Every owner of his home tries to make it as cozy and comfortable as possible. To achieve this, you should think about installing an Ariston double-circuit wall-mounted gas boiler, which will help solve problems with heating your living space. The device is very useful because it will provide heat in both an apartment and a private house with an area of up to 500 m².

Also, an Ariston double-circuit gas wall-mounted boiler will allow you to quickly heat water for immediate use. In this case, a person will not have to connect a boiler, which will require additional investments and a separate place for installation.

Descriptions of the Ariston double-circuit boiler

Today you can find many interesting models on the gas boiler market. This is quite convenient, since everyone can choose the device that is most suitable in terms of price, type, characteristics and installation method. Ariston double-circuit wall-mounted boilers gained their popularity due to rare situations with their malfunction, as well as silence during operation, which is very important for maintaining a calm environment in the house.

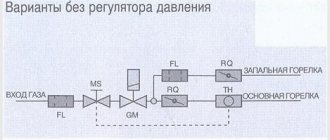

One of the most important components in all gas boilers is the burner, in this case it can be modulating or conventional. The first option is more popular than the second. When using it, the entire system will be adjusted automatically, without human intervention. In this case, the power of the installed heating equipment depends on temperature indicators.

The burner is also divided into 2 types:

- open;

- closed.

The safest is a closed system, since it does not involve combustion products entering the room in case of emergency. Also in this case, the owner does not have to worry about building a chimney. A special coaxial pipe must be connected to the closed burner; it can always be brought outside in any accessible place.

An open-type Ariston boiler, in any case, requires a chimney to remove combustion products to the street. Also, do not forget about natural cravings. Air will enter the system from the living space, so it will have to be constantly ventilated.

The coaxial pipe used in a closed combustion system has the advantage of being made of 2 layers. One is necessary to remove combustion products, and the other will ensure fresh air enters the boiler. Thus, the owner of the equipment does not have to constantly ventilate the room and worry about natural draft. The room will always have a sufficient amount of oxygen.

Features of replacing a faulty heating element

If the boiler stops heating the water to the required temperatures, then the heating element should be replaced. To do this, you need to perform the following procedure:

- Disconnect the device from the electrical network.

- Stop supplying water to the container.

- Connect a hose to the drain valve and drain all the water into the sewer.

- Remove the protective box by removing 2 screws.

- Remove the return valve from the pipe.

- Drain the remaining water from the tank.

- Using a wrench, unscrew the nut that secures the flange.

- Carefully remove the old heating element without damaging the flange.

- Clean the walls of the container from accumulated dirt. If the inside walls have a special protective enamel, then there is no need to remove scale. You may simply damage the protective film. This layer of scale will protect the walls of the vessel from rust formation.

- The magnesium anode is removed and repaired if required.

- A new heating element is being installed. You need to do exactly the opposite of all the work.

- Checking operation after final assembly of all parts. The tank should not leak. Otherwise, you need to put in new gaskets.

Ariston water heater repair

Distinctive abilities

According to reviews of Ariston gas wall-mounted double-circuit boilers, they have 4 distinctive features that are useful for their owners:

- All models of this company are equipped with automatic protection systems.

- The presence of a water pump, which is necessary for constant circulation of water through the pipes.

- Possibility to choose a model with an expansion tank. With its help, pressure will be automatically adjusted inside the heating system.

- Ariston equips its equipment with various types of ignition. It can be automatic, which will make life much easier for the owner of a particular boiler. Otherwise, every time the unit starts, the person will need to press a special button.

You might be interested >> The principle of operation of the Proterm double-circuit gas boiler

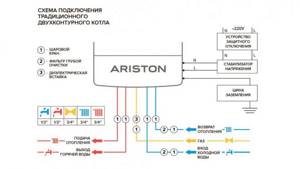

Filling the heating system with water

Starting a gas boiler begins with filling the heating system with water. Everything is simple here - modern double-circuit boilers do not require the installation of a special system feeding unit. It is already built into the boiler and equipped with a special tap, which, as a rule, is located at the bottom of the boiler in close proximity to the cold water connection pipe. Open the feed tap and slowly fill the system with water.

Starting the boiler - how to fill the system with water

A very important point in the operation of any boiler equipment is fluid pressure. To control this parameter of the heating system, almost all boilers are equipped with a pressure gauge. During the process of filling systems with water, it is necessary to monitor the pressure and after it reaches 1.5-2 atm, filling the system will need to be stopped. In principle, the operating pressure of a boiler may vary depending on the manufacturer and model - therefore, see the instructions for the boiler for the exact operating pressure.

Do-it-yourself first start-up of a gas boiler

What are the advantages of Ariston gas boilers

Recently, the popularity of the Ariston brand has increased significantly due to high-quality gas boilers, and this is not in vain. Double-circuit equipment operates silently and consumes fuel in the smallest quantities possible. This will allow the owners of the unit to save on utility bills and, at the same time, provide comfort and warmth to the home.

The client will receive a high-quality device that provides round-the-clock water supply and heating to the house, even with a large area of up to 500 square meters. Also, do not forget about the longevity of each boiler. The periods specified in the guarantee are much more modest than they actually turn out to be. The dimensions of the equipment are much more compact than those of other brands, which means that it can be installed absolutely anywhere, even in a small apartment with limited space.

Advantages and disadvantages

Ariston gas boiler systems are popular all over the world, this is due to their exceptional performance characteristics:

- effective built-in protection system against power surges in the network - devices can operate in the voltage range from 150 to 260 V;

- the ability to effectively regulate the rate of water heating: in the case when the flow rate does not go beyond 6 l/minute, the temperature can reach up to 37 degrees; in order for the water to heat up faster, you simply need to increase the boiler power;

- simultaneous operation in the mode of a water heater and an efficient heating device;

- the ability to automatically shut off the gas in the event of flame extinguishment, regardless of its causes;

- automatic shutdown of the heater if the water pressure in the system drops to a critical level;

- the presence of two heat exchangers;

- wide range of models;

- excellent adaptation to use in Russian conditions;

- Italian assembly;

- European quality control system.

However, there are also disadvantages, among them the following should be highlighted:

- very high cost in comparison with analogues;

- use of components produced in China.

Russian users highlight boilers of this brand as high-quality, reliable and practical. Reviews from owners of private houses indicate such advantages of Ariston as compact dimensions, energy-efficient gas consumption and ease of control of the mechanism. Among the disadvantages is the dependence of its operation on the power supply, but this feature concerns not only Ariston - almost no gas equipment operates without being connected to an alternating current network.

Specifications

Almost all gas boilers from the Ariston brand have a power of 15 to 30 kW. Thus, each client will be able to select the necessary indicators for the size of their apartment or house. It is also worth noting other distinctive characteristics of such gas equipment:

- at maximum efficiency, boilers have a high level of efficiency;

- all wall-mounted boilers have Russian instructions and symbols on the equipment itself, so citizens do not have problems with operating the unit;

- most models from this manufacturer are able to cope perfectly with water in the system and low pressure;

- Particular attention to this equipment should be given to those people in whose homes voltage surges often occur. Ariston boilers cope with such network surges without any problems;

- All models are very easy to operate. To start using the boiler, you don’t need to study the instructions for a long time; all operating features are intuitive and accessible even to those who are installing such a unit for the first time.

In some cases, the boiler cannot simultaneously heat water and provide sufficient heating of the room; this applies to budget models. In this case, a person needs to think about installing an additional boiler.

Note! If we talk about expensive units, they have a special display that displays various characteristics, including the temperature inside and outside the boiler. This is very convenient in terms of entering the necessary characteristics for the correct operation of the equipment.

Removing air pockets in the system

It's better to start with batteries. To remove air pockets, a Mayevsky tap is usually installed on them. We open it and wait for the water to run. Did you run? Let's close. Such manipulations must be done with each heating device separately.

How to start a boiler with your own hands photo

After the air is removed from the batteries, the pressure in the system will decrease and the pressure gauge needle will drop. At this stage of work, the solution to the question of how to start the boiler involves re-filling the system with liquid.

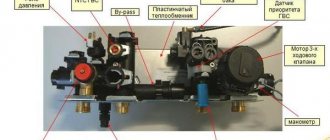

Now, the most difficult thing is that starting gas boilers requires bleeding air from the circulation pump. To do this, the boiler needs to be disassembled a little. We remove the front cover and look for a cylindrical object with a shiny lid in the middle, which has a slot for a screwdriver. After we have found it, we put the boiler into operation - we supply it with electrical power and set the water heating controls to the operating position.

Relieving air from the circulation pump when starting the boiler photo

The circulation pump will immediately turn on - you will hear a faint hum and loud gurgling and many incomprehensible sounds. This is fine. As long as the pump is aired, it will be so. Take a screwdriver and slowly unscrew the cap in the middle of the pump - as soon as water starts seeping out from under it, screw it back. After two or three such manipulations, the air will come out completely, the strange sounds will subside, the electric ignition will work and start working. Check the pressure again and add water to the system if necessary.

Basically, that's it. While the system is warming up, you can begin to study the instructions in detail (if, of course, you have not already done so) and start debugging the system that involves starting the boiler. Everything is simple here - the batteries closest to the boiler need to be screwed on, and the ones farther away need to be turned on to their full potential. This debugging is carried out using control valves installed on the supply connection pipe to the heating radiator.

Operating instructions for Ariston gas boilers

Before purchasing an Ariston gas boiler, you need to understand that if the buyer does not understand its installation, it is better to contact experienced specialists and entrust all the work to them. After all, even with the most detailed instructions, it is not a fact that the matter will end successfully. In this case, there is every chance of damaging the equipment, after which you will have to call repairmen, and this will result in additional costs.

You might be interested >> The main differences between a single-circuit and a double-circuit gas boiler

It is very important to keep children away from the equipment. To do this, after installing the gas boiler, you need to have a conversation with them and explain in clear language that you cannot twist or place anything on the unit, this should only be done by an adult. If the family leaves, for example, on vacation, after the boiler is turned off, it is also necessary to shut off all gas and water supply pipes. Only after this is the equipment disconnected from the network.

If any model has a display, all indicators that it displays must be strictly monitored. It may display any problems or deviations from normal operation that occurred during the heating process.

One of the most important points in the instructions for gas equipment is safety precautions. Before connecting the boiler, you need to familiarize yourself with it first.

How to work with the menu

By pressing the “OK” button once, the number 2 will blink on the digital indicator - this will be the first digit of the future three-digit code (Menu Group Number)

Using the plus and minus buttons you can change this value from group number 2 to any other group. To fix the selected group for further entering the code number, you need to press “OK” again - after this the second digit of the future three-digit code begins to blink (Submenu)

Having selected a submenu, fix it by pressing the “OK” button again and similarly select and fix the third digit (Parameter)

All! Now the screen will no longer display the three-digit code itself, but the set value of this parameter, which can be changed by pressing “plus” or “minus”. Having made the necessary changes, do not forget to commit them by clicking “Ok”.

Please note that after selecting the desired menu, after a few seconds of inactivity, a three-digit code will begin to be alternately displayed (to remind you where you are) and the parameter corresponding to this menu.

The ESC button is used to exit the settings menu and return to the previous step. The exit is carried out step by step, one press is equal to one step back.

Let's practice

Now, if you want, practice to better understand the switching order. For example, enter menu code 701; this will turn on the forced air removal mode, essentially turning on the pump in the boiler for 6 minutes.

When this mode is turned on, the “P I -” symbol will light up on the display. You can exit the “Anti-Air” mode without waiting 6 minutes by pressing ESC.

Then, using ESC, try to go back and switch to mode 300, which means (Set water temperature in the boiler) in the values you can see the temperature that is currently set by your DHW regulator.

What types of Ariston wall-mounted boilers are there?

All Ariston boilers are divided into 3 series. They have different technical indicators and functions, namely:

- Clas - this series refers to more bulky and powerful devices for heating residential premises. They are equipped exclusively with special regulators that automatically regulate the gas supply. This is necessary to save fuel, which is very convenient in terms of utility costs and for frequent business trips of the home owner.

- Genus. These are the most innovative and multifunctional models of Ariston gas units. They have more features than other boilers from this manufacturer. Along with the equipment itself, the buyer will receive additional accessories such as a fan necessary for smooth speed control, as well as heat exchangers, primary and secondary. All devices from the Genus line are distinguished by the presence of a large liquid crystal display. It will display all the characteristics that correspond to the operation of the boiler at the moment.

- Egis. The units from this series are small in size and attractive in appearance, which is why they have earned great popularity among owners of small apartments. The device will fit well into any interior. An important feature of these boilers is that, given their size, they have a fairly high level of efficiency and low fuel consumption, which is controlled by an intelligent control system.

Causes of malfunctions

In most cases, the cause of breakdown is violation of the rules in the operating manual. The main mistakes when using Ariston hotpoint refrigerators are as follows:

- The door remains open for a long time - to prevent this situation, refrigerators are equipped with a sound signal that beeps and warns of the need to close the door, but most owners ignore this “request” of the refrigerator.

- Often the door remains loosely closed due to incorrect placement of dishes and food on the shelves of the unit.

- Dishes that have not yet cooled down are sent to the refrigerator.

- When using a model with periodic defrosting, the manufacturer's recommendations regarding timing are not followed - icing occurs on certain components of the unit, which often leads to failure of the refrigeration equipment.

The electronic control system helps check the functioning of the unit, signals malfunctions, and if defects are eliminated in a timely manner, the operating period increases noticeably.

Error d, displayed on the screen, indicates a failure to open the valves. When the unit was released in 2012, this problem is global and applies to all refrigerators of that year. At home, it is impossible to eliminate the problem on your own, since this is a “development defect” that can only be solved in a service center. The problem is that the top door has a plastic gasket at the bottom that wears out when the door is opened and closed frequently. It is only possible to smooth out the depth of the problem a little on your own by cutting out a gasket from rubber to replace this plastic - in order to lift the sash. But not all models can carry out such repairs.

Tables with three-digit codes, descriptions and set values

The values added in the white fields are the values used in my boiler. If there are no corrections, then I have the same values as those printed in the table. To enlarge, click on the photo of the table.

Do you want to install individual heating in your home? Have you already installed and connected gas equipment? Great, then all that remains is to figure out how to turn on the gas boiler. Do you think it’s enough to insert the plug into the socket and select the temperature? No matter how it is. Before this, it is necessary to bleed the air and fill the system with water. You will find instructions with the sequence of actions in our article.

Peculiarities

Gas boilers made in Italy by Ariston are presented in a wide variety of models, however, regardless of the modification, the equipment of this brand is aimed at installing heating systems on an area of no more than 500 m2. Some boiler options only work for heating, while others are used not only to supply heat to the house, but also to supply hot water.

Speaking about the essential options for gas boilers from this manufacturer, we can highlight the following characteristics.

- The presence of a multilingual menu - this allows users to choose a language familiar to them to effectively control the operation of the boiler.

- The “auto” function makes it possible to configure the required power parameters in autonomous mode based on monitoring the actual temperature in the room, as well as inside the boiler.

- Heat and noise insulation - ensures silent operation of the equipment, and in addition helps to maintain the coolant at a given temperature for a long time even after stopping work.

- The warranty on all of our equipment is 2 years for standard boilers, and longer for condensing models - for 3 years.

- Ease and ease of use - the menu is thought out very competently, thanks to which even beginners who have not yet dealt with gas installations can effectively operate the boiler.

- A safety system that prevents breakdowns caused by power outages.

- Built-in electrified elements that maintain the operation and performance of the unit even in conditions of low water or fuel pressure.

A characteristic feature of all Ariston models is a well-thought-out and highly technological protection system, which ensures long-term and uninterrupted operation of the gas installation.

It includes:

- mechanisms for replenishing the boiler with water;

- built-in system for timely pumping out accumulated air;

- blocking the circulation pump;

- anti-scale and anti-freeze protection mechanism.

Common parameters of all Ariston models include small dimensions and the ability to supply hot water. The basic package includes: a double-type heat exchanger, a burner control module, a carbon monoxide control system, a mechanism for maintaining a normal indoor microclimate, and a device responsible for controlling the freezing of water inside the heating system.

Cold or insufficiently hot water flows from the boiler

The cause of a malfunction of this nature may be a breakdown of the heating element, thermostat and a large layer of scale on these devices. Before determining the cause of the malfunction of the Ariston 80-liter water heater and doing the repair yourself, you should turn off the power supply and drain the water.

Then, using a 13 mm wrench and a Phillips screwdriver, remove the protective box and unscrew the bolts on the mounting plate

Carefully remove the flange on which the heating element and thermostat are attached. Now you need to descale these 2 devices

The thermostat should be unscrewed, cleaning the attachment points to the flange from sediment, then carefully, using a screwdriver, free the thermostat from scale. You can check the functionality using a tester; the absence of a signal on its contacts indicates a malfunction and the need for replacement, since the thermostat cannot be repaired

You can also check the heating element for functionality using a tester by connecting the ends of the tester to the contacts of the heating element. If there is voltage, the heating element is working, but it needs to be cleaned

The heating element can be cleaned using a screwdriver, carefully removing pieces of deposits

Then you need to prepare a solution of citric acid - 100 g per 1 liter of water and immerse the heating element in the solution. The effect of the solution on the device will be indicated by air bubbles that appear as a result of the reaction. If this action is not enough for complete cleansing, you can put the vessel with the solution and heating element on low heat.

After cleaning the heating element, you need to descale the tank

Be careful not to damage the inner surface of the tank. If it is possible to remove the heater from the wall, cleaning can be done using a solution of citric acid, pouring it into the tank

After these manipulations, assemble all the parts in the order in which they were disassembled and carefully insert and secure the flange. Make sure that during assembly there are no distortions of parts, do not overtighten the bolts, change the gasket between the body of your storage boiler and the flange, since the flange gasket was also exposed to salts

Correct maintenance of the device

The fact that problems have arisen in the operation of the device may be indicated by some changes in its operating mode. For example:

- increasing the time for heating water to a given temperature;

- the appearance of unusual sounds accompanying the operation of the device;

- the appearance of foreign impurities in tap water, changes in its color, smell or taste.

If at least one of these signs is observed, you should immediately clean the water heater. To do this you will have to perform the following operations:

- Disconnect the device from the power supply.

- Remove the protective cover.

- Disconnect the contacts of the electrical wires.

- Shut off the cold water supply.

- Use a hose to remove any remaining water from the tank.

- Unscrew the bolts that hold the heating element.

- Remove the heating element and descale it.

- Clean the inside of the drive from dirt and scale particles.

- Rinse the device thoroughly.

- Check the serviceability of the magnesium anode.

- If necessary, replace this element immediately.

- Wait for the cleaned tank to dry completely.

- Reinstall the heating element.

- Reassemble the device.

- Check the reliability of all fastenings.

- Connect the water heater to the power supply.

- Check for grounding.

The heating element should be removed from the tank carefully; the bolts may be too stubborn; sometimes the heating element is difficult to remove due to too much scale. The heating element is cleaned by mechanical or chemical means, as is the removal of contaminants from the tank. If a large amount of scale is found inside the device, you should consider reviewing the operating mode of the water heater.

This phenomenon is often observed when the device operates at maximum power for a long time. It is recommended to set the maximum heating temperature no higher than 60 degrees to increase the life of the device and reduce the number of breakdowns. If the body of the heating device receives an electric current, the heating element may be deformed and ruptured, or there may be a breakdown in the control system.