Features of open and closed systems

Open heating system

To heat a house, a closed type of coolant flow structure is used, including a boiler, radiators and pipes. The system works on the principle of heating water to a certain temperature in special equipment, moving through a pipeline to radiators and further releasing heat to warm up the rooms. After cooling, the liquid is returned back to the heating device, forming a repeating cycle.

Open system

To understand what an open heating system is, it is worth using the multi-apartment building type as an example. This type of heating involves the use of a special storage tank, which is actively functioning in most multi-story buildings. On the roof of the high-rise building there is an expansion tank to collect excess water. The tank is not sealed, which allows vapors to escape into the external environment.

The open version is installed without a circulation pump. The coolant is directed through the pipes naturally. After heating the boiler to a certain temperature, the pressure increases, and the hot water, rising to the top, pushes out the cold water. The volume of water also increases when heated, so the excess goes into the expansion tank. The cooled coolant is again sent to the system.

Closed type of communications

A closed heat supply scheme involves a pump that provokes the movement of water through the pipes. Forced circulation is also realized using pipes, a boiler, radiators, and an expansion tank. The metal tank is sealed, consists of two rolled parts, and has the following contents:

- internal rubber diaphragm – heat-resistant membrane;

- gas in a small volume - factory nitrogen or air accumulated in the line.

The membrane divides the container into two compartments - for collecting excess heated water and for storing air.

The coolant moves through the system, but when it heats up, the reservoir valve takes away the excess. They enter the expansion tank, penetrate the membrane and are pushed back with the help of gas. After cooling, the circulation pump pumps water back into the system, while simultaneously monitoring pressure levels. In this way, the coolant is deaerated.

Main differences

The difference between an open and closed heating system is as follows:

- Location of the expansion tank. In the open - the top floor of a private house or the roof of a high-rise building. The closed tank can be placed anywhere.

- Isolation from air access. Unlike an open one, a closed highway is protected from air currents. Additional pressure at the top points prevents airing of the batteries.

- Complexity of arrangement. An open system will differ from a closed system in the type of pipeline. Products of large diameter are mounted taking into account the location of radiators, air slope, the presence of turns and rises.

- Organization costs. Closed heat and water supply requires financial costs for the purchase of thick-walled pipes. You can save on an open system by using small-diameter lines.

- Noise level. The forced type of circulation in a closed line involves the use of a pump. When installed correctly, the equipment will not make noise.

Creating heating for a closed house will save from 10 to 40% of energy resources per year.

What is a hot water system?

Hot water supply is a system consisting of heating devices, forced circulation of liquid, pipes and water fittings. When installing elements of a water heating installation, increased demands are placed on the quality of materials and installation work, because the water circulating through the pipes can be heated to + 75 degrees Celsius.

Attention! If you have any questions, you can chat for free with a lawyer at the bottom of the screen or call Moscow; Saint Petersburg; Free call for all of Russia.

Attention

To reduce the likelihood of getting burns during operation, during self-installation, it is necessary to carefully follow the rules and regulations for the installation of all hot water supply elements.

System connection options

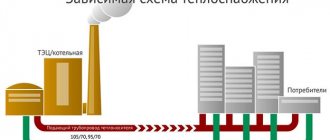

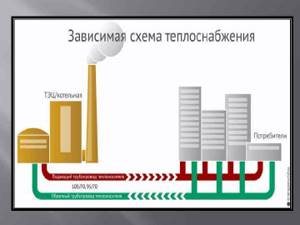

The laying of communications is carried out in a dependent and independent way. The first option is characterized by simplicity and minimal costs for components. The second method is used in new buildings.

Dependent method

The specificity of the scheme is an in-house heating unit with an elevator. The heat station mixer mixes hot water from the external main with the return one. The coolant receives a temperature of up to 100 degrees. The advantages of dependent systems include:

- supply of water for heating and supply directly from the heating main;

- simplicity and inexpensive price of input equipment for one subscriber;

- withstand large temperature fluctuations;

- small pipe diameter;

- reduction of coolant consumption.

Disadvantages of central heating include high water consumption, difficulties with temperature control and excessive energy consumption.

The internal line is dependent on external heat supply.

Independent way

The scheme provides for the presence of a main and additional circulation circuits, which are separated by a heat exchanger. In the main circuit, water is supplied from the boiler house or thermal power plant to the central heating station, and is directed from it to the heat exchanger. An additional circuit will be home heating, receiving heat from the network.

The system operates on the principle of heating water in two isolated circuits. The mechanism of the external heating main works on a closed internal network without further mixing of the liquid. The advantages of an independent scheme include:

- the ability to connect any number of heat exchangers;

- use of water for heating and household purposes;

- no pressure fluctuations in the home circuit;

- adjusting the temperature in the rooms using a thermostat;

- availability of drinking water in the domestic hot water supply system;

- filtration of coolant from salts in a small circuit.

Disadvantages of communications are the need for periodic flushing of the heat exchanger, the cost of purchasing equipment and control elements.

Implementation

Closed

How is a typical closed heating system implemented in an apartment building?

The heating main is responsible for delivering the coolant to the house - two heat-insulated mains (supply and return) connecting the boiler room or thermal power plant with consumers.

Underground heating main.

At each branch from the highway to a house or group of houses, a thermal chamber is installed with shut-off valves, vents and taps for control measurements of temperature and pressure.

Thermal camera in the process of installation.

Inside the house, the following are responsible for distributing heat to consumers:

- Elevator unit (heating point);

There may be several heating points in a house. Their number is determined mainly by the linear dimensions of the house: with a large number of apartments and entrances, creating one long circuit is unprofitable due to its high hydraulic resistance and the accompanying loss of pressure.

- Supply and return bottlings (horizontal pipelines connecting risers to the elevator unit);

- Risers that distribute coolant to individual heating devices.

Risers and heating radiators.

Now - in more detail about each element.

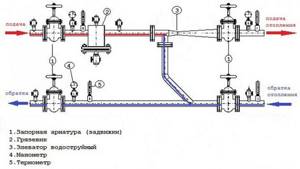

The heart of the elevator unit is the so-called water-jet elevator. It looks like a cast iron or (less commonly) steel tee with flanges for connection to the supply and return pipes. Inside the elevator there is a nozzle that provides a dosed supply of water from the supply and its mixing with the coolant sent for recirculation from the return pipeline.

Cast iron elevator and nozzle.

Why is this necessary?

Recirculation of return water allows:

- Increase the volume of coolant passing through the heating system per unit of time, with a minimum flow of water from the supply line of the heating main;

- Make the heating of heating devices more uniform at the beginning and end of the circuit.

How does an elevator work?

Its operating principle is based on Bernoulli's law, which states that hydrostatic pressure in a flow of liquid or gas is inversely proportional to the flow speed. The supply water pressure exceeds the return pressure by 2-3 atmospheres. But after the nozzle, a vacuum area is created, which draws in part of the coolant from the return pipeline through the suction.

Arrows indicate the direction of water movement.

The pressure difference between the mixture (water after the elevator) and the return is no more than 0.2 kgf/cm2.

In extremely cold weather, in order to maintain a temperature in apartments that meets sanitary standards, it is sometimes practiced to operate an elevator without a nozzle. The suction is suppressed by a steel plate mounted on the flange with a pair of rubber gaskets.

The flow of coolant from the supply to the return is limited by adjusting the inlet valve on the return pipeline: it is completely closed and then slightly opened with continuous monitoring of the pressure difference using a pressure gauge.

The elevator has been removed and the suction has been turned off.

If you simply close the valve, its cheeks can later slide down the stem and completely block the channel inside the body. The consequences of stopping circulation in extreme cold will not be long in coming: during the first couple of hours, the access heating will defrost, then accidents in apartments will follow.

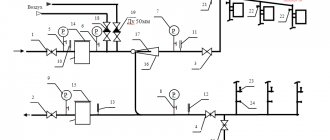

The elevator needs a harness.

It includes:

- Inlet and house valves (two at the entrance to the elevator unit and two at the border between it and the heating circuit itself);

Now gate valves are gradually being replaced by more reliable ball valves.

- Mud collectors (at least one mud collector at the feed, in front of the elevator);

- Control valves for measuring the pressure of the heating system;

Pressure gauges should be permanently installed in them, but due to mass thefts, representatives of Heating Networks and housing organizations are often forced to remove the devices.

- Oil pockets for measuring temperature;

- Discharge pipes after house valves that cut off the circuit from the elevator unit (optional - with pipes that drain water into the sewer). They are needed to reset the heating system and to bypass it during startup: if you open one of the house valves and reset on the second line, most of the air will fly out through the reset.

Configuration of a thermal unit in a closed system.

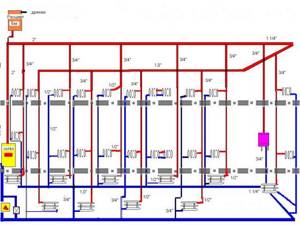

The heating distribution is laid around the perimeter of the house.

It can be mounted in one of two ways:

- The so-called top filling involves distributing the supply through the attic. The return bottling is located in the basement. The risers connecting them are turned off in two places - below and above;

Heating system with top filling.

This scheme makes it difficult to turn off an individual riser, but makes it easier to start the reset system. In order for circulation to begin in the circuit, it is enough to fill it and bleed the air through a single vent installed on the expansion tank located at the top point of the supply filling.

- In the case of bottom filling, both the return and supply pipelines are routed through the basement or technical subfloor. The risers are connected to them one by one; each pair of risers on the upper floor is connected by a horizontal jumper to ensure circulation.

Here the picture is the opposite: disconnecting a pair of risers is somewhat easier, but when starting a reset circuit, you need to bleed air from each jumper. If the inhabitants of the upper apartments are chronically not at home, starting the riser can result in a serious problem.

Bottom filling: return and supply are laid in the basement.

Risers and connections provide connection for heating devices. The typical nominal diameter of the heating riser is 20 - 25 mm, the supply line is 15-20. The connections to the devices are connected by jumpers that ensure the operation of the riser when the shut-off and throttling valves on them are covered.

Open

The only difference between an open scheme and a closed one is that there are hot water connections in the elevator unit.

In houses built before the mid-70s, connecting hot water is extremely simple: the hot water supply is connected to the supply and return between the inlet valves and the elevator. Valves or valves are installed on the tie-ins; At any given time, only one of the taps is open - either the supply or the return.

Elevator unit with two hot water supply connections.

Why are two independent inserts needed?

The fact is that during the peak of cold weather, the temperature of the supply line of the heating main at the exit from the thermal power plant can reach 150C. Water does not boil only due to excess pressure. By supplying water directly from the heating network to consumers, it is easy to get a lot of accidents and household injuries.

At the same time, the water temperature in the return pipeline is a quite acceptable 70 degrees.

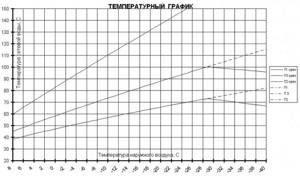

Temperature chart. Lines (top to bottom): supply, mixture, return.

In summer, the picture is different: there is no or minimal pressure drop in the route; The return temperature differs little from the ambient temperature. DHW needs are provided only by supply.

This scheme is extremely easy to maintain, but has a couple of serious drawbacks:

- In the absence of water supply, the water in the pipes cools down. Accordingly, it takes a long time to drain it in the morning. This is at least inconvenient, and if you have a water meter for hot water supply, it’s not comme il faut at all;

- Heated towel rails connected to the hot water supply heat up only when you use hot water. Most of the time the bathroom sits idle without heating.

A heated towel rail in a Khrushchev building, embedded in a gap in the hot water supply line.

In residential buildings of new projects, these problems have been successfully solved by a small modernization of the DHW connection scheme to the elevator unit:

- Both on the supply and on the return, two hot water connections are made between the inlet valves and the elevator;

- A retaining washer is installed on the flange between the cut-ins on each thread - a steel pancake with a hole 1 mm larger in diameter compared to the elevator nozzle;

- There are two domestic hot water dispensers throughout the house;

- The risers are connected to them alternately and are connected on the top floor or in the attic by jumpers - exactly as on heating with bottom bottling.

The connection diagram of the risers may vary significantly. For example, a scheme is possible in which two risers with hot water pass through each apartment - the hot water supply itself and a riser with heated towel rails.

The photo shows hot water supply risers and heated towel rails in the basement of an apartment building.

Often, dryers are mounted in a gap in the riser, and the risers are connected in groups of 3-4 pieces, corresponding to the number of apartments on the landing.

The heated towel rail opens the DHW riser.

Depending on the season, the hot water system can operate in one of three modes:

- In summer, outside the heating season, water circulates between the supply and return pipelines;

- In the lower zone of the temperature graph, two feed inlets are open. The pressure difference between them is ensured by a retaining washer;

- In extreme cold, when the supply heats up above 90 degrees, the hot water supply is switched on from return to return. The difference is again created by the retaining washer.

Features of pipe routing

Depending on the location of the main pipe, the technology for connecting batteries, and supply risers, the wiring technology is selected.

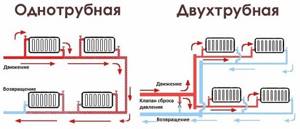

One-pipe method

When single-pipe wiring is used, a horizontal and vertical diagram is used. Laying pipes horizontally eliminates the possibility of adjusting the amount of water, so bypasses are additionally used. The vertical location of the highway is typical for high-rise buildings.

Two-pipe method

The two-pipe wiring method provides for the supply of two lines to one radiator - for supplying warm water and discharging cold water. The following schemes can be implemented in an apartment or house:

- gravity - circulation of warm water occurs naturally;

- classical – dead-end type system;

- annular - the coolant moves along the same path;

- radiant - heat is supplied from the distribution manifold to the radiators individually.

The two-pipe system is suitable for heated floors, where the heating circuits play the role of radiators, and the pipes and comb with mixer act as highways.

Types of hot water supply systems

Hot water supply systems are divided into:

- Centralized.

- Decentralized.

The first type is a circuit consisting of a boiler room and a large number of consumers. As a rule, a centralized scheme is used to supply water heated to a certain temperature to apartment buildings. The decentralized type of hot water supply, on the contrary, is autonomous, where the liquid is heated in close proximity to the water distribution elements.

DHW can also be of the following types:

- Open.

- Closed.

The open type of water heating installation is a scheme in which liquid heated to a certain temperature is taken from the heating circuit. In a closed circuit, cold liquid coming from the water supply is separately heated. Both DHW options have advantages and disadvantages, for example, for a closed circuit you will need to use additional equipment, but for an open circuit, the water quality will not be too high.

Types of communications by type of circulation

In open and closed lines, the coolant can move in two ways.

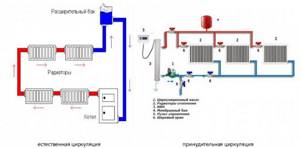

Natural circulation

The system is organized without a pump and operates on the difference in liquid density during heating and cooling. The coolant is heated in the boiler, becomes less dense and light, and as a result is directed upward. In a cold state, water moves through the outlet riser - a pipe with a large diameter. Along the wiring and to the heating devices, the coolant moves from top to bottom, cooling as heat is released.

When cold, the density of water increases and it is directed to the heating tank. The pipeline is installed at an angle. The system is characterized by energy independence - it can be used in a private home or in a country house. Among the disadvantages of natural circulation:

- complexity of installation due to large diameter pipes;

- unaesthetic appearance;

- the need to periodically top up the coolant;

- small area of heated rooms.

The system uses a leaky open container.

Forced circulation

A circulation pump is used for communications, activating the movement of water. The system is characterized by simplicity of arrangement, advanced capabilities and small pipe diameter. The user regulates the temperature himself or sets it automatically. The disadvantage of forced circulation is energy dependence.

Design and principle of operation

Now we should consider in detail what elements expansion tanks consist of and how they work. First, let's find out how such an element works.

Typically, the expansion tank structure as a whole is housed in a stamped steel housing. It has the shape of a cylinder. Cases in the form of peculiar “tablets” are slightly less common. Typically, high-quality metals coated with an anti-corrosion protective compound are used to produce these elements. The outer side of the tanks is covered with enamel.

For heating, expansion tanks with a red body are used. There are also blue versions, but this color is usually worn by water batteries, which are components of the water supply system.

On one side of the tank there is a threaded pipe. It is required to enable connection into the heating system. There are cases when the delivery also includes items such as fittings. They greatly simplify installation work.

On the other side, there is a special nipple valve. This element serves to generate the required level of pressure in the inside of the air chamber.

In the internal cavity, the expansion tank is divided into 2 separate parts by a membrane. Closer to the pipe there is a chamber intended for the coolant, and on the opposite side there is an air chamber. Typically, tank membranes are made of a very elastic material, which has minimal diffusion values.

The principle of operation of the expansion tank in the heating system is very simple and understandable. Let's analyze it in detail.

- In the initial state, at the moment the tank is connected to the system and filled with coolant, a specific volume of water passes through the pipe into the water compartment. The pressure in both compartments gradually equalizes. Further, such a simple system becomes static.

- As the temperature value increases, there is a direct expansion of the coolant in volumes in the heating system. This process occurs accompanied by an increase in pressure indicators. Excess liquid is sent to the tank itself, and then pressure bends the membrane part. At this moment, the volume of the coolant chamber becomes larger, and the air compartment, on the contrary, decreases (at this moment the air pressure in it increases).

- When the temperature drops and the total volume of the coolant decreases, excess pressure in the chamber with air provokes a shift of the membrane back. At this time, the coolant returns back to the pipeline.

If the pressure parameters in the heating system reach critical levels, the valve should start, which belongs to the “safety group”. In such a situation, it will be responsible for releasing excess fluid. Certain models of expansion tanks have their own individual safety valve.

Of course, it is worth considering that the design of the tank mainly depends on the type of specific model purchased. For example, they can be non-separable or with the ability to replace the membrane element. Such products may include such parts as clamps for wall mounting or special stands - small legs with which it is easier to place the floor-standing unit on a flat plane.

Expansion tanks with a diaphragm membrane are usually non-separable. In many cases, they contain a balloon membrane part - it is made from pliable and elastic raw materials. At its core, this membrane is an ordinary water chamber. As pressure increases, it stretches and increases in volume. These types of tanks are usually complemented by a collapsible flange, which makes it possible to independently change the membrane if it breaks.

Installation rules

The rules for connecting equipment and creating a system depend on its type.

Requirements for installation of an open system

When setting up you should:

- Select the lowest point for the heat source and the highest point for the tank.

- Use pipes with a large diameter for the movement of coolant.

- A narrow pipeline is necessary to normalize pressure.

- Install a high riser that will distribute the water evenly.

- Avoid a large number of turns, forks and connections.

- Install the system in a limited space - up to 159 square meters.

- In private households it is better to install a good circulation system.

The open system is suitable for a small country house or cottage.

Installation procedure for a closed system

If a closed heating system with a pump and expansion tank is installed, you must:

- Place the boiler in the basement and the expansion tank in the attic.

- Ensure high-quality thermal insulation of rooms with a container and riser.

- Do not use a large number of shaped elements.

- Avoid overheating the water.

- Drain the coolant if the system does not start in winter.

- Form a pipe slope of 2-3 mm per 1 m of contour.

The principles for calculating the cross-section and slope of a closed heating pipeline are prescribed in SNiP 2.04.01-85.

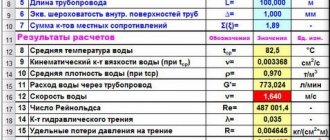

Calculation and recycling

For an open hot water supply option, calculations are made in the following sequence:

- The drawing shows circulation rings that are closed at the thermal unit. In a water heating installation of this type, supply and circulation pipelines are separated.

- On the circuit that has the maximum extent, areas with constant circulation flow are marked.

- The diameter of the circulation pipes is determined, which cannot be less than 15 mm. Also, when carrying out calculations, it is necessary to maintain the ratio of the diameters of the supply and circulation sections. To ensure a uniform flow of liquid and minimize the formation of air pockets, the circulation section of the water supply system is made of pipes, the diameter of which should be 1 to 2 sizes larger than when installing the supply section of the water supply system.

Considering the significant difficulty in independently calculating the diameters of pipelines, if the flow rate of liquid heated to a certain temperature is low, it is recommended to install a valve on the circulation riser. Thanks to this element, it will be possible to experimentally adjust the throughput of the circuit, which will allow achieving a minimum difference in pressure between the supply and circulation parts of the open DHW circuit.

Independent organization of the heating system

A good and high-quality heating option can be done with your own hands, if you take into account the costs of design, purchase of equipment and the complexity of the organization. The best option for a private home would be a closed type of communications with a circulation pump and tanks. Its creation is carried out like this:

- Communication calculations. Ordered from a design company or produced using an online calculator.

- Coordination of the project, obtaining permits and technical conditions.

- Purchase of equipment. You will need a heating boiler, a pump, pipes, an expansion tank, radiators (circuits if you plan to have a heated floor), air vents, shut-off devices, and automatic controllers.

- Boiler installation and boiler room equipment. High-quality ventilation is organized in the room and a chimney is installed. The walls, floor and ceiling surfaces are sheathed with fire-resistant materials.

- Installation of a circulation pump, distribution manifold and measuring instruments.

- Pipeline connections to battery locations.

- Installation of radiators.

- Pressure testing of the system. The first launch is carried out in the presence of specialists.

The collector circuit is difficult to install and is expensive, but by adjusting the circuits, the living conditions in the room will be comfortable.

There are several differences between open and closed heat supply communications. It is worth choosing a heating system depending on the conditions and installation location. It is easy to organize an open highway yourself. Specialists must create a closed system.

Criteria for choosing a heating system

There are only two options to choose from - a closed or open home heating system. Has anyone ever wondered why the first systems created were only open? And they were open for one simple reason - the boilers that heated the water were solid fuel. When circulation stops, the water in the boiler boils; a safety valve prevents the boiler from exploding, but it is impossible to extinguish it quickly. Therefore, closed heating systems with forced circulation began to be used for electric and gas boilers, which can be turned off automatically at any necessary time.

Open heating system

The open heating system is currently considered obsolete and is used in small private houses and country cottages. In this case, it is necessary to install an expansion tank in an open heating system at the highest point of the accelerating manifold to ensure circulation under the influence of gravity.

The modern open circuit of the heating system has borrowed the most important unit from a closed system - the circulation pump. It is usually used when starting a system to reduce its inertia. Then, during operation, the pump turns off and the bypass opens. Knowing where to place the pump in the heating system is necessary for its reliable and long-term operation. The pump is installed at the point with the lowest coolant temperature, usually in the “return” near the boiler.

The system is called “open” because atmospheric air is constantly in contact with water in an open expansion tank.

The open system is simple, reliable, and its cost is minimal. There is a misconception that its installation is more expensive because such systems require larger diameter pipes. If we take into account the cost of a circulation pump, a membrane expansion tank and electricity costs for a closed heating system, then installation will clearly not be cheaper. In some cases, there is no alternative to using an open heating system. For example, in the absence of power supply.

The main advantages of open heating systems:

- extreme ease of installation and maintenance;

- quiet operation;

- energy independence;

- reliable operation with boilers of any type;

- relatively low costs for the purchase of equipment, pipes and fittings.

Of course, a simple and reliable open heating system, usually a two-pipe design, is not without its drawbacks:

- evaporation of liquid in the expansion tank makes it impossible to use antifreeze; the water level in the tank must be monitored;

- large inertia of the system; to eliminate this drawback, a circulation pump and bypass are installed;

- For complex contours of multi-storey buildings with heated floors, the system is not suitable due to the high hydraulic resistance of such heating systems.

Closed heating system

If you choose a closed-type heating system, the scheme of which can be any - single-pipe or double-pipe, with or without heated floors, then its main feature is the absence of contact of the coolant with air, i.e. it is completely sealed. The movement of the coolant in the circuit is ensured by a circulation pump. and the thermal expansion of the liquid is compensated in a sealed membrane expansion tank. The use of forced circulation facilitates installation, because there is no need to strictly maintain the slope of pipes, which may be of smaller diameter. The presence of a pump makes the system energy-dependent.

With the increase in the number of floors of private houses and the complexity of heating circuits, a closed-type heating system is mainly used, which may include several circulation pumps, collector beam distribution and automated electronic control of the temperature of different rooms. In a closed circuit, the installation scheme of the expansion tank in the heating system differs from its placement in an open system. The best option is to place a membrane tank in the “return” near the boiler.

The popular closed heating system has both advantages and some disadvantages:

- in a closed system there is completely no evaporation, therefore, antifreeze can be used as a coolant;

- relatively lower costs for circuit pipes; pipes can be hidden under the floor or trim;

- installation is simplified; there is no need to carefully measure the angles of inclination of the pipeline;

- low system inertia and high heat transfer;

- a small amount of oxygen in the coolant reduces corrosion of steel pipes.

Legal basis for relations in the field of heat supply

The relationship between energy companies and consumers is regulated by the Federal Law on Heat Supply No. 190, which came into force in 2010.

Chapter 1 outlines the basic concepts and general provisions that define the scope of the legal foundations of economic relations in heat supply. It also includes the provision of hot water

The general principles of organizing heat supply are approved, which consist in creating reliable, efficient and developing systems, which is very important for living in the difficult Russian climate. Chapters 2 and 3 reflect the broad scope of powers of local authorities, which manage pricing in the field of heat supply, approve the rules of its organization, accounting for heat energy consumption and standards for its losses during transmission. The full power in these matters makes it possible to control heat supply organizations that are classified as monopolists. Chapter 4 reflects the relationship between the heat supplier and the consumer based on the contract. All legal aspects of connection to heat networks are considered. Chapter 5 reflects the rules for preparing for the heating season and repairing heating networks and sources

It describes what to do in case of non-payment under the contract and unauthorized connections to heating networks. Chapter 6 defines the conditions for the transition of an organization to the status of self-regulatory in the field of heat supply, the organization of the transfer of rights to own and use a heat supply facility.

All legal aspects of connection to heat networks are considered. Chapter 5 reflects the rules for preparing for the heating season and repairing heating networks and sources. It describes what to do in case of non-payment under the contract and unauthorized connections to heating networks. Chapter 6 defines the conditions for the transition of an organization to the status of self-regulatory in the field of heat supply, the organization of the transfer of rights to own and use a heat supply facility.

Users of thermal energy must know the provisions of the Federal Law on heat supply in order to assert their legal rights.