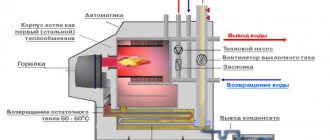

Modern heating and hot water supply systems use gas boiler models equipped with a large number of electronics. These electronic circuits react very sensitively even to minor deviations of the mains voltage from standard values. In this regard, many owners are trying to understand whether a voltage stabilizer is needed for a gas boiler, and what consequences may occur in its absence. As practice shows, various disruptions in networks are not uncommon, so the necessary measures should be taken in advance to avoid failure of expensive equipment.

Do you need a boiler stabilizer?

You can often hear the opinion that the presence of a voltage stabilizer is not so important. “My boiler has been working great without a stabilizer for ten years,” “it tolerates all changes normally,” say some owners, implying that buying this device is a waste of money.

Indeed, modern devices cope with small voltage fluctuations. Moreover, according to the interstate standard GOST 29322-2014, the mains voltage is not a constant value and should be 230 V plus or minus 10%. Accordingly, the standard voltage falls within the range of 207-253 V.

However, in real life, not everything always happens according to standards and sudden changes in parameters in the power supply network are not yet a fantasy. In addition, many different factors can cause possible problems, from weather conditions to human intervention. Therefore, installing a stabilizer still seems to be a justified decision and its purchase, in most cases, is less expensive than repairing a heating boiler in the event of an accident. In addition, many sellers define the established CH as a necessary condition for the warranty to be valid.

Nuances of choice

Selection is carried out according to power. Typically, a voltage stabilizer designed for gas boilers is chosen, with a power equal to five times the power of the heating boiler and a power reserve of 20%. This is due to the fact that when the equipment is turned on or off, the power of the device can increase almost 5 times.

There are various manufacturers of stabilizers on the market for gas boilers used for heating. The task of any buyer is to choose the brand he likes. In order not to make a mistake with the choice of manufacturer, you need to look at the power range in which they produce stabilizers. In general, in practice it is better to choose equipment whose operation has been tested by time.

Classification by installation type

According to the installation method, there are three types of equipment:

- wall;

- floor;

- universal.

Wall-mounted ones can be mounted directly on the wall and at the same time have small overall dimensions. Floor mounted ones are installed on any flat surface in a vertical position. Universal ones can be mounted in both vertical and horizontal planes.

The boiler stabilizer must have:

- required power reserve;

- overload protection, including short circuit and overheating;

- sinusoidal shape at the output, otherwise damage to the motor in the pump cannot be avoided;

- autostart when power supply is turned on after shutdown;

- protective shutdown function (cut-off) in case of overload;

- grounding

When choosing between wall and floor, it is best to give preference to the former. Such devices save space and will not suffer mechanical damage.

What types of stabilizers are suitable for boilers

Manufacturers produce many stabilizers of various models. The devices on the market can be divided into four types:

- electromechanical (servo-drive)

- relay

- electronic (thyristor)

- inverter

Each type has its own characteristics, pros and cons, which must be taken into account when selecting. Here is a brief overview of the equipment for each type.

Electromechanical

The principle of operation is based on the circular windings of a transformer, along which carbon brushes, controlled by a servo drive, move.

Pros: low cost, wide range of input voltage, accuracy and smoothness of regulation, ability to withstand overloads, ability to work at low temperatures and high humidity, reliable system of protection against overvoltage and overheating, long service life.

Disadvantages: low speed of adjustment (response), increased noise level, increased weight and dimensions compared to other types of devices.

Important! It is strictly forbidden to install electromechanical stabilizers in rooms with gas equipment! This limitation is due to the fact that during operation of a MV of this type, the formation of sparks is possible. If gas leaks, it may cause an explosion.

Such stabilizers can be installed for heating boilers, but it is not recommended to use them if there are frequent noticeable voltage surges. Also, due to safety requirements, a separate installation location is required.

Relay

A widely used modern type of stabilizer. Here, the current passed through the transformer winding is regulated by special relays, and not mechanically. Some resources provide information that relay MVs are not suitable for heating boilers due to their low performance. Indeed, the response speed of previously produced stabilizers of this type was low, but modern models do not have this drawback.

Pros: affordable cost, wide range and high speed of regulation, reliable protection system, compact size and light weight.

Cons: step control, lack of power reserve, average noise level, short service life.

In terms of price/quality ratio, relay stabilizers are the best choice and are widely used with heating boilers.

Electronic

Electronic stabilizers regulate the current by also passing current through a transformer using electronic switches, which allows for the compact size of the device and its high efficiency.

Pros: wide range and high speed of regulation, low noise level, compact size, long service life.

Cons: high cost, step control, lack of power reserve.

Electronic stabilizers are a more advanced and universal solution for heating boilers. They have a higher cost than relay ones, therefore they are less common.

Inverter

In inverter stabilizers there is no transformer, here the alternating input current is first converted into direct current and then the required alternating voltage is generated from it.

Pros: wide range of input voltage and high accuracy of output voltage, high speed and smooth regulation, lack of noise, minimal size and weight, long service life.

Cons: high cost, lack of power reserve.

Stabilizers of this type provide the highest quality regulation, but have the highest price among the listed types.

Rating of the best stabilizing devices

We bring to your attention our own TOP 7 best 220V stabilizers, which we compiled after studying numerous ratings of electrical appliance stores and customer reviews. These models are sorted in descending order of quality.

- Powerman AVS 1000D. Toroidal unit with high quality standards: low noise level, high efficiency, small dimensions and weight. The power of this model is 700 W, the operating temperature is in the range of 0...40°C, and the input voltage ranges from 140...260V. It has six adjustment stages and two outputs, and a response time of only 7 ms.

- Energy Ultra. One of the best electronic models for gas boilers Buderus, Baxi, Viessman. It has high technical parameters: load power 5000-20,000W, range 60V-265V, temporary overload up to 180%, accuracy within 3%, frost resistance from -30 to +40 °C, wall mounting type, absolute silent operation.

- Rucelf Boiler-600. An excellent device in a high-quality metal case, inside of which there is a well-insulated autotransformer. It has high technical parameters: power 600W, range 150V-250V, operation within 0...45°C, four stages of adjustment, and response time is 20 ms. There is one Euro socket, which is located below. Wall mounting type.

- Resanta ACH-500/1-C. A relay-type device with a power of 500 W and an input voltage of 160...240 V. Resanta brand products have two variations. The response time is 7 ms, has four stages of adjustment and built-in protection against overheating, short circuit, and high voltage. Connects to a grounded outlet.

- Sven AVR Slim-500. Despite its Chinese origin, the relay device has decent installation quality and technical characteristics: power 400W, four stages of adjustment, input voltage within 140...260 V. Sven is able to operate at temperatures from 0 to 40°C. Equipped with a toroidal autotransformer with an overheating sensor. Reaction time is only 10 ms.

- Calm R600ST. The only electronic stabilizer designed specifically for gas stakes. Thanks to triac switches, the operating voltage ranges from 150 to 275V. Device power – 480W, temperature range – 1…40°C, four-stage adjustment, response time is 40 ms. There is a separate circuit for each of the two Euro sockets. Completely silent operation.

- Bastion Teplocom ST-555.

Another relay type model, but the power of which is an order of magnitude lower - 280 W, and the input voltage is 145...260 V. Also, unlike the Resanta brand, the Bastion response time is 20 ms, and the number of stages is only three. In addition, the device heats up during operation and does not have an automatic fuse. How to connect the device to the boiler?

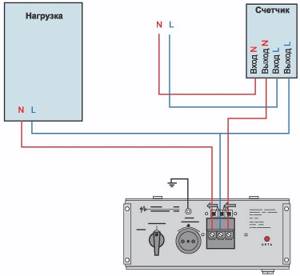

Now you need to study the diagram of the correct connection of the stabilizing device.

First of all, in order to protect your gas boiler, you need a surge filter directly in front of it, and immediately after the incoming automation, a voltage control relay.

As a rule, in places where heating boilers are used, power is transmitted using a two-wire overhead line which is equipped with a TT grounding system. In such a situation, it is necessary to add an RCD with a setting current of up to 30 mA.

This gives the following diagram:

Attention! Both the stabilizer and the gas boiler must be equipped with grounding!

In order to ground the boiler (as well as other electrical appliances), the TT system requires a separate grounding circuit, which is completely isolated from the neutral working conductor, as well as from the rest of the network. The resistance of the grounding loop is calculated in accordance with the standards of the Electrical Installation Rules.

Conclusion: which stabilizer for a gas boiler to choose

From everything described above, we can summarize which stabilizing device is best suited for a gas boiler:

- single-phase;

- with a power of 400 W or 30-40% more boiler power;

- any type, except electromechanical, or install the electromechanical device in another room.

For consumers, the main criterion for choosing voltage stabilizers is the price of the product. For the same price, you can buy a device that is not suitable for gas equipment at all, or you can purchase a reliable model that will provide decent protection. Therefore, when choosing a stabilizing device, it is necessary to take into account the listed parameters, and not just the price.

How to choose stabilizer power

The protective device must have good power to ensure the performance of absolutely all elements connected to the boiler unit: the unit control unit, the coolant circulation pump and the fan.

Therefore, first of all, it is necessary to clarify how many electrical current consumption nodes will be connected through the stabilizer.

Power data is specified in the data sheets. In addition, it must be taken into account that current consumers, for example, such as a pump, have increased starting power characteristics. Therefore, the calculated value needs to be increased by 1.3.

DAEWOO DW-TM1kVA – quality and power

Single-phase wall-mounted voltage stabilization device. It is distinguished by high build quality and stable output indicators. The response time does not exceed 20 milliseconds. The total power allows you to connect two consumers, taking into account the magnitude of the starting currents.

Reliability of control is ensured by an electronic unit based on microprocessors. The stabilizer has a low level of its own noise. Provides protection against short circuit, overload and overheating.

Pros:

- High-quality assembly, nice design, powerful.

- Filters, short circuit protection. Doesn't make any noise at all when the voltage isn't floating.

- Bright and large display, easy wall mounting, connection of two consumers.

Minuses:

- The cord is terribly short, and you can’t hang it close to the boiler - it can heat up.

- Beautiful and poorly informative instructions.

The best voltage stabilizers for gas boilers

Not all companies produce devices of several types at the same time. Usually companies concentrate on developing one type. The choice of protection for a boiler unit is significantly determined by the parameters of the district network and the load of the boiler units being switched on.

Installing the stabilizer in the circuit: Photo source: fenixled.ru

You can draw up the characteristics of a decent device:

- The lowest power is 1000 VA.

- Built-in protection against contact overheating and short circuit.

- Input voltage range 90-290 V, absolutely uncritical to the load.

- The output is a perfect sine wave.

- The lower voltage response level is higher than the normal value in the district power grid.

- Automatic start with process suspension upon completion of protection activation.

- Presence of a ground terminal.

- The speed of voltage regulation is no more than 20 ms, with processing accuracy of 2-3%.

According to this list of parameters, the rating of voltage stabilizers is:

- Cool 220V relay-type stabilizer for the Baxi gas boiler - LogicPower LPT-1000RV , price as of December 1, 2019 - 2180 rubles.

- Relay stabilizer Teplocom TEPLOCOM ST-222/500 , price as of December 1, 2019 – 2970 rub.

- The best servomotor stabilizer is Resanta ACH1000/1-EM , price as of December 1, 2019 – 3120 rubles.

- An excellent thyristor device - Shtihl for gas boilers R 1200SPT, price as of December 1, 2019 - 13,070 rubles.

Voltage stabilization speed

Most stabilizers decide to correct the voltage within 4-20 ms. But when gas heating boilers are operating, unstable voltage lasting more than 20 ms does not affect performance. Some models continue to work even if the plug is unplugged from the socket for a short period of switching off and on. For this reason, the speed of voltage stabilization cannot be called critical.

But do not forget that new models may have increased sensitivity to incoming voltage. There are gas boilers for which even 8 ms can be enough for the equipment to stop working or fail.

For such models, it is recommended to purchase inverter stabilizers. The design does not include such a parameter as response or reaction time. They produce an even voltage, regardless of the parameters of the input value.

How to connect

Manufacturers of stabilizers clearly state in the instructions how to turn on the device. First of all, you need to prepare a workplace, which must be dry. Further, the installation takes place in such a way that there is an unobstructed approach to the device.

At the same time, it must be taken into account that the regulator is air cooled. For this reason, a lot of free volume in front of it will be required. Therefore, placing it in a sideboard or drawer is prohibited. And the last limitation is that the installation is placed away from fire-hazardous building materials.

A monophase device is connected via a standard socket. The plug with the adjusted network values is connected to the socket on the boiler body.

Based on the above, it can be argued that a stabilizer is needed for the gas boiler to function correctly and not be damaged by failures in the power grid.

The specific conditions of the power supply and the power of the equipment being protected will determine which voltage stabilizer will best cope with its tasks.

How much does the input voltage drop?

Operation requires 140 to 260 V input. If a larger range is present, the device may shut down abnormally.

There is an important point here. If the equipment is critically overloaded, it may fail. And this can be considered luck. You will only have to replace the stabilizer. But if there is no protection, then high voltage can reach the gas boiler and damage the equipment.

If there is insufficient voltage in the network, a decrease in the power of the stabilizer may occur. Many manufacturers do not indicate this possibility in the instructions. Sometimes, with a strong voltage drop, up to 50% of the rated power can be lost.

Stabilizer power calculation

When purchasing equipment, you need to pay special attention to its power. First you need to find out exactly what indicator is indicated in the passport.

Boilers have several meanings:

- Thermal power, which varies from 6000 to 24000 kW.

- Power consumption – 100-200 W or 0.1-0.2 kW.

Volt-amps (VA) indicate the required power of the stabilizer. The parameter is different from Watts or kW in that it indicates full power. Others are extremely useful. This means that if the device indicates a power of 500 VA, then the final figure will be 350 W. It is important to note that the power of the device must exceed the data of the heat generator itself, but also the connected equipment. We are talking primarily about the circulation pump; it has its own parameters.

To select a high-quality protective mechanism for personal use, you will have to take into account increasing inrush currents. At the same time, the stabilizer itself must have a kind of power reserve, which exceeds the performance of all devices by 30%.

Calculation formula:

(Power of the boiler selected and installed in the house in W + pump power W * 3) * 1.3 = final stabilizer power in VA. For example, if the boiler has a power of 150 W, the pump has 70 W, then the following formula is obtained: (150 W + 70 W * 3) * 1.3 = 468 VA.

But we must not forget about current drawdowns. If the input voltage begins to drop, then the indicated indicators of the stabilizer will also decrease. If the outlet has 170 V, then the performance will drop by about 80% of the nominal value. Therefore, the power indicated on the passport must be multiplied by the percentage drop and divided by 100. Only in this case can optimal power indicators be obtained.

Checking the circuit

The first switch-on must be done without load. That is, all machines except the input one and the one that goes to the stabilizer must be turned off.

Start it at idle speed and monitor its operation. Input and output parameters, whether there is any extraneous noise or squeaking.

It also wouldn’t hurt to check the correctness and accuracy of the technical data displayed on the electronic display.

If you have a three-phase 380V network at home, then for this connection it is recommended to use 3 single-phase voltage stabilizers, each connected to a separate phase.

More details about the advantages of three-phase and single-phase devices and when to choose which one can be found in the article “How to choose a voltage stabilizer for your home.”

What characteristics of the stabilizer need to be taken into account?

To understand how to choose a voltage stabilizer for a gas boiler, you need to understand its key parameters and their effect on the operation of the heating device. This will help you choose the device that is most suitable for specific operating conditions.

Phasing

Most apartment buildings and private houses are connected to a single-phase 220 V network with a frequency of 50 Hz. To use voltage stabilizers in them, it is advisable to buy single-phase models. There are houses with three-phase input, but each line is divided and produces 220 V. This contributes to a more even distribution of the load and allows the use of the same single-phase stabilizers.

For enterprises and industries where large gas boilers with high power are installed, three-phase 380 V stabilizers will be required. The second option would be to install single-phase equipment, one for each phase, which will be cheaper in total, but will take longer to connect.

Input voltage range and output voltage accuracy

Voltage stabilizers for gas boilers must ensure that the current from the network is brought to the optimal 220 V. Depending on the scale of the voltage drop, stabilizers are also produced with different input current ranges. To find out what parameters to look for a device with, you need to do a little research.

To do this, you need a voltmeter (pointer or digital multitester). The electronic device must be set to an alternating current value with an upper limit of more than 500 V. Measurements should be carried out at different times of the day to see how the indicators change depending on the load on the network. It is optimal to observe during the week and measure the volts at: 6:00, 9:00, 12:00, 15:00, 18:00, 21:00, 24:00 hours. It’s good to have a notebook to record the data received. At the end of the experiment, you can add 10-15 V in each direction to create a small margin.

If testing shows the limits of 180-240 V, then it is with such data that you should look for a voltage stabilizer. Sometimes, outside the city, there may be differences in the network from 140 to 270 V, which will require a different model.

The output voltage of the stabilizer should correspond as much as possible to the performance of the gas boiler. In most cases this is 220 V + -10%. To avoid shutdowns due to lack of power, it is better to choose devices with an output voltage accuracy of +-5%. Then it will completely fit into the data required by the manufacturer and contribute to uninterrupted operation

Power

One of the most important criteria for choosing a voltage stabilizer for a gas boiler is power. First you need to find out what indicator is written in the equipment passport. Boilers have two values: maximum useful thermal power (varies from 6000 to 24000 kW) and power consumption (100-200 W or 0.1-0.2 kW). But during boiler startup, this value may increase by several seconds, so the stabilizer indicator should exceed the boiler data. How long? This will become clear after we learn the remaining components of the calculation.

The second component is VA. These are volt-amperes, which indicate the power of stabilizers. They differ from kW (kilowatts) or W (watts) in that they represent total power, while the latter only represent useful power. As a result, a device with a power of 500 VA will have a rating of 350 W.

The power of the stabilizer must cover not only the consumption of the boiler, but also the associated equipment installed inside or in parallel. This could be a circulation pump, which has its own power rating.

In order for the voltage stabilizer to fully correspond to the boiler and pump, its indicator must take into account the increasing starting currents and have a margin of 30% from the maximum power of the sum of all devices.

Now all this can be fixed by the formula: (boiler power W + pump power W * 3) * 1.3 = stabilizer power VA. For example: boiler - 150 W, and pump - 70 W. We get: (150 W+70 W*3)*1.3 = 468 VA.

But it is also important to take into account voltage sag. If the input current drops, then the ability of the stabilizer to increase it also drops. For example, if there is 170 V in the outlet, the efficiency of the stabilizer will decrease by 80% of the rated power, and at 130 V it will work only at 50% of the declared value. Therefore, the rated power of the stabilizer must be multiplied by the percentage drop and divided by 100.

Let's calculate: if the network is 170 V, which is 80%, then with a stabilization device of 500 VA it will work as if it were 400 VA. For the above example, a 150 W boiler and a 70 W pump, taking into account the 170 V drawdown, you need to look for a 600 VA stabilizer.

Voltage stabilization performance

This parameter is indicated by two units of measurement:

- response speed - measured in volts per second (V/s) and reports the period taken to restore normal output voltage in the event of significant fluctuations in the input;

- response time - indicated by the milliseconds it takes for the device to react to change the network signal.

The higher the speed and the shorter the response time, the better the gas boiler is protected during surges, both in one direction and the other. The highest quality voltage stabilizers have a first rating of 100 V/s and higher. This allows the protective equipment to respond almost instantly. Data of 10-20 V/s indicate some delay, sufficient for short-term incorrect operation of the boiler.

The response time is considered good from 5 ms or less. 10ms will be quite acceptable, and 20ms will be satisfactory. Large values already imply some risk. Inverter devices use double current conversion, so they do not have a speed parameter.

Output voltage form

Alternating current is indicated by a wavy line due to its changing frequency. On the scale it has the shape of a sine wave. In order for a gas boiler to operate stably and correctly, the voltage must be as close as possible to an ideal sinusoid. A clean output signal will not create errors or malfunctions in the electronics.

Availability of protection and restart function

When choosing a voltage stabilizer for a gas boiler, you should pay attention to the protection options. Very cheap devices may not have them, which can lead to failure of the stabilizer itself.

1. An important function is to turn off the device when overloaded. This happens when it is operating at its capacity limit due to the incoming voltage being too weak. To prevent the turns of the transformer or the board from burning out, the device turns itself off.

2. The same process occurs in the case of too high surges, which the stabilizer is not able to reduce to the outgoing 220 V. In order not to cause harm to the gas boiler, the current source is turned off.

3. Depending on the installation location, loads and operating area, the stabilizing device may also experience temperature effects. It would be good if, in case of significant overheating, it could interrupt the line itself until it cools down.

4. If there are protection functions, the ability to restart is also useful, eliminating various inconveniences. For example, when there was a significant voltage drop, the stabilizer turned off, which caused the gas boiler to stop. The owners were at work at the time. When turned off, the device continues to monitor network parameters, and when they are normalized to values that the device can handle within its capabilities, the power is restored.

Once connected, the boiler starts up and the owners return to their heated home. Otherwise, when there is no restart function, the whole house has cooled down when they arrive, although the voltage has long been normal. And if this happened during the winter holidays, when the family was on a trip, then the system may completely collapse.

The restart function can be set with a delay to prevent frequent boiler starts when the input value is unstable and balances at a border level.

Without the restart option, turning on the stabilizer and boiler will always require manual mode with human participation. Pay attention to the presence of a restart when choosing a voltage stabilizer.

Additional features

When choosing a voltage stabilizer for a gas boiler, you need to take into account other additional features that are not key, but will contribute to more convenient operation.

Design

Stabilizers for gas boilers can be in sizes from 200x300x70 mm to 450x500x300 mm. The dimensions of the housing depend on the technology (electromechanical, relay or electronic), as well as the size of the transformer and the number of relays, which determines the smoothness of adjustment and the power of the device. To place it in your home, you should look for compact models that can be neatly integrated into the interior, and maybe even hidden in a small furniture drawer. If the boiler is installed in a separate boiler room, then the size of the device does not matter there.

Stabilizers can be wall-mounted or floor-mounted. The first type makes it easier to monitor the indicators because it can be placed at eye level and a short glance while passing by is enough to see that everything is in order.

When the unit is placed on the floor, you may have to lean towards it. But this will not need to be done so often, so the choice is up to the owners.

When installed inside an apartment or house, wall-mounted models are practical, since they are easier to hide by surrounding them with shelves. There are also rack stabilizers, but their power far exceeds the needs of the boiler and pump, so there is no point in cluttering the corner of the room with a 19-inch vertical structure.

The design also includes the number of output connectors. Although the main consumer is a gas boiler, if there is a need to protect other electronic devices in the house from low voltage or surges, then you should choose a stabilizer with a power reserve and several sockets (3-4), which will allow you to connect another household appliances.

Indication

A stabilizer for a gas boiler can display the current voltage in volts at the input to and output from the device. For this purpose, the housing can be equipped with an LED display, pointer sensors or diode indication.

Stabilizers with LED display. Bright numbers are clearly visible in the daytime and at night, allowing you to instantly assess the situation at a glance. This is the most practical and modern option.

Voltmeter dial gauges. This is an analog legacy solution. This version does not have a backlight and in the dark you need to use a flashlight. But the accuracy of the readings remains high and helps to monitor the voltage.

Diode indication. In this case, users do not know the number of incoming volts and the level of their correction, but only see from the green indicator that the voltage is normal, and from the yellow indicator that stabilization is occurring (which means it is now too low or too high). When the red diode lights up, this indicates that the protection has tripped. Used on budget products, not very informative, but quite acceptable.

Operating temperature range

Installing a voltage stabilizer for a gas boiler is meant to be installed inside the building, so few people worry about the range of operating temperatures. But if installation is planned in a boiler room, which is a separate extension, then you should make sure that the device can withstand a temperature drop of up to +5 degrees and can operate correctly. It is also not recommended to mount it too close to the boiler and it is important to ensure that air can circulate freely around its body.

Formula for calculating stabilizer power

So we have decided on the type of voltage stabilizer. Now, in order to correctly select the desired device from the line offered by the manufacturer, it is necessary to calculate the power for which it should be designed. In order to do this you need to perform the following steps:

- We determine the consumed electrical power of the boiler, the value of which is usually indicated in the technical data sheet for the device.

Attention!

Many owners confuse thermal power with electrical power. The values of the first for household heaters usually lie in the range of 10 - 100 kW, and the second is 1000 times smaller and amounts to approximately 100 - 200 W.

- If the stabilizer also powers an external circulation pump, then in the calculations it is necessary to take into account its power multiplied by 3. This must be done in order to take into account the starting currents, which at the time of start-up can exceed the rated current by three times. For this reason, it is not recommended to connect a gas boiler and a heating system pump to the same stabilizer, but many owners neglect this requirement.

- We add the resulting values and multiply the result by 1.3. The resulting value will be the required power of the stabilizer, which should be oriented towards when choosing.

In order to better understand the calculation methodology, consider its sequence using the example of a simple task:

Task:

It is necessary to select a voltage stabilizer for the Viessmann Vitopend 100-W WH1D gas boiler with a closed combustion chamber and a built-in circulation pump.

Solution:

According to the passport, the electric power of the boiler is 63 W, the pump is 65 W. Stabilizer power = (63 + 65*3)*1.3 = 335 W

Having decided on the type and power of the device, you can proceed to choosing a manufacturer and a specific model. In the next chapter we will make a brief overview of the most popular devices on the Russian market

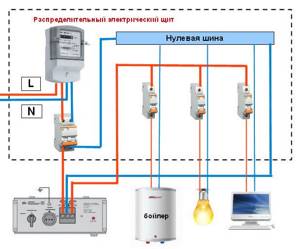

Correct connection

For long-term operation of a gas boiler, proper connection is necessary. To regret 5-10 thousand and lose a boiler worth 100-200 thousand rubles, one cannot say that this is the right decision.

We can recommend installing a voltage control relay for the gas boiler immediately after the introductory circuit breaker. To eliminate interference, connect the boiler through a surge protector.

Gas boilers are mainly installed in rural areas and country houses. Electricity is supplied via a two-wire line. With this supply, a TT system is used for grounding. To prevent unforeseen situations, we recommend installing an RCD with a current of up to 30 mA.

When arranging the grounding of the boiler, it is recommended to use a separate circuit that is isolated from the rest of the network. To calculate the resistance, study clause 17.59 of the Electrical Installation Rules.

Rucelf BOILER-600 – application in dachas

The design is specially designed to work in tandem with heating equipment in conditions of unstable power grid indicators. Used in rural areas, places with constant voltage fluctuations.

Designed to work with gas boilers, heating equipment control units, circulation pumps, household and electronic appliances. Has a wide input voltage range. Does not distort the sine wave.

Pros:

- Clear operation, works well with a gas boiler.

- Quick installation and connection, affordable price.

- Quiet, durable body.

Minuses:

Consumers do not note any shortcomings.

RUCELF BOILER-1200 – protection of boiler units

Single-phase stabilizer for reliable provision of boiler heating equipment with stabilized voltage. It is implemented in a wall-mounted version, which allows you to save space and make more efficient use of the room area.

Levels out voltage surges and eliminates impulse noise. Works over a wide input range. It has a high motor life, the internal components are enclosed in a durable and rigid steel body.

Pros:

- Performs basic functions successfully and works in a basement environment.

- Powerful – boiler and circulation boiler connected.

- Durable, rigid case, small in size, mounted on the wall.

Minuses:

No input fuse.