Here you will learn:

- What functions does automation perform for gas boilers?

- Automation design

- Varieties

- Which automation is better - mechanical or electronic?

- Checking the serviceability and replacing the automation

- How much does boiler automation cost?

- Review of popular manufacturers

Automation used for gas boilers are special devices that provide control over the operation of heating equipment after it has been started. The main purpose of automatic control devices is to ensure the safe operation of heating units and maintain optimal temperature conditions in the room.

Based on functionality, automation is divided into two main types:

- volatile devices;

- non-volatile control devices.

The first type is energy-dependent automation, used in autonomous heating systems, has a simpler design and operates on the residual principle. The temperature sensor signal about temperature changes is sent to the solenoid valve, which closes or opens, cutting off the gas supply to the gas boiler. Almost all heating boilers are equipped with this type of control equipment.

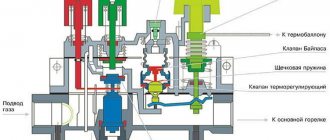

An example of a non-volatile unit for an automatic safety system for a gas boiler

The second type of automation - non-volatile devices operate on the basis of the physical properties of the substance located inside the closed circuit of the device. When heated, the substance expands, creating increased pressure inside the device. Under the influence of high pressure, the gas valve is activated, shutting off the gas supply to the combustion chamber. The boiler is turned on in the reverse order. As the temperature decreases, the volume of the substance decreases, as a result of which the pressure in the device decreases. The valve returns to its normal position, allowing gas access to the burner. Such automation devices are used to equip non-volatile gas boilers. Models of automation system units may differ only in the standard set of functions.

Volatile products

A volatile module is a small electronic device that responds to the supply of a fuel resource. It turns on and off when the main gas valve is activated or closed. It has a complex design and a large number of elements and microcircuits.

Allows owners to solve the following tasks:

- activation or termination of gas supply;

- starting the heating system in automatic mode;

- adjusting the power level of the base burner (due to the presence of a thermostat);

- turning off a running boiler both in emergency situations and within a user-specified mode;

- displaying current indicators on the display (the general level of air temperature in the room, the point to which the working coolant has been heated, etc.).

More sophisticated modules have additional functionality and offer users unlimited and most convenient conditions for monitoring the operation and control of the unit. Electronic panels provide full protection of heating equipment from malfunction of the three-way valve and prevent the boiler from freezing.

If the temperature in the room drops sharply, the “smart” system itself starts the heating equipment and turns it off when the home is filled with comfortable warm air.

The self-diagnosis option available for individual modules prevents operational failures and facilitates the timely identification of faulty parts and assemblies in the system. It makes it possible to notice a breakdown as early as possible and replace some small element even before it creates a real problem for the equipment.

Minor breakdowns of the heating system eventually turn into global complications and entail costs associated with the repair and dismantling (full or partial) of the equipment. Self-diagnosis helps to identify a malfunction and makes it possible to eliminate it in a timely manner.

Electronic automation, responsible for the safe operation of the equipment, ensures uninterrupted operation of the boiler, prevents the system from overheating and shuts off the gas supply in the event of a drop in draft or extinguishment of the flame in the burner.

The range of energy-dependent automation on the market today is pleasingly diverse. Useful and necessary mini-units are produced by world-famous brands and small companies that are just trying to earn their place in the sun.

Volatile automation is presented in the form of a control panel, where the user can set convenient operating parameters for the equipment. The cost of a “smart” element is high, but the costs are justified, because with the help of a control unit you can reduce resource consumption without any damage to your own comfort

Among the models offered there are both very simple products and more advanced units with a programming option.

On them, the user can select the most suitable individual settings for himself and program the system to operate in day/night mode or, based on the weather forecast, set a certain level of heating of the house or apartment for a period of 1 to 7 days.

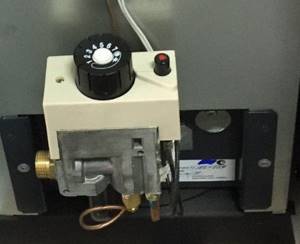

Non-volatile units

Non-volatile automation is simpler and more practical. Control and adjustment are carried out manually using mechanical rotary toggle switches and are not difficult even for those who are far from technology. The device operates completely autonomously and does not need to be connected to a central electrical system.

To heat a residential building and supply hot water to the taps, it is enough to turn the control knob in the direction of increase by 2-3 divisions. If you need to take a bath or shower, the toggle switch must be set to the maximum setting

The product is marked with a digital scale with a list of values from minimum to maximum. To activate, the user selects the desired mark and in this way sets the appropriate operating temperature directly to the boiler.

After these manipulations, the thermostat is connected and takes control of the specified heating mode. The boiler actively works until the room warms up to the desired temperature. Then the thermostat turns off the gas supply to the system and is activated again only when the room gets colder.

The operating principle is based on the specific design of the device. The gas boiler thermocouple built into the heat exchanger is equipped with a special rod. It is made from a special iron-nickel alloy called invar.

The physical characteristics of this advanced material give it the ability to almost instantly capture minimal temperature fluctuations.

If the room becomes too hot or too cold, the size of the rod changes. The connecting valve reacts to this and promptly shuts off or activates the flow of gas to the burner.

The presence of a non-volatile automatic control system allows users to set the most suitable temperature regime in their house or apartment and use fuel economically without overpaying on utility bills

Additionally, non-volatile automation has sensitive draft and flame sensors. If the pressure in the pipe suddenly decreases or the draft level in the chimney drops for some reason, the supply of the resource is immediately stopped and gas leakage can be avoided.

Non-volatile automation costs quite reasonable money and, unlike electronic analogues, does not require the purchase and installation of a stabilizer that controls voltage and equalizes unexpected surges in the central power grid

Correct operation of the flame sensor is ensured by a special plate. During normal and correct operation of the system, it is in a slightly curved state.

In this way, the part holds the shutoff valve in the “Open” mode. When the flame becomes smaller, the plate is leveled and the valve closes under its pressure.

Automation for heating gas boilers AOGV

Automation for gas heating boilers ensures stable and safe operation of the equipment. These systems significantly simplify the use of heating equipment, increase its operating efficiency and allow for the rational use of energy resources.

Automation for gas boilers AOGV

Modern models of heating boilers are equipped with automatic devices in production. Automation must ensure an uninterrupted supply of gas to the burner, but the functions of these devices are not limited to this. Automatic devices shut off the gas supply valve in potentially dangerous situations:

- The water temperature in the boiler tank exceeds the set maximum.

- The igniter goes out.

- The water supply stops.

- There is a failure in the gas system.

- The pressure drops below the established norm.

- In case of insufficient chimney draft.

What does the automation system for gas heating boilers AOGV consist of?

A standard automatic system must have several basic elements.

Ignition elements. In modern systems there is no burning splinter. The pilot burner is ignited by a piezoelectric element, which produces electrical energy as a result of mechanical pressure on the crystal. There are systems in which you need to open the gas supply valve with one hand and press the piezo ignition button with the other. In the most modern boilers, one button is responsible for the operation of both processes. The gas valve is then controlled in one of two ways:

- Due to the voltage that occurs when the thermocouple heats up.

- Due to heating of an additional thermal generator (more often used in imported boilers).

Automation of gas boilers AOGV most often operates using thermocouple energy.

In both cases, the generated energy creates a voltage that acts on the gas valve coil. It remains open, providing gas supply, as long as the gas burner is burning.

Thermoregulation system. These elements control the water temperature. They consist of a temperature sensor and a valve system that shuts off the flow of gas when the set temperature is reached. In the most modern boiler models, a room thermostat has been added to the control circuit, which, depending on the room temperature, sends a signal and the need to close or open the gas supply valve.

In a mechanical thermoregulation system, there is a thermometer on the control panel, and the temperature regulator is located at the coolant outlet from the boiler.

Control elements for efficient and safe removal of combustion products. This is a draft sensor that is mounted in the chimney. Wires connect the draft sensor to the gas valve. If there is no optimal draft, a signal is sent to the valve, it closes and stops the gas supply.

Automation for gas heating boilers does not allow you to turn on the gas supply if the equipment’s performance indicators go wrong or the slightest breakdown or depressurization of pipes occurs.

Additional elements and automation capabilities

In some models, automatic equipment for gas boilers AOGV is equipped with a thermostat that provides regulation of gas flow. The reason for reducing the intensity of work may be an increase in temperature outside or a signal from the thermostat in one of the rooms that the maximum permissible temperature has been exceeded.

Models that are installed in the Smart Home system offer the possibility of remote control of heating modes.

A modern, properly installed and adjusted automatic system on heating equipment helps reduce heating costs by 40%.

Features of remote control

Controlling heating in a country house via GSM or via the Internet will be appreciated by owners of country houses or summer cottages designed for year-round use. If you have to leave the house unattended for a long time, concerns arise about the functioning of the heating system - for example, if the boiler goes out for some reason and does not turn on automatically, the system will freeze. This is fraught with depressurization of the circuit and the need to seriously invest in repairs.

Remote heating control has a number of advantages

:

- due to operation in an economical mode, energy costs are reduced and the life of the equipment is extended, since it wears out less under reduced loads;

- the heating system can be included in the general network of the house, created for engineering systems - this will reduce the total costs of their operation.

Boiler control, both via GSM (SMS) and via the Internet, makes it possible

:

- monitor the maintenance of the standard operating mode of the autonomous heating system with uniform heating of the entire house;

- if necessary, provide selective heating of rooms in accordance with personal preferences;

- prevent freezing of the heating system pipeline during a long absence of owners in the cold months;

- switch the heating system from economy mode to standard mode in advance so that the cottage or country house is warmed up when the owners arrive;

- monitor the condition and functioning of the heating system online and promptly receive information about problems.

An autonomous heating control system can be the first step towards creating a “smart home” and providing the most comfortable living conditions.

Which systems can be controlled remotely?

Automatic heating control is used for two-pipe autonomous systems with a membrane expansion tank and a pump for forced supply of coolant into the circuit. It is especially effective to control a system where each heating device is connected separately, through a distribution comb - a manifold. The system may include circuits with radiators and warm water floors.

The system is necessarily equipped with a safety unit, which operates automatically and prevents depressurization of the boiler water jacket and heating circuit due to excess pressure. Excess pressure is released through the emergency valve.

Additionally, equipment is installed that allows you to control the system - temperature and pressure sensors, devices that allow you to regulate coolant flow, controllers, and tools for creating a unified information network.

Weather-compensating system

Controlling a heating boiler is more effective if, in addition to temperature sensors installed in heated rooms, a device for measuring outdoor air temperature is added. This option provides precise temperature control and makes it possible to configure the system so that it independently adapts to changing weather conditions.

As a result, when it gets colder, the radiators will heat up more, and when it gets warmer, they will switch to energy-saving mode. This not only helps save energy, but also reduces the inertia of the heating system.

Wall-mounted weather-compensated heating controller for heating system control

Flexible zone control ensures a comfortable environment for people depending on the situation: for example, if there are many people in a room, it quickly becomes hot as bodies radiate heat. The temperature sensor in the room reacts to an increase in air temperature, as a result of which the heating of the radiators in this room is reduced to an optimal level.

Typically, a weather-compensated system is configured to automatically turn off the boiler if the outside temperature reaches a preset level. Wireless and remote control systems are ideally combined with weather-sensitive automation - the operation of the system does not require constant human intervention; it is enough to make adjustments to the operating mode as needed.

Devices for automatically adjusting the operation of gas boilers

The latest boiler models are equipped with a whole host of elements to ensure the heating system operates automatically. These components are aimed, first of all, at maintaining stable operation of the equipment without user intervention.

Automation for boilers provides:

- safe operation of the heating system;

- automatic switching on and off of equipment;

- convenient control of the functions of the heating unit.

Armature

Gas fittings are a functional device for ensuring the operation of domestic heating systems, which responds to commands from the boiler control circuit.

Activation of the gas valve regulators involves the processes of stopping and starting the boiler equipment, and also adjusts the power of the system.

Valves

Valves are elements of boilers with built-in burners. The main task of this type of automation for a gas boiler is to open and stop the gas supply to the burners.

These elements of the heating system can be controlled mechanically or electronically, depending on the type of boiler.

Maximum pressure switch

Relay automation is aimed at protecting the system from possible overheating or failure due to an uncontrolled increase in pressure on the burners. The absence of a relay leads to an increase in the flame level and gradual burning out of the internal chamber of the boiler.

Such automation for gas heating boilers is based on the sequential connection of a minimum pressure switch to the electrical circuit. Triggering of one of the relay automation systems leads to automatic shutdown of the boiler.

Minimum pressure switch

To ensure safety when operating gas heating systems, automation in the form of minimum pressure switches is widely used. The automation element turns off the boiler when the pressure in the system drops to a level below that previously set by specialists. The value of the pressure limits can be changed in the boiler settings.

The design of such safety automatics for gas boilers is a membrane that acts on a whole group of contacts. When the pressure in the system drops, the membrane is moved by a special spring, after which the electrical contacts are switched. The result is a break in the electrical circuit, which controls the operation of the boiler.

As soon as the pressure in the system is restored to its previous value, the device returns to its original position. The contacts switch in the opposite direction, and the boiler regains its ability to start.

Thermostat

The thermostat is a relatively simple electromechanical device.

The main purpose of this automatic element of a gas heating system is to maintain the specified coolant temperature parameters.

Controller

Automation for gas boilers requires the presence of electronic devices for implementing rather complex control algorithms in the form of special controllers. According to functionality and capabilities, there are different types of controllers. However, they all necessarily contain pressure and temperature sensors.

If we talk about the classification of controllers, then devices are distinguished by algorithm and control objects, communication capabilities, and means of integration with the heating system.

Main characteristics of the controller

The characteristic indicators of electronic controllers built into the boiler include:

- the ability to control the intensity of fuel supply to the unit responsible for its combustion;

- implementation of all protective functions provided for such systems (against overheating or freezing of pipes, pump stops);

- number of control objects and the possibility of their priority selection;

- the presence of a GPS unit that allows you to control the boiler automation remotely;

- the ability to update software at certain intervals.

Modern controllers that control the operation of heating systems can be connected directly to a personal computer. This opportunity also characterizes them from the point of view of expanding functionality.

By material and type of heat exchanger

Heat exchangers can be:

- cast iron;

- copper;

- aluminum-silicon;

- made of carbon or stainless steel.

The design of the heat exchanger may also vary.

The most popular are separate heat exchangers. Heating water flows separately, and water for residents’ household needs passes separately. They are a little more expensive, but more reliable.

A bithermic heat exchanger looks like a pipe within a pipe. In the inner pipe there is DHW water, which needs to be heated, and in the outer pipe the heating coolant circulates.

The third type is a heat exchanger in which a coil is built in. The container with water is heated by the coolant flowing in the coil. An indirect heating system is good for everyone, but in the summer you will either have to heat the boiler or live without hot water.

The bithermic option is not recommended for use where there is hard water. And be prepared that every time scalding water will flow out of the tap first, and only then at the temperature you need.

Waste oil boiler “EcoBoil-30/36” 28 kW

Delivery

Specifications

up to 28 kW (adjustable) 24,080 kcal/h

The waste oil boiler EcoBoil-30/36 with a power of up to 30 kW is designed in automatic and semi-automatic versions and is intended for heating houses, cottages, garages, country houses, service stations, service centers, transport companies, greenhouses, warehouses, car washes, industrial premises, poultry houses and other premises. Using waste oil boilers is the most economical heating method. Working out costs about 2.5-7 rubles per liter, and sometimes it’s even free.

A single-circuit liquid fuel boiler EcoBoil-30/36 is capable of heating a room up to 300 m2 with a ceiling height of up to 3 meters with a normal degree of insulation.

If your area or ceiling height is larger than those indicated above, you can consider more powerful boilers:

Small service stations, garages, workshops, and industrial premises can be heated with air heaters using waste oil. Air heaters are air-heating boilers that do not require a water heating system. They can be turned off at night and started in the morning. The following heaters are suitable for small rooms: Air heater “HotAir-05”, HotAir-1/30. For larger rooms, HotAir-2/36, HotAir-3/40 and HotAir-6/60 are suitable.

Automation from different manufacturers

Wall-mounted gas boiler

If we talk about a standard wall-mounted gas boiler, then it can operate according to the coolant temperature. A room thermostat or chronothermostat can be connected to it. It is also possible to connect an openterm protocol regulator.

A special case of using wall-mounted boilers is the possibility of using weather-dependent automation. Due to the use of an external temperature sensor, additional variables appear that make it possible to more quickly adjust the burner power and supply temperature, depending on the changing conditions outside the building.

Automation Arbat

The devices have 5 degrees of protection. There is thermoelectric flame protection. The gas supply is blocked when switched off. A modulating thermostat will provide comfort in use, and a coarse mesh filter will extend its service life.

Some models are equipped with a circulation pump. The device distributes the coolant evenly throughout the heating system. It is also possible to connect to an external thermostat inside or outside the room.

Automation Honeywell

Honeywell has a wide range of automation systems for gas boilers, from the most budget (mechanical) to multifunctional automatic systems.

Main features:

- the coolant automatically maintains the temperature;

- turning off the boiler in case of gas supply interruptions;

- shutdown in the absence of draft or during reverse draft;

- blocking the gas supply when the gas burner goes out.

Some models are equipped with programmable automation with the ability to set temperature periods depending on the time of day, weather, and even develop a heating/cooling mode by day of the week. And the Smile series models control several temperature circuits at once (heating, ventilation, “warm floor”, hot water, etc.).

Automation Eurosit 630 (Eurosit 630)

The Eurosit gas valve is one of the most used. It can be found on both domestic and imported boilers. Main advantages: multifunctionality of the gas supply regulator, modulation thermostat and the function of full modulation switching on the main burner. It works both from liquefied fuel cylinders and from a gas tank, without the use of electricity. Used in various types of gas-consuming equipment that require precise temperature control.

Basic principles of operation of Eurosit 630 automation.

Ignition of the pilot burner.

- Check that the knob position matches the “off” icon.

- Move the control knob to the “asterisk” position.

- Keep the control knob pressed for a few seconds. Then release and make sure the pilot burner turns on. If the pilot burner goes out, repeat step 3.

Temperature selection.

Use the control knob to set the temperature. The gas will begin to flow into the main burner, where it will be ignited using the pilot burner.

Power modulation.

The thermostatic system regulates gas flow and gas pressure in the main burner depending on the system capillary sensor. The colder the sensor, the greater the power and vice versa. The graph schematically shows how the power changes from maximum to minimum and then until the burner is completely turned off.

Duty position.

Move the control knob from the set temperature to “asterisk”. The main burner will go out, but the pilot burner will remain lit.

Shutdown.

Set the knob to the off position. The valve will close completely, but the thermoelectric protection magnet will remain temporarily activated until the thermocouple sensor cools down. During this period of time, restarting of the thermoelectric system is mechanically prevented. The function is called "interlog". It ensures ventilation of the combustion chamber before the next burner start-up.

How to choose a GSM module for a boiler

When choosing a notification module, it is important to pay attention to its functionality and technical characteristics:

- Control – settings are made using buttons on the touch panel and SMS commands sent from the phone. Programmers from leading manufacturers are controlled by special software. The companies Viessmann and Buderus produce programs for Android and iOS that allow you to quickly remotely access the boiler.

Equipment - depending on the selected model, the module is equipped with an automatic gas control system and remote room temperature sensors.

Number of control channels – this parameter determines how many temperature sensors and other equipment can be connected simultaneously. Standard models have two channels, one is used to connect a remote programmer for remote control of a gas boiler via GSM, the second is used to transmit signals via SMS messages.

Microprocessor - budget models of control units, have only a few simple functions and fixed operating modes. Premium class equipment, has a built-in weekly programmer for controlling the temperature of the gas boiler using GSM.

Battery – the control unit operates from the mains. In the event of a power failure, power is automatically switched to the battery. The battery capacity should be sufficient to ensure autonomous operation of the module for several hours. If power outages occur frequently, choose a battery with a larger capacity.

When choosing a module, they are guided by the recommendations of gas equipment manufacturers.

Cost of GSM remote control for boilers

A gas heating boiler with a GSM remote control module consumes up to 30% less gas. The initial costs of installing a remote controller will pay off within the first heating season. The cost of the remote control, depending on the chosen model and configuration, varies from 5-12 thousand rubles.

Some manufacturers of gas equipment offer consumers boilers with a built-in GSM control unit. In this case, you will need to buy remote room thermostats and configure them to operate the module.

How to install a GSM module on a boiler

It is not difficult to organize control over the operation of the boiler yourself. To do this you will need to do the following:

- Using special connectors, connect the control unit to the boiler controller.

Insert the SIM card into the slot. To prevent third-party users from connecting, set a PIN code.

Enter all phone numbers to which alerts will be sent.

After completing all the manipulations, a verification code is sent from the phone, and in response you will receive a message about the operating parameters of the boiler. The information received will show that the unit is connected.

It is recommended that the installation of the remote control and GSM unit be carried out by qualified specialists - electrical engineers. Independent work is carried out at your own peril and risk, and is the reason for refusal of warranty service.

Features and principle of operation of gas boiler automation

Stable operation of a gas boiler depends on many factors: stable pressure, timely supply and shutdown of gas, ignition and control of the presence of flame. The principle of operation of automation is to ensure control over all these parameters and is necessary for the stable operation of household gas boilers.

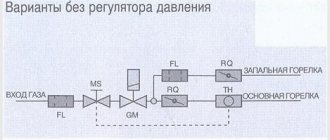

The first regulators had a simple design and ensured that gas did not leak due to flame extinction. In some boiler models, there was no igniter; the main burner was manually ignited at minimum power. The gas supply was adjusted in three modes.

Modern automation for gas heating boilers has improved functionality and ensures complete operational safety.

The automation has a design and operating principle that allows for interchangeability. In most cases, you can replace the mechanical regulator in the boiler with an electronic one.

Mechanical and electronic automation

There are two main types of automation that regulate the operation of the boiler. Based on their design, it is customary to distinguish between mechanical and electronic regulators.

Each type of controller has its own characteristics, which affect the principle of their operation:

- Mechanical automation of household gas boilers - the operating principle is based on the use of the electrical potential of a thermocouple. The device consists of two metal rods, made of metals of different densities, soldered together in several places. When heated, a low-potential voltage arises, acting on the mechanical gas supply valve and holding it in the open position. When cooling, electricity stops being generated and a reverse process occurs, leading to the closing of the gas valve. The design also uses a thermostat installed in the water heating circuit. Inside the device there is a metal rod (Invar). Under the influence of temperature, the inner strip of metal lengthens or shortens, opening or closing the valve that regulates the gas supply to the burner.

Electronic automation has a complex design. In addition to the main tasks, turning off the gas burner and adjusting the heating intensity of the coolant, it ensures safe operation and other functions. Modern fifth-generation boilers are equipped with built-in weather-dependent automation or a separate programmer that can automatically control operation during the week. The control is carried out by a microprocessor. The operating principle is based on the use of an electromagnetic valve and is volatile, therefore, in the event of power surges or lack of electricity, the operation of gas equipment becomes impossible.

For a gas boiler, it is better to choose electronic type automation. To prevent shutdowns during voltage surges and power outages, install an uninterruptible power supply and a stabilizer.

Volatile and non-volatile automation

The operating principle of non-volatile automation is significantly different from volatile devices. The main differences are as follows:

- Non-volatile mechanical automation - works using physical laws for regulation. The gas supply is opened by a thermocouple, which produces low-potential electricity equal to 40-60 mW when heated. The voltage holds the gas valve rod in the open position. The heating intensity is adjusted through thermal expansion of the internal rod located in the cavity of the temperature sensor.

Volatile electronic automation - in this case, the work is controlled by a microprocessor chip. The boiler design and water circuit are equipped with sensors that read information about operating parameters: gas pressure, coolant temperature, air flow intensity and draft characteristics. After processing the information received, the microprocessor chip gives signals to operate gas valves, fans and other shut-off and control valves .

The only drawback of the electronic controller is the dependence of the automation on energy consumption. The microprocessor automatically adapts to actual operating conditions, selects the optimal heating mode and ensures safety.

Electronic automation connected to room thermostats saves up to 30% gas compared to boilers operating with mechanical control units.

Features and Properties

GSM heating boiler control has the following capabilities:

- ensure the required temperature regime in the house at any time of the year, and there is no need to be close to the boiler to change the temperature;

- from a distance, prepare the house for the arrival of the owners, setting a comfortable temperature there (even if the building has been empty for several weeks, its owners and guests will not have to return to the cold room);

- in winter, prevent freezing of pipes and their subsequent depressurization during unexpected frosts - you can increase the temperature in the boiler while away from home by simply sending a message;

Boiler control via GSM - the possibility of optimal fuel consumption - provide remote monitoring of the serviceability of the installed heating system - messages are sent in case of failures;

- heating operation in the shortest possible time in case of emergencies;

- ensure maximum fuel economy;

- increase the operating time of a gas boiler - due to timely response to emergency situations.

That is, GSM heating control by phone or via the Internet provides a previously inaccessible level of comfort in a country house or in a private home. This device is useful for those whose work involves frequent absences, who are often away, and have no one to constantly monitor the heating condition.

Functions and principle of operation of security automation

In accordance with regulatory documents, automation equipment for boiler installations must stop their operation by cutting off the fuel supply in the following situations:

- the draft in the chimney is insufficient and there is a danger of burning;

- the gas pressure in the supply pipeline is too low or, conversely, too high;

- The flame on the igniter went out.

The listed situations can lead to the main burner going out and the room becoming gassed, which is unacceptable. For this reason, safety automatics for gas boilers must be installed on all old-style boilers where it was not provided by the manufacturer. Although it is often cheaper to replace a heater than to purchase and install automation on an old one. In addition to preventing gas contamination of the room or fumes, its functions also include maintaining the temperature of the coolant at a certain level specified by the user.

To understand how the automation of a gas boiler works, let’s briefly analyze its structure. It should be noted that both foreign and Russian manufacturers use the same operating principle in their products, although the design of the devices may differ significantly. Automatic gas valves from Italian manufacturers are traditionally considered the simplest and most reliable, which is why they are most common.

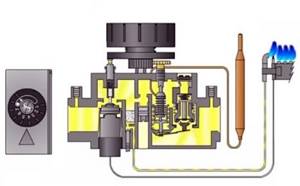

A prominent representative of such gas appliances is the Italian automatic SIT, or rather, its most popular modification 630 EUROSIT, whose device is shown below.

Automation device SIT

All structural elements are placed in one housing, to which gas pipelines are connected. In addition, a capillary tube from draft and temperature sensors (thermocouples), a gas supply line for the igniter and a cable from the piezoelectric element are connected to the device. Inside there is a shut-off solenoid valve, whose normal state is “closed,” as well as a gas pressure regulator and a spring valve.

Any automatic gas boiler equipped with a combined gas valve EUROSIT or another is started manually. Initially, the fuel path is blocked by an electromagnetic valve, which opens by pressing the adjusting washer, after which the fuel fills the chambers of the device and goes through a small gas pipeline to the igniter. While holding the washer, press the button of the piezoelectric device and ignite the igniter, heating the temperature-sensitive element for 10-30 seconds. This, in turn, generates a voltage that keeps the solenoid valve open, after which the adjusting washer can be released.

Then everything is simple, we turn the washer to the required division and thereby open access of fuel to the burner, which is independently ignited by the igniter. Since the automation of gas boilers is designed to maintain the set temperature of the coolant, human intervention is no longer required. The principle here is this: when heated, the medium in the capillary system expands and acts on the spring valve, closing it when it reaches a high temperature. The burner goes out until the thermocouple cools down and the gas supply resumes. You can study the operation of Italian SIT automation in detail by watching the video.

Features of installing automation on the boiler

The installation of automation on a solid fuel boiler should be carried out by a professional technician. The procedure has quite a few nuances that must be taken into account. Incorrect installation will make it impossible for the unit to function normally and all efforts to replace the control unit will be in vain. The cost of the service is very low, so you won’t be able to save a lot of money on this. But the damage from incorrect actions and subsequent breakdown will be noticeable.

After completing installation work, correct calibration must be carried out. You can do this yourself using the included instructions, or seek help from the specialist who carried out the installation. The automation for the boiler is configured according to the following scheme:

- 1. First, you need to fill the heating system with coolant and bleed all the air out of it so that there are no plugs that will interfere with normal circulation. It won't be difficult at all to do this.

- 2. Then you need to start the circulation pump and check that it begins to drive water through the system without any obstacles.

- 3. When the water in the system begins to circulate, you need to check the readings on all emergency thermostats, as well as the water level and its pressure in the system. All indicators must be within acceptable limits.

- 4. Now you can proceed directly to ignition. Each automation has its own characteristics of starting the flame into the combustion chamber, so at this stage you must strictly adhere to the requirements of the operating instructions.

- 5. When ignition is completed, you need to add the specified amount of fuel into the firebox and set the desired operating parameters. Occasionally you will need to add fuel and check the readings of control devices with the norm.

Automation of cascade boiler houses

The role of automation in such boiler houses is enormous to ensure their reliable and efficient operation. It is she who is responsible for obtaining the greatest efficiency from the units operating in a cascade, while ensuring the sensitivity of the boilers to consumer demands.

In these systems, cascade logic is integrated into the basic automatic circuit and configured for a specific fleet of boiler equipment. Basic functions of automation of cascade heat supply schemes:

- Collecting user data for thermal energy production and finding priority between load types.

- Calculation of the rational mode of operation of each individual unit to guarantee the requested power.

- Guarantee of uniform distribution of thermal conditions of boilers.

- Monitoring the performance of equipment, diagnosing emergency situations and signaling them.

A similar regulatory policy is used in a modern cascade boiler house. In this case, each single device must operate at a minimum modulation that guarantees the thermal load.

Only under such conditions is it possible to obtain high efficiency of a cascade installation with uniform use of the operating life of the boiler units.

Automatic coal boilers

Controlling a coal heating unit allows you to delegate to the boiler all the powers to maintain a comfortable temperature at home. The coal automatic solid fuel boiler is configured through a simple and intuitive interface, and independently works with the system according to your wishes. By loading coal into the hopper of an automatic solid fuel boiler, you can configure*:

• required heating mode (from 2 to 4 options with priority Heating, DHW, Heating + DHW and a mode when the need for heating is reduced); • a certain operating mode according to the day of the week and time of day; • weather-dependent control (when electronics monitor temperature changes outside the window and maintain comfortable conditions at home); • fuel supply volume, fan speed and operation of 2 to 4 pumps; • heating temperature of radiators; • temperature of the “Warm floor” system; • remote control with support for room thermostats.

The best known manufacturers and models: characteristics and prices

ATOS + WPA 120

One of the best and most common automation kits for solid fuel heating boilers.

The ATOS controller is distinguished by extremely wide functionality, a considerable number of customizable operating parameters and an affordable price. In addition to standard functions, there is: protection against freezing of the heating system; notification of temperature drop or overheating, lack of fuel; LED indicators of circulation pump and fan operation; adjustable hysteresis. It is also known for its reliability due to operational practice. Manufacturer: KOM-STER, Poland.

Blower fan M+M WPA 120 is also the most common, time-tested Polish model. Designed to work with boilers with a power of 25-50 kW. There are other versions on the market for more or less powerful boilers.

Cost of the set: 8,900-10,000 rubles.

COMFORT-ECO + NWS-100

The controller is another Polish model: with almost the same functionality and reliability for an even more modest price. Functionality implies the presence of all safety functions, the ability to connect a room thermostat and outdoor sensors, control of a circulation pump (but not DHW). It features a fail-safe filter and an overload fuse.

The Nowosolar NWS-100 turbine is a simple Polish aluminum model, one of the most inexpensive on the market. It has an unremarkable standard design, known for high-quality assembly and reliability. The model is designed for installation in boilers with a power of 30-50 kW.

Cost of the set: 8,500-9,800 rubles.

Tech ST24 + WPA 120

The controller is a hassle-free, simpler model, equipped only with standard functions: control of the boost fan speed, control of the circulation pump, LED indication of the operation of the elements. Installation of external sensors and automatic feeding systems is also not provided. An excellent choice, but at a price comparable to more functional models. The fan is the most common model already described above.

Cost of the set: 9,200-10,500 rubles.

KG Elektronik CS-18S + DP-120

The Polish controller KG Elektronik CS-18S is one of the most modern and functional on the market. It is distinguished by the presence of a touch screen control, the ability to control the fan, circulation pump, hot water supply, and automatic supply system. The DHW pump can be made a priority; there are also special modes adapted for each type of fuel: wood, wood and coal, coal, sawdust. All existing protective mechanisms are also provided: against overheating and freezing, stopping the circulation pump.

The KG Elektronik CS-18S + DP-120 fan is also one of the best. It features an asynchronous motor and high performance with a relatively low noise level of up to 63-65 dB. It has a metal damper at the outlet that blocks the reverse flow of exhaust gases.

Cost of the set: 11,000-12,500 rubles.

Advantages of remote control systems

First, you need to determine the method of future remote control of the heating boiler by choosing one of two options. In the first case, the boiler is controlled via the Internet, for which you must have an Internet connection. In the second case, this mission is performed by cellular communications, which is more suitable for a home located at a distance from city communications.

Internet control

If you install remote control of a gas boiler using the Internet, you can get a series of additional benefits.

After installing the necessary control elements into the heating system, the following options open up:

- remote control of various functions of the heating boiler, including operating modes of the circulation pump;

- by installing the required number of sensors, you can determine different temperature conditions for several zones;

- remote coordination of hot water supply, in case of installing a double-circuit boiler;

- 24-hour monitoring of the current state of the operating heating system;

- the most economical fuel consumption, because during a long absence there is no need to maintain the usual microclimate.

The indicated advantages constitute only a basic set of possibilities provided for an individual heating system. If desired, control over the internal temperature of the house can be taken to the next level by using a more versatile version that uses an Internet gateway and an automated heating control unit.

In this case, it will be possible to additionally control heating elements, oil radiators or electric convectors. Among other things, the list of systems for remote control of the boiler may include a fire alarm, which will not be superfluous if the house is built of wood.

Cellular control

An alternative to the control unit for the heating system of a country house is a GSM module operating from a cellular network. Remote activation via SMS messages in order to transfer information to the control panel of the water heating boiler has personal advantages:

- small dimensions of the device that interacts with a smartphone;

- mobility – easy to install in any suitable location;

- ease of operation;

- For insurance, you can use two communication lines at once; the device is designed to install an additional SIM card.

This device is used when it is not possible to connect to the Internet. This quality allows the use of a remote control unit for a gas boiler even in remote areas.

Minimum pressure switch (gas) ↑

Honeywell brand gas valve for low-power boiler equipment

Gas burners are designed to be used at rated gas pressure - that's what they are designed for. It is with these indicators that the declared useful power of the boiler will be ensured. With a decrease in gas pressure, a drop in power is also observed. Boilers equipped with atmospheric gas burners are sensitive to a decrease in gas pressure - the pipes may burn out. The falling gas pressure leads to the “settling” of the flame so that the metal part of the burner appears in the zone of the torch itself. And this can lead to breakdowns.

To protect the boiler and burner, a minimum gas pressure switch is used. The relay turns off the boiler when the pressure drops below the set value. The limit value can be changed when setting up the boiler. The gas pressure switch is structurally a kind of membrane that acts on a group of contacts. When the pressure decreases, the membrane moves under the influence of a spring and the electrical contacts switch. Switching the contacts breaks the electrical circuit, which precisely controls the operation of the boiler. The power supply to the gas valve stops and the boiler stops working. When the gas pressure is restored, the membrane will return to its original position, the contacts will switch again - and the boiler will be ready to start again. But other processes are subsequently determined by the logic of the actual control automation, and they may vary. Minimum pressure switches are mounted at the gas inlet into the boiler directly in front of the multiblock. Or in front of the front gas valve.

Dungs brand gas valve for floor-standing heating boilers

Requirements for installation of an automatic solid fuel boiler

Despite a lot of advantages, solid fuel boiler systems have important disadvantages. These include insufficient fire safety, since sparks are released during fuel combustion, and the surrounding air in the room becomes very hot.

To reduce the risk of fire, it is necessary to take into account a number of requirements for installing an automatic unit:

- For any boiler operating on solid fuel, you need to equip a special room - a combustion chamber with an area of at least 7 m².

- It is necessary to provide a powerful ventilation system in the boiler room, because... For uninterrupted operation of equipment, large volumes of oxygen are needed. Experts recommend that the diameter of the exhaust and inlet openings in the ventilation shaft be at least 100 mm.

- To finish walls, flooring and ceilings, you need to use non-combustible materials (cement, tiles, plaster).

- It is better to install the boiler unit in such a place in the combustion chamber that there is at least 50 cm of free area around it. In this case, you can conveniently maintain and configure the system.

Operating principles of automation for solid fuel boilers

The intensity of combustion of any fuel depends on the flow of oxygen into the firebox: the more air, the hotter it burns and the faster the coolant heats up. Therefore, the first option for boiler automation is draft control. Traction is controlled by:

- turning or sliding the damper in the chimney;

- opening the ash pan door;

- pumping air with fans.

Accordingly, the damper is moved manually, a mechanical draft regulator can be attached to the door (see photo below) and the blower fan is connected to the electronic unit.

The second control mechanism is the movement of the coolant. In this case, the circulation of water through the pipes is started or stopped; for this, the system must have a circulation pump connected to the control electronics:

And the third option is the automatic supply of fuel from the bunker to the firebox. By decreasing or increasing the speed of transport units (screws, belts, etc.), active or economical combustion and heating modes are set. The following photo shows just such a boiler with automatic feeding:

Reviews on the use of household automation kits: advantages and disadvantages

| Advantages | Flaws |

| Increased efficiency - achieved through precise adjustment of the blower, stable heat output throughout the entire combustion (in contrast to peak values during intense combustion and minimum values during the afterburning period with a standard boiler design) | Additional noise - the operation of the fan implies the presence of additional sounds, however, according to reviews from the owners, the noise is practically inaudible even through the thin walls of the boiler room. |

| Fuel economy - less fuel is required to achieve the same heating performance, a huge part of the excess heat does not “fly down the drain” | Additional costs - the cost of a standard “controller + fan” kit averages 7-11 thousand rubles. If desired, a room thermostat (about 1-3 thousand rubles), an automatic feeding system (from 10 thousand rubles) |

| Maintaining a constant temperature | Volatility - the boiler will require a connection to the electrical network to operate |

| Automatic ignition and extinguishing (optional) | |

| Possibility of external control - by connecting a room thermostat or outdoor sensors, the automation will focus not on the temperature of the coolant, but on the temperature in the room or outside, which is more efficient and comfortable | |

| Increasing the burning time of one bookmark, the ability to connect an automatic feeding system | |

| Safety - most controllers are equipped with protection against overheating or stopping the circulation pump |

Automation equipment for boiler rooms

Automation technical means:

- sensors of technological process parameters;

- actuators that move regulatory bodies according to commands in the desired direction;

- control equipment that processes information from sensors in accordance with the algorithms and programs embedded in it and generates commands for actuators;

- devices for selecting control modes and for remote control of actuators;

- means of displaying and presenting information to operational personnel;

- devices for documenting and archiving technological information;

- means of collective presentation of information.

All this technology has undergone revolutionary changes over the second half of the last century, not least thanks to the achievements of Soviet science. For example, pressure gauge instruments, widely used in measuring pressure, flow, speed and level of liquids and gases, as well as in measuring force and mass, have changed the physical principle of the sensing element.

Instead of a membrane that bends under the influence of force and moves the rod of an electromechanical transducer, they began to use a strain gauge method. Its essence is that some materials, when subjected to mechanical action, change their electrical parameters. A sensitive measuring circuit detects these changes, and a computing device built into the device converts them into a process parameter value.

Devices have become more compact, more reliable, and more accurate. And more technologically advanced in production. Modern actuators don't just accept "on" and "off" commands, as they did for many years. They can accept commands in digital code, independently decipher them, execute them and report on their actions and their condition. Control technology has evolved from tube regulators and relay-contact circuits to microprocessor-based control, logic and demonstration controllers.

Abroad, the use of such controllers in automation systems for various objects began a little earlier. A microprocessor controller is a computing device designed specifically to control a technological object located in its immediate vicinity.

The controller consists of the following blocks and devices:

- power unit;

- calculator;

- block for input of analog signals of different ratings with galvanic separation;

- device for inputting discrete active (in the form of voltage) and passive (in the form of a dry contact) signals;

- block for outputting analog signals of different ratings with galvanic separation;

- device for outputting discrete active and passive signals;

- an interface communication device for connecting the controller to the system information field.

Signal input and output blocks - blocks of the ICD group (communication devices with the object) - are all multi-channel, have from 8 to 16 channels. The controller is assembled for a specific task using the design layout method. The composition and number of USO blocks is selected based on the number of corresponding signals in the system. The computer block contains a processor, random access memory (RAM) and read-only memory (ROM). A library of algorithms is stored in ROM. Its composition covers almost all control tasks used in such systems - regulation, arithmetic calculations, dynamic transformations, logical actions.

Programming of controllers is carried out using the technological programming method. For modern controller models, this method is an assembly of a functional diagram of a control task on the monitor screen.

After a simple check for errors, the program circuit is loaded into the controller’s RAM. The intuitive accessibility of the method for traditional machine gunners contributed to the rapid and widespread spread of RemiKonts.

Popular models

GSM alarm Sapsan

GSM modules must be selected depending on the type of boiler equipment and the requirements for the controller.

The most famous models are:

- Xital GSM with modifications 4T, 8T and 12T.

- Sapsan Pro 6 – for any boiler equipment, connection of 10 rooms.

- Telcom 2 – only for De Dietrich, up to 5 numbers.

- Vitocom 100 – only for Viessmann, a maximum of two numbers can be connected.

- Logomatic PRO GSM – only for Buderus, maximum number of numbers – 16 pieces.

Control system "Xital"

In the market of GSM alarms for heating equipment, the undisputed leader is the Xital system.

This is a powerful, comprehensive remote control system because in many cases it covers not only heating, but also home security.

The module accumulates data on the temperature in the room, pool, pressure in the circuits, collects readings from safety sensors, and simultaneously regulates the room temperature within a given range.

GSM module for boiler Xital 4T

There are several modifications of Xital - GSM-4T, GSM-8T and GSM-12T. They differ in the number of control zones - 4, 8 and 12.

Each device has an analog temperature sensor, as well as five external digital sensors that continuously measure temperature. 30 seconds after the sensors are triggered, Xital will send a message to telephone numbers (you can configure the equipment to turn off when an alarm is triggered).

Users can register up to 10 numbers, including regular landline numbers.

Startup order

The initial launch of the system is quite simple, you just need to follow the sequence of actions:

- Insert a clean SIM card into the controller.

- Plug in the power adapter.

- Call your mobile phone to the number of the inserted SIM card.

The controller creates initial settings and templates for voice dial-up mailing lists; using Caller ID, your phone number will be entered into them. System startup is complete.

After about a minute, you can do a control check. To do this, call the controller's SIM card again. After the call is reset, you should receive a response SMS message with information about the temperature in the boiler and in the room, the state of the controller inputs, the presence of a network and the protection of the object.

The Xital package includes a battery, with which the module can continue to operate when disconnected from the electrical network. We recommend that you purchase an uninterruptible power supply for your gas boiler in advance, since the module’s battery only lasts for a short time.

Maximum operating efficiency of the entire system is ensured not only by its optimal connection diagram and the presence of automation, but also by the installation location and technical parameters of the heating batteries. In this sense, vertical heating radiators have many advantages.

Which program to choose for hydraulic calculation of a heating system?

Nuances in the installation of solid fuel units

Solid fuel boilers have their own installation standards and safety requirements that are mandatory and cannot be ignored.

- Ventilation. Ventilation must be thought out to the smallest detail; most combustion products exit through the chimney, which must also be installed in accordance with the requirements (you can watch the installation of the chimney in the video tutorial). Also, natural or forced ventilation must be installed in the boiler room to supply oxygen and remove carbon monoxide (dangerous to humans).

- Fire safety. All contacting parts and nearby surfaces must be fire resistant. The floor and walls must be protected from overheating or sparks.

- Care. It is important to monitor the boiler, clean it on time, add fuel and check the functionality of the automation.