Application area

Installing a miracle stove using diesel fuel will be the optimal solution for heating greenhouses, country houses, basements, utility rooms, workshops, tents, garage buildings built in places where there is no possibility of connecting to centralized heat sources.

It can be used as a permanent or additional heating device, and you can also heat tea or other food on it. A kerosene stove is more suitable for heating country houses. Its efficiency is higher than that of diesel analogues, during operation no harmful substances are released into the atmosphere, and there is no unpleasant odor.

Device and elements

A kerosene and diesel fuel stove consists of the following elements:

- removable fuel tank equipped with a valve;

- housings;

- burners;

- block with a replaceable filter;

- gratings;

- adjusting screw;

- reflective screen.

The body of the diesel fuel stove is covered with a fire-resistant powder paint and varnish material, and there is a reflective stainless steel screen on it, which contributes to a more efficient process of heating the room.

A fuel tank is fixed on the rear wall, from which fuel enters the body. In it, in the very center, there is a burner mounted on a cylinder-shaped base. An adjusting screw is used to adjust the heating temperature.

Ignition

It is better to ignite outdoors, and only then bring the working device into the house (this will avoid unpleasant odors in the room).

If the stove has not been used for a long time, it must be cleaned before starting ignition. The grate, burner, tank on the rear wall are removed, and the entire fuel unit is pulled out. All parts are cleaned, the reflector screen is rubbed.

It is very important to install the device strictly horizontally, otherwise it will be difficult to achieve uniform burning of the wick along its entire length.

Then ignition:

- Fuel is poured into the removable tank.

- A new wick is installed in the burner (twisted into a ring at the bottom of the burner).

- The burner and grate return to their original place.

- The valve unscrews slightly, which allows fuel to access the wick.

- The front panel opens and acts as a door.

- The edge of the rolled paper is lit and brought to the burner from below.

- When the fuel burns well and the flame rises above the grate, the valve closes completely (the red-hot bottom of the burner will indicate that sufficient heating has occurred).

- After waiting until the flame begins to go out, turn it off again, but this time to the intensity that you would like to achieve.

When you need to turn off the stove, turn the valve all the way.

While the user has little experience in handling the stove, it is very difficult to achieve even burning of the wick (this can take more than half an hour).

But if you have experience igniting, but still cannot get a blue flame throughout the entire wick, this may be one of the following problems:

- Uneven surface, tilt of the oven.

- The burner cylinder has not yet warmed up completely.

- The wick is worn out (it burns slightly every time and the more it is used, the more damaged it becomes).

You can try to extend the life of a worn wick by simply turning it over, or trimming the burnt edge with scissors. To make the wick last longer, it can be periodically washed in kerosene.

Advantages and disadvantages

The advantages of diesel stoves for heating are:

- small dimensions;

- mobility;

- availability of fuel and its low consumption;

- no open flame;

- intensity adjustment;

- no costs for the construction of a permanent chimney;

- acceptable price.

The disadvantages include:

- periodic replacement of wicks;

- frequent burner cleaning;

- A diesel fuel stove is not recommended for heating residential premises as a permanent heating device, since the smell of diesel fuel may be felt in the room and acrid smoke may enter when ignited or extinguished.

How to do it yourself?

Models of stoves for heating with diesel fuel, which can be bought in a store, are designed for a certain thermal power and are capable of heating a building with an area of no more than 30 m2. A home-made device will be more economical and ideal for the intended operating conditions.

Materials and tools

When building a diesel and kerosene stove with your own hands, you can use a used cylinder for storing and transporting liquefied propane-butane gas as a basis.

In addition, you need to prepare:

- a pipe for making a chimney no less than 4 meters long, with an internal diameter of 10 cm and a wall thickness of 2 mm;

- a copper tube about 1.5 m long;

- a small clamp with a screw;

- two-liter medical heating pad;

- angle steel 20x20 mm;

- electrodes.

The set of tools should consist of:

- welding machine;

- drills and drill bits;

- file;

- Bulgarians;

- rulers and tape measures.

1 production option

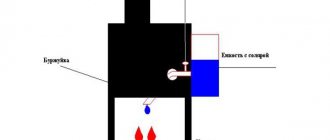

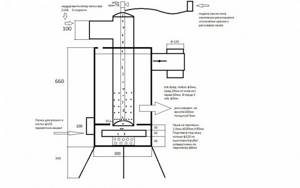

Scheme of a miracle diesel stove

- drain the remaining filler from the cylinder;

- wash it with a weak soap solution, and then with clean water and dry well;

- Use a grinder to cut off the top part, remove the valve and weld a smoke exhaust pipe in its place;

- Weld angle steel legs to the lower half (firebox) and cut a hole on the side for installing a copper tube;

- cut another hole in the housing to regulate air flow and cover it with a metal plate;

- bend the copper tube at an angle of 90 degrees, connect one end to the rubber hose from the heating pad, place the other in the cylinder;

- bend the hose in half, use a clamp with a screw to secure the bend;

- fill the heating pad with diesel fuel and hang it on the wall away from the device;

- place a cup of fuel in the combustion part, making sure that the end of the copper tube is located directly above this container;

- place a lit piece of paper in a cup on top of the diesel fuel;

- connect both parts of the cylinder;

When heated, the diesel fuel will begin to evaporate, followed by spontaneous combustion of the vapors. You can add fuel using a heating pad. From it, fuel flows drop by drop to a copper tube through a rubber hose, and then enters the firebox. To adjust the feed, a screw on the clamp is used.

Manufacturing option 2

Here is the second manufacturing option:

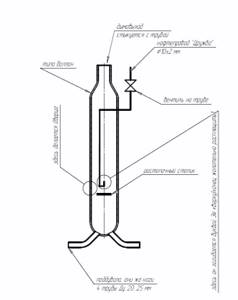

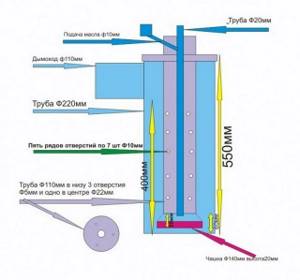

Scheme

Dimensions

Appearance

Instructions for making a miracle oven

The easiest way to make a homemade diesel stove is from a drip-type gas cylinder, since almost everyone has one. The drawing and its explanation show in detail what the structure will consist of.

- Waste gas cylinder.

- A steel pipe with a diameter of 100 mm and a thickness of 5 mm through which gases will be discharged.

- A pipe with the same characteristics for a heat exchanger.

- 4 mm steel sheet for the partition between the combustion chambers and the evaporation chamber.

- Another sheet of the same parameters for a canopy over the heat exchanger to increase the heating of the pipe.

- Evaporator bowl.

- Coupling.

- 0.5 inch pipe for supplying fuel to the combustion chamber.

- A ball valve with which the fuel supply will be regulated.

- Fireproof pipe for fuel supply.

- Reservoir for storing waste. Any cylinder with an integrated needle valve can be used as a container.

- Air flow swirler. You can use 2 corners 55 mm wide, which are welded together.

- Duct fan.

Assembly steps

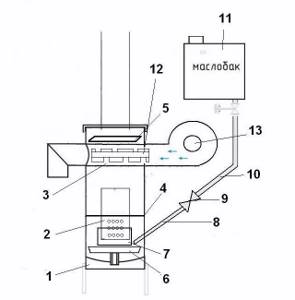

Working with the tank

To safely work with the cylinder, it is necessary to drain the remaining gas and condensate. To do this, you need to open the valve and coat the hole with soap foam. If the foam stops bubbling, it means that all the gases have escaped. Then we twist the valve. On many cylinders they are not removable. Then you need to drill a small hole in the bottom and drain all the existing liquid. After this, the container must be rinsed with water.

Then you need to make two holes in the cylinder: the first - 200 mm, the second - 400 mm, with a 50 mm jumper between them. The photo shows how they should look. We do not throw away the cut parts; they will be useful as doors that will need to be welded onto the hinges to the cylinder.

Separating the cameras

We proceed to the manufacture of a jumper that will separate the combustion chamber and the heat exchanger. To do this, we need a sheet from which we need to cut a circle so that it matches the internal diameter of the cylinder (approximately 294 mm). Then in the circle itself, in the middle, we cut out another hole for the pipe. The hole must be at least 100 mm.

Making a burner

We take a pipe 20 cm long and 4 mm thick, and drill holes with a diameter of 19 mm in one part (bottom). After drilling, all burrs must be cleaned from the inside, otherwise soot and soot will settle on them, which will lead to a narrowing of the internal diameter of the burner.

A ring cut from a sheet is put on this pipe and welded well so that there are no holes.

After this, the structure must be installed inside the cylinder and also welded around the entire perimeter.

Making an evaporation bowl

As a bowl, you can take any container that has thick walls and does not deform at high temperatures, but the easiest way is to use an old brake disc. The main thing is that it is made of heat-resistant materials, such as cast iron. You need to weld the bottom and lid onto the disk.

A fitting is welded on top of the lid, which will be combined with the burner pipe using a coupling of the largest size.

Making a fuel supply system

To make a fuel supply system, you need to insert a 0.5-inch pipe into the hole at an angle of 40 degrees and weld it to the body of the miracle stove. It makes no difference where to drill a hole for the pipe, since the bowl can be turned in any direction.

To mark the reach distance, the coupling must be lowered onto the end of the pipe.

We cut the pipe using a grinder so that there is a spout at the end. This shape will facilitate more convenient fuel flow.

A valve must be screwed to the tube, which is intended to be used in the event of a breakdown, to shut off the fuel supply.

Making a heat exchanger

The pipe must be cut horizontally into the structure body. Then you need to weld a steel sheet onto the top of the pipe, this will be a reflective screen.

In order to circulate air through the heat exchanger, a swirler is used, which must be inserted into the heat exchanger pipe. You can make a swirler from 2 squares welded together, which should be 300 by 50 mm in size.

The homemade diesel stove is ready, and in the end you should end up with a design like this.

They also make a stove using diesel fuel or waste. To do this, you only need to change the fuel.

Ready-made models

Among the most common liquid fuel heating appliances is a miracle - the Solarogaz stove, made in Russia (Penza, PA "Savo"). The products of this association have different configurations and sizes, differences in the material of the burner and shell and, accordingly, in price.

Thermal power ranges from 1.8 kW to 5 kW, depending on which such a miracle - a diesel stove can heat a room with an area of 18 to 50 square meters.

Solar gas PO-1.8

So, for example, a mini stove using diesel fuel from this manufacturer Solarogaz PO-1.8:

- made with dimensions 27x37x28 cm;

- has a fuel tank with a volume of 2.5 liters and a weight of 5.5 kg;

- can be fueled not only with diesel fuel, but also with kerosene;

- its power is 1.8 kW, fuel consumption is 0.2 l/hour.

Designed for heating a small room, the area of which is no more than 18 square meters. m. You can buy such a miracle - a diesel fuel stove for 2 - 2.5 thousand rubles.

Solar gas Duet 5.0

The more powerful device Solarogas Duet 5.0 costs more, from 4.5 to 6.0 thousand rubles, since its power rating corresponds to 5 kW. It has:

- overall dimensions – 37x42x32 cm;

- fuel tank volume – 5 l;

- fuel consumption – 0.2 – 0.4 l/hour;

- burning time before refueling is about 28 hours.

Recommended for heating warehouses and utility rooms with an area of up to 50 square meters. meters.

Aeroheat HA S2600

Popular models also include the Aeroheat HA S2600 kerosene and diesel fuel stove with a glass shell.

The technical characteristics of these heating devices are as follows:

- thermal power – 2.6 kW;

- fuel tank volume - 2.5 l;

- burning time before the next refueling is from 8 to 12 hours;

- dimensions - 35x29x27 cm;

- weight - 4.8 kg;

- fuel consumption - from 0.18 to 0.2 kg/hour.

TRITON 8.7

Powerful Hungarian diesel stoves for cottages, brand TRITON 8.7, with a water circuit and a hob, depending on the power, are capable of heating a room of up to 250 m2. They have high efficiency; a dispenser is used to regulate the fuel supply. The cost varies from 18.0 to 45 thousand rubles.

Principle of operation

The wick is soaked and burns, with a burner placed above it.

The gaseous mixture enters the combustion chamber (a system of cylinders with a large number of jumpers, holes, etc.), where it burns out layer by layer and evenly.

The design of the cylinders in the combustion chamber allows the use of convection and infrared heating mode. These stainless elements heat up to 800 °C and heat the air, infrared rays (length 620 -700 nm) are reflected from the mirror screen and directed into the room, and heat objects.

Combustion in this device takes place practically without open flame. You can determine whether the process is going correctly by eye.

The flame should not rise above the protective grill (both the grill itself and the wick can burn).

How to use it correctly?

To light a diesel stove, you need to perform the following algorithm:

- place the device on a horizontal surface made of non-flammable material;

- install the wick into the burner block;

- remove the fuel tank, unscrew the valve and pour fuel into the inlet using a funnel;

- install the valve in place and secure the tank in its original position;

- unscrew the valve and wait until the wick is saturated with diesel fuel;

- on the front panel of the case, open the door and light the wick;

- when the flame rises above the grate, the screw should be tightened completely;

- when the flame dies out, the screw must be unscrewed again and the combustion adjusted to the desired intensity.

To completely turn off the diesel stove, the adjusting screw is tightened until it stops. If the device has not been used for a long time, then before ignition it is necessary to clean all parts and rub the reflective screen until shiny.

When operating such a heating device, it is important to strictly follow fire safety rules:

- do not use the miracle stove using diesel fuel in rooms with poor ventilation;

- do not install the device near objects made of flammable materials and furniture;

- refuel with fuel in accordance with the manufacturer’s recommendations;

- do not allow liquids to come into contact with the operating device;

- During operation, ensure constant supervision by an adult family member.

To ensure a higher level of safety in a garage where there are a lot of combustible, flammable substances, you need to stock up on several fire extinguishers weighing 5 kg.