Many owners of private houses want to learn more about the operating principle of gas boilers, since these devices are used as the main elements of the heating system. This is due to the relative cheapness of the fuel used in the form of natural gas. In addition, the devices in question are small in size and safe to use.

Basic structural elements

Before touching directly on the operating principle of gas heating boilers, you should familiarize yourself with their structure. Typically devices consist of the following elements.

- The burner provides heating of the coolant. Gas is supplied to the combustion chamber through special nozzles, which allow the flame to be evenly distributed.

- The heat exchanger transfers thermal energy to the fluid circulating in the heating system.

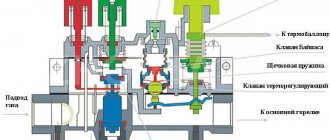

- The automation system is designed for safety and operating mode control.

- Device for removing exhaust gases.

Sometimes a circulation pump is built into the boiler, which allows for forced movement of the coolant in the pipes of the heating system. However, such models are more expensive. They are not popular with consumers. Most often, the pump is installed separately.

Expansion tank

To prevent the coolant from making a gurgling sound, the heating system must be completely filled.

But at the same time, the possibility of free expansion of the working environment when heated must be provided. This is why an expansion tank is installed.

The boilers are equipped with membrane-type tanks that do not communicate with the atmosphere (closed). Such a tank is divided by an elastic membrane into two parts, one of which is connected to the heating system, and the other contains air at a certain pressure.

The volume of the first part should be approximately 10% of the volume of the total coolant in CO. In the second part, you need to maintain a pressure 0.2 atm less than that observed in the CO when the circulation pump is running.

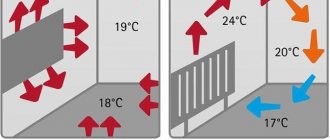

Operating principle of a gas heating boiler: heating circuit

The main function of heating equipment is to heat the coolant by direct transfer of thermal energy that is generated during the combustion of a gaseous substance. For clarity, the process of operation of a single-circuit device that is unable to provide heating of water for consumer needs is considered below.

Gas supplied under a certain pressure from the main network enters a special chamber, where it ignites. It is important that this process is completely safe. The combustion power is controlled using various sensors and an automation system.

When a flame appears, a significant amount of heat is released. It is transferred to the heating system directly through the heat exchanger, inside which the working fluid circulates. Heating is carried out externally. The heat exchanger is exposed to a jet of burning gas. The material used for this element is cast iron, steel or copper.

Construction: heat exchangers made of cast iron and steel

Bimetallic heat exchanger

In some cases, the material for the manufacture of the heat exchanger is cast iron or steel. It is noted that it is possible to choose one of the above options since none of the samples has priority.

Cast iron heat exchanger:

Based on the characteristics of the alloy used, during the manufacturing process of the boiler, the final type of device is assigned similar qualities to the base material, which include increased strength and a long service life.

In addition to the advantages, such a heat exchanger naturally has certain disadvantages, namely the need to take into account the high fragility of the original component, and the increased risk of small chips that are formed during improper transportation from the point of view of accuracy.

Please note: It is not recommended to use a cast iron element in the presence of hard water, as well as to allow systematic overheating of the liquid located in the boiler cavity.

Heat exchanger made of steel

Steel heat exchanger:

When choosing a steel sheet as a material for the manufacture of a boiler, the consumer can be completely confident in the shock resistance of the device and the ability to carry out a less gentle transportation process, since the impact does not cause any damage to the integrity of both external and internal shells.

But one should take into account the fact that in case of illiterate operation with the allowance of certain violations of the process, it is possible to carry out the process, disabling parts of the structure and rendering them inoperative.

In order to extend the operating period, it is necessary to maintain the temperature of the liquid at the maximum permissible value of positive temperatures, preventing freezing of the liquid, since this leads to failure of the device element and leading to the situation of immediate replacement of the damaged element.

Removal of combustion products

Everything has become roughly clear about the design and operating principle of gas boilers, but it is necessary to understand how other important components of the heating unit work. An important role is played by the combustion product removal system. It can be open or closed. In the first case, exhaust gases exit through the chimney of the ventilation system. As for the air supply, it is carried out from the room where the device is installed without any additional devices. Turbine burners are closed-type structures. They provide forced air intake and gas removal through special pipelines.

Boilers depending on burner type

Burner appearance

Currently, two types of boilers located on the floor are actively used:

- atmospheric boiler type;

- a mounted or fan-driven boiler that has an inflatable type of burner that pumps up the temperature of the required indicator.

A distinctive positive feature of the first version of the burner is its lower cost and quiet operation. As for the second option, according to qualified specialists, the high cost is fully justified by the higher useful power due to the operation of the heating element.

It is also possible to use an alternative type of liquid fuel to maintain operation.

When studying the offers of floor-standing boilers, it is noted that the latter are equipped with invariably atmospheric types of burner.

By the way: If there is a desire to install a more productive burner, then, as a rule, it is purchased separately from the main device and a replacement is made on site, removing the original factory-made version.

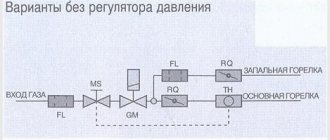

Operation of the automation system

The operating principles used for automatic gas boilers are designed to ensure safe operation and achieve maintenance of a certain coolant temperature for some time. The devices are equipped with all kinds of sensors and thermostats.

Automatic protection systems allow you to turn off the gas supply during a temporary shutdown. The system will simply stop working. It will need to be restarted manually immediately after gas transportation through the network pipeline is resumed. This can be done in a few minutes.

Modern models have energy-saving features, as well as a method of frost protection. The temperature regime of the coolant is regulated using special sensors. If the thermometer drops to 5 degrees, the boiler will turn on automatically to warm up.

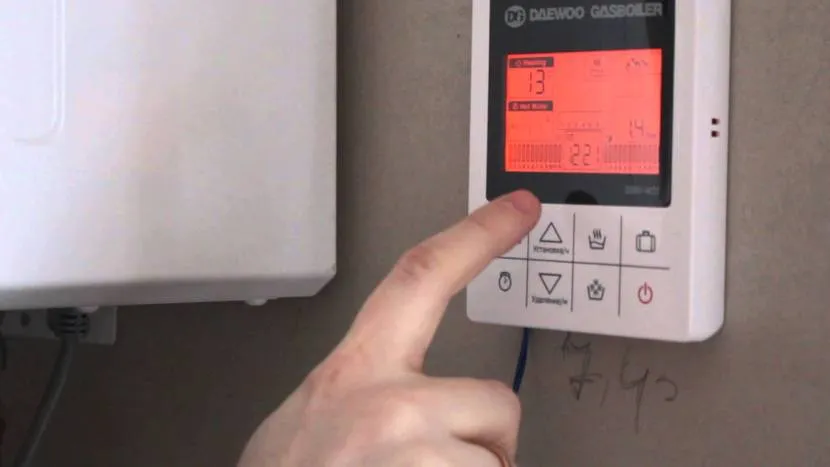

New models began to be equipped with self-diagnosis systems. During operation, the state of the main components is analyzed, after which the information is transmitted to the display via error codes. This technologically advanced method allows you to identify about 90 percent of probable faults.

Operating principle of the equipment

Gas autonomous heating in an apartment building is powered by a boiler installed in the apartment. To supply gas, electronic or piezo ignition is turned on. The spark created ignites the igniter, which burns until the device is turned off.

It is impossible to supply gas to the burner area when the igniter is not turned on due to the likelihood of an explosion. The igniter activates the main burner, which heats the coolant to a predetermined temperature.

When the required parameters are reached, the burner automatically turns off. As soon as the coolant temperature drops below a certain level, the thermal sensor is triggered and the gas supply is resumed.

Operating principle of double-circuit gas boilers

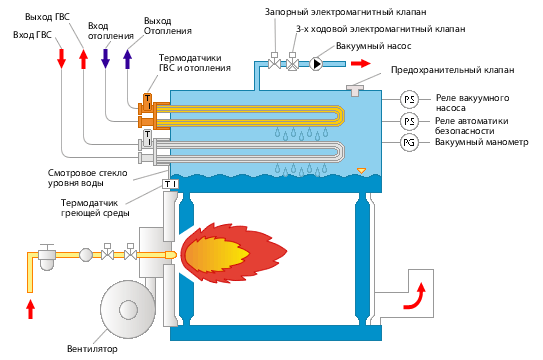

Often it is necessary not only to heat a room, but also to provide heating of water for domestic needs. In this case, double-circuit gas boilers will help. The operating principle of such devices is practically no different from single-circuit analogues. However, there are additional elements.

Heating of water in the DHW circuit occurs indirectly. To obtain hot water, it is necessary to maintain a certain temperature in the main heating circuit at all times. When the water heats up, the heating system will also work. This option is unacceptable in the summer, so a tap is installed on the return pipeline that can interrupt the circulation of the coolant. In this case, only water will heat.

What parameters should you pay attention to when choosing a boiler?

When choosing a boiler in a store, you need to understand that the branded floor-standing gas boiler presented on the display whose price exceeds $500-600, despite its reliability and functionality, may not meet the requirements of a particular circuit. In view of this, the purchase of a boiler should be made on the basis of the recommendations of an individually designed heating scheme. This document indicates the optimal power of the device, its performance characteristics, as well as data on the level of energy consumption. In addition to these criteria, the functionality of the boiler is also important. It is characterized by the number of contours.

A more functional gas boiler is a double-circuit floor-standing boiler, which implies the presence of an additional circuit for heating water.

In the store, floor-mounted double-circuit gas boilers, the prices of which are approximately $500-700, can be presented in models with different power ranges. Single-circuit models are more affordable, but gas double-circuit floor heating boilers are superior to them in practicality.

How do condensing devices work?

In conventional appliances, combustion products bypass the heat exchange surfaces and release part of the energy to the working environment of the heating system. Exhaust gases are discharged through a conventional chimney. In this case, a certain part of the heat is lost in the form of water vapor that appears during fuel combustion.

The operating principle of condensing gas boilers is somewhat different. The devices are capable of using the latent energy of water vapor. They are equipped with a blower fan that has a variable speed. In this regard, the combustion chamber is closed. Exhaust gases are discharged using a coaxial chimney.

Variable fan speed allows you to adjust the ratio of gas and supplied air. The condensing boiler does not function at its maximum efficiency in all cases. In order for the device to operate in economical mode, it is necessary to maintain the temperature of the coolant in the return pipeline less than 57 degrees.

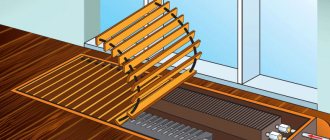

The efficiency of the condensing device increases with decreasing operating temperature of the heating system. In other situations, the effectiveness is slightly reduced. Therefore, such a device is appropriate when used with heated floors, where the operating temperature range ranges from 40-45 degrees.

Unlike a conventional boiler, the condensing analogue has a larger heat exchanger area. In it, exhaust gases are cooled to a temperature below 40 degrees. The condensation process occurs directly in the heat exchanger, so it is made of corrosion-resistant materials.

Device, main components

A standard gas fuel heating boiler includes the following main operating units:

- Burner.

Carries out gas combustion and uniform distribution of the generated heat to the heat exchange circuit. It can be conventionally atmospheric or turbocharged - equipped with forced exhaust of combustion products.

- Heat exchanger.

It is a box with a curved tube located inside through which water passes for heating. Divided into single- and double-circuit. Made from copper, steel and cast iron.

- Circulation pump.

Provides constant water pressure in the pipeline for its optimal distribution throughout the system.

- Expansion tank.

Prevents emergency expansion of water and its vapors inside the system.

- Smoke exhaust.

Carries out the removal of combustion products to the outside. It can be conventional - atmospheric, as well as turbocharged - with a fan for forced exhaust of gases to the street.

- Control block.

Provides configuration of system operating parameters. Connects wires, sensors, sensors, electrical circuits.

Gas boiler control module Source stroy-podskazka.ru

- Sensors for automatic control of safety parameters.

Gas automation for boilers monitors the stability of operating parameters and the safety of the system. Prevents the development of an emergency situation for various reasons - overheating, traction shutdown, loss of flame in the burner, etc.

Advice! A standard double-circuit boiler produces up to 8 liters of domestic hot water per minute. If higher consumption is required, it is better to install a single-circuit model combined with a storage water heater. The volume of household boilers varies widely - from 50 to 300 liters. This is quite enough for the everyday needs of a private home.

Boiler powered by a gas boiler Source domkotlov.by

How do wall units work?

For small houses, wall-mounted gas boilers are quite suitable. Their operating principle is approximately the same, but smaller parts and additional elements are used in the form of a circulation pump and a membrane tank. They differ from conventional analogues in their compact size.

As with floor-standing structures, wall-mounted gas boilers can be single-circuit or double-circuit. They can be equipped with a closed or open combustion chamber. The devices are fixed to the wall using special brackets.

The operating principle of a wall-mounted gas boiler is based on the presence of a complex automation system, which is considered the most capricious unit in terms of maintenance. It often fails during operation of the device. It is problematic to repair it with your own hands, so you have to call a specialist, which leads to additional costs.

Installation methods for heating gas units

Based on the type of installation, installations are divided into two types:

- Wall-mounted boilers are compact, so they can fit into any interior, are easy to install, easy to access, and have a reliable security system. But boilers of this design are characterized by low power and are used for heating small areas. In the case of a dual-circuit design, these units can also supply hot water to a small family.

- Floor mounted - they have significant dimensions, high power and high efficiency. As a rule, they are made of steel or cast iron.

Operating rules

As you can see, the operating principle of a gas boiler is not so simple, so when using it you must adhere to a number of rules.

- The first start-up of the device should only be carried out by a technical employee of a specialized institution. He will test the correct operation of the entire system.

- Many people neglect to carry out annual maintenance, but this should not be done. Timely removal of contaminants from the combustion chamber and elimination of carbon deposits in pipes allows you to increase the operating life of the device.

- It is advisable to avoid such situations when the temperature rises above 90 degrees. This can be detrimental to the device. During operation, it is recommended to adhere to the range from 65 to 90 degrees.

- To avoid emergency situations during boiler operation from increased pressure, you should connect a safety group consisting of a pressure gauge, an air vent device and a safety valve.

- If during use the operating period reflected in the technical passport is exceeded, then an examination is necessary for safe operation.

Review of popular manufacturers and prices

There are many boilers on the market, both foreign and domestic. The most expensive are models from German manufacturers: Wolf, Vaillant, Bosch and Buderus. The products of these companies are famous for their quality. A wide selection of models is offered, which allows you to choose a boiler that meets any needs.

Products from Italian companies - BAXI, Ariston and Beretta - also have excellent characteristics, but are sold at lower prices. Domestic and ZhMZ gas boilers, as well as South Korean Navien, are in high demand. In terms of price-quality ratio, Navien brand equipment is gaining increasing popularity among consumers.

"Ariston"

The products are famous for their high quality workmanship; translated from Greek, “ariston” means “best”.

The company produces four lines of wall-mounted appliances of different modifications:

- ALTEAS X. Premium line, the latest development of the company. Gas units have a built-in WI-FI module that is compatible with the Ariston Net application. The line has three modifications: ALTEAS 24 FF, 30 FF and 35 FF. The numbers in the names of the boilers indicate the rated power for which the devices are designed. The cost of the units is in the price segment from 50,000 to 70,000 rubles.

- Ariston Genus. Premium-class equipment, considered second in functionality after ALTEAS X. The equipment has a liquid crystal display and can be controlled remotely from the control panel. The line is represented by models: Evo - a traditional double-circuit gas appliance with an open or closed combustion chamber and Genus Premium - a more expensive condensing boiler. The power range of all models is from 24 kW to 35 kW. The cost of Ariston Genus boilers ranges from 54,000–72,000 rubles, the price of Premium models can reach 85 thousand rubles.

- Ariston Clas. Units with a large display and AUTO and COMFORT functions. Boilers are the optimal equipment for those who want to save money. Available with a power of 24–28 kW. The average cost is in the range of 25,000–30,000 rubles.

- Ariston Egis. The most common model in Russia. Can operate at temperatures of -50 ºС. Has an electronic control unit. The price of models is from 27,000 to 34,000 rubles.

Prices for wall-mounted gas boilers Ariston

Ariston wall-mounted gas boilers

Watch the video where the Ariston Egis boiler is presented - the most popular model in Russia.

"Baksi"

One of the largest European manufacturers. Produces equipment for heating and domestic hot water supply (hot water supply). The company has representative offices in seven countries: Italy, Great Britain, Spain, France, Germany, Russia, Turkey, as well as in Eastern Europe and the Middle East.

Buyers often prefer the following models of Baksi wall-mounted boilers:

- Baxi Main 4 and Main 5. Only these models have the heating and heating circuits combined in one heat exchanger. Therefore, these boilers are smaller in size compared to other models. Baxi Main 5 is available only with a closed combustion chamber. The power range ranges from 14 to 24 kW. The cost of Main 4 is 20-28,000 rubles, and Main 5 is 25-32,000 rubles.

- Baxi Eco 4 and Baxi Eco Compact. A distinctive feature of these models is the use of an additional stainless steel heat exchanger. Range of powers from 14 to 24 kW. Baxi Eco Compact has small dimensions. Baxi Eco 4 costs from 21,000 to 27,000, and Baxi Eco Compact – from 35,000 to 44,000 rubles

- Baxi 4 Tech and Baxi Eco 4S. Analogues of Baxi Eco 4 and Baxi Eco Compact, but more budget devices. Instead of copper ones, they are equipped with plastic supply tubes, which somewhat reduces the cost of the products.

Ferroli

The well-known Italian company produces a wide range of heating equipment, including wall-mounted units at very reasonable prices.

Ferroli line of gas appliances:

- Diva;

- Domina-N;

- Arena;

- Divatop Micro;

- Divatop-H;

- Divatop Micro-LN;

- Divatop 60;

- Domiproject-D.

The power of each of the models in the list increases by 4 kW: 24, 28, 32 kW. The cost varies from 24,000 to 42,000 rubles.

Prices for wall-mounted gas boilers Ferroli

Ferroli wall-mounted gas boilers

Bosch

A very popular German company whose products are famous for their high quality and functionality.

Produces the following series of wall-mounted gas units:

- BOSCH GAZ 7000 W. Premium wall-mounted gas boilers. The main components of all models in this series are made of brass, without the use of composites. Single-circuit devices: ZSC 24-3 MFK, ZSC 24-3 MFA, ZSC 35-3 MFA with a power of 24 kW and 33.3 kW and costing from 50,000 rubles and 66,000 rubles, respectively. Double-circuit models: ZWC 24-3 MFK, ZWC 28-3 MFK, ZWC 24-3 MFA, ZWC 28-3 MFA, ZWC 35-3 MFA with a power of 24, 28 and 35 kW. Price range - from 55,000 to 68,000 rubles.

- BOSCH GAZ 6000 W. Heating devices in this series are designed and adapted for Russian operating conditions. Single-circuit models: WBN 6000-18 H RN S5700, WBN 6000-24 H RN S5700, WBN 6000-35 H RN S5700 costing from 33,000 to 44,000 rubles. Double-circuit models: WBN 6000-18 WITH RN S5700, WBN 6000-24 WITH RN S5700, WBN 6000-12 WITH RN S5700, WBN 6000-35 WITH RN S5700, sold at prices ranging from 42 to 45 thousand rubles.

- BOSCH GAZ 4000 W. The two-circuit unit ZWA 24-2 K will cost 31,500 rubles. The price of a single-circuit device ZSA 24-2 A is from 35,000 rubles.

- Condens 5000W. High-power wall-mounted condensing units. Models BOSCH ZBR100-3 and BOSCH70-3 with a power of 99.5 kW and 69.5 kW, respectively, cost 244,000 and 219,000 rubles.

Watch the video for a description of the BOSCH GAZ 6000 W gas boiler.

Prices for wall-mounted gas boilers Bosch

Bosch wall-mounted gas boilers

Wolf

The German company has been on the market since 1963 and began with the production of devices for drying hops. Currently, it produces many types of climate control equipment, including a large number of gas heating heat generators of various modifications.

Models of gas units from Wolf:

- GGU-2(K). Traditional boilers. Expensive materials are used in their production, which explains the high cost of the products. Depending on the power of the device and the configuration with various functions, the price ranges from 107,000 to 122,000 rubles.

- GGG-1K. The units are of the classic type, but more budget-friendly. The cost varies from 57 to 65 thousand rubles.

- FGG-K. Traditional appliances, the most budget option. The latest model FGG-K-24 costs from 39,000 rubles.

- GGB-2K, GGB-2, FGB (-K). Condensing boilers. The most economical option in terms of gas consumption. They cost from 116,000 to 300,000 rubles.

Protherm

Gas equipment of the Proterm brand has been produced since 1991, the main production is located in the city of Slavice (Slovakia).

Proterm produces the following brands of wall-mounted boilers:

- "Gepard" - two-circuit devices with a power of 12 and 23 kW. Hot water is heated in a steel plate heat exchanger. Prices are set depending on the region - from 35 to 40 thousand rubles.

- "Jaguar" - two-circuit units in the basic version with a power of 11 and 24 kW. Equipped with a coaxial system. Cost - 30,000-35,000 rubles.

- "Panther" - single-circuit and double-circuit boilers with a capacity of 12, 25, 30 and 35 kW. Price - from 35 to 55 thousand rubles.

- "Tiger" is a coaxial two-circuit device with a power of 12 kW. Hot water is prepared from a built-in 45 liter boiler. It is installed in apartment buildings, country houses, and private properties. The price starts from 56,000 rubles.

- “Lynx” - condensing units with a capacity of 18, 25 and 30 kW, developed by Vaillant Group engineers based on extensive experience in operating boilers operating with hard water and poor quality gas. Price - from 33 thousand to 45 thousand rubles.

"Neva Lux"

The domestic company BaltGaz produces various gas appliances, as well as spare parts and components for them.

Currently BaltGaz produces wall-mounted gas heat generators Neva Lux of the following categories:

- BaltGaz NEVA Turbo - double-circuit convection units with a capacity of 11, 14, 18 and 24 kW. The price, depending on the region, ranges from 28 thousand to 32 thousand rubles.

- BaltGaz SL 11/14/17 series are single-circuit units with the ability to connect them to an indirect heating boiler with a capacity of 11, 14 and 17 kW. Starting price - 17,000-18,000 rubles.

- BaltGaz Turbo S - two-circuit devices with a closed chamber for gas combustion, power - 10, 11, 14, 18, 21 and 24 kW. The price of the units is 30,000-32,000 rubles.

Watch the video showing the new generation Neva Lux boilers.

ZhMZ

OJSC Zhukovsky Machine-Building Plant produces a wide range of gas floor-standing boilers; the production of wall-mounted appliances is not yet included in its program.

Vailant

Vaillant Group is one of the leaders in the production of heating equipment, which is supplied to 60 countries.

Vailant produces 7 model ranges of wall-mounted boilers:

- VAILLANT TURBOFIT VUW - consists of only one double-circuit heating unit Vaillant turboFIT VUW 242/5-2, with a power of 24.7 kW. One of the features of the model is a copper primary heat exchanger. Costs 44,700 rubles.

- VAILANT TURBOTEC PRO VUW. There is only one dual-circuit model Vailant turboTEC pro VUW 242/5-3 with a power of 24 kW. The price of the product is 62,000 rubles.

- VAILANT TURBOTEC PLUS VUW. The series is represented by 5 dual-circuit models. The power of the units increases by 4 kW, starting from 20 kW and ending with 36 kW. Prices - from 69,000 to 100,000 rubles.

- VAILANT TURBOTEC PLUS VU is a series of six single-circuit models. The power line starts from 12 kW and ends at 36 kW. Prices are lower than those of dual-circuit devices, from 56 to 89 thousand rubles.

- VAILLANT ATMOTEC PRO VUW. The series is represented by one dual-circuit model with an open chamber for gas combustion. The power of the unit is 24 kW. You will have to pay 58,000 rubles for the product.

- VAILLANT ATMOTEC PLUS VU - single-circuit units with an open combustion chamber. Presented in three models with 20, 24 and 28 kW of power. Prices range from 47 to 68 thousand rubles.

- VAILLANT ATMOTEC PLUS VUW. Double-circuit boilers with an open combustion chamber. Three models for 20, 24 and 28 kW. They cost from 65,000 to 86,000 rubles.

Buderus

Another German company in the heating industry market. Like all “Germans”, they are distinguished by the high quality of their products. It has its own production in Russia.

Line of wall-mounted boilers from:

- Condensing single- and double-circuit units Logamax plus GB172i. They are distinguished by innovative design, expanded functionality, power range: 20/28, 24, 30, 35, 42 kW. For such a device the buyer will need to pay from 84,000 to 117,000 rubles.

- Single-circuit condensing devices Logamax plus GB162. They provide the possibility of creating a cascade of boilers, have high efficiency, power range: 70, 85, 100 kW. Cost - 200,000-260,000 rubles.

- Condensing devices Logamax plus GB062. Single- and double-circuit devices with a power of 14, 20 and 24 kW. They cost 72,600, 74,700 and 76,000 rubles respectively.

- Gas appliance Buderus Logamax U072. Used for heating and hot water supply, designed for Russian conditions. Power range: 12-18-24-35 kW. Very low-budget models, cost from 34,000 to 50,000 rubles.

- Logamax U052/054. Single- and double-circuit gas heating heat generators Logamax U052 are closed type, and Logamax U054 are with an open chamber for gas combustion. Power range - 24-28 kW. The purchase will cost from 48,000 to 60,000 rubles.

- Logamax U042/044. Logamax U042 double-circuit heating units are equipped with a closed gas combustion chamber and a bithermal heat exchanger. Logamax U044 is an open type boiler with a power of 24 kW. The price is 40,000 and 37,000 rubles, respectively. Read about a wood-burning stove for your home on our website.