To provide the coolant with the opportunity to expand when heated, it is necessary to install an expansion tank in the heating system. This is a very important event. It will protect pipes and radiators from unnecessary loads and significantly increase the service life of the functional elements of the autonomous heating system.

We will talk about how the expansion tank works in open and closed circuits. We'll show you how to install it correctly in both versions of the system. In our article you will find a description of the technology for connecting this backup capacity and useful recommendations.

Purpose of the tank

At school, in physics lessons, they were told that solid substances are capable of expanding when they are heated, and liquid and gaseous media increase in volume. Water is practically incompressible compared to gas. If a liquid is heated in a closed container, the pressure inside the container begins to increase because the medium has nowhere to expand. As a result, a closed vessel may rupture. This is exactly the process that occurs in the heating circuit of a boiler unit with a coolant reservoir.

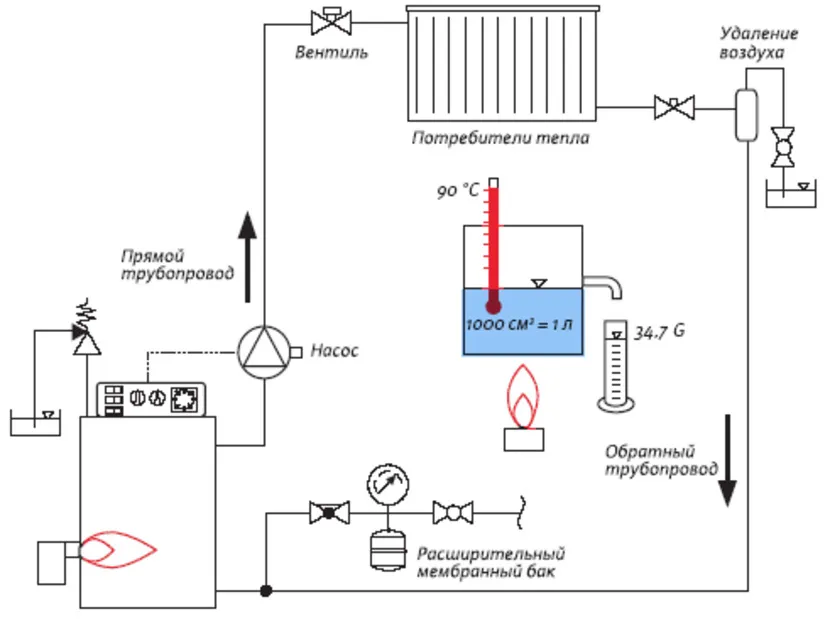

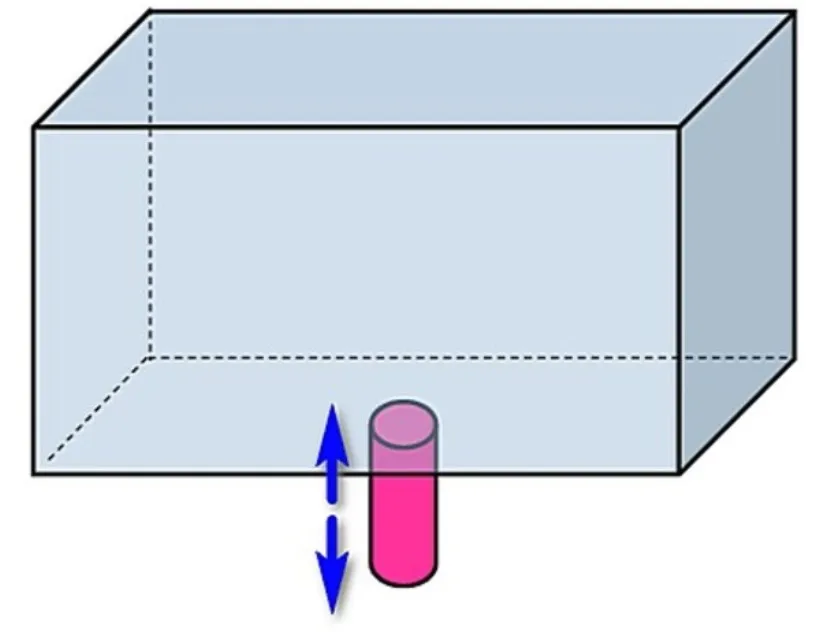

The thermal expansion of water is characterized by a nonlinear coefficient. Thanks to this indicator, you can find out how many times the volume of a liquid increases when it heats up by one degree. A well-known physical experiment illustrated in the figure below will help you understand the principle of expansion of water:

Experience in demonstrating the thermal expansion of liquid Source www.climatik.su

The picture on the left side shows a vessel with one liter of water. Liquid fills the reservoir up to the overflow hole. The ambient temperature is + 4 °C. This value for water represents the zero reference point. The figure also shows a measuring container located under the overflow pipe.

On the right side of the picture the same container is shown, but in a heating state. This leads to an increase in water temperature. Therefore, the density of the liquid decreases. In this case, the mass of the medium remains constant. However, the liquid increases in volume. After the water temperature reaches + 90 °C, about 36 ml of liquid accumulates in the measuring vessel. This quantity is excess volume.

Many homeowners will say that this is a small amount of coolant. However, when considering the issue of expansion of water on a larger scale, the increase in the volume of liquid upon heating cannot be neglected. For example, the temperature of 100 liters of aqueous medium increases. With this amount of liquid, the excess volume will be 3.5 liters.

An increase in the volume of the liquid medium during heating in the thermal circuit of a country house Source msklimat.ru

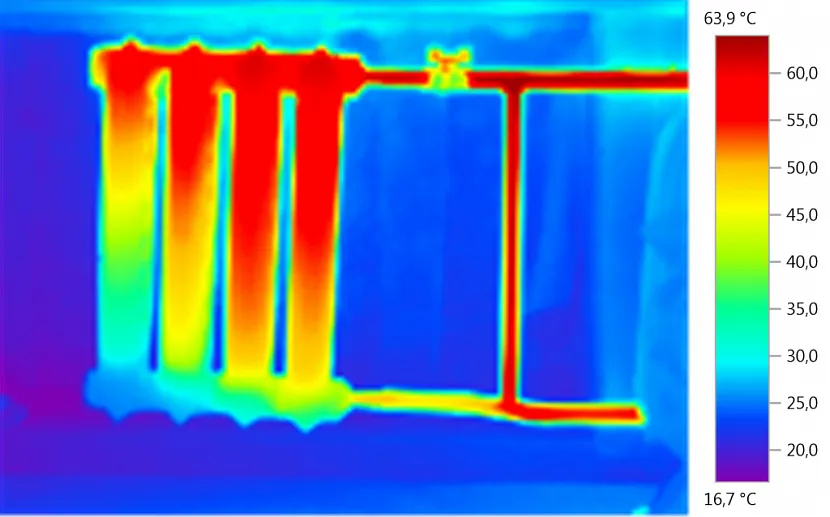

The water environment in the home heating system is heated from 20 °C to 90 °C. As the temperature rises, the heat-carrying liquid expands. When an expansion tank is not installed in the circuit, a significant increase in pressure in the network is observed. Therefore, the liquid seeks outlet at unreliable points in the system. This is the boiler unit itself, one of the radiators, a falling or return pipeline.

The situation could be corrected by a safety valve used to discharge excess hot coolant. However, it will still not be possible to establish the operation of the circuit in the house, because there is an important nuance. During heating operation, the coolant is periodically cooled. After expansion, the liquid takes on its previous volume, but as a result of the discharge of water, space in the heating circuit is freed up, which is occupied by air. This leads to the appearance of air pockets, which are a headache for all heating systems. They prevent the circulation of heat-carrying fluid in the network.

An air lock in the heating radiator of a country house prevents heat from being distributed throughout the entire battery Source sovet-ingenera.com

Air pockets are removed by bleeding air from the batteries (radiators). When installing a safety valve, you have to regularly add new coolant, and this is not economically viable. After all, heating new water requires significantly more money compared to heating the heat-carrying liquid returning to the boiler unit from the heating circuit of a country house.

An expansion tank for heating is the only correct solution to ensure stable operation of the system. The device is made in the form of a container covered with red enamel and connected to the network through one pipe. The reservoir is used to compensate for excess pressure in the heating circuit of a country house.

What will result from an incorrectly selected expansion tank?

If, when heating the coolant in the heating system, the volume of the expansion tank is not enough, then the excess coolant will be drained through a special emergency valve. After the system cools down again, there will be a lack of coolant. Plus, the pressure in the heating system will drop.

Boilers and other equipment have a lower pressure threshold, above which the heating simply will not start. Regular topping up of coolant will help correct this situation.

If this situation occurs constantly, the risk of equipment failure increases. Therefore, it is better to select the expansion tank correctly.

Types of containers for expansion of heat-carrying liquid

The expansion tank for heating is created in different shapes and dimensions. Its parameters are determined by calculation. The characteristics are also influenced by the type of system in a country home. It is possible to purchase vessels in the form of so-called tablets or cylinders.

Expansion tank in the form of a tablet Source teplowood.ru

Different types of vessels differ in design and method of use. There are two types of containers available to homeowners:

- open type vessel;

- closed tank equipped with a membrane.

Manufacturers also produce closed containers without a membrane. Experts do not recommend using this type of device in the heating circuit of a house. Such vessels represent an ill-conceived design of expansion tanks. In them, the functions of an elastic partition are performed by air. Therefore, the air actively penetrates into the heat-carrying liquid, which is categorically unacceptable for the normal functioning of the system. Moreover, the water level in the tank will constantly increase. As a result, a situation will arise where it will not be possible to compensate for the expansion due to the filling of the entire volume of the closed vessel.

Open and closed models

In total, there are three types of expanders: open, closed membrane, closed membraneless. The latter are already difficult to find: there is practically no demand and very few devices are produced. This is due to the fact that the absence of a membrane layer inside a closed expansion tank means the need to install additional equipment - a compressor. The unit will regulate the operation of the tank and will not allow special gas and incoming moisture to mix inside the device.

In any case, before installing the expander, you need to familiarize yourself with the characteristics of each model in order to make the right choice.

Open expander type

The open type provides the possibility of quick access to the internal cavity, for which a special hatch is installed at the top.

Such a unit must be installed at the highest point of the house, above all heating networks, most often it must be installed in the attic, roof, and sometimes installed on the landing. It looks like an iron box as it is made of metal sheets.

There is a special outlet pipe on the side to drain the liquid. As the open model is used, the removed moisture will partially evaporate, which will require periodic refueling. This is not always convenient, but otherwise there will be a shortage of water and the heating supply will stop.

Closed type heating expander

There must be a certain amount of liquid inside the heating network for the system to function properly. If this is not enough, the main boiler will not have enough energy to maintain the minimum permissible pressure, and it will turn off. Therefore, it is necessary to regularly check the moisture level and refill the tank in a timely manner.

Closed expansion unit

The closed expander is more convenient to use, as it is completely sealed and does not require refilling with water. It looks like a sealed cylinder with a seam in the middle, which divides the unit into two parts: air space, a place for excess water. Inside it, along the seam line, there is a hard rubber membrane, which rises when the pressure in the pipes increases, drawing water inside the tank. After stabilizing the load level, it produces a return action, pushing the liquid back into the heating network.

Connecting to a closed heating system is the most convenient option, since the equipment does not require a special location: you can install the tank anywhere in the house, the placement height does not in any way affect the operational properties of the equipment.

The absence of open areas prevents water evaporation, which frees the owner from constant refueling: the heating system will work properly.

Closed expander

In case the networks suddenly become overloaded, it is better to periodically check the device’s performance. If the pressure is high and the owners of the house are not there to regulate the load, the safety valve will operate: excess liquid will be discharged from the heating network. It is not recommended to allow this to happen, because now you will have to disassemble the installation, add water and put everything back together.

In case of damage to the membrane layer from such incidents, rubber replacement is allowed, which is done through the mounting flange.

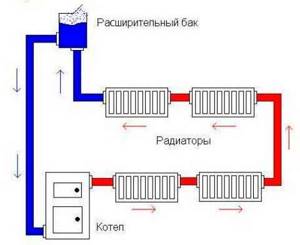

Open expansion tank

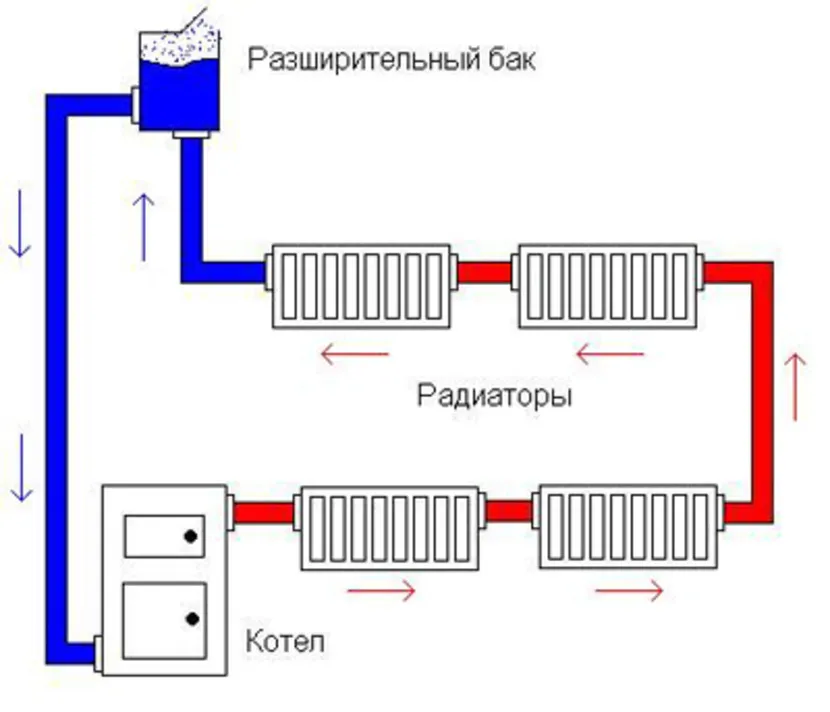

The vessel is mounted in the system of the same name. The thermal circuit of a country house is closed, but not isolated from the atmosphere. The network is not a sealed system. Therefore, excess pressure cannot arise in it.

Open heating system in a country house Source otoplenie-expert.com

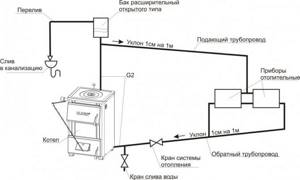

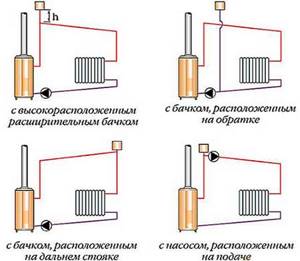

Installation features

An open-type heating expansion tank is a vessel installed at the highest level of the circuit. If you mount the tank in a different location, then the coolant will pour out of the vessel according to the law of communicating tanks. An open tank is often installed on the supply side. Its location at the top point also allows you to effectively remove air from the network, in which air is always present dissolved in water. Moreover, it often turns into a normal gaseous state. Air in the circuit is also formed due to the chemical interaction of the coolant and the material from which the pipelines and heat exchange devices are made. If you neglect the removal of air masses from the system, then an individual radiator or an entire section of the heating network may stop working. Installing an open tank allows you to remove gas bubbles from the water environment of the heating circuit. In other words, the device functions as an air vent.

An open expansion tank of the heat-carrying fluid on the supply pipe of the heating system Source stroyday.ru

Depending on the design features of the heating system, the expansion vessel can be installed on the return line of the network. However, even in this situation, its insertion is carried out at the highest point of the contour. A vertical pipeline is laid to the installation point of the device. If the tank is installed on the return line, then the tank does not serve as a gas vent. For this reason, during the installation of the system, valves are additionally installed on the batteries and the supply pipeline at its highest level.

Connecting the expansion tank

The location for installing such a tank is chosen where the intake of excess coolant will be as efficient as possible.

When figuring out how to properly install an expansion tank in an open heating system, you need to pay attention to three important points:

- select the highest point of the contour;

- place the tank directly above the heating boiler so that they can be connected by a vertical pipe;

- provide overflow in case of an accident.

The requirements are explained by the peculiarities of the functioning of gravity heating systems. The hot coolant moves from the boiler through the pipes and reaches the expansion tank, losing a significant part of the thermal energy.

An open expansion tank must be installed at the highest point of the heating circuit, as well as directly above the heating boiler

The cooled water naturally flows through the pipes into the heat exchanger for new heating. The location of the tank at the highest point allows air bubbles trapped in the system to be removed from the coolant.

Calculating the tank capacity for an open system is easy. The total volume of coolant in the circuit is measured, 10% of this indicator will be the required figure. Most often, the expansion tank is installed in the attic.

This is especially convenient if you need a large capacity, because a significant amount of coolant may be required for normal operation of a gravity system. A small expansion tank can even be placed in the kitchen under the ceiling, if this allows it to be connected correctly to the heating boiler.

If the expansion tank is installed in an unheated attic, it should be insulated to maximize the conservation of thermal energy in the house

If the device had to be placed in the attic, you need to take care of its insulation. This is especially important if the attic is not heated. Although the coolant enters the tank already cooled, you should not neglect the opportunity to save some of the thermal energy. In the future, heating will require less time and fuel, which will significantly reduce heating costs.

To connect the expansion tank and overflow, you need to run two pipes into the boiler room. The overflow is usually connected to the sewer, but sometimes home owners decide to simply take the pipe outside, and an emergency discharge is made outside.

The configuration of the expansion tank can be any; such devices are made of sheet iron, plastic tanks and other materials that tolerate heat well

After the location for installing the expansion tank has been selected and its volume has been calculated, you need to find and install a suitable container. Small tanks are mounted on the wall using brackets or clamps.

Large containers must be placed on the floor. There is no need to seal this tank hermetically, but you will still need a lid. It is necessary to protect the coolant from debris.

Some of the water from an open system evaporates, the lost volume must be replenished. The coolant is usually added to the open circuit through the expansion tank.

This point must be taken into account when choosing a place to install the device. It is not always convenient to carry water into the attic with a bucket. It is easier to provide in advance for the installation of a supply pipe that leads to the expansion tank.

Video description

Watch the video where you can install expansion tanks:

Capacity options for expansion of heat-carrying liquid

The open expansion tank has a certain volume and has a simple design. The top of the vessel is covered with a leak-proof lid. It prevents debris and dust from entering the coolant. Due to leakage, the pressure in the open type expansion tank always corresponds to the atmospheric value. Depending on the design, one or more pipes are cut into the container.

Open type expansion tanks Source teplowood.ru

See also: Catalog of companies that specialize in installation of engineering systems

Homeowners have access to open-type tanks of various sizes. They are completely ready to use. For their manufacture, galvanized or stainless steel sheets are used. The use of such material eliminates the formation of corrosion. Specialized companies often offer to manufacture devices. They also use sheet material. In some cases, ready-made products can even be used - these are metal or plastic barrels into which pipes are cut.

There are several common open tank designs. One of the simplest devices is a tank with a pipe cut into the bottom. It is with its help that the connection to the heating system of the house is made.

A simple diagram of an open tank for coolant expansion Source otoplenie-expert.com

This scheme does not allow the coolant to circulate through the vessel. When using this type of tank, the heating circuit is filled with water up to the middle mark of the tank. If there is a change in the volume of water in the system, this will be reflected in the level of liquid in the vessel.

It is important to regularly monitor the water level in the tank. After all, the environment tends to evaporate. Therefore, you have to replenish the water supply in the circuit. If this is not done, then air blockage of the system will occur or so-called “airing” of the batteries in the house will occur.

To visually monitor the liquid level, a pipe is placed on the side of the tank in the lower part for connection to a transparent hose located vertically. It allows you to see how much water is in the container.

Expansion tank with a transparent hose to control the water level Source cotlix.com

Often an open heating system is created so that the vessel is located in the attic. This allows you to hide the tank and not spoil the interior of the house. This arrangement eliminates the need to use a ladder or other device to inspect the container. After all, it will be on the same level as the floor of the attic.

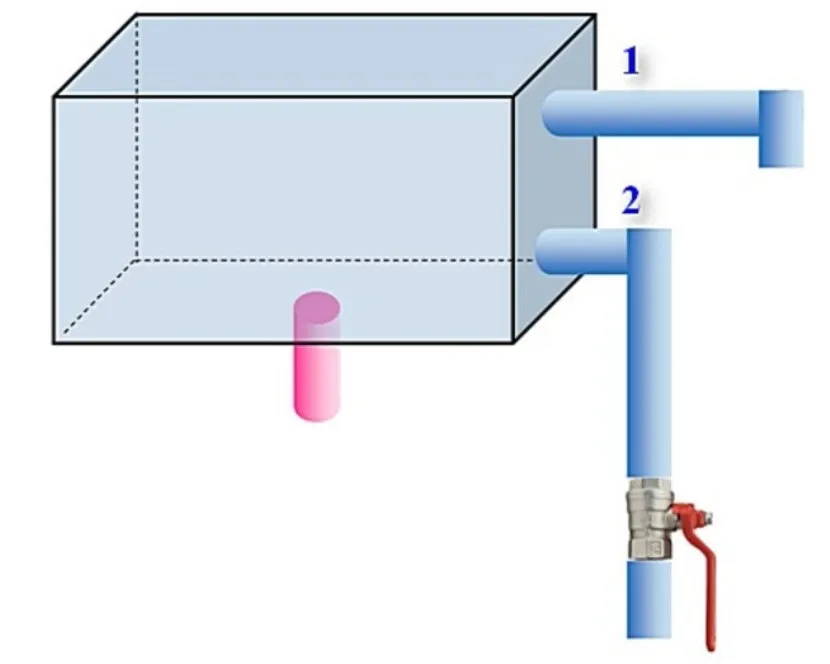

There is also another way to visually monitor the water level in the vessel. To do this, specialists cut two end pipes into the tank. One of them allows you to determine the maximum filling of the tank. It is located in the upper part and functions as an overflow element. A hose or pipeline is connected to this pipe and laid to the sewer. In some cases, an overflow is arranged, with the help of which excess liquid is discharged into the soil. It all depends on the design of the system and the wishes of the client of the design and installation organization performing the work on installing heating in the house.

Reservoir with a pipe for overflow and control of the minimum liquid level Source stroyday.ru

The lower pipe is used to connect a pipe laid into a room in a private home. A ball valve is installed on the pipeline in a convenient location for the customer. This pipe allows you to determine the minimum liquid level in the tank. The owner of the house needs to open the tap to find out whether a system subscription is required. It will be needed if water does not flow from the pipe. Liquid is added to the container until it begins to flow out through the upper pipe.

Required tank volume

There are no strict rules regarding the volume of the tank for expansion of coolant in an open heating system. You can estimate the amount of increased liquid in the heating circuit if the following values are known:

- coefficient of expansion of water with increasing temperature;

- the volume of the heating network in the house;

- temperature regime of the heating system.

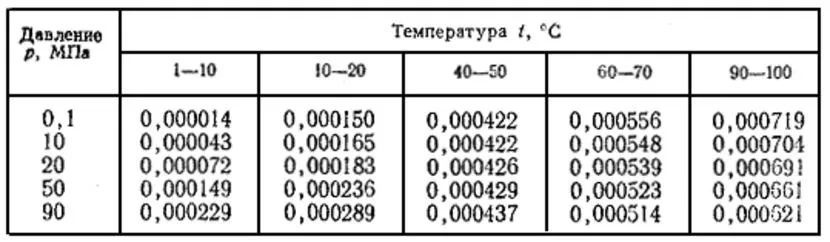

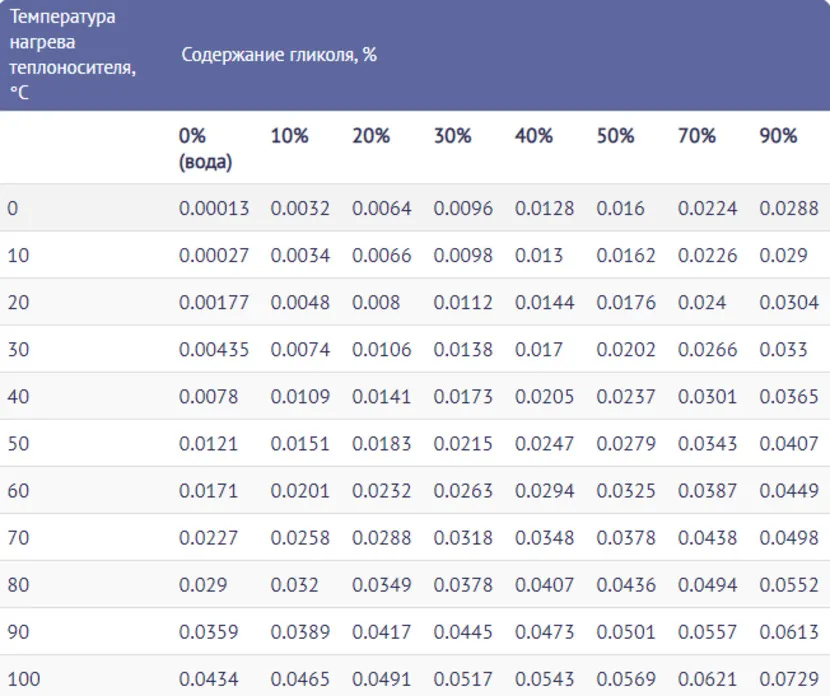

The coefficient of thermal expansion of water at different pressures and temperatures is given in the table:

Source msklimat.ru

See also: Catalog of companies that specialize in electrical equipment

If the volume of water in an amount of 100 liters increases by 3.5 liters when heated to 90°C, then in percentage terms the increase is 3.5%. One would assume that a 5 liter tank would be enough for the system. However, practice shows that this volume will not be enough. When calculating the expansion tank, it is necessary to take into account that the tank must be at least a quarter full so that air does not enter the circuit. Next, it is necessary to add volume to compensate for the expansion of the liquid and the empty space above the overflow pipe. Experienced specialists install a tank whose volume is equal to 10% of the amount of water in the heating system of a country home.

Differences from a hydraulic accumulator

The design of sealed expansion tanks is similar to the design of hydraulic accumulators, however, the purposes of these devices are different. The expansion tank compensates for the expansion of water that occurs due to heating in the heating system. The hydraulic accumulator accumulates the volume of water under pressure in a water supply system that has a pressure pump in order to reduce the frequency of activation of this pump and smooth out water hammer. In addition, more often than not, inside the accumulator there is a bulb made of food-grade rubber. It is this that is pumped with water; as a result, the water does not come into contact with the tank body. The expansion tank for heating systems is made with a membrane made of technical rubber. It divides the housing into two compartments, and the coolant has contact with the housing.

Types of hydraulic accumulators

For heating systems, manufacturers produce tanks that differ in membrane design.

Membranes for expansion tanks are divided into:

- balloon;

- diaphragm.

The diaphragm membrane is a permanent partition made, most often, of thin metal or elastic polymer.

The main difference between this option is its small internal capacity and the ability to compensate for minor pressure drops in the system.

If such a tank malfunctions, it must be completely replaced.

The advantages of such devices include simplicity of design, reliability in operation and low price.

The balloon-type membrane is a container installed inside the tank made of high-quality rubber that is resistant to significant temperature changes.

A flange fastening of the membrane is used, which allows for its simple and quick replacement (how to install pipeline shut-off valves with your own hands is written here).

The advantages of balloon membranes include:

- wide range of operating pressures at which the use of a sealed expansion tank is allowed;

- the ability to replace the membrane , thanks to which repairing the device (about a manual pipe cutter for plastic pipes is written here) becomes faster and cheaper;

- ease of setting the minimum (set) pressure for any system.

The model ranges of tanks with replaceable membranes produced by manufacturers cover a wide range of not only pressures, but also volumes.

At the same time, devices are available in various designs, for horizontal and vertical installation, with mounting on building structures or installation on legs, which significantly increases the flexibility of designing heating systems.

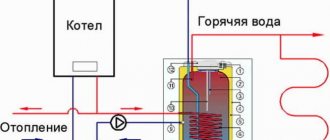

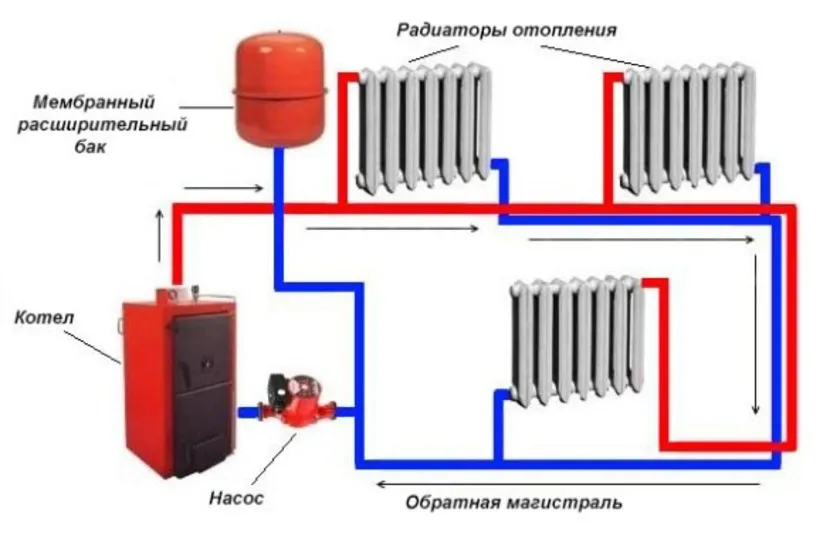

Closed tank

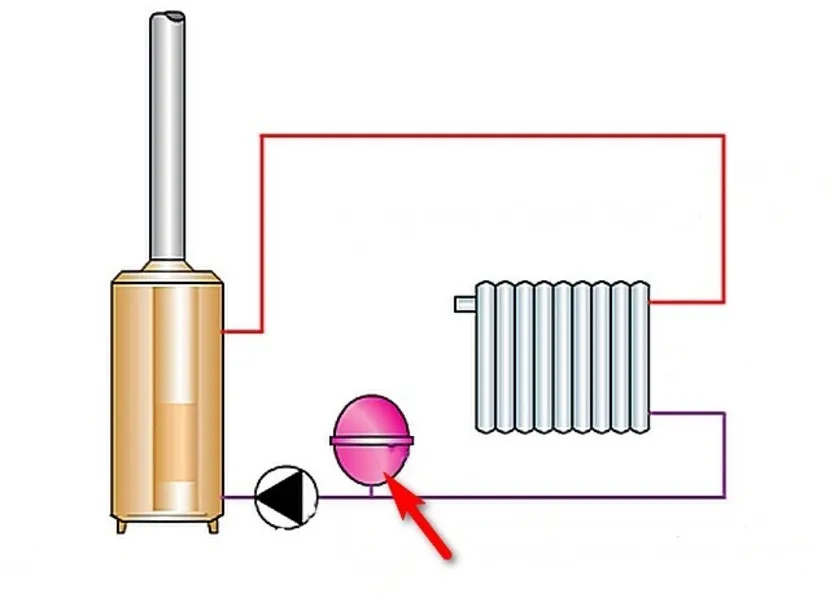

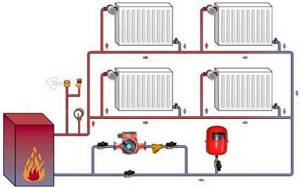

The advantages of an expansion tank for closed-type heating include the small size of the device. This element can be installed on any part of the system. The drawings often show the tank on the return pipe next to the pump. This arrangement of the tank is considered the most optimal.

Location of the tank in a closed version Source teplo-as.ru

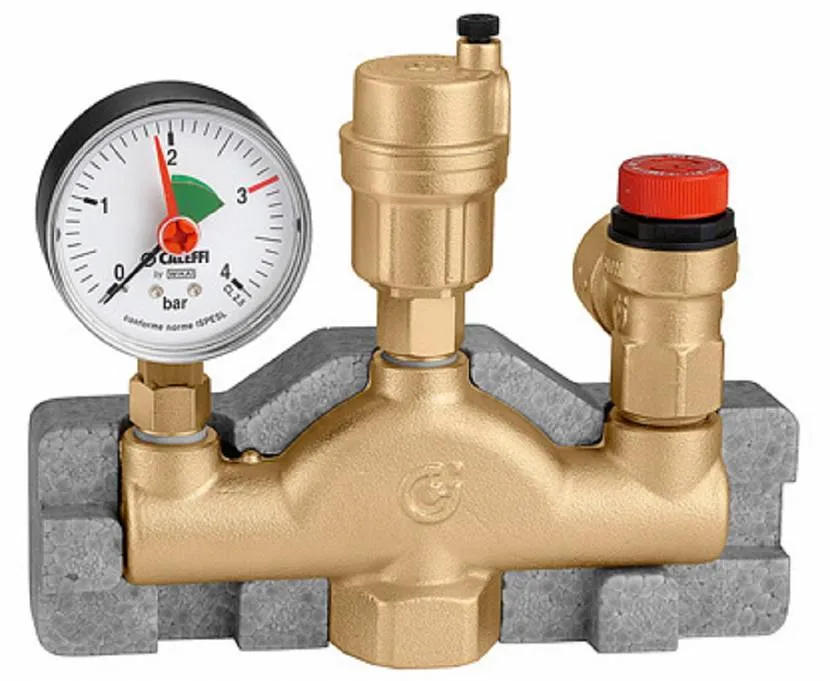

The expansion tank for heating is a closed type - a sealed vessel. For this reason, the pressure in the network increases only to a specific value. This is the reason for the additional installation of a special group of devices that ensure safe operation of the circuit. Such equipment includes the following devices:

- a safety valve that is set to open when the pressure reaches a limit value;

- automatic air vent;

- a device for monitoring and measuring pressure (pressure gauge).

Installation of all listed devices in a closed heating circuit is required. This is the only way to ensure the required level of security when operating the network.

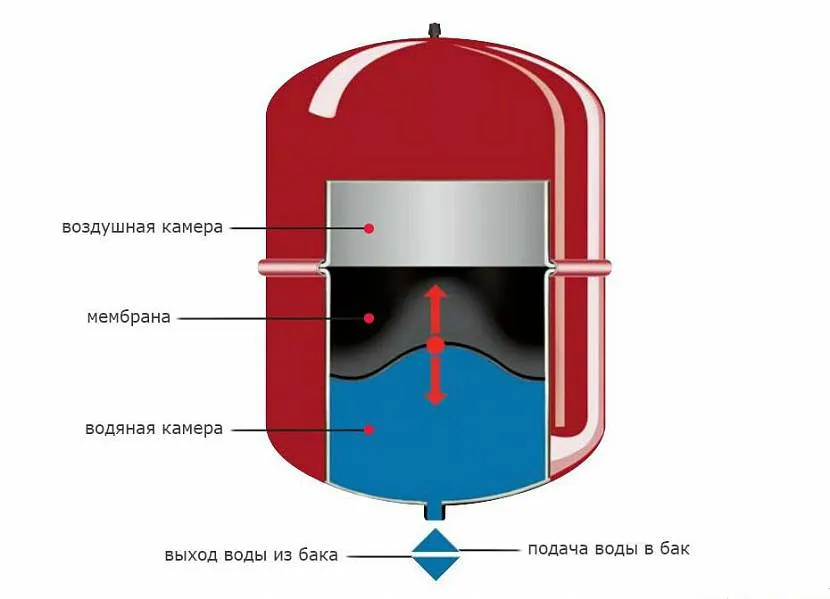

Design and principle of operation of a closed tank

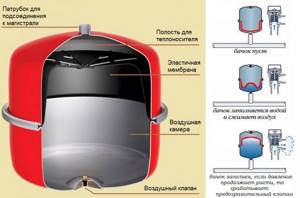

The vessel has a sealed design and has two chambers. The compartments are separated by an elastic partition (membrane). One of the chambers is designed for heat-carrying liquid. The second compartment is used for air under operating pressure.

Most closed tanks have a classic shape in the form of a red cylinder. However, containers in other designs are available on the market. They can have a vertical or horizontal orientation. The metal body of the devices is made by stamping and has a prefabricated structure. The internal cavity is treated with an anti-corrosion substance.

Approximate design of most banks for expansion of coolant Source msklimat.ru

The expansion tank for a closed heating network is always made in red. This prevents it from being confused with a vessel intended for installation in a water supply system. Such equipment is called hydraulic accumulators. They are made in blue color, but structurally they are practically no different from heating tanks. However, it is not possible to replace one device with another because the devices are designed to operate at different temperatures. Moreover, their elastic partitions are created from rubber material of different qualities. The pumped pressure in the expansion tank of the water supply will differ from the same value of the heating tank. After all, the water supply system and heating network operate at different environmental pressures.

Hydraulic accumulators and a tank for expanding coolant fluid Source sovet-ingenera.com

Setup Guidelines

After installation and insertion of the device into the heating network, it is required to configure it. It is to provide the necessary pressure in the air chamber to match your system. This is necessary to avoid water hammer in the network; they can be created by the membrane of the tank while the coolant cools and its excess is pushed out of the chamber. The operation is performed in the following sequence:

- when the installation of a closed tank is completed, the system is filled with cold water;

- using Mayevsky valves and taps, air pockets are removed from pipes and radiators;

- a pressure gauge measures the pressure in the system, and then in the air chamber of the tank;

- By bleeding or pumping up, the pressure in the chamber is set 0.2 Bar lower than the pressure in the system.

Now that the expansion tank has been correctly installed and then configured, you can start the boiler. The pressure in the container will increase equally smoothly as the coolant heats up and cools down.

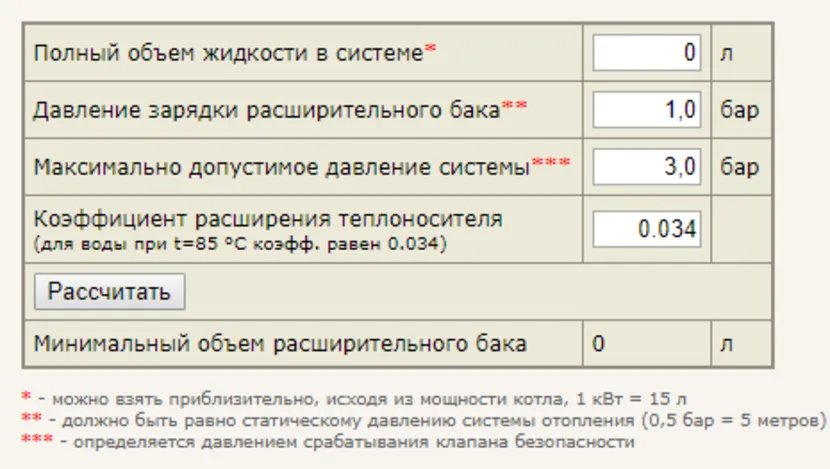

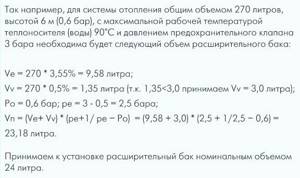

Calculation of the volume of a closed tank

The volume of the membrane expansion tank is the main value that influences the choice of tank for a specific heating network. For accurate calculations, use the formula:

V = (Vс * k) / D,

in which the following notation is used:

- Vс – volume of heat-carrying fluid in the circuit;

- k is the expansion coefficient of the coolant as its temperature increases;

- D is the value that determines the efficiency of the expansion tank.

If the coolant is antifreeze, then its expansion coefficient is affected by the temperature and the amount of glycol additives contained in the liquid. The required values are selected from reference literature.

The expansion coefficient of antifreeze as its temperature increases in the table:

Source otoplenie-expert.com

To determine tank efficiency indicators, the formula is used:

D = (Рм – Рн) / (Рм +1).

It uses the following letter designations:

- Рм – the highest pressure in the thermal circuit of a country house, usually not exceeding 3 atm. (most often the value corresponds to the valve response pressure in emergency situations);

- pH – pressure created in advance in half of the tank with air (calculated taking into account the height of the network: for every 500 cm take 0.5 atm.).

Experts recommend installing an expansion tank for closed-type heating, the volume of which was calculated exactly according to the formulas. The result obtained should correspond to approximately a tenth of the total amount of heat-carrying liquid.

To simplify obtaining the desired result, an expansion tank for heating is often selected using an online calculator. Professionals advise using the services of at least 3 sites for calculations. This will allow you to determine a more accurate value of the desired value.

An example of an online calculator for calculating the volume of a tank Source stroyday.ru

The online calculator allows you to perform approximate calculations of the volume of the container for expansion of the heat-carrying liquid. The homeowner can indicate in the program the exact amount of liquid in the network or an approximate value, focusing on the power of the boiler unit. Heating experts recommend, regardless of the result of calculating the expansion tank for a closed heating system on the calculator, choosing a tank with a minimum volume of 12 liters.

Requirements and recommendations for installing a membrane tank

Small volume tanks are wall mounted

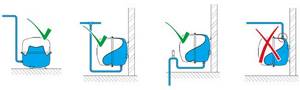

You can install the equipment yourself by following the instructions. When working, adhere to the installation requirements:

- The first stage is choosing a location. It is necessary to ensure free access to the tank for maintenance. A good place is considered to be the section of the return line between the pump and the boiler.

- To ensure the safety of a closed circuit, you will need to install a safety valve, an air vent, a pressure gauge and a thermometer.

- A drain valve is installed in front of the inlet pipe to drain water from the tank.

- Filters must not be installed in the area connecting the tank and the heating system.

- Before connecting the equipment, check the pressure of the gas space. If necessary, pump up air.

- The tank should not be located in a room with sub-zero temperatures.

The tank is securely mounted on the wall, and no additional load should be placed on it. Large volume models are mounted on the floor. A connection diagram with the inlet pipe located at the bottom is recommended. Experts advise making a detachable connection between the pipe and the drain valve in front of it. If necessary, the expansion tank can be easily dismantled.

The manufacturer specifies the requirements for the amount of antifreeze in the coolant. The stated proportions must not be exceeded.

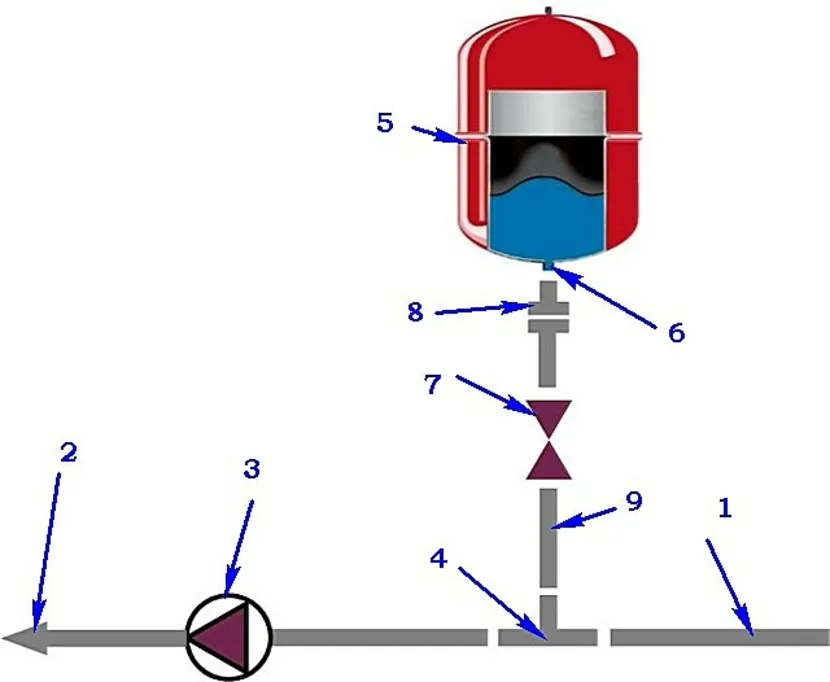

Installation of coolant expansion tank

Specialists install an expansion tank in a closed heating system sequentially and subject to certain rules. The container is mounted so that the threaded inlet pipe (6) is located at the bottom. This arrangement allows you to remove a maximum of gas bubbles from the coolant.

The classic installation is to install a tank (5) on the return pipe. The distance to the boiler unit (2) is reduced to the minimum possible, but the tank must be inserted before the pump (3) so that its operation is not disrupted by flow turbulence.

Conventional layout of a closed tank Source cotlix.com

A tee (4) must be installed on the return pipe. The method of its installation is influenced by the type of pipes. Pipe fittings (7) are installed between the tee and the tank. It allows you not to drain water from the network when repairing or dismantling the tank. The fittings are mounted at a height that is convenient for the homeowner. For this purpose, a piece of pipe (9) is used, connecting the return line of the circuit and, for example, a ball valve. Such a section can be parallel or curved. An American (8) is installed between the ball valve and the threaded pipe to obtain a detachable connection. This will allow you to easily dismantle and install the tank if necessary. After all operations are completed, the pipeline fittings are opened and all connections made are checked for leaks.

Conventional location of a closed tank Source samodelino.ru

How to connect an expansion tank

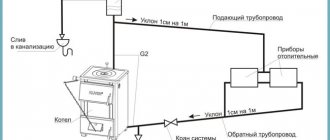

How to reliably connect an expansion tank in an open system!? An open-type heating system is characterized by the fact that the movement of coolant in it is ensured by convection.

The operating principle is as follows: the coolant heated by the boiler unit is delivered directly to the highest point of the system, as a result of which it flows by gravity into the heating radiators and, when cooled, returns to the boiler through the return pipeline. There is always dissolved oxygen in water, which is released through the process of convection, which means that air bubbles tend to rise.

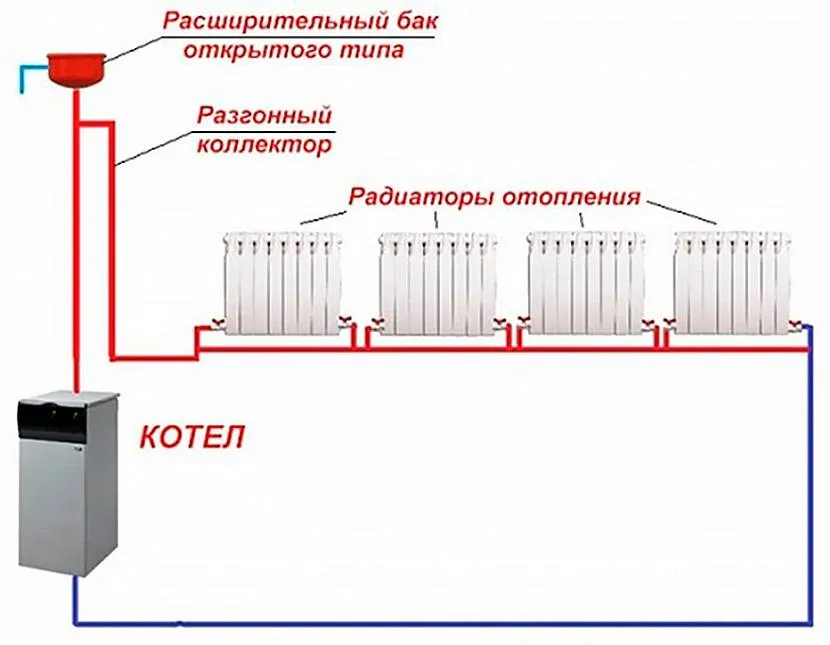

When considering this diagram, it becomes obvious that the only possible installation location for the expansion tank is the top point of the system. For a single-pipe system, this is the upper part of the accelerating manifold.

Connection diagram for a membrane tank in an open type heating system

As a tank, you can use any container of a suitable size made of heat-resistant material. A lid (not sealed) is needed only to protect it from debris getting into the system. If you don’t have a small metal barrel at hand, the tank is welded from sheet steel 3-4 mm thick.

The tank must be installed in compliance with certain rules, in particular

:

- the tank must be placed above the boiler unit and connected by a vertical riser through which heated water is supplied;

- It is recommended to insulate the body of the tank to reduce heat loss, especially if the tank is located in an uninsulated attic of the house.

Over time, the water from the tank evaporates and needs to be topped up periodically. This can be done using an ordinary bucket. If the tank is installed in the attic, where it is difficult to reach, a water supply pipe is led to the installation site of the tank, and an emergency overflow is organized to avoid flooding the house with hot water in the event of an emergency. The emergency overflow pipe is usually connected to the sewer network, but owners of private houses often simplify the task by leading it outside through a wall or roof.

Expansion tank in a closed heating system

Equipment for the heating system is selected at the design stage, taking into account the requirements for the performance of the boiler unit, the length of pipelines and the volume of coolant involved. A diagram is being developed that indicates the installation locations of all system elements, including the expansion tank. In a closed heating system, it is necessary to use a membrane device.

Expander in a closed heating system

When linking a project to an existing boiler room, it is important to take into account the following points

:

- The tank should be placed in such a way as to ensure normal access for installation and further maintenance. Floor-standing models are not recommended to be installed close to the wall.

- If the device is mounted on a wall, it is advisable to place it at such a level that you can easily reach the air spool and shut-off valve. Typically, the tank is placed under the ceiling of the room only if it is not possible to mount it at a convenient height.

- The supply pipe should not be placed on the floor across the passage or suspended at human height.

- The pipes connected to the expansion tank must be secured to the wall. It is important to avoid a situation where the load from them and from the shut-off valves falls on the tank pipes. Separate mounting of pipes and taps makes it easier to replace the expansion device in case of failure.

At the equipment selection stage, it is necessary to calculate the required volume of the expansion tank. The minimum value of this parameter is 1/10 of the total volume of liquid circulating in the system. It is permissible to use a larger tank. But a tank that is not large enough can become a source of problems, since it is not able to compensate for the increased pressure in the system.

Rules for placing the expansion tank

For approximate calculations of the volume of coolant in the system, you can take the thermal power of the boiler unit as a basis. On average, 15 liters of liquid are used per kilowatt. Exact calculations are made taking into account the length of pipelines, volume of radiators, etc.

Important! Many models of gas and electric boilers are mini-boiler rooms, that is, they are immediately equipped with a pump for forced circulation of the coolant, as well as an expansion tank. There is no need to purchase a separate tank if the parameters of the built-in membrane tank are sufficient to ensure the functionality and safety of the existing heating system.

When purchasing a membrane expansion tank, pay attention to whether the selected model has a safety valve, thanks to which excess pressure is automatically released. If one is not provided for by the design of the device, you should buy a safety valve separately and install it in close proximity to the tank.

Where is the best place to put the tank?

The optimal place for installing a membrane tank is a straight section of the pipeline, which is characterized by laminar flow of water, that is, the absence or minimal amount of turbulence. A convenient place is the spill area near the circulation pump.

Note! The expansion tank of a closed heating system can be installed at any convenient height. There is no need to place it at the highest point, since it functions solely as a surge protector. Unlike an open-type heating system, the air accumulated in the pipeline is released using special valves - air taps.

From a hydraulic point of view, it is best to install the membrane tank on the return line so that the circulation pump is located between it and the boiler. In this case, the pumping equipment will function optimally.

Scheme of possible tank placement

If desired, the tank can be placed on the supply line; this will not affect the operational properties of the heating system. But the membrane tank itself will not last a relatively long time, since the polymer membrane will be in constant contact with the coolant that has just been heated to 90 degrees, and not with water that has cooled to 45-60 degrees and returned through the pipeline.

Attention! Installing a membrane tank on the supply line is highly not recommended if the heating boiler is solid fuel. There is a risk that due to an emergency, the water in the boiler will begin to boil and steam will enter the tank. Water vapor, like air, is a compressible medium, which is why the membrane will not be able to compensate for the thermal expansion of water.

Rules for calculating tank capacity

Any type of dilator will be effective only if the volume is chosen correctly. To do this, take into account the ability of the liquid to expand during the heating period. Water in heating rings expands by at least 3% of the total volume of the water system, antifreeze - by almost 5%.

Liquids belong to the category of incompressible media, so the tank must provide them with a sufficient reserve for thermal expansion with some margin. Provided that the circuit is completely filled with coolant, even thermal expansion in the calculated volumes can lead to liquid discharge through the safety valve and spillage of coolant onto the floor.

Therefore, so that exceeding the volume of expanding coolant does not lead to accidents, closed tanks for small circuits in private houses are purchased so that their volume is equal to 10% of the total volume of coolant circulating through the system. This rule is valid for systems with a capacity of up to 150 l.

If more than 150 liters of coolant moves along the heating ring, then the capacity of a closed tank is calculated by multiplying the total volume of liquid by its expansion coefficient at specific operating temperatures in the system.

To the obtained value you need to add the size of the water seal, i.e. the volume of coolant formed in the tank as a result of standard static fluid pressure. For large heating rings, this figure is usually equal to 0.5% of the total coolant volume; for small ones, with a capacity of up to 150 liters, it is taken to be 20%.

The resulting amount is multiplied by a correction factor determined from the values of preliminary and final pressure in the heating system. The preliminary estimate is that there is 1 bar per 10 m of contour height. The final pressure is formed as a result of the operation of the system.

Calculation of the volume of a closed tank for large complex heating structures looks like this:

The calculations used: Vn – nominal volume of a closed tank; Ve is the volume of the coolant during thermal expansion (calculated using the formula Vsystem×n%, where n is the coefficient of thermal expansion of the coolant); Vv – water seal; po – preliminary pressure; pe – final pressure indicator, equal to the maximum pressure value of the safety valve minus 0.5 bar

Open type capacity is not strictly regulated by regulations, but there is a rule: the volume of the open tank to the overflow pipe should be 3.5 - 4% of the total volume of coolant in the heating circuit.

This estimate is sufficient for a small country house, but a building for permanent residence will require a more accurate calculation. First of all, you will need to find out the total volume of the heating system.

Options for calculating the total heating capacity

This indicator can be determined with varying degrees of accuracy in three main ways. Firstly, based on the boiler’s passport data. Thus, about 15 liters of liquid are needed per unit of boiler equipment power. To obtain the necessary data, you will need to multiply 15 by the boiler power indicated in the data sheet.

Secondly, you can find out the volume using a water meter when filling the system. As you fill, the amount of liquid used is taken into account. This is a more accurate and troublesome option.

The third method involves calculating the total volume of all elements of the heating system. This is the most accurate option. The capacity of the heat exchanger of the boiler, radiators, convectors, and measuring instruments can be determined from the passport characteristics. To calculate the pipe capacity, data from the table is used.

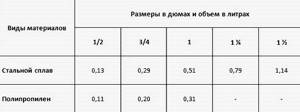

The table shows the pipe sizes in inches and their volume in liters per 1 meter, which is used to summarize the total volume

The table shows the volume of pipes per meter of length, made from the most popular and modern materials. The internal diameter is indicated in inches from 0.5 to 1.5 units.

Another method that claims to be highly accurate is calculation using the formula:

Vtotal = π x D2 x L/4,

Where:

- π – equal to 3.14;

- D – indicates the parameters of the internal diameter of the pipes;

- L – indicates the length of the system pipeline.

After receiving the necessary data, they are summed up and the total volume of the system is obtained, which is used in further calculations.

Steps and formulas for the full cycle of calculations for designing and organizing the heating of a private home are given here. We recommend that you read the useful information.

Selecting an expansion tank according to the table

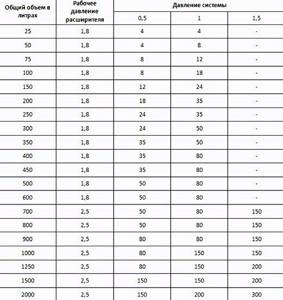

If you have the necessary data, the optimal expander option can be selected using the table of volumes and design pressure.

The total volume of the system is calculated according to the specified method; the pressure parameters are relevant only for closed modifications and are indicated in the equipment data sheet.

The data from the table allows you to select the expander volume from 4 to 300 liters

This option does not require special calculations other than calculating the total volume of the system. Using the table greatly simplifies and speeds up the selection of an expander with the required tank capacity.

Using calculation formulas

If the table data is not enough, it is possible to calculate the required capacity indicator yourself.

To do this, use the following formula:

Vb = Vc xk/D,

Where:

- Vb – denotes the desired expander capacity;

- Vc – total system capacity;

- k is the expansion coefficient of the liquid when heated;

- D – expander efficiency coefficient.

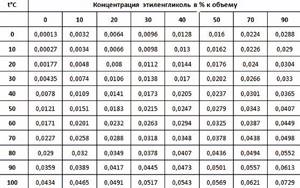

Of the data necessary for the calculation, the coefficients k and D remain unknown. The first is a tabular value, and the second is calculated using a separate formula.

A temperature expansion table also exists and is used. It allows you to determine the coefficient for systems with water or antifreeze. The value is not linear; it changes when heated, depending on the presence and concentration of glycol in the liquid.

Using these data, it is possible to determine the parameters of the coefficient of expansion of the liquid when heated (k), necessary for calculating the volume of the expansion cylinder

For water, the concentration of ethylene glycol is taken as “0”; for antifreeze, the concentration is determined according to the data declared by the manufacturer. The heating temperature is considered operational for a specific system.

To independently calculate the efficiency coefficient of the expansion tank, use the formula:

(Qm – Qb) : (Qm + 1),

Where:

- Qm is the maximum pressure of the system according to the safety valve’s nominal response threshold;

- Qb is the preliminary pressure in the air chamber of the expander according to the data sheet.

If the latter parameter is unknown, it is measured during inflation or by bleeding through the nipple of the cylinder.

Other calculation methods

In addition to independent calculations using formulas and tables, there are alternative methods. An accessible calculation option is the help of an online calculator.

There is no shortage of network resources offering online calculation of the required value. They are easy to find by keyword

Another option to obtain the necessary data is to contact professional designers. This is the most reliable way, but the accuracy of the information obtained will be quite expensive.

The following article dedicated to these issues will introduce you to the rules for installing and connecting closed and open type expanders.

Closed tank

Another type of expansion tank is a hermetically sealed container. Inside it is a membrane made of rubber. It can be either a balloon or a diaphragm. The form is not of fundamental importance. The only difference is that a balloon-type membrane tank holds more liquid, although not by much.

The principle of operation of a membrane tank is as follows. A certain amount of air or nitrogen under pressure is pumped into the back of the bulb. The level of the latter is adjusted depending on the specific model of the expansion tank.

When the coolant heats up to a certain temperature, the pressure in the line begins to increase, as a result of which the rubber membrane stretches and allows liquid to pass inside the container. When the water cools, the process occurs in reverse.

Closed tanks are used in heating systems with forced circulation of coolant. A spool is mounted in the upper part of the equipment, with the help of which air is pumped in, and liquid is supplied from below.

The installation location of such an expansion tank is not of fundamental importance. It is most convenient to place the equipment in the same boiler room where the heating boiler is located. If the latter belongs to the gas variety, then the tank can even be built into the heat generator, since it has very modest dimensions.

In addition to ease of placement, a closed expansion tank has several other advantages:

- it does not need insulation, unlike its open counterpart,

- the coolant does not come into contact with the atmosphere, and therefore the metal parts of the boiler are much less susceptible to corrosion processes.

The disadvantage of the equipment lies in the very membrane that controls its operation. Its service life is only about ten years, and this element cannot always be replaced with a new one. Quite often it is necessary to replace the entire expansion tank.

However, this point can be taken into account when purchasing equipment. The products of some manufacturers provide the ability to remove the old membrane and replace it with a new one. If you choose the appropriate model, then if the rubber bulb cracks or becomes deformed, you will not have to replace the entire tank.

In general, there are closed-type tanks in which the installation of a membrane is not provided at all. Its role is played by air, but this is an unacceptable drawback, because this leads to the occurrence of corrosive processes. In other words, expansion tanks without a membrane are the worst option you could come up with.