located outside the chimney pipe so that the user can manually adjust the position of the plate.

Depending on the design and type of damper, it is installed using a special metal frame, or is inserted inside the pipe and fixed with an axial rod.

The damper in the chimney performs the following functions:

- increases traction force in difficult weather conditions;

- increases the intensity of combustion in the furnace due to increased oxygen flow;

- reduces draft when there is a strong hum in the chimney during strong winds;

- saves fuel by reducing combustion intensity;

- prevents heat loss after the heater has warmed up.

How the gate works

Structurally, the gate is a locking device with an adjustable valve. It is thanks to the displacement of the valve that the movement of gases in the chimney is regulated. Can be installed in chimneys of round, square and rectangular cross-section. It is a metal plate that moves inside the smoke channel in a certain way.

Gate valves can be of two types:

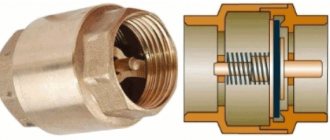

- Retractable. Moves in one plane back and forth.

- Rotary. Regulates air access by rotating around its axis.

In addition, valves can be manual or equipped with an electric drive. The cost of the latter is an order of magnitude higher and they are not used in chimneys.

Tips for choosing a gate valve

It must be remembered that the correct selection of an element such as a slide damper is reflected in the future not only on the draft indicator, but also on the safety of the heating system, of which the chimney is a part. Installation of the damper is carried out on any model of fireplaces and stoves, except for the most modern ones, which have a deflector.

The main recommendations for choosing slide valves for smoke exhaust communications are as follows:

- If the heating device operates by processing gas, it is better to purchase a rotary valve model. This is due to the fact that such models exclude the possibility of completely blocking the smoke exhaust channel. Thus, the heating system will be safer. The chimney, which removes combustion products from the gas stove, must be closed by at least 40 percent during operation;

- There are heating systems that operate intermittently (periodic). A closed damper installed in such a heating structure, as a rule, allows steam to pass during supply, and an open damper contributes to the formation of a large amount of soot on the pipe, which is located below the plate;

- It is strictly not recommended to use rotating elements for installation in sauna chimneys.

A rotating device is the most suitable option for a gas-consuming system

Note! The chimney damper is a shaped part of the chimney service, so if you purchase everything necessary for laying a chimney, it will be included with the pipes. Such shutters can be purchased at any specialized store or ordered using an online store on the Internet.

Experts recommend carefully measuring the cross-section of the smoke exhaust duct before purchasing a gate product. Perhaps this is the main thing that needs to be done before purchasing a gate.

Types and designs

The chimney damper is available in several versions.

Retractable

It is a round or rectangular frame with a plate. The plate extends and retracts, thereby adjusting the cross-section of the chimney.

This option is most often used with brick and ceramic channels. To ensure incomplete sealing and avoid carbon monoxide poisoning, a small hole is made in the plate. The main advantage of this option is ease of installation.

Rotary throttle

A rotary or throttle valve (also known as a hog valve) is a plate made of steel or cast iron that rotates around an axis. The axis is a metal rod welded inside the chimney. Used in steel chimneys.

It is less reliable - over time, the welding fastening of the plate and axle weakens. You should avoid installing a rotary damper in the bathhouse - even when closed, this type of damper partially allows steam to pass through.

In addition, gate valves differ in material (the most common are stainless steel and cast iron) and the method of adjustment.

Differences between retractable and rotary gates

The retractable damper allows you to adjust the working cross-section of the chimney, while the rotary damper only allows you to open or close the pipe. Of course, some tricks are possible - such as securing the hog in an intermediate position in different ways, but the factory equipment does not provide for this. In addition, the rotary gate complicates mechanical cleaning of the pipe.

The hog is often installed in metal chimneys, and the retractable one is installed in brick chimneys.

Operating principle of the gate mechanism

The mechanism includes:

- frame,

- gate,

- stand,

- sealing elements,

- stuffing box seal assembly.

The force by which the movement of the gate is regulated is transmitted through the rod.

Tightness is ensured by strong pressing of the gate element to the seals by the pressure of the moving medium. The design of the gates may include a retractable or non-retractable stem. Fixed stem is widely used when installing gate valves in confined spaces.

Frame

Gate valve bodies can be cylindrical or rectangular. They can be all-metal or prefabricated (for example, welded). The housings can be equipped with a removable bottom cover and a through gate. The housings are made of high-strength cast iron, non-ferrous metal or alloy steel.

The material from which the valve is made has a direct impact on its resistance to aggressive environments. Thus, cast iron elements are less resistant to the effects of:

- diesel fuel,

- motor oil,

- gasoline,

- industrial oil.

In order to reduce the cost of the valve and increase its resistance to aggressive environments, combined valves are used - the body is made of cast iron, and the gate is made of alloy steel. If cast iron is exposed to an aggressive environment, it is coated with epoxy resin for preservation purposes. In some cases, in aggressive environments, gate valves with bodies made of high-strength PVC are used.

Knife

It can be made from a thick rolled plate having sealing

parallel elements. The knife element has a through hole obtained by drilling. The diameter of the hole should be equal to the diameter of the pipe to which the gate is attached.

The gate element may have a pointed edge, which may be at an angle to the hole being closed or close it directly. This allows you to separate the elements of the gates:

- for knife

- and guillotine.

The sharpened element of the knife allows you to easily close holes through which a viscous or solid medium passes. The possibility of closing the pipeline opening as quickly as possible depends on the size of the sharpening.

High-strength alloy steel is used to make knives. The knife is polished, ensuring the easiest possible sliding along the sealing elements and the tightest possible connection to the edge of the seal or pipeline. High-quality polishing helps prevent braking or jamming when blocking flows of media containing a large number of solid inclusions.

Seals

Two types of seals can be used: metal, synthetic components.

- In the petrochemical industry, nitrile rubber is used as a sealing material.

- When working with oils and fuels at low temperatures, a sealant based on a rubber mixture and SKN is well suited.

- Silicone-based sealants are widely used in the pharmaceutical and food industries.

The seal ensures a tight seal on the top of the device. Its padding consists of cotton fiber, synthetic polymaterials, and graphite-containing material.

Types of connection to pipelines

The devices are attached to pipelines by:

- flanged,

- wafer,

- welding connection.

Strengthening the tightness of the gate with a wafer or flange connection is enhanced by means of special gaskets.

Advantages and disadvantages

Like any engineering solution, a gate has a number of advantages and disadvantages.

Pros:

- Possibility of traction control;

- Fuel economy;

- Dampers help retain heat.

Minuses:

- The devices make it difficult to clean chimneys;

- If installed incorrectly, the gate may jam and negatively affect the movement of gases;

- To make the correct adjustment, you must have some knowledge in the field of smoke exhaust systems.

How to close a furnace valve, operating rules

The operation of the furnace valve itself is quite simple, but it is definitely associated with some risks that threaten human health. If you close the structure in a stove that is still burning or if the fuel is not completely burned, then exhaust products can enter the room, poisoning the air.

Therefore, the use of a valve, which allows you to save heat in the furnace for longer, should be used extremely wisely, that is, the structure should be closed on time. It is known that due to the cast iron valve, the heat in the stove and, accordingly, in the room remains for a long time. The use of fuel such as coal increases the temperature inside the furnace by approximately 60-70 0 C.

Sometimes, in order to save fuel, the valve is closed earlier, before it is completely burned, which is extremely undesirable. After all, human health and life are higher than any savings. Closing the damper earlier than necessary increases the risk of carbon monoxide poisoning. Carbon monoxide is a combustion product that is poisonous. Therefore, to avoid such situations, you need to use the chimney valve correctly, following some rules:

- Before closing, be sure to stir the coals to avoid the presence of completely unburnt pieces.

- During the initial attenuation of the coal, when the blue flame is no longer visible on the surface, the damper should be slightly closed, but it is not recommended to close it completely. After all, the presence of coals does not mean that they are completely burned out. If there is a need to seal the pipe, this should be done after complete combustion of the coals.

- Next, you need to open the ashpit so that a draft is formed, and the remaining coals are completely turned into ash and ash.

Make it yourself or order it

The choice between a homemade or a ready-made damper should be based on the type of chimney and the degree of its readiness. So, you can install a self-made retractable structure into a ceramic or brick channel.

If we are talking about a stainless chimney that is in the process of assembly, in this case it is better to choose a finished product. The damper is usually included in the chimney system and is mounted using pipe-to-pipe technology, which I will talk about later.

In addition, it is not always possible in the store to select a product specifically for your chimney shape.

What is a gate valve

The German word Schieber in Russian has not changed either its pronunciation or meaning. If we talk specifically about stove heating, then a damper, as well as a damper, is a shut-off device that blocks the chimney channel.

When arranging a smoke exhaust duct, a valve is installed in the upper part of the base, which is located in the room, so that, if necessary, it is possible to manually regulate the movement of gases, and at the same time the quality of draft.

This is what the gate looks like when extended. When retracted (when the stove is already heated), the valve is almost invisible, only its “eye” protrudes outward.

A damper on the chimney duct is required for the traditional version of a brick stove. By retracting it partially or completely, you can reduce the draft or block the movement of heated gases.

The damper is fully retracted when the stove is heated and gases harmful to health stop flowing into the channel. There are known cases of deaths of people who were burned by a stove that was “closed” early.

If you are late in closing the damper, the heat from the heated bricks will go into the pipe, and the temperature in the room will quickly drop. A timely retracted damper is a guarantee that the house will be warm for at least a day. As you know, in village houses during the cold season the stove has to be lit every morning.

Factory-produced steel gate valve with a diameter of 200 mm. To simplify installation, it is sold together with a piece of steel pipe, built-in.

There is an opinion that dampers, which are mandatory for brick stoves, are absolutely not needed for steel stoves (although they are offered by manufacturers), as well as for models with an installed deflector.

The argument against their use is the fact that the chimney quickly becomes clogged with soot when the damper is closed. Its upper part is cooled by cold air entering the pipe, which, when in contact with a hot steel pipe, forms a large amount of condensate. This situation requires more frequent chimney cleaning.

Making and installing a gate valve with your own hands

Required materials and tools

To independently manufacture and install any type of stainless steel gate, we will need the following tools:

- Bulgarian;

- Abrasive wheels - cutting and grinding;

- Drill;

- Tap and thread lubricant;

- Hammer;

- Pliers;

- Vise;

- Welding and electrodes;

- Kern;

- Roulette;

- Compass;

- Marker.

And materials:

- Stainless steel sheet (preferably domestic brand 12×18n10t, or imported AISI304, they are more expensive, but last an order of magnitude longer).

Sheet thickness 1.5-2.5mm;

- Stainless steel tube 6mm;

- Bolts 8mm -2 pcs;

- Metal rod for the frame.

Drawing and diagrams

Before manufacturing, it is necessary to draw a drawing or diagram of the future valve.

I will give some example diagrams below:

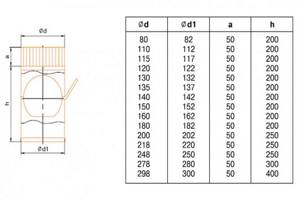

Size calculation

You need to take measurements very carefully; a gap of even a few millimeters can cause the chimney to malfunction.

Actions step by step:

- Using a tape measure, measure the dimensions of the internal section of the channel;

- Add 20-30 mm to the obtained result - you get the outer size of the frame;

- Do not forget to make an opening in the finished valve to release gas;

- The position of the welding holes should be accurately marked.

We summarize the dimensions for the rotary gate in the table:

Home manufacturing technology

Qualified specialists always emphasize that even a novice craftsman can make a rotary and retractable gate. After all, in order for the finished product to perfectly cope with its main task, you need to correctly take all the necessary measurements

If the finished damper fits tightly into the chimney, then over time it may jam, as it will be exposed to high temperature. And when there is a large gap between the valve and the pipe, it will be difficult to regulate the intensity of the draft during operation.

Multifunctional butterfly valve

To make this type of gate, you need to use a steel angle of 30x30 mm, as well as durable sheet steel, the thickness of which is at least 1.5 millimeters. The manufacturing process itself consists of several main stages, which must be implemented in strict sequence:

- Initially, you need to take measurements of the inside of the chimney. This is done in order to avoid mistakes during the manufacture of a frame from a corner, which is fixed with a welding machine.

- On one side of the frame, exactly in the center, you need to drill a small hole (7-8 mm in diameter). It will be useful for the rotary axis.

- A similar hole must be made on the other side of the frame.

- The plate for the damper must be cut from a steel sheet. This part must fully correspond to the internal dimensions of the manufactured frame.

- To make a guide axis, you need to take a piece of wire with a diameter of 9 mm and a length that will exceed the size of the frame itself by 7 cm. You need to cut a thread on one side of the wire (a die is best for this task).

- The finished axle is carefully threaded into the holes on the frame and secured with a nut.

- All cuts on the plate are processed with a grinding machine and inserted into the frame.

- At this stage, the master must weld the axle exactly in the center of the plate.

- All that remains is to make a comfortable handle for the guide from high-quality scrap materials.

Universal device

Modern gate valves include the valve itself, as well as a special guide frame. That is why, before starting work, the master must measure the internal cross-section of the pipe or brick chimney. In accordance with the available measurements, a neat rectangle is cut out of sheet steel (5 mm thick). A small longitudinal fold is made on one side, the width of which should not exceed 30 mm.

These manipulations are necessary so that the finished damper can be conveniently pulled out. Each cut must be polished, due to which the dimensions of the product are reduced by 2 mm on each side. Such actions by the technician will ensure free movement of the damper inside the chimney.

When the damper is made for a brick fireplace, the frame itself can be made of thick steel wire, the diameter of which is within 6 mm. During this procedure, the metal blank is simply bent into the shape of the letter P in strict accordance with the existing measurements.

If the chimney has a rectangular shape and is made of steel, then it is better to make the frame from a metal strip 2 mm thick and up to 35 mm wide. The prepared strip is bent lengthwise, leaving a neat gap along the thickness of the plate. Only after this can small cuts be made in two places at an angle of 45° to give the workpiece a U-shape. All gaps in the places of cuts must be butt welded.

To connect the ends of a homemade damper, you need to use two pieces of metal, which should be positioned in such a way that the damper blade can pass freely between them. At the end of all these manipulations, the master should come out with a rectangular frame with grooves for the shutter.

To make a valve in a round pipe, you need to take two identical metal sheets 2 mm thick. Round holes are cut in the center in accordance with the diameter of the chimney. The valve plate must be manufactured separately. After this, the sheets are connected to each other using a welding machine.

It is necessary to weld only three sides around the perimeter so that the holes of the finished valve on the pipe match exactly. A gap of 5 mm must be left between the top and bottom sheets. At this point, the damper manufacturing process can be considered complete, since the craftsman can only insert the valve and secure the finished product to the chimney.

Installation features

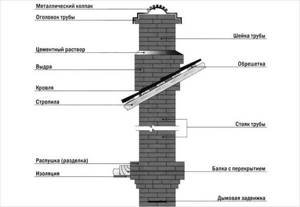

- When installing the gate at the stage of laying brickwork, the frame is placed at a height of 6-8 rows from the base of the pipe;

- The frame should stand straight, without blocking the outline of the chimney;

- In stainless steel chimneys, the valve is installed using the “pipe-to-pipe” technology. It is necessary to coordinate its dimensions with the diameter of the channel;

- An important nuance - the damper is installed on an uninsulated section of the chimney;

- The height from the firebox to the damper should not exceed 1 m (for metal channels);

- Pipe height from the floor to the valve - 1.8 - maximum 2 m (for brick);

- The damper in the grooves should move freely;

Why do you need a chimney damper - what is a damper, types, installation rules

A damper is a damper, a valve for a stove chimney, designed to improve draft in it. This part is made of metal. It is installed at the stage of construction of the chimney pipe and ventilation passage.

Draft is of great importance for the functioning of the heating unit. When it is strong enough, the fuel burns completely, resulting in reduced costs. When the draft is poor, a fire can occur at any moment, and to prevent this, install a damper for the stove or fireplace.

You can install a damper for a fireplace or heating unit in one of three ways:

- The damper is installed directly in the fireplace insert. It is placed at a distance of 100 centimeters from the heating device, which makes it easy to control.

- Combining the damper with other elements of the heating structure without the use of additional fasteners. This installation method is called “pipe to pipe”.

- The damper is installed in ventilation pipes. It is used to prevent the fan motor from overheating during operation.

Since there are a variety of models of stove units and fireplaces and heating using them is carried out in different ways, each of them requires its own type of valve.

For example, for a stove operating on gas, you will need a classic rotary-type throttle valve or a rotary automatic damper, since they are capable of blocking the chimney pipe completely and then the flame will not be able to escape outside.

At the same time, rotary valves should not be installed when installing a sauna stove, since when closed they will allow steam to pass through, and in the open position they are very difficult to clean.

As a rule, a damper for a fireplace or stove unit is sold as a complete set along with a chimney. But there are smoke exhaust structures without a damper, so you can make one yourself by buying elements for it at a hardware store. The main thing to do before purchasing them is to decide on the required sizes.

t one row of bricks. The gate plays one of the main roles in the chimney, the purpose of which is to regulate draft. Good draft means that the efficiency of the entire heating system will be excellent and fuel savings will be obvious.

Before making the design and installing it yourself, consult a specialist who will calculate the draft level of your stove. For this, professionals use a special formula. Take care of yourself!

Frequent errors and problems during installation

- Installation of a valve in an insulated area. Under the influence of thermal expansion, the damper may jam;

- Installation of a cast iron part in a metal chimney (cast iron weighs a lot);

- Using too thin steel or stainless steel with a low nickel content for the manufacture of valves. Such a product quickly deforms under the influence of hot gases and can burn out;

- Installation of a gate with a non-smooth surface;

- Installation of a valve without a hole for carbon monoxide release;

- Installation of handles that do not allow monitoring the position of the valve (applies to rotary elements).

Round furnace valve or view

A round-shaped stove valve is otherwise called a view. This is a special valve with a slightly different design than the regular version.

The view consists of the following parts:

- The housing is in the form of a plate, which can be round or square with a round hole.

- A shut-off element in the form of a disk that closes the hole and blocks air exchange in the pipe.

- The control part, in the form of a regular handle in the center of the disc valve.

You cannot use a view to control air exchange, since you need to remove the damper from the air passage manually, which is almost impossible in a heated stove, in addition to exhaust gases. The design is used exclusively as a locking element, often as an additional damper for a complete result before igniting the stove and after it goes out.

It is recommended to install both types of cast iron stove valves far from the firebox.

Features of gate maintenance

The gate, made of stainless steel, is usually polished to perfect smoothness. Soot settles on it poorly, but still settles. Therefore, it must be cleaned periodically.

The horizontal valve can be cleaned simply by pulling it out to the maximum and applying a special solution. Rotary - cleaned through the chimney with a special plastic brush. You should also ensure that the damper moves freely along the guides. It is allowed to periodically lubricate them with an anti-corrosion compound.

The need for valves and views in the chimney

The damper is an integral part of the stove, which closes the chimney after it is fired. In combined stoves, such as cooking and heating stoves, this design allows you to move between smoke exhaust channels.

The damper is usually installed in the chimney when laying the stove, secured with several rows of bricks. Often two valves are installed, especially in rooms in cold climates, when temperature changes are more significant, which leads to rapid heat exchange.

The view is installed in the chimney in the same way, but is usually used in Russian stoves. This valve is closed from the outside using a special door. If it is necessary to ventilate and cool the oven, all this can be done with the view door closed.

The design of the stove view makes it possible to eliminate the installation of an additional valve, because it completely copes with sealing the smoke exhaust pipe. When using the second valve, it is installed below the view.

Expert advice

Where to install the damper on the chimney

There are 3 options for placing the damper relative to the chimney:

- Placement in the firebox of a fireplace or stove;

- Fastening according to the “pipe to pipe” principle;

- Installation in a ventilation pipe.

Let's consider the first 2 options:

- By placing the valve in the furnace firebox or in the outlet pipe

In this case, the damper is located at a height of no more than 1 m from the firebox, on an uninsulated section of the pipe. This location is convenient for adjusting the damper.

- Pipe in pipe

Applicable for metal chimneys. This installation option does not require additional fasteners. When purchasing a ready-made system, you should install the valve strictly according to the manufacturer’s instructions.

How to adjust traction

Adjusting the draft using a slider is quite simple. By changing the position towards increasing the gap, we increase the flow of air to the fire and the flame flares up stronger. Reduce the gap - traction decreases. The valve is closed after the flame has completely died out - this way the oven cools down much faster.

The latest boiler models are made with built-in automatic baffles. All other heating units require the mandatory installation of a damper.

Gate valve installation

Installation of any type of damper is carried out at the first stages of installing a heating system. Installing the structure on a chimney pipe is not at all difficult. This can be done in three ways:

- Near the fireplace. The device is connected to the chimney pipe at a distance of one meter from the heating devices. This convenient installation of the damper allows you to easily monitor the operation of the gate.

- "Pipe to pipe." This method involves attaching a slide damper to a chimney pipe without the use of additional clamps. The valve is held securely due to its tight connection to the chimney pipe.

- In the ventilation duct. This installation option is mainly used to cool the fan motor.

When constructing stoves and fireplaces, the damper is most often installed using the first method. Gate valves are used for both round and square chimney pipes. Products with a rotating plate are most often installed in chimneys with a cross-section in the form of a circle.

Installing a damper in a brick oven

The gate valve is quite often used for brick kilns. It is installed during the construction of the chimney. Place the valve on the first meter of the pipe. This arrangement of the gate makes it easy to adjust the draft. To install such a gate you need:

- two rows of chimney bricks are laid;

- in the second row an opening of the required size is cut;

- a damper is installed;

- in any brick of the same row a recess is made for a rotary handle;

Next, the next rows are laid

In this case, you should pay attention to the tightness of the fit to the place where the gate is installed. All cracks should be sealed with mortar.

When using such a damper, all safety precautions must be taken into account. During operation of the furnace, under no circumstances should the gate valve be closed. This action will lead to carbon monoxide entering the room. Some models have a special fixing element that prevents the pipe opening from being completely closed.

Conclusions and useful video on the topic

With the help of videos, you will expand your horizons, learn more about stove valves and how to install them in a chimney.

How to make a damper in 5 hours:

Scheme for installing a damper on a brick kiln:

Option for installing a fireplace damper:

It is advisable to make your own gate valve if you have skills in working with metal, know how to use welding, a grinder and a drill - then the production process will bring benefits and positive emotions.

If knowledge and skills are not enough, it is better to purchase a ready-made valve, having first taken the dimensions from the chimney.

If you have anything to add or have questions on the topic, you can leave comments on the publication. The contact form is located in the lower block. If you made a chimney damper yourself and want to share ideas with readers, please add a photo of the product.

Selecting a location option

There are three main options for placing the damper in the chimney:

- pipe-to-pipe fastening;

- placement in a fireplace insert;

- installation in a ventilation pipe.

Brick chimney with damper

If you place a gate valve in the outlet pipe or in the furnace firebox, that is, build this element into its design, the damper is placed on a section of pipe as close as possible to the heating boiler. This guarantees ease of control and ease of turning the valve. This is explained by the fact that the handle will not touch either the portal or the cladding area. If it is located according to the “pipe to pipe” option, no additional fastenings are required for connection with other elements of the furnace.

If you place the damper assembly in a pipe intended for ventilation, overheating of the fan motor during its operation is prevented.

Typically, ready-to-install chimneys are offered, which are equipped with everything necessary, including a slide valve. In this case, it is placed in the system in accordance with the manufacturer's instructions. If it is not provided for one reason or another, it is quite possible to manufacture and install this element yourself.

Which material is stronger

In addition to structural differences, types of gate valves may differ in the material of manufacture. The only possible option is metal, since it is the only one that does not burn or deform at high temperatures, and over time, even in an aggressive environment, does not change its characteristics.

For production, either cast iron or stainless steel is used. It is not possible to build a damper from cast iron yourself, since this requires, at a minimum, a forge. However, you can find both nondescript and beautifully designed cast iron dampers on sale.

Cast iron rotary gate with a comfortable handle. This design is suitable for a brick chimney with a rectangular cross-section, capable of supporting the fairly heavy weight of the device

Steel products look simpler, but their characteristics are similar to their cast iron counterparts. The advantage of steel fixtures is their light weight.

If a cast iron damper for a stove chimney is installed only on a durable, permanent structure, then a steel damper is suitable for any smoke exhaust ducts - brick and steel, rectangular and round, solid and light.

Samples of a galvanized steel damper, chimney cross-sectional diameter – 150 mm. Galvanization, unlike ordinary steel, does not react to moisture (condensation) and does not corrode

When choosing a material, you need to focus on the characteristics of the chimney pipe and the features of the interior.

For a country heating stove, a modest steel valve is sufficient, while for upgrading a Russian stove in a cottage, a custom-made cast iron valve is better suited.

Specifications

The chimney damper is mainly made of stainless, heat-resistant steel, with a thickness of 0.5 to 1 mm. The steel damper can withstand temperatures up to 900ºС, which is very important, since the damper is usually installed on the first meter of the chimney duct from the combustion chamber. The steel gate is characterized by high resistance to mechanical loads, as well as a low coefficient of thermal expansion.

You can still find cast iron gate valves on sale (similar gate valves are used, as a rule, in the operation of Russian brick kilns). The disadvantage of a cast iron gate is the large weight of the product; moreover, a cast iron gate valve has lower strength characteristics than a steel gate.

Making a rotary gate yourself

Damper installation option

When using a chimney, it may be necessary to replace the damper, and a standard damper is not suitable for this design. In this case, the damper is made independently according to the dimensions of the pipe.

To work you will need metal scissors, a drill, a grinder and a welding machine.

Drawing of a rotary gate valve

Note! The choice of damper model depends on the design of the chimney and the type of heating system, but its installation is mandatory. The device allows you to regulate the draft level and keep the heating system in working condition.

How to install a valve on a chimney

The valve is usually installed during the construction and assembly of the stove. The process is carried out in several stages:

- Laying bricks around the fittings in a selected location at a certain stage of chimney construction. In this case, the dimensions of the hole left must completely coincide with the dimensions of the valve. Often, wire is installed in the corners of the body, mounting it into the body of the masonry.

- Installation of the valve frame with fixation of the upper part using cement mortar.

- Applying cement mortar around the perimeter of the frame and wire about 1 cm thick, followed by laying a row of bricks.

- Installing a damper in the chimney.

A conventional cast-iron stove valve is locked with a panel damper, which is mounted in the frame body through a slot. It can be installed after mounting the frame. The damper on the view is closed manually, so a special door needs to be installed above the body of this design, with which you can control the lid.

After this, installation of the chimney continues accordingly.

Functional purpose of the gate

To understand the purpose of this part for the chimney structure, you need to understand what a damper in a stove is. The damper provides a change in the traction force in the unit by adjusting the combustion of fuel in the firebox.

This element has an important advantage - it has low resistance relative to the remaining gas bubbles, which must be removed outside the room. When the chimney is inoperative, then the damper is completely closed.

The gate has a significant drawback - sometimes its welding burns out. This problem occurs quite often - its cause is usually a neglectful attitude towards the quality of this product on the part of manufacturing companies.

Required tools and materials

In order for the finished damper to meet all the requirements, the master must prepare certain devices. The main percentage of tools can be found in every home, but everything missing can be purchased at a specialized store. To work you will need:

- Roulette.

- Drill.

- Permanent marker.

- Grinder, as well as a grinding and cutting wheel.

- Kern.

- Vise.

- Stationery compass.

- Welding machine.

- Special tap.

- Pliers.

- High-quality oil for lubricating the tap when cutting threads.

- Electrodes that are designed for stainless steel.

- Hammer.

- Kern.

- Vise.

As for materials, in this case you need to prepare:

- A stainless steel pipe with an internal cross-sectional diameter of 6 mm.

- Two 8mm bolts.

- Stainless steel sheet with a thickness of 1.5 to 2 mm.

- Metal rod or nail.

Safety precautions

When talking about gate valves, first of all we should focus on safety precautions. Already from the definition it becomes clear that this device is capable of completely blocking the natural flow of air from the room through the stove and chimney to the street. The oven can be in such a locked state only under one condition - there is nothing in it that is still smoldering even a little, much less burning.

As you know, burning wood in a stove leads to the release of carbon monoxide, which is poisonous to humans. The danger of poisoning with this gas is that a person may simply not feel the harmful effects of the gas until he begins to lose consciousness, and then it may be too late. This danger should not be underestimated: for example, it is known that the famous French writer Emile Zola died in Paris in his bedroom from carbon monoxide.

We recommend a video review of the features of gate valves of various designs.

An attentive reader may notice that valve manufacturers produce them with special holes that prevent complete blocking of the chimney. However, with regular use over time, soot and resin accumulate on these holes, which gradually reduce their throughput, and then can completely block them. Obviously, the chimney periodically needs to be cleaned and the damper is no exception, but in practice this procedure is carried out much less frequently than required by safety regulations.