Features of a corner fireplace

If you are the owner of a house outside the city, it will be nice to sit on a cold evening near a comfortable fireplace. In a small room it is difficult to fold a large structure. It’s easier to make a small corner version; even an inexperienced stove maker can do this work.

Some types are made of brick, others are assembled by combining brickwork and metal parts.

The choice of design depends on the financial capabilities and desires of the homeowner.

A combined fireplace is cheaper than one built from one brick.

Advantages of installing a corner fireplace:

- The main thing is to save money on the purchase of material; less of it is needed than when building an island or wall-mounted fireplace structure.

- The second is the reasonable use of the volume of the room; its compactness makes it possible to place it both in an average country house and in a country house;

- The design has a simple masonry scheme; even a novice stove maker can figure it out. Even uneven masonry will not deteriorate the appearance of the room - the folded structure can be covered with ceramic tiles.

Corner fireplace

A corner fireplace will create coziness in the room and allow you to spend a stormy evening in comfort.

Technology of masonry work during the construction of a brick fireplace

We will assume that the foundation of the fireplace has already been built, poured with durable concrete and will support the weight of the structure.

- The concrete surface should be waterproofed with an inexpensive coating cement-polymer mixture (for example, CeresitCR 65), coating it twice with a brush or spatula.

- If the fireplace is adjacent to a wall made of combustible material, fire protection must be installed.

Preparation of clay-sand mortar. When making your own, the clay should be soaked in advance. Water is added to the finished mixture before starting work in accordance with the instructions. The brick should be soaked - lower it into a trough of water for a few minutes. If this is not done, the masonry mortar may dry out too quickly and not gain the necessary strength.

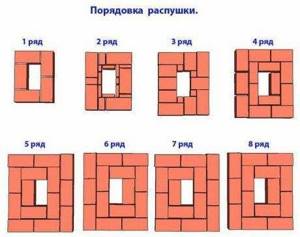

In addition, the wet brick can be moved if necessary, which is important when a fireplace is laid by a not very experienced craftsman. Lay out the first row, it should be as even as possible, the horizontal level should be carefully controlled. If you “missed a little” with the foundation, the first row can be laid out on a cement-sand mortar, this makes it easier to correct flaws in the foundation. Next, the fireplace masonry is carried out in strict accordance with the serial plans

We recommend laying each subsequent row dry first, and only then applying the solution. If the fireplace is large, pull the cord; if the structure is small, control with a level and a square is sufficient.

If there is more than one brick in a row that needs to be split or sawn, we recommend that during dry laying you number all the elements, both solid and adjusted to size. The numbering should be duplicated on the serial plan

The vertical seams of the bricks should not be located one above the other; the need for bandaging should be taken into account when drawing up the drawings.

Laying begins with corner elements, strictly monitoring compliance with the horizontal level between them

Excess mortar is removed with a trowel, the seams are unstitched, and contaminated bricks are wiped with a wet rag.

The shape of the joint determines the profile of the seam, concave, convex or rectangular

Another way to make a neat seam is to lay the bricks along the guides

Take a closer look at the photo: a square metal profile is inserted into the seam from the outside; after a few minutes it is removed.

You should not place more than 8-10 rows in height in one shift.

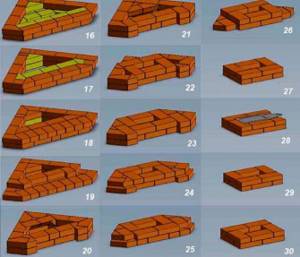

Stages of constructing a fireplace

Design and dimensions of the hearth

These fireplaces are similar in design to wall-mounted products.

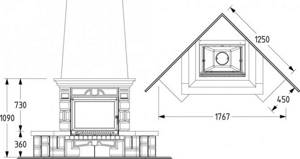

The hearth has a firebox, a cone-shaped smoke receiver and a straight chimney. Triangular structures differ only in their triangular cross-section, which complicates the masonry process.

The principle of its operation is no different from the usual one - dry wood burns in an open firebox, and the resulting smoke escapes through the chimney. Some of the heat is reflected into the room by the fireplace tooth (about 20%), and the rest is lost along with the escaping smoke.

If the draft is bad, smoke will penetrate into the room, and too strong a draft will cause large heat losses. For this reason, it is necessary to select the optimal cross-section of the smoke channel, taking into account the size of the combustion niche and the area of the room.

Burning wood sometimes shoots bits of heat through the front opening.

To prevent fire, place a metal sheet on the floor in front of the firebox.

A fireplace located close to wooden walls must be insulated with galvanized metal.

Corner fireplace saves space in the room

Calculations of the required dimensions will be simplified by the table, which shows the cross-section of the chimney and the dimensions of the portal, taking into account the volume and area of the room.

| Room | Portal | Firebox | Smoke channel cross section cm | ||||

| Area, m2 | Volume, m3 | Width cm | Height cm | Depth cm | Neck cm | Back wall width cm | |

| 12 | 42 | 50 | 45 | 30 | 12 | 30 | 14x14 |

| 16 | 50 | 60 | 50 | 32 | 12 | 40 | 14x27 |

| 22 | 60 | 70 | 56 | 35 | 12 | 45 | 14x27 |

| 30 | 80 | 80 | 60 | 38 | 13 | 50 | 27x27 |

| 35 | 100 | 90 | 70 | 42 | 13 | 60 | 27x27 |

| 40 | 120 | 100 | 75 | 45 | 14 | 70 | 27x27 |

It will not be possible to make a massive brick fireplace in an apartment.

Often in private houses they use a simplified method of laying a brick hearth with a cast-iron firebox built into it.

Project preparation

To build a corner fireplace with your own hands, you need to develop a series of instructions that will determine the progress of the work. Such instructions are called a project. It includes a description of the model, the tools and materials used, drawings of the fireplace in different planes, as well as a detailed diagram of the masonry of the fireplace body.

Ready-made projects, which were developed by professional craftsmen, allow you to build a fireplace of any complexity. To use them, you need to choose an option that is suitable in appearance and performance. Many resources that specialize in fireplace and stove masonry issues provide paid projects for personal order.

Drawn fireplace model

Self-preparation includes calculations of the main dimensions of the fireplace. Oddly enough, these dimensions do not include external dimensions. Let us list the basic requirements for the device.

- For efficient combustion of fuel and ensuring the removal of products, a pressure difference in the chimney is required. Good traction is a direct indicator of the correct execution of all installation work.

- The heating functions of the fireplace should produce enough heat to fill the room with warmth within an hour.

- The generated heat should be directed into the room and not removed through the chimney to the outside.

The implementation of all these requirements is possible with a competent combination of the dimensions of the fireplace insert and the dimensions of the heated room. There are ready-made tables that indicate the parameters of the firebox, which, according to a certain mathematical formula, depend on the linear dimensions of the room. It is necessary to select the most suitable area value and use tabular data. If this is not possible, then all the calculations will have to be done independently.

Example of a table with fireplace sizes

To calculate the main dimensions you need to remember a few elementary formulas. Area of the combustion opening = area of the room: 50. In a strict sense, this formula should establish the dependence of the area on the volume of the room, because the height of the room significantly affects the amount of energy for heating. This calculation option assumes a certain power reserve.

Good to know: Fireplace complex, which includes a barbecue, grill, smokehouse, cauldron and oven

For specific dimensions of the fireplace opening, you will have to solve a simple equation and select the height and width, which are determined in proportion by the proportion 2:3. The specific results obtained are used to calculate the depth of the firebox, which is 2/3 of the height of the opening.

The next unit to be calculated is the chimney. What is important here is not so much its length as the size of the part protruding above the roof of the roof. If you are far enough away from the ridge, you need to use the following rule. A line drawn through the ridge and the top point of the chimney makes an angle of 10° with the horizontal line. Naturally, such a principle will give very approximate results, since it is not possible to measure this angle accurately without special instruments.

How to build a brick structure

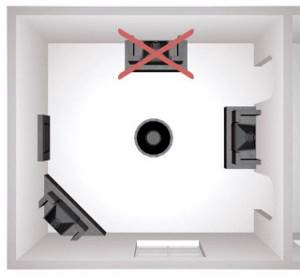

It is advisable to place this structure between 2 walls inside the house.

A stable draft is created in the walls of the fireplace located near the window, thanks to small drafts in the room.

Design like this:

- First, choose the room and corner in which the structure will be located;

- A general sketch is prepared on paper, allowing you to visually assess whether the structure fits the design of the room;

- Taking into account the location of the floors and parts of the rafter system, a working draft drawing is prepared.

The firebox comes in different shapes, each model uses its own version. When choosing a fireplace design, they first decide what it will be like, since it will not be possible to remake it later. The corner one is made with a firebox made of cast iron or made of fireclay bricks.

Calculation of dimensions

Accurate calculation of the size of the firebox directly affects the efficiency of heating the room.

The calculation is made taking into account the total area of the room. In a simplified calculation, the area of the room is divided by 50 - this value will give the approximate dimensions of the firebox window. For example, in a small room, a fireplace with a firebox with an area of 0.32-0.54 m² will be enough.

Installation of a corner fireplace can be done after designing the house

The fireplace window should be made in a 3:2 ratio, and the width of the hearth should be greater than its height. The depth of the firebox is important - it directly affects the efficiency of the structure; it needs to be 1/2-2/3 of the height of the firebox. With a large firebox, heat transfer decreases - a lot of heat will fly directly into the chimney. If it is not deep enough, smoke will begin to enter the room and soot will appear on the ceiling and walls.

Chimney

For high-quality smoke removal, the characteristics of the chimney are important; they affect the combustion of wood and the draft in the chimney. It is necessary to correctly calculate the height of the pipe and the cross-section of the chimney. According to safety rules, the diameter of the chimney cannot be made less than 15-17 cm, the optimal proportion of the cross-section of the chimney duct is 1/10 of the firebox area.

The length of the chimney must be made at least 5 meters; if the residential building is high, then its length must be increased (the pipe must be higher than the roof of the building).

The chimney is also located in the corner of the room, without occupying the entire wall

Materials and tools

Having calculated and prepared the project, they prepare building materials and tools. First you need to decide whether the structure will be finished, or whether you will fold the fireplace under the jointing. This affects the choice of brick. Work and procurement of materials begin with preparing the foundation for the structure.

Foundation

The fireplace weighs less than a full-fledged stove, and it does not require a large base. If the house is built on a slab foundation, then it is suitable for a corner structure. If there is a strip foundation under the house, then additional work will be required.

It is necessary to prepare a waterproofing material to protect the foundation from moisture - use dense polyethylene or roofing felt.

Next they make the formwork, you will need inch boards. Sometimes steel sheets are used instead of boards for formwork; it is more convenient if you have a complex or semicircular foundation. A reinforcement frame made of metal rods 8-10 mm in diameter is assembled in the formwork. They are tied together with steel wire to form a mesh. To create a cushion under the base and mix the solution, you will need clean sand and medium-fraction crushed stone.

The base of the fireplace must be laid out in any case, regardless of what type of foundation the house has

Fireplace and chimney laying

The construction of the walls and chimney for the fireplace is made from the following materials:

- You will need to buy 2 types of bricks – fireclay and red solid;

- When decorating a fireplace with jointing, buy high-quality ceramic bricks. If there is external finishing, use ordinary ordinary red brick;

- Fireclay bricks can withstand high temperatures well; they are used to build the firebox and the bottom of the chimney.

The amount of brick depends on the order; it differs for each fireplace model.

For a small corner fireplace you need to buy 350-650 bricks. When purchasing material for masonry, they buy 10-12% more - it will be needed if defective specimens are discovered or in case of unexpected damage.

The solution is prepared from clay and sand; with insufficient experience, it is difficult to select clay of the appropriate fat content and mix the solution in the required proportion. Therefore, it is better for beginners in the baking business to use ready-made compositions, which only need to be mixed according to the instructions indicated on the package. These mixtures are sold in specialized stores.

To make a masonry of tools you will need:

- A pickaxe hammer is required to split bricks.

- Trowels of different sizes.

- Large trowel.

- Level.

- Plumb.

- Cord for even laying of rows.

- Mallet for leveling bricks.

- Rule.

- Dishes for preparing the solution.

- Joint for cutting seams.

Required Tools

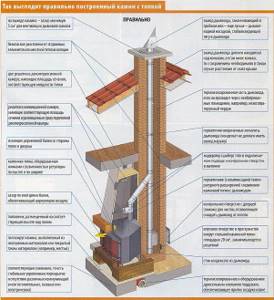

Chimney and chimney

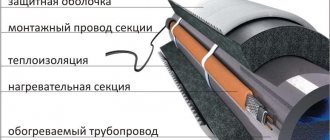

The chimney is a part of the stove, shaped like a cap, inside which there is a steel pipe (or ceramic chimney blocks), which turns into a smoke pipe. The back wall is made vertical, and the side walls are made tapering at an angle of 45-60 degrees. The internal cross-section is calculated according to the proportion: 0.1-0.15 of the portal area, and the height is made at least five meters from the fuel combustion surface. The walls are made thick enough to reduce heat loss.

A valve is installed at a height of about two meters. The frame for it is fixed with liquid mortar in the masonry.

The first point of installation of a chimney is installation above the smoke collector of the unit. Cement mortar is used to connect the openings of the pipe and the smoke collector. The brick lining is attached to the pipe by means of anchor joints inserted between the outer blocks of the pipe, which are embedded in the joints between the bricks. Internal surfaces must be free of gaps.

The pipe head is made at least 1 brick thick. To reduce the accumulation of condensate in the chimney duct and prevent fire of structures, install thermal insulation and thermal insulation.

Fireplace components:

- Chimney for fireplace.

- Support plate.

- Fireproof plate.

- The section where the pipe leads to the chimney.

- Firebox.

- To allow hot air to escape, install a ventilation hole with a grille.

- Decorative element and thermal insulation layer.

- Ventilation grille.

- A chamber with hot air, a ventilation grille, and the outside of the chamber is decorated with stone, marble and other materials.

- Facing.

- Movement of cold air.

A spark arrester and a deflector are installed on top of the pipe. The function of the spark arrester is fire safety. Structurally, this part is similar to a blank metal cone with wire mesh on all sides. The deflector is installed on the head in order to increase traction and protect the pipe from the wind. Typically the cross section of the deflector is circular.

Cladding of the fireplace and the protruding part of the chimney

If it was planned to leave the outer part of the fireplace brick, without additional cladding, then the masonry should be as neat as possible, and the mortar should not be brought to the front of the fireplace by 0.5 cm, so that it would be possible to expand the seams.

If the masonry requires additional decorative cladding, then artificial or natural stones, ceramic tiles, tiles and other materials are used. It is recommended to varnish the top of the stones to improve their decorative properties and facilitate maintenance.

The cheapest and simplest method of cladding, which is done after the masonry shrinks, is plaster. Using various spatulas, various decorative effects are created on plaster. There is a possibility of coloring the plaster.

Another popular way to cover a corner fireplace is to use plasterboard. It is cut and mounted on a special metal frame, strictly checking the corners and walls with a level.

Making a corner fireplace

If it is necessary to make a foundation, then the work is done according to the following scheme:

- First, they dig a hole in the ground 400-500 mm deep, 100-120 mm wider than the fireplace;

- The bottom of the recess is covered with sand, 100-120 mm thick. The sand layer is compacted by pouring water and compacting;

- A layer of crushed stone is poured onto the sand cushion; it is made the same thickness as the sand layer;

- A reinforcement frame is assembled on crushed stone;

- The walls of a wooden house are covered with asbestos sheets;

They install formwork from boards; if the foundation is figured or semicircular, then it is better to fence it with a metal sheet.

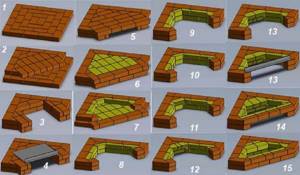

Masonry

Before starting laying, choose the best brick for laying the firebox (it’s great if you have fireclay brick).

After that, start laying the first row.

Laying is done as follows:

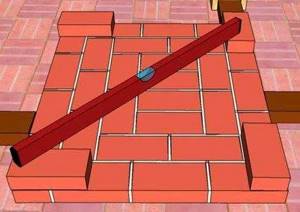

- From the edge of the base, retreating 5 cm, lay out the first row of bricks on a dry surface;

- Using a wooden plank and a square, level this row and set the angles at 90 degrees;

- Measure the diagonals with a tape measure, the deviation should not be more than 5 mm;

- After leveling, the bricks are placed on the mortar.

The laying of a corner fireplace made of bricks is carried out according to the order in the following sequence

Then the rows are laid in the same way - fitting the masonry to dry, laying bricks on the mortar. All rows are checked using a level and plumb line.

There is a simple way to ensure the correctness of the masonry. When the first 2 rows are laid out, the corner points are transferred to the ceiling using a plumb line and nails are driven in in these places. Strings with weights are tied to them, which will serve as markers.

The covering of the firebox and other parts of the fireplace is made from metal corners.

The top row is placed without mortar on the metal. The vaults of the arches are made using wooden templates - circled.

Tools and materials for construction

The main material for the construction of fireplace walls is brick. For construction, 2 solid varieties are chosen: red and fireclay (heat-resistant). The stones should not have obvious defects, cracks or burn marks (dark areas).

We use “Pechnik” plaster for laying bricks.

In addition, you need to find clay and sand for masonry. If possible, it is best to buy a ready-made dry mixture (for example, Pechnik) for stoves and fireplaces, as well as a special mixture for preparing a heat-resistant solution. The latter is used when lining the walls inside the firebox together with fireclay bricks.

For a brick fireplace you will need the following:

- red and fireclay brick;

- clay, sand or ready-made mixture;

- cement, PGS and crushed stone for the foundation;

- corner 5x5 cm;

- latch (view);

- solution container;

- trowel or trowel;

- a pick for splitting bricks;

- plumb line and building level;

Interesting solutions in interior design

For a beginner, building a fireplace is a difficult job. First, practice on simple structures - make a barbecue, grill or grill in the yard. Try it in practice and feel all the subtleties of creating masonry.

Corner fireplace in the living room interior

Corner fireplace in the interior

Corner fireplace with insert

It’s a good idea to consult with an experienced stove maker.

General provisions and recommendations

To lay out a corner fireplace with your own hands conveniently and quickly, it is advisable to frequently check your actions with the order plan while working, and mark (number) the laid out rows with chalk. The outer wall with the firebox should not be bandaged; this may lead to deformation due to temperature differences.

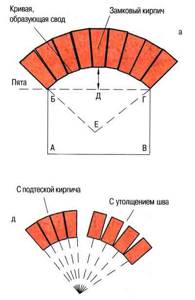

Circular masonry

After laying out five rows, wipe the masonry with a wet rag or rag, removing any excess mortar that is squeezed out of the seams under the influence of the growing mass of the structure.

The inner surface of the firebox and chimney is not plastered! The slope of the rear wall is leveled by a steel screen that can be mounted into the masonry. The smoke collector vaults are laid out with gradual overlaps of bricks, about 5–6 cm for each subsequent row. The portal opening is covered with brick lintels laid in a circle. If provided, install a cast iron door.

During the production of work, the circle rests on the racks. After laying the castle brick, double (two-sided) masonry is carried out. The pipe is brought to the roof using the same solution that was used to lay out the base.

Finishing a finished fireplace

The finished fireplace is decorated with facing materials or left as is: brick gives the room a special charm and authenticity.

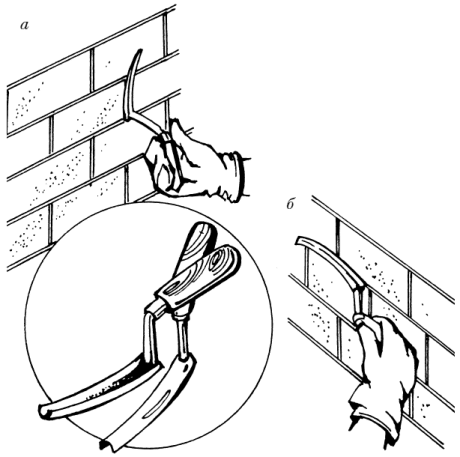

How to do seam stitching correctly

It is performed if the façade of the fireplace is not planned to be covered.

- We use a clay solution: bring the clay pulp to readiness, and then pour cleaned and dried sand into the mass, stir the mixture until a homogeneous thick composition is obtained that is easy to mold.

- To make jointing more convenient, when laying brick blocks, do not bring the cement mortar to the outer edge of the wall by 5 mm.

- We regularly check the geometric parameters of the structure using a level.

Cladding the fireplace with various materials

There are many options for decorative finishing of fireplaces:

- The finished fireplace structure can be plastered without affecting the inner surface of the firebox and smoke collector. This is the easiest method of finishing a heating structure. Using special spatulas and special techniques, you can create interesting decorative effects. In addition to regular colored plaster, you can use colored compounds.

- Another common method of decorating a fireplace structure is to decorate it with sheets of plasterboard. The material is cut and attached to a steel frame. In this case, it is necessary to strictly check the geometry of the walls and corners using a level.

- The fireplace can also be lined with fireproof tiles or elegant tiles, or lined with synthetic, wild stone or marble. To improve the aesthetic characteristics and facilitate the maintenance of the fireplace, decorative stones should be coated with a special fire-resistant varnish.

- To make the fireplace even more aesthetically pleasing, it is worth installing a special screen in it. To make fireplace screens, metal mesh and artistic forging elements are used. In accordance with fire safety standards, it is necessary to lay a steel sheet in front of the fireplace.

Finished fireplace cladding

If you wish, it is quite acceptable to leave the “front” part of the fireplace unfinished, especially if you used nice red brick. It’s worth thinking about this even during laying; if no further finishing is planned, it is better not to lay the mortar end-to-end to the very edge, leaving characteristic slits between the bricks. Making them is then problematic and threatens to damage the integrity of the masonry. If you still decide on cladding, make a choice on one of these materials:

- Stone (any variations, even natural.)

- Tiles (preferably tiled).

- Drywall, do not forget that it must be fire and temperature resistant. In addition, it will require a special frame (only made of metal).

- Classic plaster.

Some tips will help you maintain the original appearance of your fireplace. For example, if you use stones or tiles, it is better to immediately varnish them. This will make it easier to wipe off dust.

By the way, one more thing, if you chose plaster as a finish, remember an important rule: plastering is allowed only after complete shrinkage. Otherwise, huge cracks will appear across the entire plane, which will definitely not add grace.

Plaster itself, at first glance, is a simple finishing method, but taking into account the variation of different shades and design styles, you can create a more attractive and expressive cladding, even better than that of natural stone. Plaster can be used to apply a variety of ornaments and patterns, which cannot be done with any other finishing material.

How to choose a site for construction

It is customary to attach such a fireplace to a load-bearing wall opposite the outer door and away from the windows. This arrangement is considered optimal for efficient heating of the room. At the same time, there are many options for installing a fireplace: build it into the wall, place it in a blind corner, or install the device separately. The choice of location depends on the interior of the room and the availability of free space.

A properly built fireplace will not smoke or throw sparks, but it should still not be placed near flammable interior items. It is advisable to choose a place in such a way that there are no windows in the immediate vicinity of the fireplace, or opposite it: this way, maximum heat will be retained in the room.