Often a heat accumulator for heating is called a heat accumulator and a buffer device. They are designed to accumulate excess heat from various sources (fireplace inserts, solar collectors, various boilers, heat pumps, etc.), and also serve as a hydraulic decoupling of large heat flows used for heating.

Thermal accumulators create a temporary balance between the production of heat sources and its use by consumers.

TOP 10: Nibe BU – 500.8

Application

This type of heat accumulator is used for heating boilers with different heat sources, be it a heat pump or a boiler, a solar collector or another, and also, as an alternative supplier, effective when the centralized supply is turned off.

Important: when operating with boilers using solid fuel, overheating of heat accumulators is eliminated, the efficiency increases and the service life of the boiler equipment is extended. Additionally, it is possible to reduce the frequency of loading it with fuel.

Peculiarities

For this heat accumulator model they are as follows:

- attractive design;

- effective polystyrene foam thermal insulation up to 140 mm thick. It was easy to remove it in order to reduce the size of the device if it was impossible to pass through doorways. It is similar in appearance to molded panels, the outer side of which is covered with white PVC;

- allows connection of more than one electric heater;

- use as an alternative source, in the absence of centralized heating;

- the ability to consume cheap energy (night tariff) when working with two-tariff meters and electric boilers;

- the presence of additional coils for individual modifications installed in the lower part. Thanks to them, you can connect additional heat sources;

- there are flanges for connecting heating elements and a thermometer;

- the ability to distribute the coolant along the entire height of the device, thanks to the vertical bar available at the inlet of the heat storage tank (on the left);

- suitability for organizing the most complex heating systems, including those for which the heat load is quite large.

Technical indicators

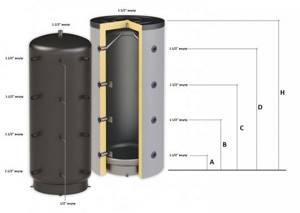

- Type – floor;

- Tank capacity - 500 liters;

- The maximum pressure in the external tank is 6 bar;

- Maximum heating temperature - 95 Cº;

- Device weight – 106 kg;

- Diameter – 750 mm;

- Height – 1757 mm.

Buy

Operating principle

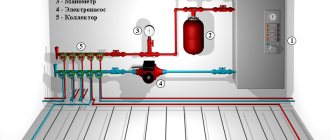

The heat accumulator for boilers has a simple functioning scheme. A pipe is connected from a unit of any type of fuel to the top of the device, through which hot water enters the storage tank.

When the water cools, it falls to the ring pump, which feeds it back into the main pipe, and the water returns to the heating device for the next cycle.

If you install a heat accumulator, this will prevent overheating of the water when the unit is operating at maximum power, will ensure heat exchange and economical fuel consumption. Therefore, the load on the heating system is reduced and its service life is increased.

A boiler with any type of fuel has a stepwise operation, turning on and off from time to time, reaching the required temperature. The work stops, the coolant ends up in the tank and is replaced by hot liquid.

It did not cool down because there is a heat accumulator for the heating boiler. If it happens that the boiler turns off and becomes inactive until the next fuel load, then the radiators will still be hot for some time, and the water in the tap will also be warm.

TOP 9: ETS 200

Review

These heat accumulators for heating boilers have a steel body and heat-resistant insulation on top. Underneath there are blocks that accumulate heat. They are made of composite material with high thermal conductivity, which are heated using heating elements.

Heat accumulates at night when reduced electricity rates apply. Then, during the day, it is used to heat the room.

For faster heating, a fan is built into the design.

Important: In order to regulate the room temperature, in other words to control the discharge, you need a built-in regulator, which is not included in the package, so it must be purchased separately.

There is a switch on the front panel, thanks to which it is possible to manually adjust the charge volume.

In order to be able to set the charging start and end time (during the energy payment benefits are valid), it is necessary to install an electric siren (signal) or a timer. It's also not included in the kit. It can be purchased for an additional fee.

Technical indicators

- Power value, kW – 2.0;

- Dimensions, mm – 650x605x245 (HxWxD);

- Weight, kg – 118;

- Operating temperature range, degrees - +7-+30;

- Manufacturer – Germany;

- Mounting type – floor;

- Warranty period – 3 years.

The purpose of the model is to regulate the output of heat received from one or another source of heat for effective heating of the room.

Device

There is a tubular heater inside, made of high-quality steel. It heats the stones, which are capable of accumulating heat; they release it, cooling naturally, to the air passing through them under the influence of a fan.

By installing a sensor in a room, you can regulate heat with high precision, saving (due to the built-in battery) a significant portion of electrical energy.

Comfort mode is set by the power regulator.

Price

| Where can I buy | Price in rubles |

| https://tepla.shop/product/ets-200?_openstat=bWFya2V0LnlhbmRleC5ydTvQotC10L_Qu9C-0L3QsNC60L7Qv9C40YLQtdC70YwgKNCi0LXQv9C70L7QsNC60LrRg9C80YPQu9GP0YLQvtGAKSBTVElFQ kVMIEVMVFJPTiBFVFMgMjAwO1R2VmMzTG5DdG56OGgwQ25OODhVdnc7&frommarket=https%3A//market.yandex.ru/catalog/69097/list%3Ftext%3D%D1%82%D0%B5%D0 %BF%D0%25B&ymclid=285742735834950992200004 | 55000 |

| https://www.vseinstrumenti.ru/klimat/obogrevateli/konvektory/elektricheskie/stiebel_eltron/ets_200_74484/ | 29900 |

| https://thermomir.ru/subitem/teploakkumulyatoryi-stiebel-eltron-ets-200 | 55000 |

| https://aley.ru/cash/info/11039.html | 49500 |

| https://otmorozok.com/index.php?route=product/product&product_id=2908 | 77600 |

TOP 8: HAJDU AQ PT 500

Hajdu buffer storage tanks (also known as heat accumulators) are designed to supply hot water to a closed heating system. Depending on the type chosen, heaters using gas and fuel oil, boilers using solid fuel and biomass for operation, solar panels and fuel pumps can be connected to them.

The volume of such heating structures supplied to the retail chain varies from 300 liters to 870.

There are many varieties of them:

- AQ PT series (empty tanks);

- AQ PT C (with coil);

- AQ PT C 2 (combined).

Device

The inside surface of the tank is not covered with a protective anti-corrosion layer, which is why it is recommended to fill the tank with water exclusively for heating.

Additionally, thermal insulation for the structure is purchased, since the package does not provide it. It is made of soft polyurethane foam. Its thickness is 100 - 120 millimeters.

For the manufacture of the casing, artificial leather was chosen. The insulation and casing can be quickly removed if the device does not fit through the door. Without them, there is no such problem even if we are talking about a heat accumulator of maximum volume.

Installation at the place where the device will be used is carried out in the same way, without them. With such designs, no unforeseen situation will arise.

They are quite capable of providing the space with warmth. At the same time, the efficiency of the generated energy increases many times.

Options

- Manufacturer – Hungary;

- Weight – 99 kg;

- Warranty – 3 years;

- LxH – 650x1675 mm;

- The highest possible pressure in the tank and storage tank is 3 bar and 0.3 MPa;

- The installation size of the heating element, water and temperature sensor is 1″1/2, 1″1/2 and 1/2.

Price

You can buy a heat accumulator model for heating at a profit in online stores:

Molten salt technology

The sensible heat of molten salts is also used to store solar energy at high temperatures. Molten salts can be used as a method for storing residual thermal energy. At the moment, this is a commercial technology for storing heat collected by solar concentrators (for example, from tower-type solar power plants or parabolic cylinders). The heat can later be converted into superheated steam to power conventional steam turbines and generate electricity in bad weather or at night. This was demonstrated in 1995-1999 as part of the Solar Two project. Estimates from 2006 predicted an annual efficiency of 99%, citing a comparison of energy stored as heat before being converted to electricity versus converting heat to electricity directly. Various eutectic salt mixtures are used (for example, sodium nitrate, potassium nitrate and calcium nitrate). The use of such systems as a heat transfer medium is noticeable in the chemical and metallurgical industries.

Salt melts at 131C (268F). It is stored in a liquid state at 288C (550F) in insulated "cold" storage containers. The liquid salt is pumped through the solar panels, where the focused heat from the sun heats it to 566C (1,051F). It is then sent to a hot storage container. The tank insulation itself can be used to store thermal energy for a week. When electricity is needed, the hot molten salt is pumped into a conventional steam generator to produce superheated steam and run a standard turbine generator set used in any coal, oil or nuclear power plant. A 100 MW turbine would require a tank 9.1 m (30 ft) high and 24 m (79 ft) in diameter to run for four hours using this principle.

A single tank with a separation plate to store both cold and hot molten salts is in development. It will be much more economical to achieve 100% more energy storage per unit volume compared to twin tanks, since the molten salt storage tank is quite expensive due to its complex design. Salt warmers are also used to store energy in molten salts.

Several parabolic power plants in Spain and Solar Reserve, a developer of solar tower power plants, use this concept to store thermal energy. The Solana power plant in the United States can store energy in molten salts, which is generated for 6 hours. In the summer of 2013, the Gemasolar Thermosolar power plant, which operates as both a solar concentrator and a molten salt power plant in Spain, achieved 36 days of continuous electricity production for the first time.

TOP 7: HAJDU AQ PT 1000 C

Description

The tank of this heat accumulator is designed for 1000 liters. The device is designed to work together with a solar collector and a solid fuel boiler.

The buffer design, in addition to storing excess heat generated by a solid fuel boiler or any other alternative energy source, can redirect it to a heat accumulator.

Among such additional sources, solar batteries are actively gaining popularity, the cost of which is not as high as it might seem.

Their advantage is that they supply practically free heat all year round, even with little lighting. Even in cloudy weather, the heating system can receive tens of kilowatts of energy from them.

Design

Inside the Hajdu AQ PT 1000 C tank there is a heat exchanger in the form of a spiral. Its area is 4.2 square meters. The coolant heated by the sun's rays, flowing through the coil, gives off its heat, which is directed to the heating system for heating.

The coolant is supplied and removed through pipes that are located on the same vertical line, which is important because boiler room space is saved.

The dimensions of the device allow it to function in tandem with a solid fuel boiler, whose power is 25-35 kW.

Important: the system that ensures the accumulation of heat by a buffer capacity is only capable of functioning in a heating system with a forced cycle, and is not suitable for a gravity system.

The designers of the Hoidu brand did not limit themselves to the described function of the device, i.e. the ability to accumulate heat. Therefore, they provided a technological hole that makes it possible to install 2, 3, 6, 9 - kilowatt heating elements. The importance of this solution is the ability to increase the time between downloads. This was appreciated by those living in country cottages and dachas.

We recommend:

- Portable phone chargers: advantages, features, price - TOP 7

- Thermal accumulators: purpose, features, price - TOP-6

- TOP 6: inexpensive solar collectors for heating and heating swimming pools, prices and where to buy

Now they can load cheap heat, i.e. load the energy storage device at a discounted rate. There is no need to insert an electric boiler into the heating system, because the heating elements heat the storage tank directly, releasing the heat accumulated during the night into the system during the day.

To ensure that the price of the heat accumulator is affordable to a wide audience of users, the developer does not equip it with external insulation, which can always be ordered as an option, just like heating elements.

Inner surface

On the inside, the walls do not have an enamel coating, like boilers with indirectly heated water heaters, so heat accumulators are not recommended for use in hot water supply.

Buy

| Where can I buy | Price in rubles |

| https://avangardteplo.ru/products/name/teplonakopitelj_hajdu_aq_pt_1000_c?_openstat=bWFya2V0LnlhbmRleC5ydTv/ | 40030 |

| https://xn—-7sbcqc4aneonsmco5krb.xn--p1ai/products/bufer-emkost-hajdu-aq-pt-1000-c | on call |

| https://vsegdateplo.ru/vodonagrevateli/teploakkumulyatory/hajdu/hajdu-aq-pt-1000-c-bez-izolyatsii / | 42725 |

| https://nasos-kotel.ru/bufernyy-nakopitel-hajdu-aq-pt-1000-c/ | 40030 |

| https://mrklimat.ru/teploakkumulyatory/teploakkumulyator-hajdu-aq-pt-1000-c.html | 40030 |

Battery buffer tank volume

Let's figure out what volume the heat accumulator should be. There are differing opinions that are based on calculations based on:

- room area;

- boiler power.

Let's look at each of them. Based on the area of the room, there can be no exact recommendations. Since there are many factors that influence the battery life of a system without a boiler, the main one is the heat loss of the room. The better the house is insulated, the longer the buffer tank will be able to provide the home with heat.

Of course, the larger the tank, the better, but to heat a larger amount of coolant you will need more heater power. Calculation of boiler power is done based on the heated area. One kilowatt warms up ten meters. You can install a five-ton tank, but if the boiler cannot handle such volumes, there will be no point in installing such a large heat accumulator. This means that adjustments need to be made to the calculation of the power of the boiler itself.

It turns out that it may be more correct to make the calculation based on the power of the boiler. Let’s take for example the same house of 200 sq. m. An approximate calculation of the volume of the buffer tank is as follows: one kilowatt of energy heats 25 liters of coolant. That is, if there is a 20 W heater, then the volume of the heater should be about 500 liters, which is clearly not enough for such housing.

Based on the results of the calculations, we can conclude that if you are planning to install a heat accumulator, then you need to take this into account when selecting the boiler power and take not one, but two kilowatts per ten meters of heated area. Only then will the system be balanced. The volume of TA also affects the calculation of the capacity of the expanzomat. An expansion tank is an expansion tank that compensates for the thermal expansion of the coolant. To calculate its volume, you need to take the total volume of coolant in the circuit, including the capacity of the buffer tank, and divide by ten.

TOP 6: S-TANK HFWT -300 SERIES

Description

This model is distinguished by the ability to connect any number of heat sources, which is important for creating a multivalent heating system.

Internal structure

The tank of the model has a built-in heat exchanger in the form of a spiral, made of high quality stainless steel. Its area can be in the range of 3.5-8.4 square meters. Principle of operation

The tank maintains a constant temperature - 39-95 degrees. The water passing inside the spiral is heated to almost the same degrees - 37-93, giving the DHW user a volume corresponding to the size of the tank. Advantage

It consists in the device performing two functions - storing heat and using it to solve DHW problems.

Technical indicators

- Manufacturer – Belarus, S-Tank;

- Warranty – 5 years;

- Weight – 76 kg;

- Height – 157cm;

- Diameter – 63 cm;

- Tank volume – 300 liters;

- The maximum pressure in the tank and heat exchanger is 6 bar each;

- Number of heat exchangers – 1;

- The permissible temperature in the tank and heat exchanger is 95 and 110 degrees.

Buy

| Where can I buy | Price in rubles |

| https://www.termokit.ru/catalog/kotelnoe_oborudovanie/teploakkumulyatory/teploakkumulyatory_s_tank/teploakkumulyatory_s_tank_serii_hfwt_teploobmennik_dlya_gvs/teploakkumulyator_s_tank_serii_hfwt_300.htm?frommarket=https%3 A//market.yandex.ru/catalog/69097/list%3Ftext%3D%D1%82 %D0%B5%D0%BF%D0%BB%D0%BE%D0%B2%D1%8B%D0%B5+%D0%B0%D0%BA%D0%BA%D1%83%D0%BC%D1 %83%D0%BB%D1%8F%D1%82%D0%BE%D1%80%D1%8B%26cvredirect%3D3%26track%3Dsrch_ddl%26onstock%3D1%26deliveryincluded%3D0%26local-offers-first%3D0&ymclid =285168597851724698000006 | 48702 |

TOP 5: S-Tank AT 300

Review

The purpose of the design is to accumulate heat given off by various sources and organize multivalent heating systems. This means that if it is necessary to combine work from two or more heat sources (a carbide boiler, for example, with an electric or gas boiler), the model will be quite effective.

Tank

The device for storing heated water is made of carbon steel. For the heating system, it acts as a hydraulic separator and improves the flexibility of the latter.

Pairs perfectly with the following boilers:

- solid fuel;

- using biomass as fuel;

- pellet;

- electrical;

- gas.

And also with heat sources:

- fireplaces with water jackets;

- fuel pumps.

Insulation

It is made using NOFIRE technology and environmentally friendly polyester material, 100% recyclable. Insulation thickness 70 mm. Its main advantage is considered to be high heat transfer and fire resistance (class B-s2d0 according to European standards).

The tank is also protected from the outside, for which the developer uses plastic lining (up to 1000 l) and fabric lining (more than 1000 l), the color range of which is very diverse.

The top of the tank is painted with high temperature resistant paint. The internal walls do not allow paint to be applied according to existing requirements. Optionally, a zinc-containing composition can be applied to the inner walls. This is done in order to store hot water.

Hole size

To connect instrumentation devices, holes with 1 ½ “internal threads are provided, turned to each other at right angles.

Price

How to connect

At the initial stage, the boiler should be installed according to the diagram. A special safety group and a three-way valve will need to be installed on the pipe that will go to the storage tank to prevent condensation from occurring. In the future, a heat accumulator should be connected to the system, and a three-way mixing valve will need to be connected to the pipe coming out of it.

The heat accumulator cannot do without installing a circulation pump, which must be equipped with a relay thermostat with an immersion sleeve. Two check valves should also be installed.

TOP 4: S-TANK AT AT-1000

The storage tank, which occupies 4th place in the TOP-10, serves the same tasks as those described above - accumulating heated water.

Description

- The material used for the body is carbon steel;

- Country of origin: Belarus;

- Weight – 131 kg;

- Height – 2035 mm;

- Diameter – 92 cm;

- Volume – 1000 l;

- The pressure in the tank and the highest temperature are 6 bar and 95 degrees.

The buffer heat accumulator does not have a heat exchanger. Its volume is 1000 liters, which allows the device to be used with 6-10 kW boilers intended for small areas. A low-power solid fuel boiler is most suitable for the specified volume of coolant.

The structure is protected on top by 70 mm of thermal insulation, which is closed with a plastic casing with an aluminum latch for ease of transportation, installation and dismantling. There are 8 holes with one and a half inch internal threads for supplying and discharging boiler water.

The pipes are turned at an angle of 90 degrees and located at different heights for the convenience of connecting different heating circuits and installing the storage tank in a corner.

In addition to them, there are 4 more half-inch holes, which are intended for thermomanometers and temperature control sensors. The pressure inside the working area is 6 bar. It is sufficient for the normal functioning of the drive.

Price

TOP 3: HAJDU AQ PT 1000

Job

The TOP 10 models occupying 3rd place can work from several sources (depending on the execution):

- from the energy of the Sun;

- gas boilers;

- coal, etc.

Connection

It is recommended to entrust the first start-up to a specialist. The user needs to study the instructions and always follow them.

Device

It consists of:

- steel container (tank);

- thermal insulation made of polyurethane;

- protective casing;

- artificial leather covers.

There is no corrosion protection inside, so the tank can only be used for its intended purpose. It is not suitable for storing drinking water.

Insulation

Like its analogues, it is made of polyurethane foam, which maintains the water temperature for a long time without requiring heating. The thickness of the protection is 10 cm. For the casing, as mentioned, artificial leather is used.

The casing is insulated and can be easily removed. This is convenient when transporting, installing and dismantling the device.

Advantages

The main one is the possibility of temporary equalization of discrepancies in heat production and consumption.

Important:

- Heat exchangers with storage tanks must not be exposed to high pressures. Is it dangerous!

- Installation of a safety valve is required, purchased at an additional cost.

- The installation of any water shut-off valves between the valve and the storage tank is prohibited.

Peculiarities

- Ergonomics.

- Good thermal insulation.

- Well-placed pipes.

- Removable insulation and casing.

- Painted outer surface.

- Possibility of connecting a heating electric cartridge.

- Compatible with various types of boilers.

- Long service life.

- Convenient installation dimensions.

Technical specifications

- Volume – 750 l;

- Weight - 93 kg;

- Storage type water heater;

- Heating method: electric;

- Mounting – floor;

- Diameter with and without insulation – 99 and 79 cm;

- Height – 191 cm;

- The internal tank is made of steel;

- Anti-corrosion protection – not provided;

- Working pressure – 3 bar;

- Manufacturer - Hajdu, Hungary;

- Voltage – 220 V.

Price

TOP 2: HAJDU PT 300

Review

The newest of the latest developments is given 2nd place in the TOP-10. The device accumulates heated water for a closed heating system. Compatible with boilers that use various types of fuel, with thermal pumps and solar batteries.

An indirectly heated floor water heater is connected to heating equipment, to gas boilers, for example. Water is heated during operation, accumulated in a tank and used for domestic needs.

Such boilers are installed directly on the floor and work together with other equipment that is also installed on the floor or mounted on the wall.

Like the models already described, the model is necessary to equalize the time difference in the accumulation and use of heat. The volume of tanks can vary in the range of 300-1000 liters.

Options

- Country: Hungary;

- Height – 1595 mm;

- Weight – 87 kg;

- Tank capacity 300 liters.

Device

The buffer tank does not include a heat exchanger. There is no anti-corrosion layer applied to the inner surface, which is why the tank can only be filled with water for heating.

casing

For its manufacture, artificial leather was chosen. The dimensions of the device are such that they allow it to pass through the doorway without any problems.

Thermal insulation

Its quality is said to be exceptionally high. Thanks to this, the heat is retained in the storage tank for several days, which ensures uniform heating of the home.

Peculiarities

- Can be used for closed type heating;

- Allows you to install heating elements;

- Easy design to use and install.

- Easy installation and maintenance

- Use of renewable energy

- Complies with European safety requirements

- Supplied without heat exchanger.

Price

Types of accumulating models

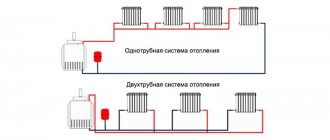

Drives function the same way, but differ in their design, so the following types of storage devices are distinguished:

- hollow (does not have an internal heat exchanger);

- with 1 or 2 heat exchangers (ensures correct operation of the unit);

- with a built-in small diameter boiler.

Hollow heat accumulators are the simplest and have the lowest cost. They can be connected to one or more units. You can also install an additional heating element that runs on electricity. The heat accumulator guarantees good heating of the living space, reduces the likelihood of overheating of the coolant and ensures the safe operation of the system. A heat accumulator with one or two coils is an advanced type of device with a wide range of uses. The heat exchanger, which is located at the top, removes thermal energy. The one at the bottom intensively heats up the buffer tank.

A thermal buffer unit costs significantly more than a hollow unit, but this is completely justified. The device significantly increases the functionality and efficiency of the system. A storage tank with a built-in tank accumulates the heat generated in excess of the norm and supplies hot water.

TOP 1: S-TANK AT PRESTIGE -500

Short review

The best model TOP-10 is recommended for use in various types of heating systems.

Stainless steel is used to make a cylindrical storage tank. Therefore, the device will serve for a long time, reducing heating costs.

Advantages

The model has enough of them:

- simple maintenance and installation;

- fast heating of water, independent of conditions;

- protection against overheating, so operation is permitted even in commercial buildings;

- unique parameters and versatility, the choice of which is determined by the size of the heated room;

- continuous heat accumulation thanks to built-in heat exchangers;

- compatibility with heat supply sources of any type.

Additional thermal insulation can improve efficiency. The insulation can be polyurethane foam or mineral wool, which slow down the cooling of the coolant.

By using a combined heating device you can significantly reduce costs. Each user can maintain a comfortable temperature by choosing a heat storage device based on parameters such as power, design features, volume, etc.

Characteristics

- Manufacturer – Belarus;

- Weight – 105 kg;

- Size in diameter – 78 cm;

- Height – 157 cm;

- Tank volume – 500 l.

Advantages and disadvantages of heat accumulators for heating boilers

Before choosing a buffer drive, you need to carefully study the advantages and disadvantages of such equipment. This information will allow you to learn about all the strengths of the heating tank and prepare in advance for possible problems.

Main advantages:

- Increasing the efficiency of the boiler and the entire heating system;

- Saving energy resources;

- Reducing the risk of coolant overheating;

- No need for frequent human intervention in the operation of the heating system;

- Ensuring uniform heating of all rooms of the house;

- Ease of conversion to use other energy sources;

- Troubleshooting hot water problems;

- Reducing financial costs.

Main disadvantages:

- Long period of heating of the coolant during initial startup of the equipment;

- The need to use a higher power boiler;

- Increasing the size of the heating system;

- Difficulties with installation;

- Long payback period for equipment.