Design and principle of operation

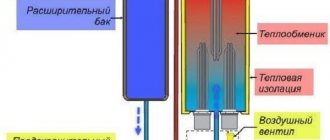

Household smoke exhausters for boilers have the following structural elements:

- impeller housing – made of heat-resistant steel;

- electric motor – runs on alternating current, installed outside the housing;

- drive shaft – mounted on bearings with sealed seals;

- branch pipes – supply and discharge;

- impeller - made of alloy steel;

- bunker – compartment for collecting ash;

- damper

What does a smoke exhauster for a boiler look like?

When the wheel rotates, the air flow is directed to the center of the smoke exhauster, then it is rejected by the walls of the unit, due to which a vacuum occurs with a gradual influx of a new portion of air masses.

Varieties

Manufacturers of thermal power equipment offer the following types of smoke exhausters: draft fans, flow units, centrifugal duct smoke exhauster.

Natural draft enhancers

The devices are devices with an axial fan, the performance of which is regulated using a thyristor control unit. The unit is installed at the end of the gas-air duct, immediately in front of the chimney pipe. The working mechanism is protected from high temperatures and volatile inclusions in combustion products.

Flow-through smoke exhausters for boilers

The structures serve to increase natural draft and are mounted on the outlet pipe of the equipment. Due to the design features, the impeller of a flow-through exhaust fan is not capable of developing high pressure. For this reason, it is used as an exhaust amplifier, and cannot always serve as a traction device. Only the housing with the impeller is installed in the smoke channel, and the electric motor and other elements of the unit are located outside, which allows you to turn the equipment on/off as needed. The control is manual; if desired, you can connect the device to the automation of the boiler installation.

Centrifugal duct smoke exhausters for solid fuel boilers

Centrifugal-type units are capable of developing high pressure and creating a vacuum in the combustion chamber. To ensure consistency of operation of the entire heating equipment system, it is recommended to link the functional control to the electronic unit of the heat generator.

How to make an exhaust unit

The main difficulty in assembling a smoke exhauster with your own hands is making a balanced impeller; the remaining parts are not difficult for a home craftsman who knows how to weld. If the impeller blades vary in weight, normal fan noise will turn into rumble due to vibration.

In addition to the blades, you will need the following elements:

- electric motor with a power of up to 150 W, maximum shaft speed – 1400 rpm;

- snail or homemade box shown in the drawing;

- a shaft with ventilation holes or an additional cooling impeller;

- studs with M8 nuts and other fasteners;

- power cable.

We offer ordinary homeowners the least thorny path - buy a factory electric motor with an impeller and a cooling impeller, weld the box and assemble a fully functional duct smoke exhauster for a TT boiler. How to do this correctly, watch the video.

The smoke exhauster is an electromechanical type device. It is intended for removing fuel combustion products from furnaces and boilers and is an exhaust fan mounted in chimneys. Such devices are mandatory elements of steam and water heating units for industrial use.

As for smoke exhausters for solid fuel household boilers, they are installed only when provided for by the manufacturers of heating devices. As a rule, such units operate due to the presence of natural draft created by the smoke exhaust system. To control the traction force, a gate is used. If the chimney is designed correctly, there is no need to use the device.

You need to think about installing a smoke exhauster for a solid fuel boiler when the unit is not functioning well, and the draft in the chimney overturns or its strength is not enough to remove the smoke, and in addition, combustion products do not evaporate into the atmosphere, but penetrate into the interior of the house.

Only in this case does the need arise to increase traction, select and install the device. Creating conditions in the chimney for additional vacuum promotes complete removal of gases. But still, using a smoke exhauster does not completely solve the problem.

Advantages and disadvantages

The integration of a smoke exhauster into a smoke removal system is relevant not only when natural draft is not enough to effectively remove combustion products. The advantages of using the device include the following points:

- fuel costs are reduced;

- the efficiency parameters of the heating boiler are improved;

- the level of deposits on the walls of the chimney system is reduced, which leads to a decrease in the frequency of pipe cleaning.

Among the advantages of household smoke exhausters, the efficiency of the units in all weather conditions is noted. I am also impressed by the fact that when this device is introduced into the chimney, the functional characteristics of the heating system are improved, regardless of the brand of the boiler installation and the type of fuel.

Reviews on the use of household forced-air fans: advantages and disadvantages

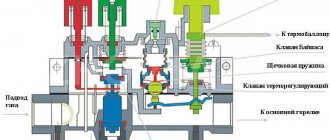

The task of the vent door in a Russian stove is to regulate the supply of air oxygen to the burning fuel; in modern boilers this is performed by pressurization fans. When they turn on, they forcefully supply the oxygen necessary for the combustion process to the firebox. If there is not enough air pumped by the fan, the boiler will not achieve the declared characteristics, but if the fan is more powerful than necessary, then the coolant quickly heats up and the engine operates in “start-stop” mode.

In order to maintain boiler performance at a given level of coolant temperature, the boost fan is always controlled by a controller that analyzes various parameters from feedback sensors. The air from the fan is supplied through its own pipe, which is closed when turned off. Its components do not come into contact with hot combustion products and do not require the use of alloy steels. The electric motor is most often used as an adjustable one, so that after reaching a given performance level, the boiler operates in process maintenance mode.

Pressurizing air into the boiler furnace creates excess pressure in it, so when it is opened, smoke, sparks or flames burst out. This must be taken into account when operating the boiler. A flexible draft and pressurization control system from a computer allows you to coordinate the operation of the blower fan and smoke exhauster for the most efficient operation of the boiler and to avoid various negative phenomena.

Without automation, manual control of the boost fan makes no sense, and the smoke exhauster is manually operated only during ignition and the appearance of smoke in the room. We have already talked about the most effective, most often used combination of a fan and automation in one of the previous articles; before making any decision, I recommend that you read it.

| Advantages | Flaws |

| Asynchronous fan motor: | |

| Reliable design; | Large starting current; |

| Easy to maintain; | |

| Elementary control and protection circuit. | |

| Synchronous motor: | |

| Small control range; | More often used for continuous injection in large systems; |

| Low starting torque; | Can get hot at low speeds; |

| Low price. | |

| Electronically Commutated Motors (EC): | |

| The best option for a flexible boiler control system due to the wide range of fan speed control | Expensive in price, poorly compatible with domestic regulators and sensors |

Features of choice

The main criteria for choosing a device include the size and power of the smoke exhauster, as well as the nuances of the connection diagram.

Select a smoke exhaust model depending on the type of boiler equipment, taking into account the features of the heating unit and chimney system:

- smoke exhausters for solid fuel boilers are equipped with pockets in which solid particles of combustion products are captured. This prevents soot from settling on the walls and clogging the smoke passage;

- models with or without a soot trap are suitable for pyrolysis combustion boiler devices;

- A smoke exhauster for a gas boiler is a low-power device, since during the operation of the ventilation equipment only gaseous masses pass through.

Supplementing the chimney system with an appropriate model of smoke exhauster ensures a significant increase in the efficiency of the boiler, while eliminating the possibility of smoke, fumes and soot entering the room.

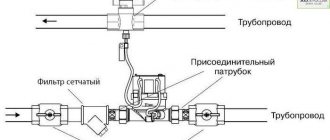

What is needed to install a smoke exhauster

To install a smoke suction device on a chimney, you need

- know the diameter of the chimney;

- know the diameters of the discharge and suction parts;

- you need to understand how to choose the right adapters for them.

What does it mean to install a smoke extractor? This means that the smoke must go inside the smoke exhaust part. There should be no smoke coming back. To do this you need to choose the right adapters.

The duct exhaust fan is installed correctly in this way. First you need to raise the chimney a little, and then lower it. This is not always possible.

The injection type smoke exhauster is an external addition to the chimney. To install it you will need a sealing gasket and two ties. Also, to mount it, no adapters are needed. It is enough to cut a hole in the pipe according to the size of the perimeter of the injection exhaust fan. It turns out that the installation of such a smoke exhauster is simpler than the duct type.

It has a cable to connect the injection structure.

Thus, its installation is quite simple. To install it, you don't need any special knowledge. You can deal with it yourself. This will take you no more than 1 hour.

Installation features

It is necessary to install a smoke exhauster outside if the equipped chimney pipe cannot be disassembled. At the same time, indoor installation is recommended for electrical structures.

Most often, the power unit is attached to a snail-shaped structure, which is welded directly to the chimney pipe and is equipped with a damper. During installation work, you must first make a connection drawing indicating the parameters of the pipe and pipes. To check the operation of the smoke exhauster, a hatch is installed at the bottom.

Installed according to the appropriate rules, the device operates quietly; the noise of the operating mechanism is difficult to distinguish, despite the fact that the device is located inside a metal pipe.

What are smoke exhausters made of?

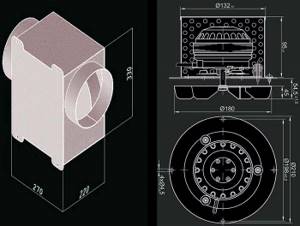

What parts is the duct exhaust fan divided into? He has

- frame;

- fan;

- suction pipe and discharge pipe.

You need to install it according to the smoke. The suction pipe is larger, the discharge pipe is smaller. The fan can be adjusted according to rotation speed.

There are also wires attached to the fan, there is a capacitor and it is connected via the network or to external power. An important part of a duct exhaust fan is the thermostat and temperature sensor. It is installed in the sleeve. Helps protect the smoke exhauster from overheating.

The fact is that all smoke exhausters for household solid fuel boilers have a certain value or threshold at which they can operate and at which they overheat.

The duct smoke exhauster slightly interrupts the draft in its design. It has a transverse bar at the discharge part. Therefore, if the traction is not very good, it will be even worse.

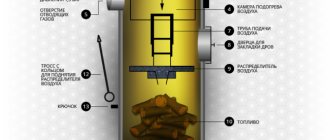

Technology and recommendations for self-production

To make a homemade hood, you need to purchase an electric motor; the remaining structural elements can be easily made from available materials. When deciding how to make a boiler smoke exhauster with your own hands, they often assemble a unit based on a purchased set of an electric motor and a cooling impeller, and the body is made of pipes.

Required tools:

- electrical equipment – grinder, drill, welding machine;

- locksmith tools;

- ruler, caliper

DIY technology for making a smoke exhauster for a boiler:

- The impeller is selected in accordance with the size of the exhaust pipe and secured to the motor shaft.

- Use a pipe whose diameter is 2-3 cm wider than the turbine.

- The engine is installed in the pipe using fasteners. The length of the pipe protrudes beyond the fan by 3-5 mm.

- One end of the pipe should be welded with a lid, and a hole should be made in the center for the chimney. There is a hole on the side for attaching the outlet pipe.

- The back cover is welded to the pipe and the engine is attached to the stand.

- The assembly is completed by connecting air ducts and electrical wiring to the device.

During a test run, the direction of the air flow is checked and the operation of the unit is adjusted.

Prices: summary table

| Model | Power | Weight, kg | Cost, rub. |

| WPA 120, Poland, M+M | 83 W, for boilers up to 60 kW | 2,1 | 4 800 |

| NWS-100, Poland | 80 W, for boilers up to 50 kW | 2,0 | 4 620 |

| DP-120, Poland, KG Elektronik | 90 W, for boilers up to 60 kW. | 2,1 | 5 660 |

| RR 152-3030 LH, Poland, M+M, developer – Germany, EBM. | 44 W, for boilers up to 30 kW | 1,0 | 6 000 |

Maintenance and operation

In order for the unit to work efficiently, it is recommended:

- carry out regular lubrication and cleaning of the rubbing parts of the engine and fan;

- protect the unit from moisture. To do this, install a deflector on the top of the pipe. This prevents the possibility of precipitation and eliminates the risk of premature corrosion of device elements.

As experts note, with proper installation and regular maintenance, the service life of a household smoke exhauster for a boiler is comparable to the service life of a heat generator.