Home / Boilers

Back

Published: November 23, 2019

Reading time: 3 min

3

5554

Owners of water heating boilers quite often come across information about the magnesium anode, but, as a rule, only a few know what the anode for the boiler looks like and what role it plays.

In short, it can be noted that the primary task of a magnesium electrode is considered to be anti-corrosion protection of the internal surfaces of the tank.

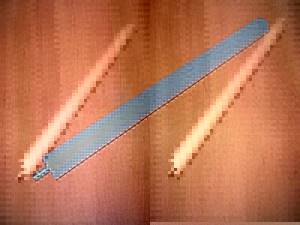

Dismantled anode. Photo source: tehnika.expert

- 1 Purpose of a magnesium anode for a water heater

- 2 Operating principle

- 3 Types of anodes 3.1 Magnesium

- 3.2 Titanium

- 3.3 Aluminum

Purpose of a magnesium anode for a water heater

When a water heater operates, chemical reactions occur in the water. Thanks to cathodic protection, all foreign substances are deposited on the passive anode. This is why the water heater requires a magnesium anode. It promotes:

- protection of the tank and all its parts from corrosion;

- preventing the formation of scale on the walls of the heating element;

- reducing water hardness.

When a magnesium electrode is used for a long time, it gradually deteriorates. At the same time, the level of chemical elements in the water does not decrease. This means that it is absolutely safe to use. For this reason, it is necessary to regularly replace this part in the boiler. To carry out this procedure less frequently, you need to monitor the quality of the water. It is important to note that the more often a person uses the boiler, the faster the anode fails.

Important! It is possible to operate the water heater without this element. Then the boiler will quickly break down. By the way, when purchasing a new part, you need to pay attention to its quality. An electrode with cheap magnesium quickly fails. During its use, the water becomes hydrogen sulfide-smelling.

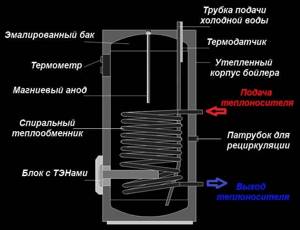

Anode device

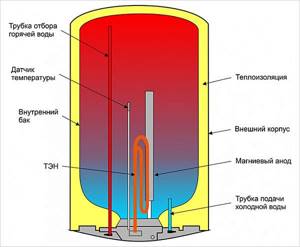

The water heater element is a round steel rod with a 10-15 mm thick layer of magnesium alloy applied to it. The electrode is attached to a threaded connection to the bottom of the tank body next to the heating equipment.

In some boilers they are mounted on the top of the tank. The working length of the anode ranges from 14 to 66 cm. In addition to magnesium, titanium, zinc are used for their manufacture, or active electrodes connected to the electrical network are used.

Due to their electrochemical properties and low cost, magnesium anodes have gained great popularity. The boiler needs a kind of protector for the metal parts of the tank from exposure to oxygen and salts resulting from the heating process.

In this video we will learn about the anode devices:

Principle of operation

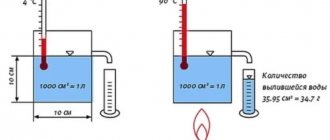

The operating principle of the electrode is based on its activity , since magnesium in all compounds is a divalent metal, and the iron from which the tank is made is trivalent. In addition to corrosion, when heating water, scale forms due to settling salts of heavy metals.

Since magnesium has increased activity, the salt atoms interact with it, and not with iron. Therefore, the magnesium anode binds oxygen atoms and attracts iron salts as a magnetic material. At the same time, the formation of calcium carbonate salts sharply decreases, and carbonic acid salts are formed from magnesium.

As a result, the scale becomes looser and can be easily removed when cleaning the unit. This prevents corrosion of the tank and the coating of the heating element. This process is called sacrificial protection, and the electrode is called anode-protector.

When to change the boiler sacrificial anode

After a year of operation, corrosion is visible on the surface of the magnesium anode - oxides, which crumble and gradually dissolve, destroy the electrode. As a result, the length and diameter of the anode decreased.

Products for construction and repair

⇆

Sulfate-reducing bacteria use organic matter (CH2O) or hydrogen (H) as an electron donor and sulfate (SO4) as an electron acceptor to obtain energy

2CH2O + SO42- + 2H+ => 2CO2 + H2S + 2H2O

Simply put, there are two types of sulfate-reducing bacteria. Both varieties require sulfates - sulfur compounds - as well as hydrogen to survive. But one species of bacteria extracts hydrogen from organic matter in the sludge . Other bacteria use molecular hydrogen , which is found in water.

It is important that the development of sulfate-reducing bacteria occurs under anaerobic conditions , in the absence of free oxygen in the water.

Sulfates are salts of sulfuric acid H2SO4, for example, potassium sulfate K2SO4, sodium hydrogen sulfate NaHSO4. Sulfates are widespread in nature, forming a whole group of minerals. Many sulfates are soluble in water and are found in natural water.

Kinds

It is imperative to install a sacrificial anode for a boiler covered with ordinary metal. After all, such material without additional protection has a short service life. Even if the inside of the tanks is covered with a layer of stainless steel, this still will not save the water heater. Therefore, you need to buy additional parts so as not to spend money on repairs later. Any heater manufacturer puts forward its own recommendations on how to select the anode size. In principle, anodes can be divided into two types - magnesium and titanium.

Magnesium anode

The magnesium anode, as mentioned above, is made of an ordinary rod or, in other words, a rod, inside of which there is a threaded steel pin. The studs themselves can be of different diameters and different lengths. It is worth paying attention to this when buying a new anode, because if its size is many times larger, it will not fit into the hole in the tank. However, there are some designs where you can install even two anodes. In floor-standing gas or electric structures with a large volume, they are changed only from above.

The anode rod is very large, approximately one meter long. Therefore, replacing it will be problematic in rooms with low ceilings. Since the water heater itself has a height of up to two meters, plus a meter-long rod must also be inserted into it. For such purposes, multi-section protective magnesium anodes began to be produced.

Since development does not stand still, new products have recently appeared on the markets - flexible plastic anodes.

They are made from a plastic tube with micropores. Magnesium granules are poured inside this tube. The advantage of this new product is that there is no sediment left inside. In addition, magnesium can be added to the tube as it is produced. Magnesium powder is sold separately.

A high-quality aluminum water heater does not need such additions. But at the same time, the high price makes it inaccessible to ordinary people. But an ordinary boiler, supplemented with a magnesium anode, will be affordable for almost everyone. At the same time, it is no worse in functionality. The principle of its operation is that active magnesium atoms leave the anode and themselves produce oxide. The iron atoms remain completely intact.

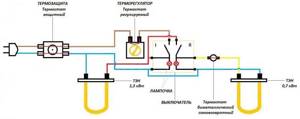

Titanium anode

But a titanium-coated anode works on a slightly different principle. It is used as a measuring and supply electrode. In this case, the current is supplied by a voltage source located outside, and it is also regulated by external electrical control. After some time, the current stops flowing and then the titanium anode analyzes the condition of the internal parts of the structure. It identifies what kind of violation occurred during a given period and then with great accuracy regulates the possible feed force to restore the damage.

The titanium coated anode is not subject to destruction and therefore does not need to be replaced at all. It works throughout the entire service life of this structure. The greatest demand is for heaters for 50 liters of water, supplemented with such an anode. They are not only compact, but also easy to use. By the way, to make sure that the anode is really titanium, you can use a magnet. This material has a weak magnetic field, so it is not magnetic at all.

Aluminum

This is another version of the protective electrode, coated with aluminum coating. It is also made in the form of an ordinary threaded rod.

When water is heated, the metal expands and the alloy of the body lengthens, losing its characteristics. Microcracks form on the surface of the tank. After which the oxygen in the water begins to oxidize the metal, causing irreversible corrosion processes.

The steel body and the electric heating element create a galvanic couple, with the body becoming the anode. To prevent it from being destroyed under the influence of water, the manufacturers placed an alloy containing aluminum near the heating element.

It takes on the role of an anode - as a result of which all aggressive oxygen is consumed for its oxidation, and the container remains intact. The aluminum anode prevents the boiler elements from oxidizing, but it has a very sophisticated design and is easily damaged by mechanical shock.

Stainless steel for the production of water heaters

The following stainless steels are used in storage water heaters today: SUS 304, SUS 316, SUS 316L and AISI 444. SUS 304 and SUS 316 steels are austenitic steels, include iron, chromium and nickel, non-magnetic. AISI 444 steel is a ferritic stainless steel, contains iron and chromium, and is magnetic.

Table of correspondence between steel grades and different standards:

| GOST | USA AISI, ASTM, ASME | Asia JIS, SUS | Germany DIN | Europe |

| 08Х18Н10 | 304 | 304 | 1.4301 | X5CrNI18-10 |

| 08Х17Н13М2 | 316 | 316 | 1.4401 | X5CrNiMo17-12-2 |

| 03Х17Н14М2 | 316L | 316L | 1.4404 | X2CrNiMo17-12-2 |

| 02Х18М2БТ | 444 | 444 | 1.4521 | X2CrMoTi18-2 |

Mark 304

— steel with low carbon content, non-hardening, corrosion-resistant, non-magnetic, easy to weld, with high strength at low temperatures, can be polished. It is most often used in the production of containers and tanks for installations in the food, chemical, textile, pharmaceutical, paper, nuclear and refrigeration industries. To protect welded joints, electrochemical passivation is possible. Water heaters made of SUS 304 steel are the optimal price/quality ratio! 304 steel is used in the vast majority of water heaters (Termex, Timberk, etc.)

Mark 316

- An improved version of 304, with added molybdenum and a slightly higher nickel content. This composition in 316 significantly increases corrosion resistance in most aggressive environments. Molybdenum makes steel more protected from pitting and crevice corrosion in chloride environments, sea water and acetic acid vapors. 316 has higher strength and has better creep resistance at higher temperatures than 304. When there is a risk of corrosion in heat-affected weld zones, the low carbon grade 316L should be used. It is used in the production of containers and tanks for chemical equipment exposed to particularly strong chemical influences. To protect welded joints, electrochemical passivation is possible. Steel grade 316 was used in some Ariston models.

Mark 444

– magnetic low-carbon steel, which does not contain nickel, but does contain molybdenum and titanium. The absence of nickel impairs the mechanical properties and weldability of this steel (it is impossible to use gas TIG welding). 444 steel is a cheaper alternative to 316L, but has approximately the same corrosion resistance as 316L steel. Therefore, this steel is used in water heating equipment with increased requirements for corrosion protection (including in water with a relatively high chlorine content). This grade of steel is used by manufacturers: Oso, Ariston Industrial series.

How to replace a magnesium anode with your own hands

Let's look at how to unscrew the parts yourself:

- Disconnect the equipment from the network. Turn off the machine if there are contacts leading to it.

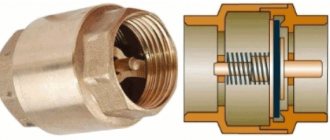

- Drain the water. The fastest way to do this is through a check valve. Turn off the water at the main valve, unscrew the water hoses and turn the check valve.

- In Gorenje models, the magnesium part is located on top. To avoid removing the boiler from the wall, simply lift the top cover. If this is not possible due to its proximity to the ceiling, you will have to remove the housing.

- In other models you need to remove the bottom cover. To do this, unscrew the mounting bolts and remove the latches.

- If the heating element is attached to a flange, unscrew the nuts and screws and pull out the flange. Sometimes the heater needs to be pushed in first and then removed from the tank.

- The anode is unscrewed from the stand next to the heater.

How to select a new element? If you don't know what to replace the old one with, take it to the store. The part must be selected according to the thread diameter. For example, in the Thermex Flat Plus model the number is M4.

Install in reverse order.

Average service life

Most water heaters do not come with a replaceable system. They do not provide any kind of warning system that the anode needs to be replaced. To check the condition of the water heater, you must first dismantle the tank, then unscrew the anode and inspect its appearance. If the magnesium balance is less than 20%, then it needs to be replaced. A used electrode looks wrinkled. To avoid disassembling the water heater, it is recommended to make notes about replacing the electrode. After a year, the device needs to be replaced again.

What is this device?

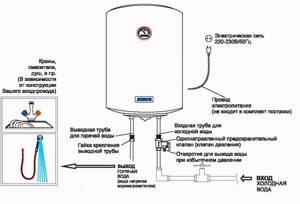

For owners of country houses, the answer to the frequently asked question: What is a water heater does not cause any difficulties. Its appearance resembles a container of a certain volume in which a heating element is mounted. The main task of any such device is to heat water. Today there are several models that can operate on different power supplies. They can be plugged into a power outlet and connected to the gas supply.

Water heaters are divided into two types:

- Household;

- Industrial.

The latter have greater power and are used in production. The most widely used systems are household systems. They are small in size and have lower productivity. These devices are installed where there is no hot water supply. These are mainly old areas of cities and villages where there is no centralized water supply.

Water heaters are also divided by fuel type:

- Electrical;

- Gas;

- Combined;

- Solid fuel;

- Solar;

- Liquid fuel.

The most common are gas and electric devices.

Useful tips

To ensure that your water heater is always in order and functions for a long time, you should use the following recommendations:

- Regardless of how long the boiler is used, constantly monitor its condition; if a slight hiss is heard during its operation, this indicates that the heating element is already covered with scale and requires immediate replacement;

- There will be a deposit of salt in any case, regardless of the quality of the water, but when there is too much salt, even the most reliable and high-quality anode cannot cope with it, so it is necessary to check it more often than once a year;

- From time to time, check the anode, or rather the indicator of its wear, the first check is approximately 6 months after its purchase, and if you find even minimal traces of wear, you should replace it;

- If the boiler does not have an anode, it is strictly prohibited to put it into operation. When replacing, some people often turn on the boiler without installing a new element, putting it off until later, but it is worth remembering that the anode is a cheap element, but the consequences of working without it will cost you much more;

- During the replacement process, all water valves must be closed and the power turned off.

Manufacturers of water heaters recommend descaling them at least once a year. With active use, it is possible more often, since constant use of boilers leads to the formation of plaque and scale that settles on the walls of the tank. Naturally, this leads to deterioration in the operation of the water heater, while preventive inspection and replacement of the magnesium anode will help to significantly increase the life of the boiler and save money on repairs.

How can you determine if there is a breakdown in the anode?

If you notice malfunctions in the operation of the boiler, a slowdown in the usual rate of heating water is a sign that the anode has ceased to perform its functions of protecting the heating element from scale. Typically, an 80-liter boiler needs 2-2.5 hours to fully heat water. If your heater begins to work slower, it is worth checking its condition. If it fails, you can also observe the following:

- During operation, sounds and hissing are clearly audible;

- the surface of the barrel may be excessively hot;

- the boiler consumes too much energy with minimal use;

- the amount of heated water has significantly decreased in volume, the boiler heats very slowly.

It happens that the boiler is not in use, but is turned on in standby mode and consumes energy of more than 400 kW per month - this is a clear sign of the need to check the anode for serviceability. All these are the main reasons why you may suspect a breakdown in the operation of the anode and decide to replace it.

Replacement

Replacing the magnesium anode is necessary only after the electric water heater has been inspected. It needs to be cleaned if it is not turned on, the time for heating the water increases and hissing appears when water is heated. If cleaning occurs infrequently, more electricity will be used to heat the liquids. Scale will appear on the heating element, which will then lead to difficulties when disassembling the water heater. If the heating element does not work, the anode will need to be replaced. It is located near the heating element.

If the first one has not collapsed, then there may be a small pin instead. In this situation, it is necessary to dismantle the anode residues. After this, you need to install a clean tank and a new device. Next, you need to assemble the electric heater in its original position. Assembly occurs in reverse. It is important to ensure that the tank gasket is intact and the electrical components are carefully insulated.

Cleaning the water heater and replacing the anode is easy. If you approach this work with all responsibility, then such a procedure can be performed with your own hands, without resorting to the help of craftsmen.

Instructions for cleaning the water heater and replacing the anode

Required tools:

- hose;

- basin or other container;

- cleaning agent;

- knife;

- screwdriver;

- magnesium anode;

- keys.

Next you need to carry out a series of sequential actions listed below.

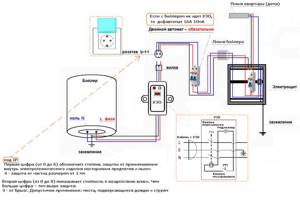

Shut off water and power supply

Disconnect the boiler from the power supply. To do this, remove the cover located at the bottom of the electric water heater and disconnect the wiring. If the device is connected to the network using a plug, remove it from the socket. If the electric water heater is connected by twisting, then it is equipped with an automatic circuit breaker. In this case, you need to turn off the machine.

Disconnecting the boiler from the power supply

We shut off the water supply to the water heater and pipeline. The pipes from the water heating tank must also be disconnected.

Draining water from the tank

First of all, we connect a hose of suitable diameter to the drain valve. We place the other end of the hose in the place where we will drain the water. We open the valve and the pipe through which cold water is transmitted. Water draining time is approximately 30 minutes.

Structurally, the electric water heater is designed so that cold water comes from below, and hot water is supplied from above. If you open a cold water tap, it will not flow because a vacuum is created inside the device. In this regard, it is necessary to create an air supply through the hot pipe.

Draining water from the tank

It is undesirable to drain water through the safety valve, since it may become clogged and subsequently become a Magnesium anode in an electric water heater is necessary to prevent corrosion processes in the boiler. The more effective the anti-corrosion protection, the longer the service life of the water heater. However, it is periodically necessary to descale the equipment and replace the anode.

Disassembling the device

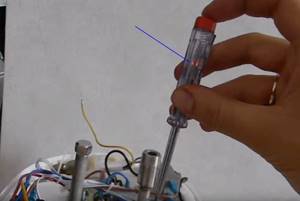

We place a basin under the electric water heater and use a Phillips screwdriver to unscrew several screws and remove the protective casing. In addition to screws, the casing can be attached with special latches. As a result of removing the casing, access to temperature sensors and heating elements opens. Remove the sensors and flange.

Removing the Sensor and Flange

The heating element (heating element) must be slightly loosened and pulled out.

Note! When pulling out the heating element, it is important not to damage the rubber gasket. If the electric water heater has not been cleaned for a long time, it may not be so easy to remove the heating element, since salt build-up may interfere with this. In this case, a screwdriver will come in handy to help clear the scale near the heating element.

In this case, a screwdriver will come in handy to help clear the scale near the heating element.

If the electric water heater has not been cleaned for a long time, it may not be so easy to remove the heating element, since salt build-up may interfere with this. In this case, a screwdriver will come in handy to help clear the scale near the heating element.

Cleaning the electric water heater

We clean the tank manually - direct the hose towards the tank and rinse it, not forgetting to place a container under the electric heater. We clean the tubular electric heater from scale with a solution of citric acid - 50 grams per 1.5 liters of water. We use a plastic bottle of appropriate capacity to create the solution. If necessary, the height of the bottle can be increased (using insulating tape) by adding another bottle. To avoid spilling the solution, such a structure can be placed in some container.

Cleaning the tank from scale and dirt

If the heating element has not been cleaned within 2 days, you need to replace the citric acid solution with a new one.

Replacing the anode

If the heating element does not function, you will need to change the anode. We purchase the required magnesium anode at a store or service point. The anode is located near the heating element. If it is destroyed, then only a small pin may remain in its place. In this case, you need to dismantle the remains of the anode. After this, you need to install a clean heating element, and place a new magnesium anode nearby. Next, we assemble the electric water heater into its original position. The assembly process is the reverse of the water heater disassembly process.

We pay close attention to the integrity of the heating element gasket and the insulation of electrical components

Magnesium anode for boiler

Note! All electrical contacts must be dry. The electric water heater is connected to the network only after filling it with water and testing it for leaks.

The electric water heater is connected to the network only after it has been filled with water and tested to ensure there are no leaks.

Cleaning the water heater and replacing the anode is not a technically difficult procedure. Therefore, if you approach the matter responsibly, you can carry out all the manipulations yourself - without the help of specialists.

Changing the protective anode of an electric boiler

In suspended vertical boilers of this type, the cathodic protection rod is installed on a common platform with a heating element attached to the bottom of the steel vessel. In horizontal models of water heaters, the heating element block is attached to the wall of the tank facing down.

Reference. The Thermex brand produces universal devices of the Optima series, equally suitable for vertical and horizontal installation. There, a flange with a heater and anode is mounted at the end of the tank. Universal boilers from Gorenje are made differently: the heating element is located at one end, the rod is at the other (see diagram).

To replace the anode element of the boiler with your own hands, prepare the following tool:

- a set of wrenches for nuts measuring 8…19 mm;

- magnetic screwdriver for Phillips slot;

- pliers;

- flashlight - illuminate from below and inside the container;

- sandpaper (to clean the heating element);

- hose for emptying the water heater;

- rags;

- wide plastic basin.

You will probably only need 1 key from the entire set, but its size will become known after removing the cover. The basin is necessary for cleaning - you don’t want to shovel dirt directly onto the floor or into the bathroom (if the boiler hangs above it).

Preparatory stage

What to do before disassembling the device:

- Turn off the power to the water heater in any available way - turn off the circuit breaker, remove the plug from the socket.

- Shut off the cold water supply to the inlet pipe of the storage tank.

- If the boiler is connected according to the above diagram, open the “hot” valve on the nearest mixer. About a liter of water will flow out from there, then open the drain valve and empty the tank into a bucket or directly into the bathtub.

When connecting the heater directly to the pipes, repeat the above steps, but drain the water through the standard safety valve, as the technician suggests in the video:

If the valve is clogged and there are no taps at the entrance to the boiler, you will have to use a radical method - unscrew the flexible hoses from the fittings of the device with a gas wrench. To drain water in portions, for example, using a bucket, periodically close the “cold” pipe with your hand - the flow will be interrupted under the influence of vacuum. Just remember to cool the drive to a comfortable temperature.

Disassembling and cleaning the tank

Now let's look at how to remove the heating element block from the water heater and replace the protective anode:

- Using a magnetic screwdriver, unscrew the screws securing the cover, remove it and move it to the side.

- If there is enough free length of wires, immediately remove the thermostat and sensor from the tube (held by the contacts). Otherwise, disconnect the power cable, then remove the fuser.

- Using a wrench, unscrew the block flange. The size and number of bolts depends on the modification of the boiler. For example, on Aristons there is a fastening with 5 10 mm wrench nuts or a spacer bar with one 14 mm nut.

- Place the basin and carefully remove the block. First, apply a little force - the rubber seal will probably stick to the landing pad. Up to 0.5 liters of water remains in the container, which will immediately flow out along with the dirt accumulated at the bottom.

- Using pliers, grab the old anode (or the thin rod that remains from it) and unscrew the part from the socket.

- After removal, proceed to clean the heating element mechanically - remove scale with a screwdriver and sand it with sandpaper.

Advice. To avoid mixing up the wires during the assembly process, before disconnecting, sketch out the circuit, or better yet, take a photo with your smartphone camera.

After disassembly is complete, you should take a moment and thoroughly wash the inside of the tank using kitchen products. To rinse, briefly open the cold water supply - the stream will wash away dirt from the walls and flow into the basin.

Corrosion of the water heating element

Why does the heating element body corrode and collapse? The fact is that the heating element in the boiler is equipped with a magnesium anode.

Without it, a galvanic couple is formed inside the titanium:

- tank - heating element

And with a magnesium anode:

- heating element - anode

Through this anode, all stray currents flow to the ground, gradually taking with them some part of the anode body. When it is completely destroyed, these currents begin to flow down the body of the heating element.

The growths on the heating element do not form evenly. Because of this, different parts of its copper shell acquire different expansion coefficients. As a result, surface tension is created, which breaks the shell of the heating element.

In many service centers, if the boiler breaks down completely, you may even be denied a warranty if you do not have a receipt for timely replacement of the anode.

Ultimately, corrosion becomes through and the working element burns out.

By the way, with the anode intact, the water from the tank may have a slight odor. When the smell disappears, this may be some kind of sign of corrosion of the electrode.

Modern models have special sensors that monitor the condition of the anode.

With timely replacement of the anode and mandatory cleaning, your heating element will actually last several times longer. Grounding the housing also increases the service life of the heating element by at least two times.

However, for some reason many people lose sight of this point. Meanwhile, during intensive work, it is recommended to clean the boiler at least once a year.

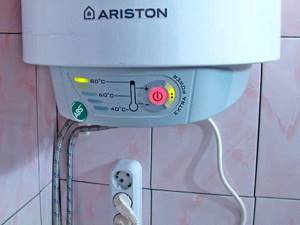

It cannot be said with certainty that some models, for example Electrolux, Ariston or Gorenje, have a longer service life than Thermex or Indesit. It all depends on many factors:

- amount of water consumed

- the average heating temperature of this water, its chemical composition

- how the plug is inserted into the socket (where the phase comes and where the zero)

- is there grounding or not?

Ways to eliminate the smell of hydrogen sulfide from boiler water

A water heater tank may contain sulfate-reducing bacteria in both the sludge and water at the same time. But usually, one type of bacteria is the most active. Depending on what type of sulfate-reducing bacteria in the boiler tank is causing the smell of hydrogen sulfide, the method of getting rid of the smell is chosen.

Eliminating bacteria that live in the sludge layer

It may be enough to do at least one of the following:

- The easiest way is to raise the water temperature above 70 °C and use this water for three days until the smell disappears. In the future, constantly keep the water temperature in the boiler above 55 ° C. It is recommended to periodically increase the temperature above 70 °C.

- Regularly clean the boiler to remove scale and sludge deposits on the bottom.

- Take measures to reduce the amount of organic contaminants in tap water. To do this, you can change the water intake horizon - instead of a well, take water from a well or deepen the well. Install filters to purify tap water from mechanical and organic contaminants.

Eliminating bacteria from boiler water

To suppress sulfate-reducing bacteria living in boiler water, it is often enough to do the following:

- Try raising the water temperature above 70 °C and using this water for three days until the smell disappears. In the future, constantly keep the water temperature in the boiler above 55 ° C. It is recommended to periodically increase the temperature above 70 °C. But this method does not always help. Bacteria living in boiler water are often resistant to these temperatures.

- The activity of sulfate-reducing bacteria is suppressed if the molecular hydrogen content in water is reduced. For this purpose, the operating mode of the tread protection is optimized. Replacing a magnesium anode with an aluminum one eliminates “overprotection,” which reduces the hydrogen content in water. Read about replacing anodes at the beginning of this article.

General measures to combat bacteria in the boiler

The following measures can suppress the development of bacteria in both water and sludge:

- Aeration, saturation with air, of tap water leads to an increase in the content of free oxygen in the water. As a result, the anaerobic habitat of bacteria changes to one less favorable for their life.

- Disinfect tap water using methods whose antibacterial effect persists for a long time after treatment - chlorination, etc. Ultraviolet water treatment is not suitable for this.

- Take measures to reduce the amount of soluble sulfur compounds in tap water. To do this, you can change the water intake horizon - instead of a well, take water from a well or deepen the well. These measures should be selected after testing the water source for sulfate content.

More articles on this topic:

⇒ Hot water supply for a private country house ⇒ Either cold or hot water comes from the boiler ⇒ Solar collector - water heater for a house, swimming pool

More articles on this topic

- Frost index on the map

- Gas detector - detector of domestic and carbon monoxide leaks in the house

- How to properly make natural ventilation in a private house

- Frame house with communications - features and advantages

- Ground ventilation heat exchanger in a private house

- Dew point, vapor barrier and ventilated wall gap

- Heating schemes with a solid fuel boiler

- Choosing façade plaster for finishing the exterior walls of a house

Checking the serviceability of the heating element

How can you understand that the heating element has burned out and it’s time to change it? If the indicator lights light up and show that the boiler is on, but it does not heat, this is only an indirect reason.

The issue may be wiring, poor contact, or a thick layer of scale. The main check should be carried out with a multimeter by measuring the resistance. How to do this is described in detail in the article “Connecting the boiler to the electrical network - errors and rules.” You can also check the presence of potential between zero and the body of the device. When the heating element is destroyed, its current-carrying spiral comes into contact with water, and through it the voltage reaches the boiler body.

It is better to take measurements with a multimeter in AC voltage measurement mode. The dial can show either a couple of tens of volts or all 220V. This already indicates a 100% malfunction and the need to change the heating element.

If you have an RCD, as it should be in a normal circuit, then it starts to knock out when you try to turn on and supply power.

A correct RCD (not 30mA, but max 10mA) is a mandatory element of the circuit when connecting any boiler, otherwise the voltage can easily appear on the faucet, tap water in the kitchen and in other unexpected places.

What is stainless steel

First, let's understand what stainless steel is. Stainless steel is an alloy steel that is resistant to corrosion in the atmosphere and aggressive environments. The reason for the corrosion resistance of stainless steel is explained mainly by the fact that a thin film of insoluble oxides forms on the surface of a chromium-containing part in contact with an aggressive environment, and the condition of the surface of the material, the absence of internal stresses and crystalline defects, is of great importance. The resistance of stainless steel to corrosion directly depends on the chromium content: with a chromium content of 13% and above, the alloys are stainless under normal conditions and in mildly aggressive environments, more than 17% are corrosion-resistant in more aggressive oxidative and other environments. There are several classes and hundreds of grades of stainless steel with different properties.

Draining water and disassembling the water heater

And so, when you decide that you still need to open it, the first thing you do is turn off the power by unplugging the plug from the socket. Then drain the water from the titanium. To do this, turn off the hot and cold water supply taps.

Unscrew the cold water hose, placing a suitable container for drainage.

If water does not flow from the removed hose, this indicates an air lock. We need to remove it. To do this, just slightly loosen the nut at the point where the hot water pipe connects to the pipe.

Next, open the safety valve and release water through it. If the valve suddenly becomes clogged, you will have to twist the entire valve. Water will flow out of the boiler in a continuous stream.

After draining, completely unscrew both valves from the titanium (hot + cold) to open the bottom cover and gain access to the heating elements.

There are modern models where the bottom cover is collapsible and to remove it, it is not necessary to touch the valve. It comes in the form of a plastic insert secured with several screws.

Disconnect the power wires, first remembering or marking with a marker which one is connected where. Better yet, draw a diagram. As a rule, all wires are colored and this will be easy to do. Otherwise, you can get confused in such a pile of wiring.

If you don’t want to draw anything, then just take a couple of photos on your cell phone. You will know exactly the location of all elements and wires.

After this, unscrew the nuts or screws securing the heating element itself around the perimeter.

You can unscrew them in any order, but you need to screw them in the same way as the engine head or the wheels on a car, that is, crosswise.

If you immediately tighten a nut all the way, this will cause the flange to bend and there will not be the required tightness. Consequently, the gasket will not hold and will leak.

Carefully pull the heating element out. It will be all covered in rust, and from the magnesium anode, except for a thin burnt piece of iron, there may be nothing left at all.

Flushing

After the heating elements are removed, the boiler itself must be rinsed with clean water to remove all the rust and dirt that has accumulated inside. Therefore, for a quality replacement, the water heater still has to be removed from the wall.

Rinse the insides with an ordinary tap hose. Pour only a little water, since the boiler with a volume of 50-80 liters will still have to be lifted manually to drain all the scraps. Some people add citric acid when washing, others don’t.

Washing tip: It is best to rinse the tank in the bathroom, placing it vertically on a linen board. Twist the watering can from the mixer shower and insert the hose into the hole where the heating element was.

Filling with water and checking functionality

Connect the hoses and open the cold water and begin to fill the tank. The hot water tap must also be open to allow air to escape. At the same time, make sure that there are no leaks anywhere. As soon as water comes out of the “hot” tap, the boiler is full. There is no need to close the tap immediately; let all the “slurry” spill out and finally flush the tank and pipes.

Only when clean water comes out do you turn off the mixer.

After this, the water heater must stand for at least half an hour or an hour so that condensation leaves all surfaces and there is confidence that there are no leaks.

You can then apply voltage by plugging the titanium into an outlet. To check the operation of the thermostat, use the control knob to force the adjustment to maximum and minimum.

In this case, the boiler on/off light should light up.

If the boiler operates quietly, without making any sounds, and it is not clear to you whether it is heating or not, you can check the energy consumption using the meter.

At maximum heating power of the heater, the counter will spin or blink much faster. This means that the heating elements work as they should. The entire repair with the purchase of spare parts will cost you around 1500-2000 rubles. In any workshop that calls a plumber to your home, they will ask for at least 3,000-5,000 rubles for such work, and this does not include materials.

So self-repair can save you a significant amount of money, the main thing is not to make some mistakes.

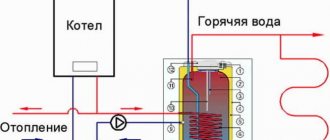

We service the indirect heating tank

Let us note right away that the replacement operation here is much simpler than in electric boilers. Since the anode in an indirect water heater is located at the top and is in no way connected with other elements - a heat exchanger or an additional heating element in combined models.

Combination heating apparatus design

How to change the anode in a floor-mounted indirect heater:

- Turn off the cold water supply.

- There is no need to empty the tank, you just need to relieve the pressure. Open the “hot” valve on the mixer and drain 2-3 liters of water through the drain valve of the device, then cut off the DHW line.

- Using an open-end or spanner wrench, unscrew the plug on the lid of the container and pull it out along with the old anode.

- Unscrew the rod with pliers, screw a new one in its place and tighten it by hand.

- Insert the element into the tank and tighten the plug with a slight force so as not to squeeze the rubber sealing ring. It is advisable to check the latter after disassembly and, if necessary, replace it.

Advice. Before disassembling, it is worth turning off the boiler circulation pump so that the coolant does not circulate through the coil.

The rod is changed in a similar way on stationary water heaters equipped with a gas burner. The work order is shown in the video:

If it is necessary to service the wall-mounted version of the “indirect”, the water will have to be drained. The protective rod is removed using the technology described in the previous section about electric models.

Errors when replacing heating elements

1Tighten the heating element fastening nuts in a circle.

As discussed in this article, this method will lead to bending of the flange and subsequent leakage. That is, you will have to remove the boiler from the wall again, unscrew everything and reassemble it again.

2Application of sealant when installing the gasket.

No sealants should be used when replacing heating elements. Tightness should be created only by uniform pressing of the gasket material.

3Using an old gasket.

No matter how intact it may seem, in any case, every time you open the heating elements, be sure to replace the sealing elements.

4Replacement of heating element only without replacement of magnesium anode.

Even if you don’t find a suitable anode in your store, never install heating elements inside the tank without it. Not only does this reduce the service life of the heating elements, but ultimately it all ends in burning out the body of the boiler tank.

Then a leak appears, without the possibility of recovery or repair.

True, some expensive boiler models have titanium anodes with electronic potential removal.

They just don't require replacement. Therefore, before unscrewing anything, carefully study the product data sheet.

5Control board.

When washing the tank and draining the water, be very careful; you can accidentally flood the electronic control board with the display, which is located on the side of the housing, with water. In this case, the boiler simply will not start after switching on.

You will search for the cause for a long time, ringing all the terminals, but it will lie literally on the surface. You can soak this board even with the boiler upside down.

Look closely at the hole where the lone control wire goes.

Water can simply flow through it directly to the electronics. So, it is best to close this hole initially, even before pulling out the heating elements, by pushing any seal there.

Why is hydrogen sulfide dangerous?

Hydrogen sulfide (H2S) is poorly soluble in water. Flammable. The concentration limits of ignition in a mixture with air are 4.5-45% hydrogen sulfide.

Hydrogen sulfide is very toxic. Inhaling air with a small content of hydrogen sulfide causes dizziness, headache, nausea, and with a significant concentration it leads to coma, convulsions, pulmonary edema and even death. At high concentrations, a single inhalation can cause instant death. When inhaling air with small concentrations, a person quickly adapts to the unpleasant smell of “rotten eggs” and it ceases to be felt. A sweetish metallic taste appears in the mouth.

When inhaling air with a high concentration due to paralysis of the olfactory nerve, the smell of hydrogen sulfide almost immediately ceases to be felt. Hydrogen sulfide is also used for medicinal purposes, for example in hydrogen sulfide baths.

The appearance of hydrogen sulfide in boiler water is not only an unpleasant odor and a health hazard. A solution of hydrogen sulfide in water is a very weak hydrogen sulfide acid. Hydrogen sulfide turns the water in the boiler tank into acid , albeit a very weak one. An increase in water acidity accelerates the electrochemical dissolution of the magnesium anode for sacrificial corrosion protection.