Coaxial chimney, install it yourself

There is currently an opinion in society that safe and stable operation of a gas boiler in a bathhouse depends solely on the correct installation of the coaxial chimney and where it goes outside. The truth is, in fact, the removal of waste harmful to the human body through a special coaxial chimney is of great importance. Coaxial – “together along the axis.” Its main advantage is that for the boiler to operate, air is taken not from the boiler room of the bathhouse, but from outside. This chimney differs from others in that it performs two very important functions at once. Firstly, it removes flue gases outside. Secondly, it supplies the boiler with the oxygen necessary for its operation. Its structure is somewhat similar to a sandwich - “a pipe in a pipe”, but cold air enters through the outer pipe, and only hot combustion products rise through the inner pipe.

And “burning out” oxygen in the room is also bad because in such a situation the stove door smokes, the fuel does not burn completely, and a lot of soot collects in the chimney. Do you want to get rid of all this? Then let's figure out together how to install a coaxial chimney in a bathhouse yourself.

Installation features:

- The chimney duct should not have more than two bends.

- For horizontal chimneys, the section facing outside must be inclined downward by 3° to allow condensate to drain. If the horizontal section is included in the common chimney, the slope should be in the opposite direction (down towards the boiler).

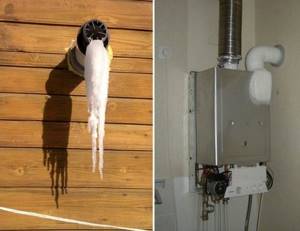

Frozen condensate at the outlet of a coaxial chimney.

- Installation of a gas boiler with a closed combustion chamber does not require any windows or sashes in the room.

- The installation must be carried out in such a way that during subsequent routine maintenance the relative position of the boiler and chimney cannot change.

- The adapter, areas for inspection and cleaning, and the condensate drainage area must be accessible for periodic inspection.

- It is not allowed to install the chimney below ground level.

- The distance from the pipe to the wall of the neighboring building must exceed 8 meters. When installing a deflector, the distance can be reduced to 2 meters (for a blank wall) or 5 meters (for a wall with openings).

- If the outlet is less than 1.8 meters above the ground, a deflector grill must be installed to protect against hot smoke.

- In order not to interfere with the movement of the smoke flow, when installing a chimney, the previous section is inserted into each subsequent section (direction from the boiler).

- If, at the location where the horizontal chimney is installed, winds prevail that are directed against the smoke removal, a tin barrier is installed at the outlet of the pipe. The distance from the outlet to the barrier must be at least 40 cm.

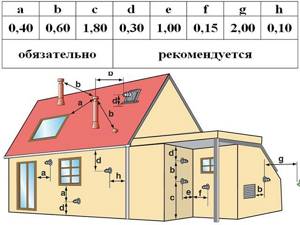

Options for the location of a coaxial chimney in a private house and the minimum distances between the axis of the pipe and the nearest objects, m.

Each chimney system must be supplied with detailed assembly and installation instructions. Before starting installation, you need to compare the requirements set out in the instructions with the requirements of currently valid regulatory documents, and be guided by the more stringent of them.

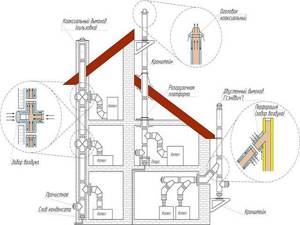

Options for the location of coaxial chimneys with vertical outlet.

The coaxial chimney and closed combustion chamber of the gas boiler eliminate the influence of the combustion process on the atmosphere inside the room, thereby increasing the comfort of the people living in the house. Thanks to their positive qualities, pipe-in-pipe chimneys are gaining more and more adherents every year among those who plan to equip their home with an efficient and economical gas heating system.

Interior solution: decorative grilles for heating radiators

Optimal thermal insulation for heating pipes

Do-it-yourself insulation of heating pipes on the street

Advantages of coaxial chimneys

Here's why such chimneys are good:

- Quite high efficiency, thanks to the highly heated incoming air.

- Compactness - instead of two large pipes, there is only one volume.

- No need for additional ventilation.

- Very high environmental friendliness.

- The air in the boiler room is safe for the human body. In this case, the boiler already takes “its own” oxygen, specially supplied.

- Reducing the price of drainage systems.

- Solution to a known problem with chimney condensate.

- Significant reduction in fuel costs for a bathhouse.

Another advantage of a coaxial chimney: the incoming cold air perfectly protects the walls from overheating.

But what certainly may not please you is the risk of freezing of a pipe of too small a diameter. This happens due to the fact that when leaving the chimney, the temperature of the flue gases is already very low - after all, it simultaneously heats the inner pipe. Therefore, the formation of condensate for coaxial chimneys is the norm. But only at an outside temperature of about -15 degrees, which is quite normal for the Russian Federation, can the pipe freeze over with all the dire consequences.

There is even an opinion that coaxial chimneys are absolutely unsuitable for cold Russian winters - they were originally designed for the latitudes of southern countries. That's why they freeze. But some experts believe that such freezing is just the result of improper design of such a chimney, and nothing more. However, the result here is the same: the burners, turbocharging and galvanized chamber break down quite quickly due to icing and freezing, and they are very expensive to repair.

Nevertheless, as a rule, models in which, in pursuit of too high efficiency, the temperature of the flue gases reaches almost the dew point, freeze over. For this purpose, the diameter of the coaxial chimney is reduced to a minimum. For various southern continents, this changes practically nothing, although in the cold Russian winter, with its not at all the lowest temperature of -15˚C, the chimney freezes almost until the boiler stops. Manufacturers generally answer this question like this: “We have not tested the system at such temperatures.” Thus, it is worth remembering that the narrower the coaxial chimney pipe, the less suitable it is for winter. Take note of this.

Coaxial chimneys, among other things, do not tolerate power outages and voltage surges quite well.

Advantages and disadvantages

Gas heating equipment equipped with a coaxial gas exhaust system has a number of positive qualities:

- Fire safety. The exhaust gases are cooled by the cold air flow coming from outside. This is extremely important when installing boilers in wooden buildings.

- Easy to install and small in size. Saving space in the room.

- Efficiency. The forced outside air is rich in oxygen, so the fuel in the chamber burns completely, and the burner efficiency increases.

- Environmentally friendly. With more complete combustion of gas, virtually no toxic emissions are formed that pose a danger to nature.

- When using coaxial pipes, oxygen coming from the street is burned; room air does not participate in the combustion process. The requirements for the arrangement of the boiler room are reduced, since there is no need for ventilation of the room.

- Correct installation eliminates the possibility of combustion waste entering living rooms.

- Chimneys of this type can be installed not only in private individual houses, but also used in the construction of multi-apartment buildings.

- Long service life. It is believed that stainless steel structures will last at least 30 years.

The disadvantages of coaxial air exhaust systems include:

- It is advisable to use this design only in heating devices with a closed combustion chamber.

- Unaesthetic appearance. Horizontal pipes spoil the facade of the house.

- High cost compared to conventional chimney pipes.

- Due to the strong temperature difference between the air circuits, a large volume of condensate forms in the pipes. Therefore, it is necessary to install receivers that remove condensed moisture, or to install pipes with a correctly calculated slope.

- Icing. Exhaust gases cool down at the outlet, so when the outside temperature drops to -15...-10°C, they cannot melt the condensate that freezes in the pipes (settling from moist air). As a result, the outlet head of the chimney becomes covered with ice, which is dangerous due to the failure of expensive equipment. Additional insulation will be required.

Various options for connecting a coaxial chimney to gas boilers.

Which chimney to buy for a bath

There is no universal chimney for a bathhouse. It is selected depending on the fuel used, the isolation of the boiler room, the power of the boiler, and the thickness of the walls. However, the design of coaxial chimneys for various stoves is identical.

The pipes of coaxial boilers are usually made of plastic or aluminum. Both are quite high quality. Just when purchasing, you should pay attention: inside such a chimney there are special jumpers that prevent two different pipes from coming into contact.

But it is not advisable to design a coaxial chimney yourself. Although its design seems quite simple, any mistake can be quite expensive later. The correctness of its design in the Russian Federation is determined by special standards and laws. It's not easy to understand them at all. It is much better to buy a ready-made, high-quality chimney with all the necessary certificates for the steam room.

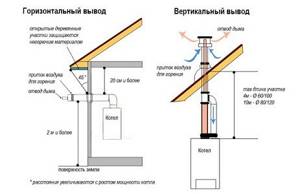

There are horizontal and vertical (for low-temperature mounted boilers) coaxial chimneys. This is what you need to start from when purchasing them.

Installation of a coaxial chimney

Such a chimney is installed in all gas boilers, radiators and convectors that have closed combustion chambers.

So, here is what you will definitely need to install a coaxial chimney:

- knee;

- flange;

- smoke exhaust pipe;

- crimp clamp

- boiler adapter;

It is necessary to install such a chimney at the shortest distance from the wall to the boiler, and from this area it is necessary to completely remove all materials and objects that are afraid of too high a temperature. It is also important to accurately determine the point at which the pipe will be discharged to the street - it is advisable that it be located approximately one and a half meters higher than the chimney outlet from the boiler. The hole should be made with a diameter of 110-125 mm - absolutely exactly along the pipe. Thus, the requirements for the location of such a chimney are much less stringent than for a conventional one.

It is best to conduct a coaxial chimney through the log walls of a bathhouse through a sleeve made of a special asbestos-cement pipe, then hammer corded asbestos around the chimney - it is fireproof and quite practical. If for some reason the boiler is located far from the wall, then in this case it is necessary to increase the length of the chimney - the maximum is 3 meters. To do this, additionally purchase connecting elbows, and then stretch the extension points of the coaxial chimney with a crimp clamp.

Recommendation. When removing the pipe from the wall, you should arrange for a slight slope of approximately 2-3˚. Thus, the condensate will flow down by gravity and there will be no waterlogging.

After installing the chimney, you need to close the hole in the wall with a decorative trim exactly to the diameter of the pipe. Use liquid nails or construction adhesive for this. The hole from the street, as a rule, is foamed so that air does not enter the boiler room from the outside and does not create either condensation or drafts.

It is also worth saying that it is not at all necessary for a coaxial chimney to pass through the wall - today, schemes for various collective chimneys are quite successfully implemented.

Varieties

According to the method of installation and orientation in space, coaxial chimney systems are divided into the following groups:

- Horizontal smoke exhaust duct of coaxial type - exhaust gases exit through a hole made in the wall of the building. This option is more popular because it is the simplest and most affordable. When installing pipes at a slight slope, independent condensate drainage is ensured.

- Vertical coaxial chimney for a gas boiler - the channel is directed upward through the roof. In such structures, it becomes necessary to drain condensate using special devices.

Smoke exhaust systems differ in location:

- External - structural elements are located outside (on the outer wall of the house) and are attached directly to the facade. External chimneys are simple to install and operate, but they spoil the exterior of the building, so they try to place them on the rear and not very visible walls of buildings.

- Internal - structural elements are placed in special shaft wells running inside the building and separated from the living rooms. Such systems are quite difficult to install and maintain.

The following materials are used in the manufacture of coaxial pipes:

- Plastic. The components are inexpensive, weigh little and are easy to install. But they can withstand heating up to a temperature of no more than 200°C. A plastic smoke exhaust system will last no more than 5-6 years and is recommended only for thermal units with low-temperature combustion product emissions.

- Stainless steel. Stainless steel pipes are more practical and durable; they are not afraid of heating up to 550°C. Individual elements of such systems can be made of acid-resistant or galvanized metal.

Fire safety requirements for coaxial chimneys

Installation standards for a coaxial chimney:

- Half a meter horizontally to all open vents, doors and windows.

- One meter vertically to the windows, if the chimney exits under them.

- Half a meter vertically to the windows, if the chimney exits above them.

- Two meters from the ground level - regardless of whether anyone walks on it or not.

And lastly: when there is a gas pipe under the coaxial chimney, the distance between them should be at least 20 cm. And the distance from the corner of the building in this case is no longer regulated - install it as you can.

What is a coaxial chimney

The concept “coaxial” is used to designate any structure consisting of two objects located around a common axis. In the case of a coaxial type chimney, this is a smoke exhaust channel consisting of pipes of different sections.

The distance between the pipes is the same along the entire length of the chimney, including rotary elbows, bends and other elements. This is achieved through special jumpers, which are located along the entire length of the chimney.

The coaxial chimney is made of two pipes with a common central axis, separated by special internal jumpers

The principle of operation of a coaxial chimney

The channel between the inner and outer pipes ensures a constant supply of fresh air, which is necessary to maintain combustion processes. The inner pipe is a channel for removing flue gases and other combustion products. In fact, the special design of the coaxial pipe allows the chimney to perform two functions at once: removal of harmful substances and supply ventilation.

Flue gases are removed through the internal channel, and fresh air enters the combustion chamber through the inter-tube space

The main area of application of coaxial chimneys is wall-mounted and floor-mounted gas boilers with a closed combustion chamber, geysers and convectors. Coaxial type chimneys are not used with equipment operating on solid fuel.

Advantages and disadvantages of the coaxial chimney design

Among the advantages of coaxial type chimneys are:

- Versatility. Installation of a coaxial pipe is carried out by leading it through a load-bearing wall, ceiling or roofing. Depending on your needs, you can select the required dimensions of the chimney.

A coaxial chimney can be brought out in the traditional way through the ceilings and roof, but it is much easier to do this through a load-bearing wall if a boiler with a closed combustion chamber is used

Despite many advantages, the design of a coaxial pipe is not without drawbacks. At temperatures below -15 o C, the coaxial chimney can freeze severely.

This is due to the fact that, in fact, this is an advantage of the design in question - the cold air is heated due to the temperature of the flue gases escaping outside. The combustion products cool greatly and can condense at the outlet of the chimney, which leads to severe icing on the chimney head.

One of the main advantages of a coaxial chimney turns into its main disadvantage - at low temperatures outside, combustion products condense and ice freezes on the pipe head

To prevent icing, you should choose special devices designed to operate at subzero temperatures, and also calculate the cross-section of the chimney more carefully.

How to protect a coaxial chimney from icing and wind

The main problem associated with the operation of coaxial systems is the possibility of pipe freezing during severe frosts. Icing of the air supply channel leads to a decrease in the flow area and, as a consequence, a lack of oxygen in the combustion chamber. This leads to a sharp increase in gas consumption and a significant drop in the efficiency of the heat generator.

The appearance of icicles at the end of the chimney clearly indicates violations made during the design and installation of the coaxial gas exhaust system. With correct calculation of the chimney parameters and high-quality installation, the likelihood of icing is minimized.

In order to prevent and eliminate icing, it is recommended to use the following methods:

- Installation of a special tip that allows you to eliminate icing even if the coaxial device is installed incorrectly;

- Installation of a chimney with a slope towards the boiler. This allows the condensate not to stagnate in the pipe, but to flow into a special collection located inside the unit. If there is a condensate drain, the pipe head should be extended to a distance of 55 - 65 cm from the outer wall;

- Insulating the outer pipe with mineral wool or other heat insulator also helps reduce the intensity of condensation and freezing.

Another problem that may arise during the operation of a coaxial chimney is the possibility of reverse draft. In order to avoid this phenomenon, it is necessary to take measures to provide protection from wind and draft. Installing a special diaphragm will help prevent the burner from going out and carbon monoxide entering the living room.

In addition, when installing a chimney, SNiP should be strictly observed, which stipulates the distance from the outlet pipe to window and door openings. The minimum permissible distance is 1 - 1.2 m. For efficient and safe operation of the coaxial installation, you should first of all follow the equipment manufacturer's instructions.

Types of coaxial chimneys

Depending on the method of laying the chimney, coaxial type chimneys are divided into two types:

- Vertical - the chimney is located strictly in a vertical position. Gases and combustion products rise from the fuel chamber and are released into the atmosphere above the ridge level. Mostly vertical structures are used in residential buildings and provide a good level of natural draft.

- Horizontal - the main chimney channel is represented by a structure located in a horizontal position, which is discharged through a load-bearing wall. In this case, flue gases come out in the immediate vicinity of the heating equipment. It is most often used in private homes where closed heating systems are installed.

A vertically oriented coaxial chimney, despite some advantages, is a more expensive and difficult to install system. The total length of the smoke exhaust duct usually exceeds 5 meters, which significantly complicates the process of installation and fixation of the structure.

To manufacture a coaxial type chimney, various grades of steel and plastic are used. In accordance with this, several types of chimneys can be distinguished:

- galvanized - the most affordable option for a coaxial type chimney. The average service life of the product does not exceed 5–7 years, after which the structure partially rusts or becomes damaged. The cost of the product depends on the manufacturer and technical parameters, but rarely exceeds 2–2.5 thousand rubles;

- made of plastic and aluminum - a combined option for private use. The internal chimney channel is made of aluminum up to 2 mm thick. The outer pipe is made of high-strength heat-resistant polypropylene. Such chimneys are used only in the private sector for operation with boilers of low and medium power;

Coaxial chimneys made of galvanized steel are designed to last 5–7 years, plastic products will last much longer

A coaxial chimney made of high-alloy steel, unlike stainless steel, is not destroyed by aggressive chemicals contained in combustion products and lasts at least 15 years

The range of some manufacturers (Electrolux, Viessmann, Schiedel) includes models of coaxial chimneys with an additional thermal insulation layer. This is a classic design with two channels, which is located in another pipe. The voids between the outer pipes are filled with non-flammable heat-insulating material, which prevents freezing and blockage of the air channel.

Which chimney to choose

Metal or plastic have their advantages and disadvantages. After evaluating them, the user makes a choice.

Plastic systems

For their manufacture, polymer materials are used that can withstand temperatures up to 205°C. The maximum permissible values must not be exceeded, as this will lead to failure of the chimney. Such pipes are lightweight, which makes installation easier, as well as low cost. The main disadvantage is their fragility, so they have to be replaced more often. The service life of such models is 5 years. In addition, plastic chimneys can only be used with condensing boilers; they are not suitable for other types of heating equipment.

Stainless steel coaxial pipes

Steel chimneys are more in demand among consumers, especially in the northern regions. Stainless steel is used for their manufacture. When gas burns in condensing boilers, a large amount of hydrogen is formed, so the dew point value is high. The result is a lot of condensation and an aggressive acidic environment.

Stainless steel is resistant to external negative qualities: its heat resistance reaches 550°C, which is more than 2 times higher than that of plastic. The strength of the metal pipe is also high.

There are the following types of coaxial stainless steel chimneys:

- Uninsulated. These are double-circuit products, the inside of which is made of acid-resistant steel. In order for such a chimney to work well, it will have to be additionally insulated.

- Insulated. They consist of 3 layers, 1 of which has high thermal insulation characteristics. They are used to create vertically or horizontally directed chimneys, as well as with systems that have natural and forced draft. They are distinguished by high aerodynamic characteristics, and their service life is 25-30 years.

Stainless steel pipe.

Basic elements of a chimney

A coaxial chimney consists of various elements that make it possible to produce a chimney of the desired configuration for specific operating conditions and structural features.

The coaxial chimney kit contains everything needed for its installation.

Fittings, connecting elements, nozzles and other structural elements are manufactured according to a certain standard, which simplifies the process of assembling and installing the chimney. The range of leading manufacturers includes more than 80 elements of various configurations.

A ready-made coaxial chimney kit from the manufacturer includes the following elements:

- pipe - a straight section of pipe to form a smoke exhaust duct;

- elbow - an element for changing the direction of the pipe by 45 or 90 o;

- coupling - a device for connecting two straight sections of the chimney;

- condensate collector - a device for collecting and removing moisture flowing through pipes. Used in vertically oriented systems. To maintain constant pressure inside the combustion chamber, it is equipped with a special shutter;

- inspection - a separate section of the chimney used for inspection and cleaning of the smoke channel;

The range of leading manufacturers of coaxial chimneys contains more than 80 items of various connecting, fastening and functional elements

To ensure the tightness of all connected parts of the structure, special sealing rings made of heat-resistant material (thermoplastic) are used. When heated to high temperatures, the ring expands into a more elastic form, which allows it to maintain a seal even at high pressure.

Making a coaxial chimney with your own hands

In order for the chimney to cope with its tasks throughout its entire service life, it must be correctly calculated and correctly installed.

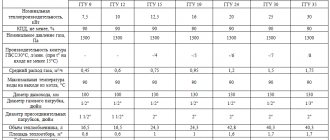

Calculation of chimney parameters

When designing a chimney, special attention should be paid to calculation operations, since the performance of the system as a whole will depend on the parameters of the chimney. The cross-sectional area of the outlet channel of the coaxial chimney should not be less than the cross-section of the connecting pipe of the heating equipment.

The cross-section of the smoke duct of the coaxial chimney is selected to match the dimensions of the heating equipment pipe

In collective systems, when connected to two or more heating devices, the channel cross-section increases in proportion to the size of their pipes. This is necessary in order to ensure sufficient throughput of the smoke exhaust channel when several boilers are operating simultaneously.

Distance from chimney to gas pipe

Installation of chimneys of gas boilers, as well as other heating equipment, must be carried out in accordance with building codes and fire safety requirements. You can read the instructions on how to repair a brick chimney here.

The photo shows a chimney for a gas boiler.

Requirements

Fire safety requirements when installing a chimney for a gas boiler:

- the height of the ceilings of the room in which the boiler equipment and chimney system will be installed must be at least two meters;

- the volume of the room for installing one heating device must be at least seven and a half cubic meters, for installing two heating devices the volume of the room must be at least thirteen cubic meters;

- ventilation must be provided in the room.

It is recommended that when installing a chimney, maintain a distance of at least 20 cm from the chimney pipe to the gas pipe.

If, during the operation of a gas boiler, partial destruction of the chimney occurs, for further use of the heating equipment it is necessary to carry out a lining procedure.

The thickness of the steel from which chimneys for gas boilers are made must be at least 0.5 mm. The steel must be alloyed and have increased anti-corrosion resistance, as well as resistance to acid-containing substances. For a gas boiler, the optimal choice would be a chimney made of AISI 316 steel; a more budget-friendly option, but also suitable for gas boilers, are chimneys made of AISI 304 steel. Read the manual for connecting a gas water heater to the chimney.

Dimensions

The diameter of the chimney must be no less than the diameter of the outlet pipe of the heating equipment.

The diameter of the chimney pipe also depends on the rated power of the heating equipment, for example, the diameter of the chimney pipe for a 24 kW gas boiler must be at least 12 cm.

The total length of the horizontal sections of the chimney can be from three to six meters.

Device

You can familiarize yourself with the chimney structure of a gas boiler using the diagram presented.

The most optimal chimney option for a gas boiler would be to install a modular chimney system made of steel sandwich pipes; a coaxial chimney system is also gaining popularity. A guide on how to install a coaxial chimney and installation requirements here: https://mykaminz.ru/dymoxod/vidy/koaksialnyj/rukovodstvo-kak-ustanovit-koaksialnyj-dymoxod-i-trebovaniya-k-ustanoe.html.

The chimney of a gas boiler in a private house can be mounted in two versions:

- exhaust pipe outlet through the wall and installation of an external chimney;

- installation of an internal chimney; in this case, the chimney is discharged outside through the roof of the house.

What is a coaxial chimney

An autonomous home heating system for any device requires complete removal of combustion products. Traditional chimney systems are still used today. However, they are being replaced by new devices that solve several problems simultaneously - coaxial chimneys.

Their appearance is associated with solving the problem of fuel combustion in a furnace, which occurs with the participation of oxygen from the heated room. If concentration is not restored by ventilation, the room becomes stuffy and uncomfortable. The conclusion is obvious - isolate the fuel combustion device (boiler) and supply oxygen to the furnace from the outside. For this, two-layer pipes were used, in which combustion products are removed from the inside, and air from the street is discharged through the gap between the inside and outside.

Coaxial chimney device

Advantages of coaxial chimneys

They are as follows:

- Increased efficiency of boiler equipment compared to traditional devices, obtained by supplying heated air with a normal oxygen content to the boiler furnace. This promotes more complete combustion of fuel;

- there is no need for additional supply ventilation in the room;

- increased environmental friendliness obtained by efficient combustion of fuel;

Flaws

These include the tendency of the inner pipe to freeze. This becomes possible due to the low temperature of the flue gases already at the outlet of the furnace. As a result, condensation forms, which freezes when the outside air temperature is below -15 degrees, which is not at all unusual for Russia. The degree of freezing can completely block the channels of gas and air movement, which means an emergency situation.

Attention! The pipe must not be allowed to completely freeze, as this will damage the boiler equipment.

As practice shows, such phenomena often arise from the desire to maximize the efficiency of the system by reducing the diameter of the internal chimney pipe, which leads to a decrease in the temperature of gases down to the “dew point”, increased condensation and, accordingly, to the formation of ice.

Devices for removing combustion products of this type are divided according to several criteria.

Indoor and outdoor systems

Internal systems are located in shafts specially constructed during the construction of the house. In no case do they come into contact with the living space. In some cases, such devices are installed in a standard brick chimney, but it should be noted that such chimneys are inconvenient for maintenance and repair.

Methods for installing a chimney in the house

External chimney systems are installed directly on the wall of the house from the outside. There is an opinion that they spoil the design of the house, so they are placed with access to the patio. This device design is easy to install and convenient to maintain and repair.

Exiting a coaxial chimney through the wall of a building

Cold and insulated devices

As noted above, in our harsh winters the chimney freezes. To avoid this effect, you need to insulate the chimney. There are several ways to do this:

- Using an additional casing made of a larger diameter pipe. In this case, the gap between the outer pipe and the casing is filled with insulation. Mineral wool is used for this;

- The outer pipe of the coaxial system is wrapped in roll insulation. Wrap a protective jacket of aluminum foil over this layer and secure it with clamps. The direction of winding should be carried out in such a way as to prevent moisture from leaking into the insulating layer, that is, from the bottom up.

Vertical or horizontal output

Coaxial designs were originally designed as purely horizontal devices. But this is a theory, but in practice the decisive factor is the location of the heating unit, which in some cases requires a combined design.

Vertical outlets are used only for boilers without forced draft.

Internal vertical and external combined coaxial chimney

How to choose the right gas boiler with a coaxial chimney

A condensing boiler is far from a cheap purchase, so when choosing it, you need to take into account the following nuances:

- The power of the unit must correspond to the heated area, since operation at partial load can cause premature failure of the boiler. It is generally accepted that heating 10 m2 requires a thermal power of 1 - 1.2 kW; based on this ratio, the power of the device is selected for a specific house or apartment. In addition to the area, you should take into account the quality of external thermal insulation, the number of door and window openings, ceiling height, etc.

- Possibility of using a coaxial gas boiler to provide hot water supply (double-circuit installations);

- Unit efficiency;

- Consumption of mains or liquefied gas. The feasibility of operating a particular model depends on this indicator;

- Heat exchanger material. Since condensate is nothing more than a solution of organic acids, the compensation heat exchanger is made of silumin (an alloy of aluminum and silicon) or stainless steel. Steel heat exchangers are a welded structure, while silumin heat exchangers are cast;

- Degree of automation of the unit. Modern electronic control systems can ensure completely autonomous operation of the device. In addition, some models provide the ability to control and configure using a mobile phone;

In addition to the above criteria, the cost of the boiler is also of great importance, but this is a purely individual issue and has nothing to do with the topic of our article.

Design and principle of operation

The coaxial pipeline kit includes a different number of parts depending on the design of the chimney exhaust device.

Design of a coaxial chimney

- adapter for connection to the combustion unit;

- 90 degree elbow to change the direction of the pipeline;

- Straight coaxial pipe. Structurally, it consists of two parts located one inside the other with longitudinal partitions between them;

- coupling with seal and clamp to strengthen the joint;

- air intake.

The operating principle of a chimney of this design is that when fuel burns, flue gases are formed and immediately rush into the chimney. The created low pressure zone is filled with outside air through the channel between the walls of the pipes. Warming up along the way from the inner pipe, it enters the firebox and the heated oxygen actively reacts with the fuel. At the same time, the efficiency of the device increases significantly. The cooled outer wall is favorable for the fire safety of the device.

Materials and tools for chimney installation

The completeness of the chimney depends on the location of the heating unit. The device consists of a number of standard units that allow the construction of chimneys of any configuration. The modules are modified, which makes it easy to equip the device with the necessary parts and simplifies installation work. When creating a coaxial chimney, the following components are used:

- straight pipes are the main element of the chimney;

- tees - made at angles of 30, 90 and 45 degrees, designed to change direction during installation;

- couplings and corner bends - pipe connections;

- condensate collectors - used in each vertical section, equipped with a water seal to prevent the suction of outside air, which reduces the draft in the chimney;

- inserts with inspection windows for chimney repair and maintenance;

- Inlet and outlet nozzles - come complete with heads, used to remove furnace gases and take air from the atmosphere. The outlet nozzle is installed at a distance from the air intake to avoid mixing clean air with combustion products;

- adapter - devices for connecting the chimney to the heat generator;

- fastening fittings in the form of flanges, clamps and brackets;

The material for the manufacture of chimney elements can be:

- Stainless steel sheet.

- Galvanized sheet.

- Heat-resistant plastic.

- Aluminum alloys.

The general requirement for them is resistance to temperatures of at least 250–300 degrees.

When assembling a chimney, the simplest tools are used to install fasteners, such as screwdrivers and keys. To attach the brackets to the walls you will need an electric drill and plastic inserts - dowels. A hole in a brick wall can be made with a bolt and a chisel.

Preparing for chimney installation

Despite the apparent simplicity of the chimney assembly process, it must occur according to a certain algorithm:

- Purchase of a heat generator. It should be taken into account that coaxial chimneys are used only with closed type devices with forced draft. Their power is up to 30 kW.

- Determining the installation location, securing.

- Execution of a preliminary design of a chimney taking into account bends, rise and other features depending on the architecture of the building.

- Purchase of a set of standard parts that ensure exact fulfillment of the requirements of the preliminary design.

At this point, the preparatory work can be considered completed.

Kinds

Depending on the installation method, chimneys can be vertical, through the roof, or horizontal, through a wall or window. Durability and performance parameters are determined by the properties of the material from which they are made.

Aluminum

It is lightweight and can withstand temperature fluctuations and all kinds of corrosive effects without damage. But due to the low operating temperature, it is extremely rarely used for the production of coaxial chimneys. Typically used in combination with plastic.

Stainless steel

For the manufacture of chimneys, acid-resistant stainless steel is used, which can safely withstand sudden temperature changes and can operate at temperatures up to 550 ⁰C. Guaranteed service life - at least 30 years. Manufacturers produce two varieties:

- Pipes without insulation are used in heating systems in industrial and domestic facilities. The disadvantage is the formation of a large volume of condensate during operation. To reduce it, it is necessary to install a layer of thermal insulation.

- Insulated - most often used as vertical collective chimneys in multi-storey buildings. They have improved aerodynamic properties. The rules do not prohibit the connection of heating systems with both forced and natural draft. Installation is carried out during the construction of the house according to a project developed by a specialized organization.

Double-channel plastic chimneys

They are made of heat-resistant material with operating temperatures up to 205 ⁰C. Plastic is inexpensive, weighs little, and is easy to install. Coaxial structures of this type are designed to work with gas condensing boilers with low-temperature flue exhaust. Disadvantages include a short service life and restrictions imposed on use in conventional gas boilers.

When choosing coaxial pipes, it should be taken into account that some manufacturers produce boilers with non-standard pipes. Therefore, for installation it is necessary to use components from the same manufacturer.

DIY installation of a coaxial chimney

Before you begin assembling the chimney, you need to clearly understand the basic regulatory provisions:

Rules for the combustion products removal device

When assembling the chimney, you must adhere to the following rules:

- The straight section crossing the wall should be installed with a slope of 3 degrees towards the street for unimpeded drainage of condensate.

- The chimney channel along its entire length should not include more than two elbows.

- Inspection windows, transition devices and condensate collectors must be installed in easily accessible places for ease of use.

- The chimney should not be discharged below ground level. The distance to the nearest building must be at least 8 meters. When using a deflector at the end of the chimney, this distance can be reduced to two meters for a blank wall and to five for a building with window openings.

- A horizontal chimney installed in a location with prevailing winds opposite in the direction of smoke removal must be equipped with a canopy - a damper. It should be located no further than 40 cm from the smoke outlet.

- Coaxial chimneys located at a height of less than 1.8 meters must be equipped with a reflector grille to protect against hot smoke.

Installation of a horizontal coaxial chimney

Compliance with these rules will allow for safe operation of the heating device with high-quality removal of combustion products.

Assembly order

Installation of a horizontal coaxial chimney is carried out as follows:

- connecting the adapter from the heat generator to the chimney;

- installation on the elbow adapter to change the direction of the channel;

- Marking the location for making a hole in the wall corresponding to the diameter of the chimney pipe. Important! the junction of the pipeline elements should not be inside the wall;

- installation of decorative caps at the intersection of the chimney and the wall;

- installing a deflector at the end;

- installation of an inspection unit and a condensate collector.

Upon completion of assembly, it is necessary to check that the assembled device complies with all the rules outlined above. Something to remember! The use of sealing gels and sealants in coaxial chimneys is prohibited.

Installing a coaxial chimney vertically, as a rule, is a necessary measure due to the impossibility of performing it horizontally without violating the installation rules. The peculiarity of the design is that such combustion product outlets cannot be installed in a straight line from the furnace due to the formation of a large amount of condensate. With this design, it will fall directly into the firebox, which is extremely undesirable. Therefore, you need to make an elbow from the stove for the horizontal component. Next, a second elbow and a condensate collector are installed. After this, the chimney is mounted vertically. The intersection with the ceiling and roofing pie is carried out using cups - insulators. On the roof, the pipe is equipped with a sealing umbrella to prevent leaks.

Attention! A vertical coaxial chimney is not used for closed boilers with forced draft.

Mounting options

Complete with a factory-assembled coaxial chimney, detailed installation instructions are required. Following and carefully implementing these recommendations is reflected in the operation of the boiler and the efficiency of the smoke exhaust system. According to experts, the main reason for the boiler to blow out, the appearance of frost or ice, is associated with errors in calculations and when connecting the chimney.

Horizontal installation of coaxial pipes

Horizontal installation is carried out taking into account the technical characteristics of the building. Initially, the location where the pipe exits the wall is selected. There are restrictions related to the distance to the nearest neighbor's window when removing a horizontal coaxial chimney from the wall, which must be carefully observed.

Additionally, the following parameters are calculated:

- The height of the pipe is from the boiler outlet to the passage hole in the wall; for floor-standing gas boilers, the height must be at least 1 m. Direct pipe outlet from the outlet to the street is not allowed. For wall-mounted gas boilers, the height can be reduced to 0.5 m.

- The number of rotary couplings on the site should not exceed 2 pieces.

- The maximum length of the horizontal section is 3-5 m, depending on the boiler model. To extend the pipe, a coupling with heat-resistant sealing rubber bands is used. The use of silicones and sealants is prohibited.

A peculiarity of using a two-channel chimney in winter is the increased production of condensate. The reason for moisture loss is that the system was originally designed for more favorable operating conditions. If the formation of condensate increases, the pipe will need to be insulated.

Vertical installation of a two-channel pipe

Vertical installation of the chimney provides two connection methods:

- Cascade diagram for connecting collective chimneys of condensing boilers. Several heating units are connected to one pipe at once. The cascade scheme is used in apartment buildings. The chimney is installed outside or inside the building. Vertical installation of the pipe is carried out only after careful calculations and preparation of design documentation, taking into account the rules set out in SP 60.13330 (SNiP 41-01-2003).

- Individual connection - the maximum length of the vertical coaxial combustion product removal system is 7 m, which allows installation in a two-story building. In a house made of aerated concrete blocks, the pipe is installed exclusively inside the building. The walls of the building cannot withstand the heavy load on the walls. In brick houses, a smoke removal system is installed inside and outside the building. In any case, mandatory thermal insulation of the coaxial type chimney is carried out.

Features of operation

First of all, you need to pay attention to the noticeably higher efficiency of stoves with such devices for removing combustion products. The efficiency increases due to the optimal fuel combustion mode.

With normal heating of a home, the air in it does not deteriorate, remaining clean, since oxygen from the outside air is used for combustion. There is no need for mandatory organization of supply ventilation, although it is usually created anyway; it will not be superfluous.

Coaxial chimneys are characterized by long-term operation because the pipes, which are constantly cooled by an influx of air, do not overheat.

Repair and service

The device requires virtually no special maintenance. At the beginning of the heating season, you need to inspect all fasteners and ties, and tighten loose connections.

A regular maintenance activity is periodic draining of condensate from the storage tank. Moreover, the frequency of such an operation is determined by the weather, which affects its formation.

The need to clean the inner pipe wall is determined by a visual inspection through the inspection window before the start of the heating season. The procedure is performed with a special brush equipped with stiff bristles. Chemical agents are used to soften carbon deposits and soot.

Coaxial chimneys should be considered the most advanced for saving heating costs, decreasing by 15–20%. At the same time, living conditions in the house improve.