The cabins are intended for short-term accommodation of people in field conditions. These are structures that are made of metal sheets and decorated from the inside, and often from the outside, with finishing materials. To avoid freezing during the cold season, the walls, floor and ceiling of the temporary buildings are lined with insulation. But in order to be able to live in the house during the winter months, it is necessary to take care of heating the room.

To heat temporary huts, special equipment is used - fireproof devices that, when heated, do not create an open fire. They can be equipped with wooden and metal cabins for various purposes. Most often, the following units are installed in temporary shelters:

- Solid fuel stoves

- Autonomous gas heaters

- Electric furnaces and electric radiators

- Equipment running on diesel fuel

Each device has distinctive characteristics, after studying which the consumer can make a choice in favor of the most suitable device.

Furnaces for heating cabins

If the change house has a sufficient area and requires long-term use, then installing a wood stove will be a good option. Hiring a craftsman and purchasing materials is not cheap, but in the long run the stove will pay for itself thanks to cheap firewood and good efficiency.

The disadvantage of a stationary stove is the inability to remove it after the end of the heating season.

Heating the cabin with electricity

Heating a cabin with electricity in winter breaks records of popularity. If you have access to electricity, then this method is easy to install, safe when used according to the instructions, and has a huge number of types of stoves and heaters. Many models have the ability to adjust the temperature.

Electric heating of the cabin is carried out using:

- mobile oil batteries (radiators);

- electric fireplaces (stoves) with imitation of live fire;

- convectors, which heat the room using air flow;

- film or infrared heaters.

The first and second options are not very good for heating a container, because such stoves and radiators heat up the space around them more. The far corners of the trailer will be cold, especially if the area is large. And the heating is slow. Considering that working outbuildings at the dacha are not used constantly and do not require round-the-clock temperature control, this will reduce comfort.

A convector that blows warm air into a room copes better with hard-to-reach places, but for uniform heating it is better to purchase several of these devices.

Film and infrared devices are compact, heat evenly, and are used for additional heating. Infrared heaters also do not dry out the air, which significantly increases the comfort of being in the trailer.

You can heat the room using an air conditioner. It must have a heating function, but even in this case it cannot heat in the same way as a stove. The difference between the temperature inside and outside the room should not be more than 10 degrees.

- Expensive. Electricity is not that cheap.

- Access to electricity. Not all cabins are equipped with this feature.

- Infrared devices do not heat the air itself, but the surfaces in the room, and then the objects give off heat. This is not always rational; there are few things in the room, and heating only the walls does not provide adequate heat.

But the devices do not require any additional purchase of fuel or particularly complex installation. They are safe, easy to use - you just need to plug them into the network.

IR heaters for change houses. electric infrared heaters for change houses

View:

Brands:

Frico Neoclima Ballu AEG Almak Veito MO-EL

- ceiling

- wall-mounted

- economical

- waterproof

- with thermostat

- maximum power

- permanent job

When the question arises about heating a cabin, the first question raised is the safety of this process. Previously, builders installed a wood-burning or waste stove in trailers, but over time, technological progress takes its toll.

This was also facilitated by high fines from the Ministry of Emergency Situations and the sad statistics of fire victims. Infrared heaters for households are an opportunity to get a safe, effective and at the same time economical heating option.

Why infrared heating for a cabin?

Infrared wall and ceiling heaters do not have open heating elements, which is an indicator of relative safety. They can be left unattended for a long period of time, even if there is a large amount of construction dust in the room air.

This heating system is relatively inexpensive, does not require constant maintenance and control work, consumes a relatively small amount of electricity and can be used with a thermostat. Because of this, infrared heaters can be used not only in cabins, but also in small shops, kiosks, and at checkpoint security posts.

The operating principle of infrared heaters for change houses

Infrared heaters can be of two types: electric and gas. Both types can be used in construction sheds.

Electric heaters for cabins have the following operating principle: an electric current is supplied to the heating element, which is later converted into heat waves in the infrared radiation range.

They fall on a metal reflector installed behind the heating element, and thereby spread throughout the room. The operation of these heaters begins 27 seconds after it is plugged into the power supply.

Because of this, it will be comfortable to be in the change house right away - there is no need to wait a long time until the room is completely warmed up. Infrared radiation acts directly on people and objects in the room, heating them. Only after this do objects and walls begin to reflect heat, thereby warming the air in the room.

Unlike gas ones, they do not burn oxygen and do not require a cylinder or a constant supply of gas. They turn on at any outside temperature. Many models are equipped with protection against construction dust and high humidity.

They can be easily dismantled if it is necessary to transport the cabin or install it in another place. In addition, they can easily withstand voltage fluctuations in the network, which is especially important for rural areas when light bulbs barely light up in winter. They will produce a little less heat, but this will not lead to failure.

Convenient to place above resting or heating areas, drying rooms.

In particular, electric ceiling heaters are installed in construction cabins , mounting them on the wall or ceiling. These heaters are very convenient - they can heat almost the entire room, do not interfere with movement and are very safe.

Ceiling heaters for households have a lot of advantages, namely:

- low cost. buy a heater for a cabin - there are many products on the market with different price ranges. However, their effect is almost the same - regardless of the price, the heater will do its job efficiently, consume a minimum of energy and have a long service life. In particular, the low price is due to the simple design and minimal number of parts;

- safety. Household heaters can be left unattended for a while - they will not overheat and cause a fire. The heating element is reliably protected from overheating and does not negatively affect the human body or objects in the household. In addition, they are equipped with a thermostat, which allows, if desired, to significantly reduce or increase the heating temperature;

- noiselessness. They have no moving mechanisms. Because of this, complete silent operation is ensured, which does not interfere with being in the shed;

- long service life. Due to the fact that all elements are designed for long-term continuous operation - the power regulator, heating element and reflector, they have a long service life. There is practically nothing to break in it; all you need to do is periodically wipe the metal reflector to more effectively reflect heat;

- mobility. IR heaters for households can work both indoors and outdoors.

Ceiling electric heaters for households are an innovative modern solution that allows you to constantly stay warm at a relatively low price. Cheap electric heating, the absence of flammable oil and noisy blades - IR heaters are the best solution not only for cabins, but also for apartments.

Heating with solid fuel

The so-called potbelly stove runs on wood or coal.

Due to emissions of combustion products, a chimney is required! This is the basic requirement. It is important to monitor safety - the stove is installed at a distance from the wall (at least 30 cm), the proximity of sleeping places is excluded, the stove should not interfere with the movement of people.

But the potbelly stove also has undeniable advantages. Cheap fuel allows you to use the device for a long time. Firewood is prepared for a long period of time.

If the stove runs on coal, it saves space; the fuel will take up less space.

This is the second most popular method after electric heaters.

Preparing for insulation

If the trailer was not initially insulated, then in the cold weather it will have to be done. Without proper thermal insulation, any heating methods will be unnecessarily expensive. It will be needed for both wood and metal change houses. All surfaces (floor, walls, ceiling) are insulated; the ceiling and walls are sheathed either inside or outside.

Options for thermal insulation materials:

- Styrofoam;

- cotton insulator;

- mineral wool;

- polyurethane foam.

The first step is to select and purchase the material. The calculation of the area takes into account whether the room is sheathed outside or inside. When upholstering, space is eaten up inside, but you don’t have to worry about the impact of the environment on the material and appearance.

Polystyrene foam does not burn, does not allow moisture to pass through, and is light in weight. But it is destroyed by chemicals and does not tolerate the sun. Therefore, it will have to be plastered. It also does not bend, the rounded parts will not be protected.

Cotton insulation is environmentally friendly, easy to install, but difficult to cut.

Mineral wool is durable and soft, not flammable. It is easy to upholster due to its texture. When working with cotton wool, take precautions: protect the skin from the smallest fragments of the material, breathe through a respirator. The price is noticeably higher than polystyrene foam, but cheaper than cotton insulation.

Polyurethane foam is a synthetic material, relatively flammable and toxic, susceptible to destruction, but very easy to install. This compensates for its high cost. Toxic substances evaporate from it in a few days.

Thermal insulation is placed in a wooden or metal frame. The cleaned surface is treated with an antiseptic. Then a frame is made with cells 50x50 cm. The material is placed in them. For the work you will need screws, nails, a hammer, wood mastic, a stapler, and a vapor barrier.

When laying thermal insulation on the roof, the slate is removed.

Materials for insulating cabins

A modular building is erected using the half-timbering method, which is a type of frame technology. The frame initially has internal cavities between the outer and inner wall cladding and the elements of the load-bearing frame. Therefore, insulation is usually placed inside the frame sheathing to reduce the cost per square meter.

In this case, all elements of the load-bearing frame, between which the heat-insulating material is laid, automatically become cold bridges. That is, the manufacturer seems to have insulated the modular cabins from the very beginning, but most of the thermal energy is spent on heating the street. That is why there is a need to improve the thermal contour of the building.

Requirements for insulation

Before insulating a trailer with your own hands for the winter inexpensively, you need to take into account a number of requirements:

- compatibility with wall and frame materials;

- layer thickness depending on specific thermal resistance;

- state of aggregation (loose expanded clay, ecowool, hard polystyrene foam, soft basalt wool).

In case of an error, at best, the repair budget will be wasted, at worst, the load-bearing frame will have to be changed, that is, the house will actually be demolished.

Bulk insulation made from cut paper impregnated with brown and boric acid has the following characteristics:

- not suitable for screeds, fits into cavities of walls, ceilings, floors;

- in its category it is considered the only material that repels insects and rodents;

- has a high operational resource;

- susceptible to caking over time - the formation of cold bridges at the junctions of walls/ceilings;

- moderately smoke-generating, flammable, combustible;

- capable of absorbing, retaining, evaporating 20% moisture as needed;

- thermal conductivity 0.04 W/mK;

- impregnated with antiseptic and fire retardant, does not rot, does not burn;

- at low density, vapor permeability is also low, only 0.3 mg/mchPa;

- It is considered a chemically passive medium with pH=8 and does not cause metal corrosion.

Ecowool is poured into wall cavities between sheet materials, stretched films, and membranes. The thickness of the layer is 10 - 15% less than that of basalt fiber and expanded polystyrene, respectively. With this material it is impossible to perform comprehensive insulation from the inside of a trailer if there is a flat roof, since there is no access to the ceiling from above.

Basalt fiber

The main disadvantages of basalt wool insulation are the lack of rigidity and loss of properties when wet. The material cannot be laid in a screed; after getting wet, it will have to be dried to restore its characteristics. The main properties of stone wool are:

- thermal conductivity about 0.037 W/mK, vapor permeability 0.3 mg/mchPa;

- the material does not burn, melting point +870°C;

- the density is low, subsidence in the walls is possible.

This insulation is considered the best option for wooden cabins. The lumber from which the racks, crossbars, and floor beams are made inevitably absorbs moisture from the rooms. Mineral wool makes it easy to evaporate back because it has high vapor permeability.

Basalt fiber is safe for steel structures; you can insulate a metal trailer from the outside or inside.

One of the few insulation materials that retains its properties even when completely immersed in water is polystyrene foam. The material is cheap, but it crumbles a lot when working with it and breaks down over time. A better analogue of polystyrene foam is polystyrene foam:

- extruded XPS boards are used to insulate foundations under the sole and outside;

- self-extinguishing pressless PSB-S is used for thermal insulation of building envelopes.

How to insulate and how to heat construction trailers

A metal trailer requires a thick layer of insulation, because it was not originally intended for use in the winter months. A minimum of 50 mm of good insulation will provide not only heat but also sound insulation.

You can also use insulation such as penoizol - with proper experience, it will provide excellent insulating properties. This is a liquid mixture that fills the walls of the trailer. It hardens quickly in the air; there is no need to make a wooden frame. But mineral wool is also good.

If electricity is available, then the heating issue is considered resolved - buy a heat gun, wall heater or stove. If there is no electricity, but there is a sufficiently powerful exhaust hood or ventilation, then gas or diesel heating will do. In terms of economy, multi-fuel devices attract attention.

How to insulate and how to heat wooden and metal cabins for a summer residence

If there are no rounded bends in a metal room, then foam plastic is suitable for insulation. It should be of good quality, not crumble in corners and cuts. If there are doubts about the quality or the cabin is made of wood, then stone wool is better suited. And if you have the means, then use cotton insulation. Under the foam, the wood may become covered with condensation, because it does not allow moisture to pass through.

The tree must be treated with an antiseptic. The ceiling is upholstered on the outside, and the walls and floor are on the inside.

Vapor barrier is stuffed onto the cotton wool.

If the room has windows, then it is better to install modern double-glazed windows for additional warmth. If replacement of windows is not expected, the joints are filled with sealant.

Insulating a cabin on your own is cheaper than hiring workers. This is more profitable than buying an insulated trailer right away, but the main advantage is that this money is not required right away. The material is selected taking into account all conditions, including the heater.

When selecting a heater, attention is paid to the area of the room, availability of electricity or fuel, and safety.

With the correct calculation of the amount of materials, careful installation and a properly selected heater, you can work and live comfortably in such a room.

Source

How to insulate a cabin, materials and methods

Buying a high-quality cabin is not a problem. Manufacturers offer a large number of models of various purposes, sizes and performance levels. This can be a simple structure to store materials or a small building that is fully prepared for habitation. However, the cost of such cabins is very high.

The ability to handle tools, plumbing and construction skills will allow you to make a change house with your own hands, and its cost will ultimately be several times lower than the options offered on the market. The frame is assembled from profiled metal; the outer cladding is best made from sheet metal or wood boards.

After completing the assembly of the load-bearing structure and securing the external cladding, it is necessary to carry out work on insulating the cabin premises. This will allow the room to be used for living in winter, and in summer the presence of insulation can protect against heat.

Heating the cabin with electricity

This is the most popular and sought after method. Today, a huge number of models are produced, differing in configuration, type of heating element and performance. When used correctly, such devices are safe (many have tip-over protection), allow you to quickly heat the air and set the temperature at the desired level. In addition, they are easy to transport not only indoors, but also between different objects.

There are several types of electric heaters:

- Oil radiators;

- Electric fireplaces;

- Convectors that create warm air currents;

- Infrared panels.

Radiators and electric fireplaces can be used as an additional heating element or to maintain temperature conditions. But they are not capable of independently heating the air in a large room, even with constant operation; in the case of small-area cabins, this option is suitable when the temperature outside is low and there is insulation in the metal structure.

Convectors and heat guns are more effective, as they create movement of air masses in the room and affect the most remote corners of the cabin. Disadvantages include constant noise and dry air.

Infrared heaters consume little energy, so they can be used as an additional source of heat on an ongoing basis. They do not dry out the air and at the same time help maintain comfortable conditions in the trailer. In addition, the panels are very light and compact. They can be installed on the ceiling or walls without taking up space. But in empty cabins they will be less effective.

Infrared panels heat surfaces, which then release heat into the space, so they should not be placed above places where people rest or spend long periods of time.

Another option is to use air conditioners with a heating function. However, if the temperature difference between outside and inside the room is more than 100C, they will be ineffective.

Electrical devices are easy to use, mobile and do not require additional purchase of fuel. However, they require an electrical connection to operate. And the resource itself is not cheap.

Wood-burning stove for a change house

It is not always possible to complete the construction of a facility during the summer period and temporary residence in it may continue with the onset of cold weather. Therefore, the issue of heating in winter must be thought out in advance and normal living conditions must be ensured, regardless of the outside temperature.

At the same time, heating the room must be economically justified in terms of the cost of the heat source and fuel consumption for heating. One of the most important conditions for effective heating is proper insulation of the cabin.

Heat loss through the enclosing structures of the cabin trailer should be minimal due to the use of high-quality insulation, the absence of cracks and loose connections.

To use temporary structures during the cold season, you should immediately purchase insulated cabins or properly insulate them yourself. This will further reduce the cost of purchasing fuel and will allow you to avoid performing additional work related to installing insulation and sealing leaks.

In the event that the change house is placed on posts or foundation blocks, mandatory cladding of the base is required. It will reduce heat loss through the floor and create a space protected from the cold in the lower part.

Applicable heating options

For heating cabins, only fireproof equipment without open fire is installed. The choice of method for heating a shed depends on the availability and cost of fuel, financial capabilities, internal volume of the room and operating modes.

The most common 5 types of heating equipment for block containers:

- stove "potbelly stove" for heating with wood;

- wood-burning multi-pass stoves;

- electric heating devices;

- gas heaters;

- liquid fuel equipment.

Stove heating

Installation and operation of a potbelly stove requires compliance with fire safety standards

A “potbelly stove” is inexpensive, can be made independently and will provide quick heating of the room. The installation site of the “potbelly stove” must be protected by sheet metal, which is used to cover the adjacent walls and floor. In addition, it is necessary to insulate the structure of the cabin with basalt cords at the point where the chimney exits to the street.

A potbelly stove is operated manually and requires a constant supply of fuel. The efficiency is low due to the high temperature of the flue gases. The main advantages are low cost, combustion of any type of solid fuel and the possibility of making it yourself.

Wood stoves have a more complex design and allow the use of inexpensive fuel in the form of wood waste and firewood for heating. Requires a chimney and combustion air supply. During installation, additional fire safety measures are required. Maintenance is manual with the need for periodic removal of ash.

| Advantages | Flaws |

| Does not require additional communications | Weak efficiency |

| Cheap fuel | Need to constantly add firewood |

| High fire hazard | |

| It is necessary to have and maintain a chimney |

Heating using electrical appliances

Electric heating devices include:

- oil radiators;

- air convectors:

- electric boilers;

- other equipment that uses electrical energy for heating.

Electrical appliances operate automatically, maintaining the set temperature in the room. The equipment operates silently, does not require constant maintenance and creates comfortable conditions for people to stay. However, it has a high level of operating costs due to the high cost of electricity.

Modern heaters do not need to be monitored; they are equipped with automatic relays that will turn off the device if it overheats. This eliminates the possibility of fire.

| Advantages | Flaws |

| Fully autonomous operation | Requires connection to mains electricity |

| No smoke or noise during operation | Requires high-quality power supply |

| Fire safety | High electricity consumption |

Gas heaters

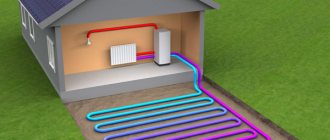

Liquefied gas is used to operate gas convectors. The equipment is convenient to use and does not require complicated installation. To install the convector, a chimney is not required. Warming up of the room occurs in 20-30 minutes and can be successfully used for cabins with temporary occupancy.

Disadvantages include the high cost of gas equipment and the need for periodic refueling. In addition, a metal box is required for outdoor installation and storage of gas cylinders. However, propane convectors are the best alternative for heating without electricity on site.

Temporary buildings are not allowed to be connected to central gas distribution systems, and obtaining special permission is very difficult. Therefore, convectors use liquefied gas from cylinders.

| Advantages | Flaws |

| Fully autonomous operation | Expensive equipment |

| No smoke or noise during operation | |

| Fire safety |

Another option for gas heating of cabins is portable (portable) gas heaters.

They are able to heat the room quickly enough and such devices are cheaper, but the fuel supply in the cylinder is not large.

The cylinder itself should be located not far from the device, this is due to the length of the hoses. This means that it will be located indoors, which requires strict adherence to all operating rules.

Heating the cabin with gas

Today there is a wide variety of devices, some of which are designed so that the gas does not burn, but only oxidizes, releasing heat. These heaters are perfect for work cabins made of sandwich panels. If the operating rules are followed, they are safe, characterized by high efficiency and availability of fuel. The cylinder is purchased once and then filled as needed. It is best to use propane, which has higher heat transfer.

When using gas burners, be sure to install a thermostat and fuel leakage protection.

Solid fuel stoves

To heat large-area cabins, the most effective and at the same time economical option would be to build a stationary wood-burning stove. To make it, you need to pay for the work of a craftsman, buy the required number of bricks and thermal insulation materials. Firewood and coal are used as fuel, so even in the coldest year you can maintain a comfortable room temperature without extra costs.

The disadvantage of wood stoves is the lack of mobility. It takes up quite a lot of space and is installed in a permanent place without the possibility of transfer. In addition, it does not provide for autonomous temperature maintenance.

An alternative option is modern metal stoves with additional air ducts, a stepped hood and a damper. Such models ensure the most efficient use of the generated heat. They are as economical as wood stoves, but are more compact. However, when installing such a stove, you need to take care of high-quality thermal insulation. To prevent fire, the stove is located at a distance of 30 cm from walls and other objects.

The walls of a potbelly stove become very hot, so such stoves should not be located on walkways or interfere with the free movement of people.

Heating the cabin with electricity

Creating comfortable conditions in temporary structures, utility rooms and construction sheds is a serious problem. Heating in cabins, for example, can be organized in various ways, but not every one can have a stove or electric fireplace installed. There are real risks of fires, smoke or carbon monoxide poisoning, and there is practically no way to maintain heating in a construction shed when people are not present (at night or on weekends).

Heating a cabin with electricity based on the use of TM heating film does not have all these disadvantages. Moreover, this material has a number of advantages that distinguish heating systems based on it from others. Experts have proven that infrared heating today is the most effective and least expensive of all that use electricity.

Pros and cons of heating equipment

Stoves that run on solid fuel (coal, coke, wood) are also called “potbelly stoves.” These are simple units in a metal casing, operated manually. They quickly heat up the makeshift room, and the heat will remain inside the house for a long time. The advantages include the affordable cost of the device and ease of operation. When installing a stove, you will need a smoke exhaust device. The disadvantage is the need to constantly replenish the fuel reserve.

The gas heater is characterized by autonomy, mobility, and efficient operation. Heating of an average temporary shed takes 15-20 minutes. According to the instructions, it does not need a smoke exhaust system. This device is indispensable in conditions of lack of electricity. Disadvantages include the high cost of operation, as well as the need to refill gas cylinders.

The category of the most efficient and easy-to-use heating devices includes electric furnaces and heaters of various modifications. They are distinguished by their compact dimensions, safety (equipped with tip-over and overheating sensors), and affordable cost. A significant drawback can be considered high energy tariffs (electricity is the most expensive resource). In addition, the use of electrical appliances is only possible in cabins equipped with an electrical network.

Operating principle and advantages of TM heating film

The example of heating a change house clearly shows how quickly and relatively inexpensively it can be heated. TM heating film works on the principle of generating thermal energy when electric current passes through its elements. As a result, infrared radiation (10 microns) is released.

Under the influence of infrared radiation, heating in cabins occurs many times faster and more evenly, since the surfaces of objects located inside, walls and floors, are heated, and not the internal air. In just a couple of hours, the average temperature rises by ten degrees, and the energy consumption when operating the TM heating film is minimal.

As for safety, it is almost absolute. Electrical shock, involuntary fire, and the release of harmful and toxic substances when heating a construction shed or any other room are excluded. It is impossible to get burns when touching the working surface of the film, unlike many open-type electric heaters, because infrared film heats up to a maximum of 45-50 degrees.

Moreover, the automatic control and monitoring (thermostat E 51.716) of the heating of the cabin allows you to maintain the optimal temperature inside in the absence of people or turn on the heating before they arrive to ensure comfortable working conditions. Workers will not have to freeze while waiting for the heating of the construction shed to create warmth inside. The only condition under which infrared heating will be effective is sufficient thermal insulation, which minimizes heat loss.

Heating in a change house

A heat shield must be installed around the stove.

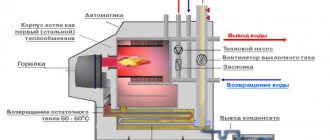

How to heat the cabin, other than a stove? Today there are many models on sale, the leader of which remains the Buleryan pyrolysis oven. It is very economical, as it works on the principle of afterburning pyrolysis gases. It quickly warms up the air due to convection pipes and practically does not burn oxygen; one load is enough for 6 hours.

If electricity is supplied to the cabin, then the best option would be an infrared heater or a heat fan with a ceramic heating element. Both devices allow you to quickly warm up. The disadvantage is the same rapid cooling. At the same time, to install the heater, you do not need to prepare a place, unlike a stove.

The installation of the furnace must be carried out according to certain rules:

- a metal plate is placed on the floor with a minimum distance of 30 cm in front of the firebox door;

- there should be at least half a meter to the walls;

- heat shields need to be installed on the walls;

- a chimney pipe is required.

By the way, the chimney is one of the most important elements. The use of penoizol is much faster than insulating a cabin with polystyrene foam. You can see this in the video below.

How to provide heating for a change house based on TM heating film?

The consumer qualities of the material are very high and have already been appreciated by many users. They include versatility, ease of installation, simplicity of cut, and a large number of standard sizes that make even independent installation easy.

TM heating film is easily attached to the ceiling at the rate of 60–70% of the heating area. The material is available in lengths of up to 5 meters and various widths (500, 800 and 1000 mm); for ease of cutting, a cut point is provided every 200 or 250 mm of length.

You will not need any special devices or tools to heat a cabin based on film materials. We provide simple step-by-step instructions to each client. Moreover, during operation, the heating system of the cabin does not require any preventive maintenance or special care; it can be easily dismantled for transfer to another room, and decorated with most existing materials.

The system operates from a standard network (220 V), can be controlled and monitored remotely, has the highest efficiency among all electrical heating devices and is affordable. The guaranteed period of flawless operation is at least 15 years.

How to order a set of TM heating film for heating a cabin?

It is enough to provide us with a simple plan diagram of your shed indicating the linear dimensions and characteristics of the enclosing structures. Even a hand-drawn diagram is quite suitable.

Based on the provided plan, our specialists will calculate the optimal parameters of the heating system and provide a commercial proposal for the facility (including materials and components, with or without automation). After receiving the prepayment, we will prepare a set of films and components for heating your cabin and send it to your address by a transport company. The choice of carrier will definitely be agreed upon with you; orders are delivered throughout the Russian Federation.

Source