Chimney deflector: dimensions, drawings, manufacturing and installation

If there is not enough draft, the operation of the stove will not be complete, anyone who has an idea about chimney pipes knows this.

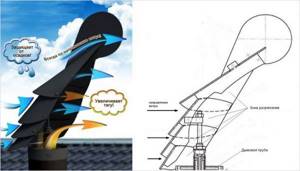

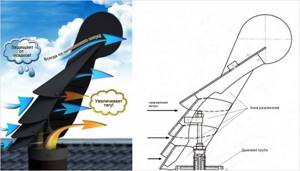

In order to fully ensure normal draft, it is necessary that the air flow be sufficient and the gas outlet be carried out on time; for this, a deflector is needed on the chimney. Properly designed and high-quality smoke exhaust devices ensure the correct and trouble-free operation of any stove. The efficiency of the stove and ensuring normal draft is influenced by such factors as: changes in climatic conditions (wind, snowstorm, various types of precipitation), the presence of debris, which often falls directly into the chimney and clogs it.

To ensure the normal operation of a pipe in which there is no pressurization, a high-quality chimney is needed, which is able to ensure the timely and regular removal of combustion products. If the option under consideration is not possible for some reason, the presence of such a mechanism as a chimney deflector is an excellent assistant in this matter. Let's take a closer look at the topic - how to make a chimney deflector with your own hands: instructions and drawings.

What causes a chimney pipe to smoke?

A deflector is a device on a chimney pipe, the use of which creates obstacles in the path of air flow created by the wind. To put it simply, this is a very simple, but at the same time highly effective device for protecting the chimney from various types of litter, precipitation, etc.

Experts say that to increase the efficiency of the stove by 25%, it is enough to install a deflector on the smoke exhaust pipe. In order for it to work efficiently, correctly and without problems, it is necessary that the chimney itself be installed as expected (the required height of the structure, its location, the correct cross-section, etc.).

It often happens that the chimney pipe begins to smoke, and in order to eliminate this problem, you first need to find out what are the reasons for this behavior of the structure. So, the first reason is the increased speed and power of air flows due to strong, gusty winds. In this case, the smoke is simply “not allowed” to come out, crushing it with a strong flow entering the pipe.

The second reason is the incorrectly selected chimney diameter (the importance of this factor was previously mentioned). If the diameter is too small, the smoke will not have enough space to exit the pipe normally.

Smoke will be a regular process even if the chimney itself is not located correctly on the roof (as it turns out, even such seemingly insignificant details can affect the efficiency of the structure).

Differences from similar elements

There are many other similar devices and for a better understanding and to avoid confusion, their distinguishing features are described below:

- Pipe cap. This generally refers to all devices that prevent precipitation from entering the chimney pipe.

- Dymnik. A cap having a square or rectangular shape, intended for decorative purposes.

- Umbrella. It has the simplest design and is capable of performing the simplest protective functions.

- Header. Equipped with a special device installed in the internal part, which increases the level of traction force.

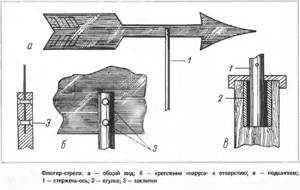

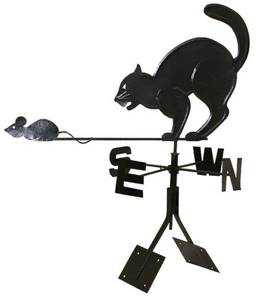

- Wind vane . A cap equipped with a rotating element in the internal cavity, which serves to release air masses in the same direction as the wind.

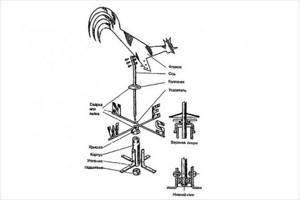

Wind vane device

Drawings, dimensions and parameters

Each of the available types has its own parameters and manufacturing methods. In order to understand the designs and parameters of such a device, we will consider several of them, and also find out how to make a chimney deflector with your own hands using drawings.

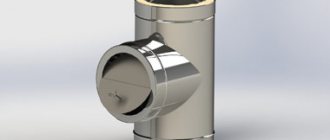

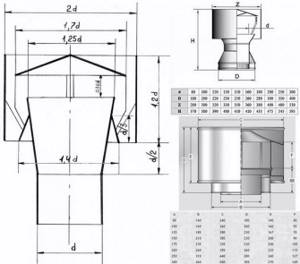

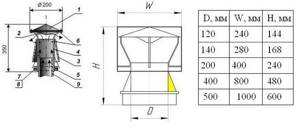

Deflector for the Grigorovich chimney pipe: this type is characterized by its simple design and high efficiency. The height of the device in question is 1.6 d, the width of the manufactured cap should not exceed 1.9 d. During manufacturing, it is also worth paying attention to the carefully selected width of the diffuser; in this case, the parameter in question will be equal to 1.3 d (it is also worth noting that the d value means the selected diameter of the chimney, or more precisely, its channel).

TsAGI deflector: in the form under consideration, the correctly selected size of the diffuser (more precisely, its wide part) plays an important role. This parameter is equal to 1.25 d, since it is necessary to make a ring here, you need to know its dimensions (height 1.3 d, diameter at this height should be equal to 2.5 d). Since this design contains a part in the form of an umbrella, its parameters must also be calculated accurately - the width of the part is 1.8 d.

Installation

Installation on the chimney is carried out only after completing the assembly work of the weather vane.

Installation of a chimney on a chimney is carried out in several stages:

- Installing the cylinder on the pipe.

- Fixing the cylinder with fasteners.

- Fastening the diffuser and hood using clamps.

For better operation of the chimney, the cap should be attached to the cylinder in the form of a reverse cone, which will allow the product to function at any wind speed and direction.

Operating principle and design of the chimney deflector

Before you start making a deflector for a chimney with your own hands, you need, first of all, to know its structure, drawings and understand the principle of its operation. So, such devices, despite their multiple varieties, consist of three main parts: a diffuser, a cylinder and, directly, a cap. We should not forget about the seemingly insignificant, but in fact, important component of the deflector - ring-type rebounds.

Despite the variety of types of chimney deflectors, the principle of their operation is identical:

- The movement of air flows that enter the chimney is hindered by the walls of the cylinder, which is located in the upper part of the deflector. It turns out that the air flows hit it and a portion of the air mass from the jet moves up the cylinder itself, taking with it the smoke that comes out of the chimney.

- As a result, it turns out that the speed of smoke exiting the chimney becomes greater, while the draft increases significantly, which in turn increases the efficiency of the chimney itself.

- If there is a deflector, it does not matter at all what the speed of the air flow from the outside is, and from which direction the wind blows, because there are special gaps in the cylinder that suck the smoke into the air.

Features of this design

If the wind blows from below, some turbulence is formed under the structure’s hood, which causes the smoke output to slow down (this is a minor, but still a drawback of the products in question). But here there is a way out, namely a solution to this problem - installing an inverted cone under the umbrella of the device itself.

Chimney deflectors are quite simple devices in design and operating principle, but at the same time, their efficiency can undoubtedly be called high. Each device, and deflectors are no exception, has certain disadvantages, but if we conduct a general analysis of all the available characteristics and capabilities of this device, then the pros and cons clearly have advantages over the cons and disadvantages.

Installation of a deflector on a chimney pipe

Correct manufacturing of such a design is not the key to the success of its operation, because installation, which is the final stage for using the device, plays an equally important role.

The deflector is installed on the chimney, and it will be easy to install both a self-made structure and one purchased in a store. Since the device consists of many parts, before climbing onto the roof and proceeding with installation, it must be assembled into a single whole. Making a deflector, the instructions and drawings of which will be discussed below, is quite simple to install, and in this case no additional skills and knowledge are needed.

The installation method will depend on the chimney pipe itself on which the deflector will be located. Most often, for a strong attachment it is enough to use a couple of drill holes and a clamp (you cannot do without drilling holes in the chimney itself). If the material with which the roof is covered is flammable, then you will have to additionally purchase a spark arrester, which must be installed on the deflector.

Definition of a weather vane and its varieties

A weather vane is a metal device that consists of a flag and a counterweight. Its use was first recorded in Europe. The design is an original decoration of the roof and a protective element against precipitation and birds getting into the chimney. A weather vane fixed to the chimney aesthetically complements the roof, giving it completeness.

The simple principle of operation is as follows: wind flows act on the counterweight, directing it in the direction of the air flow, and the flag indicates the direction. It is the flag that has a decorative role. Its execution can be in the form of various figures: a crane, a cat, an animal or a person. Even from Old Russian fairy tales, we are familiar with the tower with the figurine of a rooster, because in ancient Rus' there was a belief that it was the voice of this bird that drove away evil spirits. Today, a figurine of a ship with sails, considered a symbol of happiness and good luck, is relevant. The image of a lion is marked by the symbolism of the enormous potential of the owner’s strength, justice and the desire to move forward.

There are the following types of weather vanes:

- indicating wind currents. This type is relevant for use at meteorological stations. Even despite the large amount of modern equipment, weather vanes are still used. They play a major role in coastal cities, where the direction of the wind determines the performance of ports. The sensitivity of the weather vane is very high and even at a low level of wind flow, the device will detect it, at a time when modern equipment does not yet work.

- Wilda. A modern type of weather vane that determines both the direction and strength of the wind flow. This device is equipped with a vertical plate, the angle of inclination of which indicates the force. from which the wind blows.

Tip! To make a weather vane yourself, you will need to strictly follow the step-by-step instructions, focusing on the drawing diagram.

Step-by-step instructions for creating a weather vane

A fairly large selection of variations on how to make a weather vane on a chimney is available on the Internet. With the help of drawings this process will not be difficult.

Unusual weather vane model

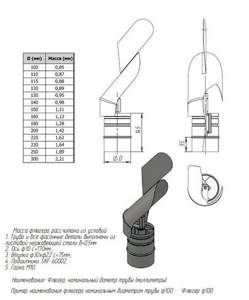

This model can be made of stainless steel or copper alloy, with a thickness of at least 1 mm. Both the first and second materials have positive anti-corrosion characteristics. They are quite light and have a durable composition.

Advice! By choosing copper as a manufacturing material, you can significantly increase the service life of the weather vane, but the estimate should take into account the expensive cost of the metal.

Making your own weather vane consists of the following steps:

- It is necessary to select dimensions and determine the approximate weight of the future structure. Using the figure below, this point can be easily understood.

- The elements of the weather vane are cut out from the prepared sheet of metal.

- All components are assembled based on the instructions in the picture.

- The assembled protection element must be installed on the chimney.

This type of weather vane is installed on the head of the chimney pipe. This element is not only decorative, but also helps prevent reverse draft.

Advice! Any vagaries of the weather: rain, hail, strong wind or sudden temperature changes - significantly reduce the service life of the chimney. Therefore, a weather vane is installed to protect it.

How to choose a weather vane?

When choosing a wind vane for a chimney, it is better to be guided by the following points:

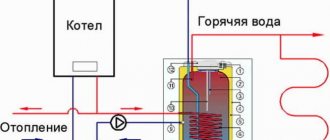

- Type of fuel. The temperature level of the exhaust smoke, as well as its composition, depends on the type of fuel to which the heating equipment is adapted. In addition, for each type of fuel the gas service has certain requirements, this also applies to weather vanes. A mandatory requirement is the presence of a through channel that can be closely attached to the chimney pipe, becoming its continuation.

- Impact of external factors. There are also some requirements for such a criterion. Precipitation and sunlight should be well reflected by the device. In some cases, wind vanes are installed that are equipped with a special reflective screen, which increases their service life. Such a screen can protect not only the weather vane from overheating, but also the chimney pipe itself. If the house is heated with wood or coal, then it is not recommended to purchase a painted steel weather vane; after a short period of time it will be contaminated with soot.

You should not treat the weather vane as an element for decorating the exterior of the house. This seemingly simple device can provide protection to the chimney, which will increase its service life and allow the heating system to always work properly.

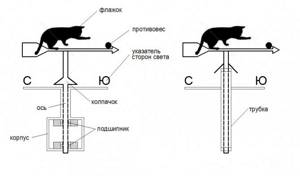

Weather vane deflector

Another popular option for making a protective element for a chimney yourself is a weather vane deflector. Below is a diagram of such a model. Its manufacture also does not require any special skills.

The weather vane deflector is mounted on a dome that covers the chimney. The manufacturing material must have anti-corrosion properties.

The first thing to do is the dome. To do this you will need to follow the instructions on the drawing:

- The first to be attached are the struts (4) to the bottom of the cylinder (9).

- Here M6 square nuts (8) will be used together with M6 bolts (7).

- Next, install the upper part of the cylinder (3), which is secured with a clamp (5).

- At the very top of the posts, a reverse cone (2) is fixed using rivets (6).

Let's move on to making a weather vane.

It is worth using the drawing below, which demonstratively shows the process of creating a decorative weather vane.

Manufacturing process:

- A support is made, which is a pipe 12.5 cm long and 1.3 cm in diameter.

- The pipe will need to be threaded.

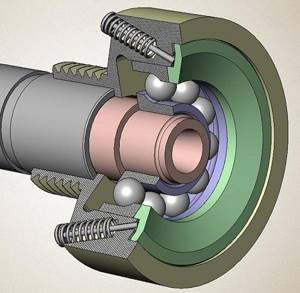

- We select a bearing according to the diameter of the pipe, which then needs to be installed in the cavity of the base.

- Two metal plates are welded on the sides of the pipe, with an angle corresponding to the dome. Installation is carried out in such a way that during rotation the elements do not touch each other.

- It is necessary to mount a wind rose, represented by thin rods on which letters are attached indicating the cardinal directions.

- To prevent moisture from getting into the middle of the compass rose body, a visor is made above it.

- A lid made of steel is placed on a threaded base.

- A counterweight and a flag will be attached to the arrow-cover.

All elements of the weather vane have been assembled and you can evaluate the work done.

The presented weather vane models are an excellent solution for decorating and protecting the roof of your home. By choosing another design option, it can be recreated using a similar principle.

Barbecue oven with cauldron

Price on request

BBQ oven with smokehouse

Price on request

Still have questions? We'll be happy to help!

Manufacturing process

When choosing a material for making a chimney, you should be guided by the requirements that ensure certain properties in the finished product:

- resistance to corrosion;

- strength;

- ease.

When making your own weather vane, it is recommended to use sheet steel or galvanized iron with a sheet thickness of 1 mm. This material provides lightness, which is important in this product, strength and resistance to corrosion.

The more expensive material is copper. Its advantage lies in the relatively high values of corrosion characteristics.

The manufacturing process can be divided into several stages:

- Selecting the chimney material.

- Designing a future product in accordance with your wishes and mandatory requirements. The design results should be presented in the form of a drawing. The secret to fast and successful work in the production of weather vanes is the manufacture of all structural parts in accordance with the drawing data.

- Drawing patterns of the constituent elements of the weather vane onto hard cardboard.

- Attach the cardboard patterns to the material used and trace along the outline with a construction marker.

- Cut out parts using a tool. To cut metal sheets, you can use electric shears, a plasma cutting tool, or a jigsaw with a special file.

- Manufacturing the brackets necessary for attaching the hood to the surface of the chimney pipe. To do this, you need to measure the circumference of the pipe. Cut a rectangular blank from sheet iron, the length of which corresponds to the measured value, the width is equal to the depth of processing of the pipe, usually 10-20 centimeters. The larger the diameter of the pipe, the larger the width of the blank for the bracket. After pre-drilling holes on the smaller side of the workpiece to make a clamp, you need to wrap it around the pipe from the outside and fasten it with bolts at the joint.

- Assembling a deflector consisting of a diffuser, an outer cap and a cylinder. The cut parts of the cylinder, reverse cone and diffuser must be connected into a single structure using a welding machine, rivets and bolts, according to the drawing.

The deflector has been tested in action by more than one generation of home/cottage owners. Its effectiveness has been proven repeatedly, so it is not surprising that the device is in demand. And demand, in turn, creates supply.

The price of such offers can sometimes be steep - not every thrifty owner is willing to pay $140 for a simple device.

It will cost much less to assemble a deflector from scrap materials. Especially if you want to build something useful with your own hands. The entire production process of the device will take 2-3 hours - the time depends on the dexterity and skills of the assembler.

We suggest you familiarize yourself with How to install sandwich pipes for a chimney

The process of making a reflector that enhances traction with your own hands consists of the following stages:

- create a drawing;

- make blanks;

- assemble the device;

- install and secure it to the chimney.

The first stage of creating a drawing is best done on paper. To do this, it is important to correctly calculate the diameter of the inlet pipe and the diameter of the cap. And also, the height of the deflector itself.

There are special tables that show diffuser sizes for the most popular pipe diameters. If the chimney is non-standard, then you will have to do the calculations yourself ( )

To avoid mistakes, you can use generally accepted formulas for your calculations.

The main role in the calculations is played by the internal diameter of the chimney pipe:

- height=1.6-1.7*diameter;

- diffuser width=1.2-1.3*diameter;

- cap width=1.7-1.9*diameter.

Once you have the formula, all that remains is to correctly measure the internal diameter of the chimney pipe and substitute the resulting value. Knowing the dimensions, you can begin to draw the contours of the blanks on paper.

It is best to create a prototype of the finished paper product after creating a drawing. This will make possible errors and shortcomings more clear. If there are none, then you can proceed to the second stage - creating real metal blanks.

In the process of creating prototypes of the parts of the future deflector, it is best to use paper. If something fails, you can always correct your mistake

The material can be used as a sheet of galvanized or stainless steel with a thickness of 0.5-1 mm. Sometimes you can come across the opinion that it is best to use copper for the deflector.

This statement has the right to life if you accidentally have an unnecessary sheet of copper in your garage or workshop. Otherwise, such an expensive purchase will not justify itself. And the service life of stainless steel cannot be called short enough to neglect this material.

When the blanks are cut with metal scissors from the prepared sheet, you can begin the assembly stage of the product. To do this, you can use a riveter and a drill or welding. When working with welding, you need to be extremely careful so as not to accidentally burn through a section of the future deflector.

If you plan to use rivets, then it is convenient to make allowances for connecting the parts together on a rolling machine. If this is not the case, then a hammer will do just fine. Having made allowances, you have to connect the parts evenly together, make holes with a drill and install rivets.

The legs for attaching the cap to the base of the deflector are attached at an equal distance from each other

The cap must be secured to the base with legs, which are also drawn and cut from a stainless steel/galvanized sheet.

All parts of the product are connected to each other with rivets - this is the fastest and safest method of fastening. Welding requires skills and such a product will not look so attractive

When the 3rd stage is finished and the homemade product is ready, you can proceed to the last and most important moment - installation on the chimney.

The last stage of manufacturing a deflector for a chimney pipe is to install it in its permanent location - on the chimney. You can install either a home-made device or a purchased design yourself. There is no difference - you still have to climb onto the roof.

To avoid problems with installation, even a purchased model that comes disassembled must be assembled at the bottom, securely fixing all the fasteners. Only after this can you take the necessary tool and head to the chimney.

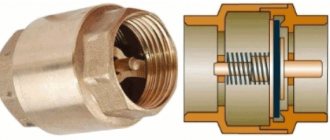

Depending on the type of pipe that acts as a chimney, mounting options will differ. Sometimes it is enough to use several screws or add an additional clamp

When installing the deflector on the chimney pipe, you must carefully drill holes for mounting. Then all that remains is to securely fasten the screws or rivets and check whether the installed device is tilted in different directions.

If it dangles, then you can additionally install a clamp. This option is suitable if the chimney is not lined with brick.

For brickwork with a square or rectangular chimney cross-section, you will have to use special adapters. When the work is completed, you can test the deflector you installed yourself by lighting the stove/turning on the heating boiler.

Another important point is the spark arrestor. Whether it is needed or not is looked at in a particular house. You can make a spark arrestor yourself from stainless steel sheets or metal mesh.

If the roof covering is soft and can easily ignite, then it is important to take care of additional protection against sparks flying out of the chimney when the heating boiler is operating.

What is a weather vane and its types?

The weather vane is an antique decorative element and also covers the chimney pipe, protecting it from the penetration of precipitation: rain and snow. A weather vane attached to the chimney will give the roof an aesthetically pleasing and complete appearance. It is a metal structure consisting of a flag and a counterweight.

A weather vane mounted on the chimney is the finishing touch. Dome on the chimney - protection, weather vane - decor

The principle of operation is simple: the counterweight is directed in the direction from which wind currents are blowing, and the flag indicates their direction. The tradition of installing a weather vane came from Europe. The flag is now a real decorative element. It can be made in the form of a figurine: a bird, an animal, a man. In Rus', the most popular figurine was the one depicting a rooster, since a popular legend said that its voice was capable of driving away demons. Nowadays, the image of a ship, which is considered a symbol of a happy and successful life, is relevant. The lion, in turn, is a symbol of enormous vitality, nobility, justice, as well as the desire to move forward.

Weathervane-arrow - you are probably already familiar with it

Main types of weather vanes:

- indicating the direction of the wind. It is widely used in meteorology. Despite the availability of many modern devices, weather vanes are still in demand. They occupy a special place in coastal cities, since the functioning of ports directly depends on the direction of the wind. The response of the weather vane is noticeable even at the slightest appearance of wind flow and is detected even when other devices are still powerless;

- Wilda. This is a more modern weather vane model, capable of determining not only the direction, but also the strength of the wind. This model has a plate mounted vertically. The angle of inclination shows strength.

We also recommend studying this topic: Do-it-yourself chimney deflector: drawings and diagrams

The chimney vane has a simple design and can be made with your own hands.

Advice! The process is simple and will not be difficult, the main thing is to strictly follow the instructions and focus on the drawings.

Readers found these materials useful:

- Do-it-yourself ceramic chimney installation, tips and tricks

- We install the heat exchanger on the chimney ourselves

How to install

An important point is how well this element is installed on the chimney.

To install it yourself, you will need to do the following:

- Initially, the required number of holes is drilled in the element skirt, which depends on the size of the device.

- Next, parallel points are drilled in the chimney pipe and a self-tapping screw is inserted into each of them.

- After this, the weather vane itself is attached using a screwdriver.

The process of attaching the chimney is very simple, but it is very important to make sure that the element is securely attached and that a strong gust of wind will not rip it off the roof. This cannot be neglected, because the weather vane has quite a lot of weight and if it is detached from the chimney, it can cause damage to both the roofing and anything on which it falls.

NOTE!

In addition to weather vanes, in some cases, protection covers are installed.

In addition, with their help it is possible to hide defects in the chimney pipe and create a finished look to the structure. The casing also protects the pipe walls from various external influences.

Installation of a weather vane

Step-by-step instructions for making a weather vane

There are many options for making a chimney weather vane with your own hands. The drawings will help with this.

Original weather vane

A chimney deflector made of stainless steel and bronze for a more durable service.

The material for the manufacture of such a model will be stainless steel or copper, the thickness of which is 1 millimeter. Both of these metals have good anti-corrosion properties, they are lightweight and durable.

Advice! If copper is used, the service life of the weather vane increases, but it should be taken into account that this metal is more expensive.

The process of making a weather vane with your own hands:

Step 1. Select the mass and dimensions of the future model. Drawing will help

Calculation of the mass of the future weather vane based on the parameters of the pipe diameter, steel thickness, weight of the axle, bushing and bearings.

Step 2. Parts for the weather vane should be cut from the selected steel.

Using metal scissors, parts are cut out of stainless steel for the future weather vane-dome for the chimney

Step 3. We assemble the structure as shown in the figure.

The design of the weather vane and the schematic principle of assembly. Help for those who want to create it themselves

Step 4. The weather vane is ready.

The final version of the weather vane. Blue arrow - air intake, red smoke exit

Installation of such a weather vane is carried out on top of the chimney. It not only serves as decoration and gives the chimney duct a finishing look, but also prevents the occurrence of reverse draft.

Advice! Wind, temperature changes, and precipitation are factors that destroy the chimney pipe. Installing a weather vane is necessary to increase its service life.

Materials and shapes

In the 19th century, weather vanes were only forged, and there were simply no other ways to make a device from metal. Currently, various materials are used to make the wind vane, on which the performance of the mechanism will depend in the future. Manufacturing materials include:

- Copper. Copper structures will last a long time (about 50 years). Mechanisms for fastening a copper weather vane should also be made of copper, because a chemical reaction can occur with other materials, which will subsequently lead to a modification of the design. The color of copper structures under the influence of UV rays can change, from brown to green.

- Galvanized iron and steel. These manufacturing materials are not inferior to copper structures in terms of reliability and strength. These materials can be painted in any color.

- Stainless steel. The stainless steel construction will last about 20 years. These devices are resistant to high heat. The only disadvantage of using stainless steel is that such products lose their original appearance over time.

- Zinc-titanium is a modern building material, which in its performance qualities does not differ from copper structures. Service life of at least 50 years.

Weather vane with deflector

There is another option, how to make a weather vane for a chimney with your own hands. The drawings are presented in the article. You can buy it at the store or make it yourself. This model is the second manufacturing option, which does not require special skills.

The weather vane is installed on the dome, which covers the chimney pipe. The material must be selected to be corrosion-resistant.

Original dome affairs:

Scheme for assembling a dome for a chimney. Simple and clear

- Initially, the posts (4) should be secured to the lower cylinder (9).

- For this purpose, M 6 nuts (8) and M 6 bolts (7) are used.

- After this, the upper cylinder (3) is placed and secured with a clamp (5).

- After this, attach the reverse cone (2) to the very top of the posts using rivets (6).

The base is ready. Next you should make the weather vane itself.

Chimney weather vane with flag and counterweight. The flag figure can be anything, but the construction principle is similar

To do this, you should pay attention to the drawing, which exactly illustrates how easy it is to create a decorative weather vane.

Scheme for creating a weather vane. Its main parts and the order of their arrangement

Manufacturing stages:

- Stage 1. You need to make a support. It requires a pipe. A piece of twelve and a half centimeters should be cut off. Its diameter should be approximately 1.3 centimeters.

A pipe with a diameter of 13 millimeters, which will be the basis for the future weather vane

- Stage 2. The pipe needs to be threaded.

A pipe with a thread applied to one edge for fastening

- Stage 3. A bearing that fits in size should be placed inside the workpiece.

A pipe with a bearing inserted into it. Blank for a weather vane.

- Stage 4. It is necessary to weld two steel plates on the sides of the pipe, which will correspond in angle of inclination to the dome. It should be installed so that they do not interfere with the rotation of the structure.

Fasteners for a weather vane on a dome with plates welded on it

- Stage 5. You need to install a wind rose, which is thin steel rods. Letters are attached to them.

Rose of Wind. Arrows pointers indicating direction. They are set according to the compass.

- Stage 6. To prevent moisture from entering the case, a cap is installed above the compass rose.

The number 5 indicates a dome to protect the body of the future weather vane from water ingress.

- Step 7: Pay special attention to the lid. Made from steel. It should fit perfectly onto the pipe thread. It is made in the form of an arrow.

The uppermost part of the weather vane, which sits on a thread pre-made on the base

- Stage 8. A flag and a counterweight are attached to it.

The flag and counterweight of a weather vane to indicate the direction of the wind. Installed on the arrow-cover.

- Stage 9. The weather vane is ready.

A ready-made version of a weather vane, which will be installed on a previously prepared dome for it

Making a weather vane with your own hands is not difficult. These are just a few options for its manufacture. But the principle is basically the same in all models.

After the model is completely assembled, it should be properly secured to the roof; these tips will help with this.

How to make a Volpert Grigorovich Deflector

The most common method of removing combustion gases (chimneys) and ventilation all over the world is natural draft, which arises due to the difference in temperature and pressure indoors and outdoors, but this is precisely the problem, since in summer the edges are erased. There can be two solutions here: creating forced traction using an electric motor with an impeller, or installing a Volpert-Grigorovich deflector or another model that you can assemble with your own hands (drawing attached).

Each of these deflectors is designed to improve traction

A deflector is a device that improves draft in a pipe. It does this due to the fact that as a result of air flowing around the deflector, areas of low pressure are formed directly above the pipe. And this entails the leakage of air (or furnace gases) from the pipe. Those. there is an effect of elongation, lifting the pipe by about 15-20%.

But this is often more than enough to provide good traction in short (low) pipes. Deflectors have been known for quite a long time, since the discovery of the laws of aerodynamics, but they are widely used only in industrial systems. And although their manufacture is very simple and everyone can do it, the reason for their absence on our pipes is solely ignorance and lack of information.

There are many deflector systems: TsAGI, Volpert-Grigorovich, Khanzhenkov, etc. But the most common option for heating is the Volpert-Grigorovich deflector. Although, according to some reviews, the TsAGI deflector has proven itself better for ventilation systems.

The deflector circuit is quite simple. A truncated cone is installed above the pipe - a diffuser, so that the pipe fits slightly into it. A protective umbrella is installed over the pipe as usual. But to compensate for the damage (high pressure zones under the umbrella), an inverted cone is attached under the umbrella. As a result, inside this structure, when the wind blows from the side, a reduced pressure is formed, and the smoke more readily rushes out of the pipe outside.

Before you start making the deflector, you need to calculate its dimensions. All of them are tied to the diameter of the pipe. (If the pipe is square, then a square deflector is made, although it works worse due to its angularity). The diameter of the pipe is considered the initial value D. And all other dimensions are calculated with the coefficients corresponding to the sketch.

The diffuser diameter at the bottom is 2D, at the top – 1.5D, the diffuser height is 1.5D. The “immersion” of the pipe into the diffuser is 0.15D. The height of the umbrella cone, the reverse cone and the distance between the umbrella and the diffuser are 0.25D each. All these dependencies were obtained as a result of blowing the deflector in wind tunnels. Therefore, it is strongly recommended to adhere to them.

So, knowing the dimensions, we begin to calculate and cut the workpiece. The ideal material for the deflector would be thin stainless steel. But regular galvanized steel will do just fine. It will last for many years, but making a new one will take several hours. The article “How to calculate a cone pattern” will help you in calculating the size of the blanks.

To avoid fussing with the bends and twists of the steel, I used blind rivets and a rivet gun. Since there is no need for tightness here, fastening the edges of the pattern with rivets is much faster. It is convenient to use some kind of mandrel in the form of a hanging bar on which the diffuser is placed. Holding the part, we drill holes in two edges at once, insert a rivet and “pull it out” with a rivet gun. Fast and reliable fastening. Lightly straighten the rivet with a small hammer.

We also do the cones of the umbrella and reflector, but do not connect them yet. To attach the umbrella to the diffuser at the desired height, I used pieces of threaded rod. For stable fastening, 3, arranged in a three-pointed star, are sufficient. On the diffuser, the pins are attached to special loops made from a strip of metal and also attached to the diffuser with rivets. The studs are simply screwed into the hinges and secured with nuts. This system allows you to very accurately and quickly set the umbrella to the desired height.

We invite you to familiarize yourself with the DIY sauna stove (125 photos): foundation for the boiler, how to make a stove with high efficiency, drawings and diagrams

3 holes are drilled in the reverse cone and the reverse cone is fixed with nuts and locking washers at the desired height. Now you can attach the protective umbrella. Since it is slightly larger in diameter than the reverse cone, along its perimeter in several places the protruding edge is cut to a width of 1-2 cm.

Now all that remains is to attach the deflector directly to the pipe. To do this, it is convenient to use a short piece of pipe, so that you can slowly and efficiently connect it to the deflector, and then install the entire structure on the chimney.

Having marked and drilled the necessary holes in both the diffuser and the pipe, we fix the deflector using threaded rods, ensuring the required amount of pipe entry into the diffuser. Now you can install everything on the pipe.

Perhaps the design will seem somewhat cumbersome to some. However, the deflector actually significantly improves the draft in the pipe. Even with a slight wind, the draft even in a cold oven can be felt very clearly with your bare hand and by ear. During combustion, even when the furnace is ignited, the draft increases as the pipe warms up. And a strong wind creates a very significant draft, as if air is being forced into the firebox, as if pressurized.

According to subjective feelings and experience, the pipe is approx. 3 meters works the same as a height of 5 meters. If the firebox of the stove is not overloaded with fuel, and a good air supply is provided, then the height of the flame in the firebox is no more than 15-20 cm, versus the usual 40-50. In this case, the combustion process is very active.

By spending just a few hours making a deflector, you can significantly improve the combustion process in your stoves.

The question of whether it is advisable to purchase a deflector worries thrifty homeowners. This is not surprising, because the simplest device costs about 17-18 dollars. The average purchase price is $45-60.

The options for weather vanes offered by manufacturers and private companies are very diverse. Some models are made so skillfully that they look like a real work of art

In this case, making the device will not be difficult. And the aesthetic component does not always come first. Sometimes a deflector is needed for the chimney of a boiler heating a garage or other utility room.

The cost of the simplest deflector options starts at $17. To buy a Khanzhenkov, TsAGI or Volpert-Grigorovich model made of galvanized steel you will need up to $50. Moreover, these can be factory products or handmade ones.

The efficiency of the device does not depend on the manufacturing method. The main thing here is to choose the correct diameter of the product and the right model that can meet the needs of a particular chimney.

When purchasing, you should pay attention to the characteristics of the deflector:

- material type;

- metal thickness;

- diameter of the pipe for mounting on the chimney pipe.

Manufacturers also offer stainless steel options. They differ in cost - the price of rotary stainless steel models can reach $140 or more.

The most common deflectors used for chimneys in private houses, cottages and baths: TsAGI, round “Volper”, H-shaped, star-shaped “Shenard”, Grigorovich and open Astato.

For chimneys on the roofs of houses located in areas with gusty winds, N-shaped deflector options are often chosen

Whether to buy or build a traction amplifier is a matter of individual decision. For those who like to do something around the house, this task will be a pleasant and interesting activity.

If you don’t have any tools or skills for doing housework, then it will be easier and more convenient to purchase a finished product, choosing the most suitable model that will not stand out from the overall picture of the roof.

Now it’s not a problem to choose a deflector model that can organically fit into the roof composition

When purchasing or making your own device, it is important to consider the material of the roof covering. If it is a flammable material, then it is imperative to provide a spark arrestor. This is an important point that ensures the safety of all family members living in the house.