Hello, dear friends! Today on the agenda is such a process as grouting the joints of the brickwork, as well as subsequent decorative jointing.

Many buildings are erected and clad using ordinary bricks, masonry, clinker tiles, etc. But still, the main emphasis will be on bricks.

The material has a number of positive properties, including good thermal insulation, as well as a decorative function. To make the building look even more attractive, grout is used. This can be a mortar like Polyplast PSM-081, or ordinary cement mortar. The mixture can be prepared white. For others, colored grout is suitable. Preparing the mixture is not difficult. The main issue is the process of filling the seams itself.

Grouting brickwork joints

Grouting is the application of a special additional layer to the surface between the bricks after they are laid. This material is used for vertical or horizontal wall laying, after the excess mixture has been removed from the joints of each brick, but small irregularities remain. Grouting, or as it is also called jointing, is used precisely for such purposes. The brick laying turns out beautiful and even. The layer that will protect from moisture has increased tightness and strength. As a result, the service life of the structure increases.

They try to carry out the jointing immediately after the construction has been completed. Of course, there are also cases when this work is done several years later. In this case, the wall has already absorbed a large amount of moisture and is gradually collapsing.

Grouting is done only on those walls on which plaster or cladding will not be applied in the future.

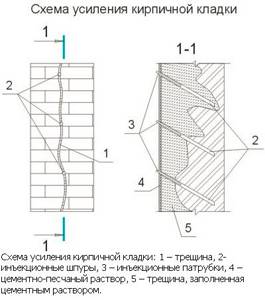

Restoring cracked masonry

Before laying a whole brick to replace the removed one, first all the cracks in the depths of the masonry are clogged. Where the cracks are too large, you can mix the mortar with brick chips so that it does not float. It is more convenient to do these operations with gloved hands, without any tools.

To install a whole brick, mortar is generously applied to the place under it, including on the vertical plane in depth. The solution should be applied with a large margin if tile adhesive is used - it has sufficient elasticity, all excess will come out. The bricks are pressed in, and excess mortar is removed from the outside.

As a rule, on a cracked wall, when installing new bricks, the vertical joints are much thicker than 1 cm. Here everything depends on the size of the cracks: if they are too wide, then additional “chucks” are inserted into the large vertical joints - narrow pieces cut out of brick. If the divergence of the seams is not too large, then a clean solution is sufficient. Actually, using the same method, cracks where dismantling was not carried out are sealed.

However, it is quite difficult to drive mortar into “unbroken” cracks. The same plastic bottle can help here, but without a cap-nozzle. The solution is made thinner and filled into a bottle. Next, the neck of the bottle is placed against the crack, and the solution is squeezed out by twisting the bottom of the plastic container. Agree, the operation seems dreary and ineffective, but it will be possible to hammer the crack less deeply by hand or with a trowel. Nevertheless, even with such complex manipulations it is possible to clog cracks no deeper than a few centimeters.

There is a better alternative to sealing unstitched cracks. All mother-in-laws are first injected with silicone sealant from a gun, and then covered with a solution. Naturally, you need to leave a few centimeters under the solution in the crack, closer to the surface, and also cover it after the silicone has dried.

In general, you need to work based on the individual characteristics of the cracks, the desired result and your capabilities.

Well, in conclusion, I would like to repeat: repairing cracks is more of a cosmetic operation than a strengthening one. Of course, to some extent the masonry will become stronger, but it will be far from its original state. Before cosmetic repairs, you need to solve the problem with the foundation (strengthening and repairing, installing a reinforcing belt), otherwise you can repair cracks every year, just like road workers uselessly patch holes in asphalt.

Why do they do it?

Experts call the procedure for processing the seams of brickwork jointing. The grouting process is the application of an additional layer to cement joints. Performed if the walls are not planned to be subjected to additional cladding work. The jointing has a decorative function and also has practical characteristics.

Decorative properties are as follows:

- highlighting the texture of lines and brick patterns;

- combining vertical and horizontal lines;

- strict and clear appearance of the facade.

Practical properties include:

- increasing the level of sound insulation;

- protection from excessive moisture;

- improved heat retention;

- increased service life of the building;

- tightness.

Brick joint grout seals all cracks and covers the cement layer.

This procedure is not able to eliminate errors in the form of uneven masonry, excess cement, curvature, or stains on the wall.

Some buildings are operated without jointing, so it is necessary to note the main purpose of this procedure. As mentioned above, in this way it will be possible to increase the aesthetic perception at the first glance at the building. By resorting to this method of decoration, you can mask differences in color that may arise if the solution was mixed gradually.

Grouting for external use helps prevent the destruction of the cement mixture, thus extending the life of the building and postponing the need for major repairs for a long time. This result can be achieved by protecting the joints from excess moisture, which has a destructive effect on the cement mortar.

Repairing minor damage

Home coating and grouting

Old walls are often built with lime mortar, so this is what is used when restoring brick walls.

Other reasons to use lime mortar:

- high ductility.

- good adhesion to old masonry elements.

- slow hardening.

- no cracks during operation.

To restore seams and seal cracks in brickwork, restorers recommend MM-01 masonry lime mortar.

It is necessary to re-process all external joints to avoid differences in the color and structure of the old and new mortar.

Benefits of grouting

- Improving the appearance of the building facade. The grout has a rich color palette. Using contrasting colors, you can emphasize the harmony of the masonry.

- Protection from moisture not only the seams, but also the walls of the house, which increases their service life.

- The sound and heat insulation properties of floors are significantly increased.

It is not always possible to see buildings with similar decoration. If the masonry is subsequently to be plastered or faced, grouting is not required. Advice. When subsequently decorating the seams for masonry, you must use only intact and flawless material, and the seams must be the same in thickness. There are craftsmen who make horizontal seams somewhat thicker than vertical ones. This is a design decision.

Types of syringe guns

The devices are used for filling and rubbing seams. They are different from each other. But essentially there are only two types of them:

- Guns that work with stone.

- For working with ceramic tiles.

They are equipped with a special mechanism that squeezes out a specially prepared mixture, like in a syringe. But different models may differ from each other in the following characteristics:

- The material from which all components of the pistol are made.

- Case color.

- Various volumes of cylinders for solution.

- Availability of additional components.

Models with a large cylinder have a reinforced body that can hold high pressure inside. Usually all elements are galvanized.

That is, the larger the cylinder volume, the more parts wear out. This is also due to the fact that at some sites we have to work in an accelerated mode. This affects the operation of the pistol.

The feasibility of using jointing

In construction, grout has decorative and practical significance. The first option has the following properties:

- Emphasize the correctness of the lines.

- A new color is added to the created design.

- The drawing turns out clear and bright.

- The appearance of the structure is improved.

- The masonry is more neat and expressive.

- Grout combines horizontal and vertical lines.

Important! Beginning craftsmen need to remember that processing seams does not eliminate surface defects: excess cement, curvature of walls, fragments of hardened composition on bricks.

Practical value:

- Protection of cement composition from the destructive effects of moisture.

- Increased sound insulation characteristics.

- Significant extension of the protective properties of the cement base.

- Strengthening the thermal insulation of the building.

- Increasing the strength of brick masonry.

- Strengthening the density of joints.

- Additional tightness.

- Hiding small cracks and crevices.

You can seal the holes if the masonry is done carefully. If there are decorative seams, use whole bricks, without flaws. It is necessary to ensure that the solution has the same thickness on all parts of the surface.

According to accepted SNiP standards, the width of the horizontal and vertical space left should not exceed 15 mm. Grout is used for decorative, building material, gypsum tiles. A special composition is also used for facade panels and natural stone.

Final processing of a brick wall

Why is it needed?

Grouting the seams of brickwork is the alignment of the seams formed during the laying of bricks, their decorative design, possibly applying an additional layer of mortar of a different color, which will effectively emphasize the correctness of the lines and the neatness of the masonry itself. This is a unique way of finishing walls, thanks to which they will become more expressive and neat. The grout combines the horizontal and vertical seams formed during the bricklaying process into a single whole.

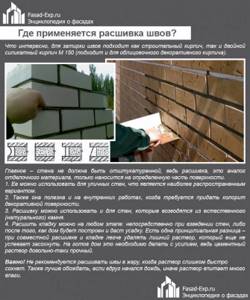

Where is seam stitching used?

Grouting the joints of brickwork is necessary not only for decorating the facade of the house. It makes the masonry more resistant to weather conditions, increases its tightness, and increases the service life of the entire structure. That is, it increases the density and strength of the masonry seam and makes it possible to give clarity to its pattern.

On a note! Grouting joints is not always able to improve the appearance of masonry. If the work on building a brick wall was carried out carelessly and carelessly, then even the best and carefully applied grouting mixture will not correct the curvature of the seams and walls, unremoved pieces of excess cement and other defects.

Grouting decorative brick joints

The main purposes of using grouting or grouting.

- Improving the appearance of the facade of the house. The use of grout mixtures that have different shades (and their color range is quite rich) can emphasize the neatness of brick laying. Contrasting shades are often used, for example, light-colored grout looks good in combination with dark brick and vice versa.

- Grouting will protect the cement mortar seams from moisture, which will significantly improve its service life, as well as the house and walls as a whole.

- The thermal and sound insulation values of walls made of bricks are significantly increased by grouting the joints.

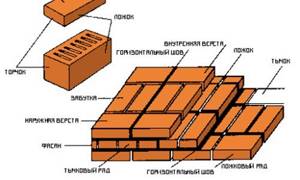

Brickwork for jointing

Where can jointing be used? After all, it’s not always possible to see houses with such finishing, which means, theoretically, you can do without it? Grouting is necessary if the walls of a brick house will not be tiled or plastered in the future.

Convex jointing of masonry joints

Advice! If the walls of the house will be decorated using grouting, then during masonry it is necessary to use only intact and neat bricks without flaws. And the seams between individual bricks should be of the same thickness, although some craftsmen make the horizontal ones slightly thicker than the vertical ones - this is a kind of design move. In general, according to the requirements of SNIP, the thickness of the joint layer of brickwork should be as follows: vertical joints from 8 to 15 mm, horizontal joints from 10 to 15 mm.

Grouting joints

Grouting joints is suitable for any type of brick - construction, facing. The main thing is that the bricks themselves are beautiful if grouting work is planned specifically for aesthetic purposes. It looks very good both on the facade walls of the house and inside the room. Grouting the joints of natural stone masonry can also be an excellent option.

Demonstration of the grouting process

Possible options

There are several options for how to do the jointing. The visual effect that the wall will receive depends on the chosen method.

When working on the filling, you need to follow the sequence, starting first with the vertical seams, and then with the horizontal ones.

Special attention is not paid to the thickness of the seams. The indicator can vary from ten to fifteen millimeters for horizontal seams, and from eight to twelve for vertical ones. But most often you can find thin seams, four millimeters thick. This decision was driven by the desire to save on cement mixture. Also, the thickness of the seams depends on the worker’s approach to performing the procedure and climatic influence.

The process of finishing the seams is important regardless of the thickness, because a clear pattern will not only decorate the walls, but also increase the performance characteristics of the building. What methods exist to highlight brick seams?

Flush

This option is the easiest to implement. You can do jointing in this way even without a special tool. Filling mortar that protrudes beyond the brick or gets on it is removed with a trowel. After the main process, the seam is processed using a stiff brush.

We recommend: Installing ceiling plinths with your own hands, how to properly adjust ceiling plinths, see photos and videos

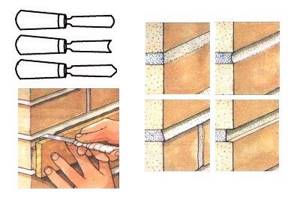

Concave

This method requires a special narrow spatula. This small tool will fill the seams. For ease of working on all lines, the spatula should not be long. The cement mortar is removed from the masonry, as in the previous version, after which they go along the seam with a jointing tool. The grout solution is applied inside in the same way.

Convex

To work on jointing with a convex effect, you need an arched spatula. The tool is applied to the seam with the arc part facing outwards, the resulting space must be filled with mortar. Afterwards, the spatula is moved further to the untreated area and the construction mixture continues to be applied.

Undercut or flush

This method is considered the most accessible and is most often used for making masonry joints.

The main idea is that the mortar protruding from the masonry is trimmed with a trowel, after which the seam areas are additionally treated with a hard-bristled brush. Using this method, the joining areas are given ideal smoothness and aesthetics.

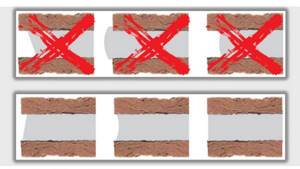

Rectangular

This option is more difficult to work with than the previous ones. First, you need to remove five millimeters of cement from the seam, even if it has already dried. After this, the gaps are filled with grout mixture. This design looks interesting, but experts do not recommend using this method for facade decoration due to poor drainage.

Beveled

This method is suitable for buildings that are being built in harsh climates. In this option, the mortar between the seams is not cut straight, but at an angle. The cutting angle should be sharp, 3-5 millimeters.

Facade repair

If there are few defective areas, then they are not difficult to repair with fresh cement mortar. Repairs begin with preparation: using improvised means (screwdriver, chisel, etc.) you should remove all remnants of the dried mortar. Under no circumstances push the chipped pieces deeper. The brick wall is moistened with water so that it does not absorb it from the applied mortar. After this, you can begin to carefully fill the space between the bricks with cement mortar.

The consistency of the solution should be thick so that it does not leak. To do this, add water carefully during the cooking process, controlling the resulting mass. The first step is to seal the vertical seams, and then the horizontal ones. They are sealed as tightly and flush as possible. In all areas there should be good adhesion to the existing masonry.

The solution that is located at the outer surface should contain less water than the one that fills the seam in the depths of the masonry.

Unstitch the seam in the same way as other sections of the wall so that there are no visible differences. For this purpose, not only a trowel, but also cuttings of a hose will do. When the repair comes to an end, excess mortar and other inclusions are removed from the brick wall. After drying, the influx of cement mortar is mechanically removed.

The desire to get black seams has become popular among owners of brick houses. To obtain such a visual effect, industrial dye or simple coal is added to the solution. The resulting brickwork looks more contrasting. Visual emphasis is placed on

brickwork structure. It is advisable to whiten the seams of white brickwork using a roller made of soft material. In the case of red brick, this operation should not be done.

Sometimes minor cracks can form in the seams, which cause moisture to penetrate through the brick wall. The repair will not be difficult: they can be eliminated quite simply by purchasing a special sealant in tubes. This product will cover all visible cracks. The sealant will protect the interior from moisture and slow down further cracking of the mortar.

Advantages and disadvantages

Jointing masonry joints has the following advantages:

- this finishing option requires almost no additional building materials;

- the service life of brick walls increases;

- the need for cosmetic repairs is reduced;

- protection of the surface from natural factors is created;

- the work is carried out independently, the involvement of professional specialists is not required;

- the aesthetic appeal of the walls improves;

- masonry mixture is saved.

Unfortunately, there are also certain negative aspects:

- with some jointing methods there is a slight decrease in the thermal insulation properties of the walls;

- walls made of silicate stone require special attention when jointing - it is difficult to remove cement stains from the surface of the facing material;

- the work is painstaking. The slightest mistake spoils the entire appearance of the surface.

Types of grout for stone

To grout the seams on the stone, you can use the material on which the decorative trim was attached. This could be glue or cement mortar.

Experts recommend purchasing a specialized product – grout. The nuances of the composition give special properties to the material, which increases its performance and strength characteristics.

Regardless of the type, all grouts for decorative stone must meet the following requirements:

- reliability;

- strong adhesion to the surface;

- frost resistance;

- resistance to ultraviolet radiation;

- elasticity.

Also important is the ease of wiping the composition off the surface of the stone. When selecting a mixture, it is necessary that it meets the criteria listed above.

According to the form of release, the mixtures are dry and wet. The latter are more convenient to use, since they are already ready for use. Dry formulations should be diluted in the correct proportion.

To grout decorative stone joints over a large area, it is better to purchase just such mixtures, since they can be diluted in the amount necessary so that the residues do not have time to harden. As for the shade, most manufacturers offer white grout. Gray and yellow are also common. Using a coloring pigment, you can easily give the mixture the desired color.

Types of jointing and their main characteristics

In fact, there are several types of seam stitching. Previously, only two options were considered: concave and convex. In practice, you can find many more of them. These are:

- To the pruning.

- Pustoshovka.

- Simply connected and doubly connected concave.

- Doubly connected convex.

The most popular options are worth considering:

1. Flush - the most common type of jointing. The procedure consists of the following steps: the remaining mortar is cut off from the surface of the wall using a construction trowel, then the gaps between the bricks are processed with a brush, resulting in smooth and clear white seams.

2. Recessed rectangular - this type is used when creating decorative finishes. This variety requires significant labor costs and is more suitable for treating walls indoors, since such jointing cannot withstand constant exposure to precipitation and atmospheric phenomena. The processing technology is as follows: in the seams at a depth of 5 mm, you need to remove the mortar, then compact the new mixture, smooth it using construction tool.

3. Concave – another common option, which involves the use of a special “jointing” tool. Excess mortar is cut off, the seams are processed with semicircular jointing.

4. Beveled - grout is able to withstand harsh climatic conditions, therefore it is common in the relevant regions. To process joints you need to use a carefully sharpened trowel. Grouting is carried out using the following technology: excess mortar is cut off with this tool, located at an acute angle, with a recess of 3-4 mm.

Do-it-yourself methods for sealing cracks

First you need to prepare:

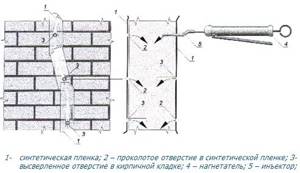

- Expand the crack with a chisel or hammer. This is necessary for the cement mixture to penetrate into the defect. As an alternative, injection technology can be used. Holes with a diameter of 3 cm and a depth of at least 10 cm are drilled along the entire length of the crack in increments of 80-150 cm.

- Remove debris and remnants of old masonry mortar from the gap. For this purpose it is better to use scarpel.

- Moisten the surface with water from a spray bottle.

1. The procedure for eliminating cracks up to 5 mm in size:

- Fill with the usual DSP consisting of 1 part cement and 2 or 3 hours of sand or a ready-made dry mixture. It should completely cover the crack and protrude slightly beyond it.

- Press the reinforcing tape into the fresh solution.

- After a few minutes, apply a small amount to the wall and close the tape.

- After the cement has dried, polish the surface with a special grater.

If injection technology is chosen, the cement composition is injected under pressure using a special apparatus into injectors installed in pre-drilled holes. If you decide to use liquid glass, then prepare a mixture of it, cement and sand in a ratio of 1:1:3.

2. The procedure for sealing cracks up to 10 mm in size:

- Cover the surrounding surface with primer.

- Drill holes for dowels along the gap in increments of 25-50 cm.

- Attach a metal mesh with 5x5 mm cells using self-tapping screws.

- Add a little sand to the cement plaster and cover the mesh with the mixture.

- After drying, apply a finishing material similar to the main façade finish.

To seal a crack in a brick wall, you can use foam or sealant (not silicone). After the product has dried, the layer is cut to a depth of 2 cm and filled with CPS. If the gap has a critical width - more than 1 cm, then only a solution will do; the use of metal T-shaped anchors is mandatory. They are fixed with dowels: if the gap is through, then on both sides. In particularly difficult cases or in the presence of very large defects, often the only right solution is to invite specialists to carry out the work.

Additional wall reinforcement

Options for strengthening brick walls when sealing deep cracks that grow in width:

- Completely or partially disassemble the masonry.

- Install metal brackets or trims.

- Strengthen supporting elements.

- Strengthen the foundation.

- Extend the wall.

- Strengthen the walls.

A fragment of a wall of a brick house with cracks more than 1 cm wide is most often dismantled starting from the top. New masonry is carried out using reinforcing rods, which fill all the cracks.

Required tools and materials

Before you start jointing the brickwork, you should prepare the following tools and materials:

- brushes - with hard bristles and wire;

- hammer;

- a stitching tool, which can be used as a finished factory product or home-made devices;

- a flat wooden strip with a length of at least 1 m;

- roller or soft brush to wet the surface.

If you plan to restore an old wall, you will additionally need:

- a hammer drill, a wooden wedge or a narrow chisel with the width of the working part slightly less than the thickness of the seam;

- a special mixer designed for mixing the solution;

- container for preparing cement-sand mixture;

- trowel or trowel.

In addition, you will need cement, sand, lime and water in the required quantities.

How to erase them?

For high-quality processing of the seam, you need to study the instructions on the packaging of the grouting material and also prepare for work. Tools and materials you will need:

- mixer;

- spatula/gun;

- drill for mixing;

- sponge;

- rags or rag;

- gloves;

- mixing container.

Regardless of the purpose of the grout, it is applied with a gun or a trowel/trowel.

Let's look at how to properly fill and grout joints when laying stone cladding. Work progress when sealing seams:

- Surface preparation: clean the cladding and allow to dry.

- Mix a small amount of grout to prevent excess from hardening.

- Treat the seams in one of the following ways - using a gun or a spatula, apply the mixture, compact it into the seam gap. Excess must be wiped off immediately.

- Let the solution set.

- Treat it with a fixative.

Important Each mixture has its own instructions for use. On average, dry formulations are prepared in proportions of 1 kg per 200 ml of water

The mass is stirred until smooth, the grout has the best characteristics in the first three hours, then it begins to thicken and loses its elasticity. It is recommended not to use a stale solution, as this will lead to loss of waterproofing and if the seam is sealed with such a product, microcracks may appear.

We recommend watching a video on how to grout seams on decorative bricks:

Jointer

Joint jointing is the final stage of surface finishing. It is necessary to secure the facing elements, complete the composition, and additionally treat the gaps between the elements from various influences (temperature, dirt, moisture).

For jointing, you need to prepare the following materials and tools:

- grout for seams;

- foam sponge;

- several containers: for water and breeding fugue;

- grout spatula;

- masking tape;

- latex gloves.

To joint joints, you need to purchase a special grouting gun or rubber spatula. The latter is a small plate with a handle. Tools made from different materials are selected depending on the process in which they are used. To apply and press the grout into the gap between decorative stones, spatulas with a springy rubber surface with a narrow blade are used.

Advice: It is faster to rub with a spatula than with a gun, but this requires skill in execution.

Before work, you can cover the stone with masking tape so as not to stain it and not to wipe it off again. For final cleaning of surfaces from contamination with fugue and its residues, special synthetic cellulose or foam sponges are used. But a soft cloth moistened with warm water may also work if it does not damage the stone (it is better to check first).

After work, it is better not to store the remains of the diluted fugue: after use, it dries out and loses its elasticity.

You can familiarize yourself with the options and principles for decorating a corridor, hall, bedroom, area near the TV, balcony, doorways, arches and columns with decorative stone.

Preparatory activities

Joining can be carried out immediately after laying the brick or after erecting the walls. In the first case, the mason brings the masonry into proper shape after several rows have been completed and the mortar begins to set.

In the second case, when laying, the master leaves the outer part of the seam empty for subsequent filling with jointing mixture, and they begin refining the wall after a certain time has passed, necessary for complete shrinkage of the masonry.

Before restoring old masonry, it is necessary to remove the mortar from the joints to a depth of 15 mm and clean the wall from dust and dirt

Preparing the masonry is carried out in the following sequence:

- If it is necessary to update the cladding of an old wall, parts of the old jointing are removed from the seams to a depth of 10 - 15 mm. To avoid damaging the bricks, it is better to use a narrow wooden wedge and a hammer. If it is not possible to knock off parts of the frozen solution, use a chisel;

- Use improvised means to remove dust and dirt from the walls of the building;

- The seams are cleaned using a stiff brush or a high-pressure apparatus. This work should be carried out very carefully, since dirt and dust particles interfere with the adhesion of the jointing solution;

- After cleaning, the seams are moistened using a roller or soft brush and a bucket of water.

The preparation of the cement-sand mixture begins only after the surface has been completely prepared for the next stage, at which the jointing solution is prepared.

You can make the jointing mixture yourself or use a ready-made factory-made composition, which is sold dry. and in wet form. Since the solution is used for decorative purposes, concrete dyes can be added to it. A concrete mixer will speed up the process of preparing the jointing mixture

We recommend: A few words about soundproofing an apartment

If you prefer to do everything yourself, then to prepare the optimal mixture, take lime, sand and cement in a ratio of 1:10:1 and mix with water until the consistency of very thick sour cream is obtained. Remember that the composition remains mobile for up to 1.5–2 hours, so mix only the amount that you can use during this time.

If the mixture you receive is too liquid, you can remove excess moisture from it by placing dry red brick in a container with the solution for 1 - 2 minutes.

For large volumes of work and the presence of assistants, a concrete mixer will help speed up the process.

Mixtures

Brick grout is sold ready-made or dry. It can come with the addition of pigments and plasticizing additives. But the main thing in any chosen composition for seams is its base. Today there are two options for embroidering walls:

- cement (Quick-Mix, Mixonite);

- epoxy resin (Litokol Litochrom, Mapei).

But you can prepare an inexpensive mixture yourself. The simplest grouting for masonry consists of two parts of lime and cement, taken equally, and 10 hours of fine sand. This solution has a pot life of about 90-120 minutes, so you shouldn’t mix a large volume for jointing right away.

Another recipe: for one part of cement, take the same amount of ground volcanic trace and 5 hours of sand as a filler. This type of grout should be used if the brick wall “pleases” the eye with efflorescence and whitish streaks from the seams. A purchased or self-prepared jointing solution is stirred to the consistency of liquid sour cream: it should not spread, but stick to an inverted trowel in a lump.

Having prepared the grout according to the instructions on the package, you can begin to make vertical joints. The composition should be soft and plastic to make it easier to work with, but not liquid, otherwise the solution will not hold its shape and will simply flow along the masonry. After all the preparations, the jointing is carried out using the following technology:

1. Apply the finished grout with a trowel - a little more than is needed to fill the seam. In order not to stain the bricks of the bottom row, you can substitute a plaster falcon.

2. Remove excess mixture with an edge and smooth the surface using a suitable hand tool. Each seam is pressed with force so that there are no voids left between the old mortar and the grout.

3. After filling, the seams are actually opened, that is, they are given shape. To work in horizontal rows, it is more convenient to use a straight strip - under it, like under a ruler, you can draw an even line.

Safety precautions

You should not grout in hot weather, because the mortar mixture dries out much faster. Craftsmen recommend waiting out rainy weather so that the solution does not absorb a lot of moisture.

Carrying out such work requires the use of protective equipment - helmet, goggles, gloves, overalls and a respirator. Before working on scaffolding, you should study the safety requirements for high-rise repairs.

It is prohibited to hang yourself on a wall or lean on freshly laid brickwork, work on random supports, or leave tools unattended.

Expert recommendations

To ensure that no defects or errors occur during the work, you need to read the recommendations from the craftsmen.

- When preparing the grout composition yourself, it is necessary to use sifted components so that they do not contain large fractions.

- After preparing the solution, it should be allowed to sit for 10–15 minutes and then mixed again to improve plasticity.

- When grouting, you should avoid applying the mortar to the bricks.

- If the solution gets on the decorative finish, it must be removed immediately, preventing it from drying out.

SNiP indicates that the thickness of the seam should be up to 1 cm, and therefore it is recommended to make small gaps between the bricks themselves, adjusting the size depending on the climatic conditions at the work site. There is no need to start grouting joints on hot days, as the solution will quickly harden, which can lead to disruption of the technological process. You should also avoid carrying out work in wet weather. The solution must be mixed in small portions in order to quickly produce it and not allow it to harden.

As you can see, grouting is a responsible but effective way to improve the appearance of a ceramic or other coating after finishing work, and it will also make it possible to create a complete finish. Professionally applied grout will improve the appearance of the base and protect the wall from damage. In addition, it will increase the thermal insulation properties of the masonry, which will allow it to stand for a long time and not require annual repairs. To do this, you just need to complete all the work according to the recommendations and written rules.

You can see an example of grouting joints in the video below.

Jointing technology during construction

In this case, the seams are processed immediately after laying several brick lines. The starting point for work is the beginning of hardening of the composition. The composition itself must retain its plasticity.

It is important to follow the following sequence:

- When laying this material, the entire composition that protrudes outwards is cut off flush with the laid masonry. Such pruning significantly increases the rate of jointing. An example of this is shown in the figure below:

Pruning

- The wall surface is thoroughly cleaned. The working tool is a stiff fleecy brush.

- Sewing vertical seams. The tool moves from top to bottom and is pressed into the masonry. Air is removed from the composition by pressure. The density and strength of the composition develops. First of all, short seams are unstitched vertically.

- To make the seams horizontally even, a wooden strip is attached to their underside. You should lean on it and guide it along the masonry line. Uniform pressure here will create a pleasant aesthetic finish.

- Filling seams vertically. Then - horizontally. Movement on the working surface: from top to bottom.

- When the composition has completely set, the elements of the jointing mixture are removed from the wall. A broom or brush is used here.

How to apply grout and how it can be done

Grout for joints for decorative stone can be applied in various ways. The most popular technique is slurrying, as well as filling joints using a gun or spatula. Each of the listed methods has its own nuances and requires certain preparatory work.

Don't miss: Warm floors on the balcony under tiles - an overview of the best options

Application technique using a syringe gun

Grouting of natural and artificial decorative stone joints can be done using a gun or a cone-shaped bag. This method is very convenient to use and allows you to minimize surface contamination.

The technology involves performing a number of processes:

- thoroughly clean the seams with a stiff brush;

- moistening the seams to improve adhesion;

- preparing the solution according to the instructions (if a dry mixture is used);

- filling a syringe gun;

- performing jointing using a spatula or by hand (performed 15-20 minutes after applying the composition);

- removing excess grout from the decorative stone (this must be done before the mixture has completely hardened).

For more effective cleaning, you can pre-prime the façade surface.

Slurry method

On smooth and even tiles, the seam can be grouted using the slurry method. This technology allows you to obtain ideal seams with maximum adhesion to the side surface of the decorative stone. This type of grouting is much easier to perform, and cracking at the end of the procedure is practically eliminated. The only disadvantage of this option is the high consumption of grout mixture.

Sliming is performed according to the following algorithm:

- cleaning seams;

- moisturizing the entire surface of the decorative stone;

- applying grout over the entire facade, evenly filling the recesses;

- if necessary, apply an additional layer;

- smooth the mortar on the seams;

- Use a wet sponge diagonally to completely clean the surface of the decorative stone;

- Wipe the facade with a dry soft cloth.

An additional advantage of this type of grouting of decorative stone joints is that there is no need for subsequent jointing.

Spatula technique

An excellent option for filling the seams of decorative stone is to use a spatula. With its help, it ensures complete and uniform filling of the cracks, but it also has its drawbacks. Cleaning must be done before the mixture sets, so treatment should be carried out not on the entire surface, but in separate areas. This is especially true when working with embossed surfaces, where hardened grout can worsen the visual appeal of the facade.

To grout decorative stone joints with a spatula, it is necessary to carry out the following measures:

- prepare the mixture for work using a drill and mixer;

- thoroughly clean the cracks with stiff bristles;

- moisten cracks;

- Apply a small amount of mortar to the seams with a spatula;

- rub in the mixture, apply a second layer and rub in again;

- make jointing;

- Clean the wall surface from excess mixture.

After application, regardless of the chosen technology, it is necessary to provide it with protection from atmospheric influences.

Plastic film works best for this purpose. When covering the surface of decorative stone, care should be taken to ensure an adequate level of ventilation.

Methods of carrying out work

Grouting can be done in two ways, in which the seams will have either a convex or sunken appearance. When performing a processing method called sunken, you will need a small spatula, with which both vertical and horizontal seams are simultaneously filled with the mixture. When the grout is applied, the tool with the arc is turned inward and the excess mortar is removed.

In order to perform convex grouting, an arc-shaped tool is applied to the gap between the bricks with an arc outward and the space is filled with mortar. When one of the seams is filled, the tool is pulled further. Thus, all horizontal seams are filled. When the mixture dries, you can do convex grouting of the vertical joints. All excess mixture is wiped off the surface of the bricks with a damp cloth.

As can be seen from the information presented, grouting the joints of brickwork can be successfully done with your own hands. A properly prepared solution will last a long time and reliably, giving brick walls an aesthetically attractive appearance and preventing moisture from entering the masonry.

What is used for grouting

What might be needed to grout the joints between bricks? Not as much as it might seem. First, you need the grouting solution itself, the creation of which we will talk about a little later. Secondly, we also need tools with which all the work will be done.

To grout the joints you will need:

- spatula (trowel);

- “spinner” for a hammer drill or a construction mixer;

- the hammer drill itself is directly used for working with the “turntable”;

- fine sieve for sifting sand;

- container for mixing the solution;

- jointing of such a size that its width is equal to the width of the seam between two bricks. If the width of the vertical and horizontal seams is different, then two types of this device will be needed.

Brick jointing tool

Construction mixer price

Construction mixer

Note that the main tools that may be used are listed here. But in some cases they may not be useful at all. For example, if you do not plan to make a shaped gap, then you can simply remove fresh excess cement during laying with a trowel.

Grouting old masonry joints

Grouting of joints can be done not only on fresh masonry. Using this method, you can improve the appearance of an old brick building. This is especially true if the mortar in the gaps has already begun to deteriorate, causing the thermal insulation of the entire structure to deteriorate.

Old brickwork

If grouting is done on old brickwork, then you must first remove part of the old mortar (about 1-2 cm). This is done using a chisel and a hammer. You can also wash off the remains of the old mortar using a special device that blasts the masonry with a powerful stream of water (for example, a mini high-pressure washer).

Preparing the solution

The color of the grouting solution is determined after the masonry is completely completed. But in general, you can choose the color scheme at the stage of choosing a brick. It is better to buy materials that match each other in color as closely as possible; they should be in harmony with each other, and not make you want to immediately look away from the wall of the house. But often designers experiment with a combination of two bright contrasting colors, and such experiments often look very impressive and beautiful.

Contrasting grout for seams

On a note! If the desired color was not available, then you can grout the seams with ordinary cement-sand mortar. In any case, it will look nice, as it has a grayish natural color that is in harmony with all other shades.

To prepare the mixture itself, which will be used to grout the joints on the brickwork, you will need the following components:

- high quality cement - 4 buckets;

- clean fine sand - 2 buckets;

- dry ready-mix for preparing grout mortar;

- clean water - about 6 liters.

Note: the volumes of materials are approximate, but will allow you to roughly calculate costs.

Cement-sand mortar

To prepare the solution, you need to carefully sift the sand using a fine sieve, removing large fractions and possible debris from it. One part of the entire sifted material must then be mixed with two parts of dry cement, after which a little water is added to this composition and everything is mixed to a thick mixture of uniform consistency with a construction mixer. Then the grout mixture and water are added, and everything is thoroughly mixed again.

The finished mixture should be allowed to brew. After the solution swells a little, having absorbed the liquid, it is mixed again. That's it, the solution is ready for use.

Quick Mix series VK 01 – Masonry mortar with route for facing bricks

Prices for cement and basic mixtures

Cement and base mixtures

Main stages of grouting

The seams are processed after finishing the bricklaying. The process is monotonous and it takes a lot of time to solve the problem. A novice master will be able to do the grouting himself. For inexperienced masons, experts have created step-by-step instructions:

- Prepare the surface. You need to clean the masonry and seams with a regular stiff brush.

- Rinse the wall with clean water. The most convenient way to do this is with a pressure hose. Wet the wall surface. This is necessary so that the brick does not draw moisture out of the mortar, and cracks do not form during natural drying.

- After preparation, prepare the solution according to the instructions.

- Use a large spatula to scoop up the working mixture, gradually applying it to the seam. It is better to use narrow jointing. To do this, craftsmen carefully embroider the joints located horizontally.

- To remove accumulated air and achieve maximum density, the tool is pressed into the gap.

- Vertical joints are filled with cement-sand mortar according to the standard pattern. The prepared composition is held in the palm of your hand.

- The entire area is cleaned with a brush.

- At the final stage, the type of jointing is formed. This procedure begins immediately after the solution has set.

Important! Experts recommend determining the amount of solution in advance in order to have time to use it before it hardens.

Surface preparation

Shaping the finish

How to care for tiles

In order for the coating to last for a long time, you need to know how to properly care for tiles.

For glossy structures, strong acid-based detergents should not be used. This may damage the gaps and seams between the products.

It is best to purchase special products for tiles, ceramic tiles and porcelain tiles.

Do not use metal brushes or abrasive powders because they will severely scratch the surface of the coating. This is especially noticeable on glossy ceramic tiles.

The Best Tile Cleaners

To ensure that the tiles retain their attractive appearance for a long time and do not fade, it is better to use specialized mild detergents:

- Mister Muscle. Eliminates plaque, rust, removes stains from the surface of tiles and gives it shine. It is necessary to apply the liquid to the dirt, wait 3-5 minutes and walk again with a damp sponge. It copes well with old, stubborn stains and does not run off vertical surfaces. In this case, there is no need to scrape and rub the plaque with a washcloth. The detergent perfectly removes even formed mold from the grout.

- Frosch. Suitable for most types of tiles. Effectively removes dirt, grease, stains and plaque from ceramic tiles. Frosch is harmless to the body. The product neutralizes unpleasant odors and kills germs. To clean the tiles from dirt, dilute 2 caps of detergent in 5 liters of water and clean the surface. Not intended for use in its pure form.

- Cif Anti-plaque. Removes accumulated dirt thanks to a unique water- and dirt-repellent formula. In a matter of seconds it will remove limescale and soap stains from the surface of the tile. SIF should be applied evenly to the dirt, wait 5 minutes and rinse with clean water.

- Domestos. Effectively eliminates fungus, whitens grout joints between tiles and disinfects. Directions for use: Dilute 2 caps of gel in a five-liter bucket of water and remove dirt with a sponge or soft-bristled brush. Then rinse the surface with water and wipe dry.

- San-klin (Santik). Liquid for removing limescale, rust and other contaminants from tiles. It must be applied to the surface for 5-10 minutes and then remove any remaining dirt.

You can also use the following aids to clean tiles:

- Bleaching powder. Dilute the powder with clean water. Pour the solution into a spray bottle and spray it onto the desired surface. Then leave for five minutes and rinse with plenty of clean water. Let the ceramics dry or wipe the surface with a dry cloth. Chlorine solution kills germs and gets rid of mold.

- Melamine sponge. Easily wipes off minor stains, removes limescale and does not spoil the appearance of the cladding. You just need to wet the sponge and rub away the dirt.

- Steam cleaner. A gentle alternative to aggressive cleaning liquids. Steam cleans the tile surface no worse than chemicals. And at the same time it does not have any mechanical effect. Steam supplied under high pressure dilutes grease stains on the tiles and disinfects the surface being cleaned, killing germs. The steam cleaner is excellent at removing mold and limescale in the bathroom. It easily removes even greasy stains in the kitchen.

To prevent ceramics from fading and scratches appearing on it during use, you need to treat it with a special varnish. A durable protective coating is created, the color does not change for many years, and caring for the tile surface is greatly simplified because almost no dirt accumulates on the varnish coating.

With proper cleaning and good timely care, ceramic tiles will last for many years.

Joint jointing of brickwork

We recommend: Is it worth asphalting the courtyard of the local area?

Grouting the joints of brickwork is considered the finishing action of wall finishing, giving it a finished look. This action is aimed at creating an aesthetically pleasing surface.

It is necessary in most cases, since during masonry it is impossible to avoid the appearance of errors that negatively affect visual perception.

Currently, there are many different materials used for these purposes, which differ significantly from each other not only in their final appearance, but also in the chemical composition of the components.

Main goals

The grout will protect the masonry from wind and sun

If everyone knows the reason why it is necessary to grout the seams between the tiles, to give a finished appearance, then for brickwork you can give several understandable motives.

Some professionals call this action jointing, and the meaning does not change. Compulsory implementation is required for the following reasons:

- The grout composition protects the walls from the harmful effects of the environment (wind, ultraviolet rays, temperature changes, precipitation). The cement mortar deteriorates over time and the integrity of the surface is compromised. It plays the role of waterproofing; the use of high-quality material guarantees that in a few years the walls will not crack under their influence.

- There is a specific property for the seams of brickwork that protects it from blowing by strong winds. The use of grout mixtures allows them to be protected from the penetration of cold air through the micropores of the cement mortar.

Varieties of material and methods

Epoxy-based compounds are used for interior finishing.

Masonry joints must be treated with special compounds. Several different types of grout can be used for these purposes. However, in Russia, with frosty winters, only 2 types are widely used:

- cement-based mixture;

- composition made from epoxy resin.

The first is mainly used for treating external walls, the second - internal, as it is much easier to wash and clean. The color of the composition is determined depending on the wishes of the owner and is achieved by mixing with the color scheme.

In addition, you can use chemical components that will prevent the formation of fungus and mold, as well as increasing resistance to sudden changes in temperature conditions.

The appearance of the wall will depend on the grouting method chosen. The final result will depend on what tool will be used to complete the work. While some of the grout joints can be applied using a spatula, more complex compositions will require a special device.

To a greater extent, seaming is done in the following ways:

- Flush, in this case the composition is placed inside the seam, and the excess is removed with a spatula. After this, the brick is cleaned with a brush.

- A convex seam is applied using a similar method, however, the excess is not removed with a spatula, but, on the contrary, a special arc-shaped device is passed along it, after which a neat mark is formed. Thus, horizontal masonry is processed; vertical seams must be made after the first ones have partially hardened.

Why grout joints in brickwork?

When laying the external brick walls of a house, an unsealed seam may remain. The main reason for the defect is the poor quality work of the masonry team, because when forming the order, it is necessary to treat the entire surface of the masonry with mortar.

However, sometimes this technology is not followed, resulting in an empty seam, which not only spoils the appearance of the facade, but also causes the formation of cracks and breaks in the wall.

Filling the joints of brickwork is carried out in order to prevent such problems and prevent further destruction of the structure.

Mashing compounds

In hardware stores and markets you can purchase the most suitable grout for gypsum brick tiles, which vary in composition. Depending on the main component, they are:

- cement mixtures;

- based on epoxy resin.

The most popular mixtures for grouting decorative brick joints are cement-based mixtures. The main advantages of grout for decorative gypsum bricks are high resistance to temperature changes and other aggressive environmental influences and ease of application and preparation of the mixture.

Compositions based on epoxy resin have a higher level of viscosity. This property of the material allows for quick and high-quality application of the solution, so it is recommended that only professional craftsmen work with it.

As for specific brands of grouting compounds, the most popular are the following.

Ceresit

The most popular materials from Ceresit for work on surfaces lined with decorative bricks are:

- ce 40 aquastatic. Used for sealing seams whose width does not exceed 1 cm. Suitable for use on surfaces lined with stone, ceramics, glass, and decorative bricks. They are characterized by a high level of water repellency and resistance to stains. The surface of the seams is “velvet”. The material acquires maximum hydrophobicity 5 days after completion of work;

- se-33 Super. Brickwork grout is used for joints whose width does not exceed 5 mm. It is characterized by moisture resistance, frost resistance, and is available in 50 different colors. Grouting for bricks is carried out at a temperature of plus 5 degrees and above;

- ce 43 Super Strong. Brick grout is intended for external use and is used for joints up to 2 cm wide. It is characterized by a high level of moisture resistance, frost resistance, and has increased strength. It has a disinfecting effect and is not deformed.

Kiilto

They use Kiilto brand materials for work both indoors and outdoors. White grout for bricks is made from cement with the inclusion of a certain amount of lime and various polymers. Characterized by high elasticity and easy to apply. After completion of the work, it is easily removed from the surface of decorative bricks or tiles.

It has good moisture-resistant properties, is resistant to temperature changes, and frost-resistant. Used for filling joints whose width does not exceed 6 mm. The composition can be applied to a surface with a humidity of 90%, drying time is 15 minutes.

Mapei

Mapei materials are characterized as follows:

- the composition of the mixture is represented by a hydraulic binder, fractionated aggregate and modified additives, due to which increased resistance to the formation of efflorescence and fading is ensured;

- The material line is available in 5 colors;

- preparing the solution for use is as simple as applying it;

- after the material has completely hardened, no shrinkage is observed;

- characterized by a high level of adhesion and a long service life;

- due to its high density, the material does not form stains either on the surface of the seam itself or on the facing material;

- characterized by sufficient vapor permeability, a high level of frost resistance, resistant to precipitation and adverse environmental conditions;

- grout for facing bricks can be used at temperatures of plus 5 degrees and above;

- work should only be carried out in dry weather.

Tips and secrets

And finally, a few tips and secrets that will help improve the quality of the work performed.

- The sand must be sifted through a sieve so that no large inclusions remain in it. Otherwise, they may ruin the appearance of the grout.

- There is no need to rush to work with the newly mixed solution. You need to let it brew a little.

- During the work, the brick is protected from the mixture getting on it. By the way, when laying bricks, it is better if the mortar does not completely fill the gap on the front side of the wall.

Decorative seams

- If concave grout is done, then you can fill both horizontal and vertical joints at the same time. If it is convex, then first vertical, then horizontal.

- After completion of work, the remaining solution is removed immediately.

- You need to work with the mixture as quickly and carefully as possible, because it dries in a short time. But at the same time, it is important to seal the seams carefully and without mistakes, because after drying it will be difficult to simply fix them.

- To obtain a specific color, tints are purchased.

- It is important to carry out work in cloudy but dry weather.

- You can make the jointing yourself from any dense metal product, for example, from a knife.

Grouting errors

Grouting brickwork joints is one of the most durable ways to decorate the appearance of a brick facade wall. It looks very impressive, and all the work is easy to do yourself, without the help of specialists. And this is undoubtedly a huge plus.

Features of grout for bricks

Brick grout is the final part of wall decoration, creating its final appearance. Decorative finishing of a brick surface is the final stage of wall construction, aimed at giving an aesthetic appearance and increasing its attractiveness. As a rule, during the construction process it is almost impossible to avoid various errors, which provides the initial plane with a rather unflattering appearance.

Grout is needed to decorate the appearance of the wall, as well as to prevent the appearance of mold and germs.