07/11/2017 9414 Pechnik (Moscow) A metal fireplace with your own hands is a great opportunity to recreate an original heating structure that will have a certain list of characteristics and an exclusive appearance. Despite the fact that it is quite difficult to create a metal hearth without assembly skills, it is quite possible to make the simplest option!

Do-it-yourself fireplaces made of metal will have the simplest design if they require classic solid fuel to operate. Such fires, unlike electric and gas ones, do not require complex manipulations and time-consuming assembly of the internal contents.

You can learn more about the preparatory work process, basic safety rules and step-by-step assembly instructions below or by watching the video in this article.

Design features

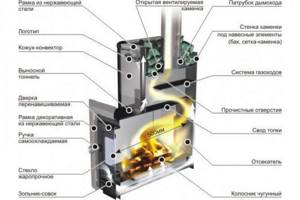

Iron wood-burning fireplaces have an interesting design. The firebox, which looks like a chamber, stands on a special support or stand. There is no need to install an additional foundation for this heating device, but due to the large weight of the unit, a reliable foundation must be provided.

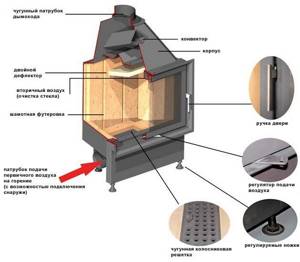

Metal fireplaces with side and top chimney connections

The firebox is connected to a chimney pipe, which removes all combustion products from the heating system. In order to harmoniously fit the device into the interior of the house, its outer surface can be lined with fireproof materials.

Finishing

In absolutely all cases, the resulting fireplace will have to be decorated from the outside. It can simply be coated with a layer of glossy or matte paint. Here you need to remember the elementary laws from the physics course. Dark bodies emit more energy, and since our task is to remove energy, black colors will be a priority.

Good to know: How to properly build a brick fireplace with a stove bench at home

The fireplace can be finished with special fireproof materials. These include tiles made of ceramics, artificial and natural stone. When gluing tiles, you should remember the thermal expansion of the metal, so the seam gap should be slightly increased.

With the possibility of making your own fireplace, a lot of opportunities open up for you to realize your old dream exactly in the form in which it interprets itself. Desire and work in a certain sequence will ensure an excellent result.

Types of units

Depending on the method of placing the installation in a heated room, the following metal fireplaces are divided:

Built-in metal firebox

- wall;

- corner;

- mounted;

- central;

- built-in

At the same time, there are different units depending on the shape and size of the firewood chamber. The firebox can be cylindrical, cone-shaped, in the form of a parallelepiped or other geometric shape.

copper

Fireplaces made of non-ferrous metal are more expensive than cast iron or steel. But they allow you to bring warm copper shades into the interior. A bronze fireplace is less prone to corrosion and rust. And the plasticity of the material makes it possible to make parts of any complexity and filigree from it, which allows you to make the fireplace a real work of art.

According to their purpose, metal fireplaces are divided into the following groups:

heating devices. This is the most common group of fireplaces, performing only the main function - heating the room;

stoves-fireplaces. The upper surface of such ovens is the hob. This way you can even heat food on small fireplaces or, for example, boil a kettle;

grill It turns out that this is also one of the types of metal fireplaces. The main function in such open-top structures is to cook food over coals or wood with low combustion;

decorative fireplaces. They do not provide much heat, but in metal decorative fireplaces you can watch the play of live fire. There are very compact models of decorative fireplaces, suitable for installation in the smallest niches.

Advantages and disadvantages of devices

A wood-burning metal fireplace has the following advantages over other types of heating devices for a private home or cottage:

What does a metal firebox consist of?

- high efficiency;

- light weight of the unit;

- no special maintenance required;

- ease of installation;

- lightning-fast heating of the room;

- can be installed anywhere.

Despite all the benefits that the user of wood-burning fireplaces receives, these devices have a number of disadvantages. First of all, it is very easy to get burned on the stove, since the body gets very hot during combustion. Also, this device cools down quite quickly, which contributes to uneven distribution of heat in the room.

Installation location

It is permissible to mount a metal hearth almost anywhere in the room, even in the center if desired. But such a location will be inferior from an aesthetic point of view and will not comply with fire safety regulations, since the structure can easily be touched and overturned.

The optimal solution is to install a metal wood-burning fireplace near the wall of the room; you can build the structure into it, which will save square meters of space. In this case, the chimney is carefully laid along the wall, and taking it outside is not difficult.

This option for placing the fireplace will prevent smoke in the air in the room. True, the wall behind it will not be clean - it will become smoky and black. The fireplace can be placed near the wall, stepping back a short distance from it.

In this case, if necessary, it will be easy to move it from one wall to another. It is also easier to care for since the structure is movable. This fireplace is accompanied by a fire partition, but even this will not be able to protect the walls from damage to the whitewashed and painted surface or darkening of the wallpaper.

In addition, a metal fireplace can be placed in the corner of the room, which is now considered a stylish option. In this case, it takes up less space: the room visually seems more spacious, since the living space is not overloaded.

The commercially available designer models of corner fireplaces stand out for their originality. They usually have small parameters and are stable. They are much easier to heat and then clean. The chimney will not be difficult to bring outside.

So, experts recommend the following options for placing fireplaces made of metal:

- built into an external wall;

- wall;

- angular;

- located separately.

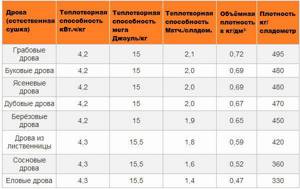

What fuel should I use?

For heating a dacha or country house, it is best to use dry firewood. In this case, give preference to aspen. A special type of metal unit is a stove that uses pellets as an energy source. They are loaded into the firebox in the required volume, and the heating intensity is adjusted automatically or using a manual control unit.

What kind of wood is better to burn?

Also, some types of metal units can operate on gas. These devices are safer for heating, but it is impossible to make them yourself.

Installation

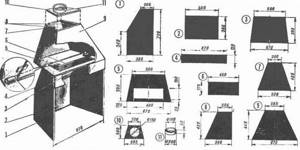

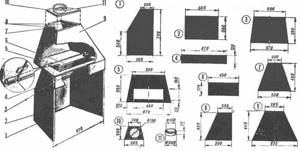

Before starting installation work, you need to create a drawing of the future product. When drawing up a diagram, it is necessary to take into account not only the structure itself and its individual parts, but also the exact dimensions of the object

It is also important to define a clear assembly order, which should also be reflected on paper

After the preparatory activities, you can begin assembling the future iron fireplace. First, it is recommended to connect the side parts of the structure by welding. The front and rear parts are attached to the resulting structure. At the same time, we must not forget that a special hole must be made in the front part. It is necessary to place firewood inside the structure.

A metal sheet is also attached to the resulting structure by welding. It will be the bottom of an iron fireplace. Before installing the base, you need to attach the legs to it. Their standard length is 10-12 cm. The number and width of supporting parts depends on the weight of the main item.

At the end, as a rule, a special damper is installed. It serves as a partition between the compartment in which wood is burned and the compartment in which ash accumulates. Quite often, such products are made from several layers. They are also made from different metals.

Necessary materials for a homemade fireplace or stove

In order to make a stove with your own hands for heating a private house or cottage, you need to use the following materials:

- metal sheet 5 mm thick. This will be needed for the construction of the combustion chamber and smoke exhaust duct;

- metal sheet 0.5 mm - for making an ash pan with your own hands;

- metal elbows for chimney;

- stainless steel pipes for the construction of a smoke exhaust duct;

- grate;

- good quality door for the combustion chamber;

- various fasteners;

- stand for the case (you can use corners and slats).

Do-it-yourself fireplace with a cast iron firebox

After procuring all the necessary materials, you need to start designing the stove. It is best to draw up drawings before the assembly process with your own hands, which will greatly simplify the installation of a heating device in a private house or cottage.

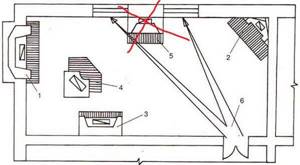

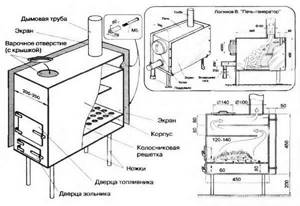

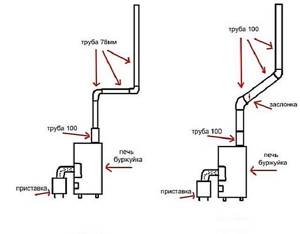

Chimney installation for fireplaces

What a chimney is and what requirements are placed on it is probably not necessary to say. The chimney is a long pipe, at least 5 meters, otherwise there will be problems with draft. The channel is led out to the street through the roof; in some cases, it is allowed to be discharged horizontally through the side walls. The main thing to remember is that it is better to do no more than three zigzags and turns, otherwise you are guaranteed to have problems with traction.

The pipe is installed in a specially cut hole in the lid, where it is secured with a special fastening system. Welding tightly is not recommended. Do not forget that the joints, as well as all connections, must be treated with heat-resistant sealant. By the way, it wouldn’t hurt to separate the transition in the roof with thermal insulation. The head is located at a distance of 50 cm from the roof and it is recommended to install a flame arrester and deflector on it.

How to make a heating stove yourself?

Step-by-step instructions for building a wood-burning stove for a summer house or a private house with your own hands: From metal corners, make a rectangular frame on legs, which will act as a base for the heating unit. After this, securely attach it to the floor. Place a sheet of metal on top of the frame.

Drawing of a metal heating stove

Build a box from sheets of metal that will act as a chamber for firewood. The firebox should have double walls to increase the productivity of the stove. Also divide its inner surface into two parts and install the damper. The process of burning wood will take place in the first compartment, and the accumulation and removal of smoke will take place in the second.

Install the door on the firebox, and then install it on the prepared base. When the firebox is ready, proceed to installing the chimney. It can be made from pipes. They need to be joined together using sockets, and all seams should be lubricated with heat-resistant sealant. To make the curved part, use your knee.

Chimney for a homemade stove

Attach the chimney to the wall with clamps and brackets. To ensure that the finished stove has high fire safety, carefully insulate the transition points of the chimney through the ceiling. Do this using basalt cardboard and glass wool.

Cover the wall behind the fireplace with heat-resistant material. Perform the same operation for the floor near the heating device.

At the final stage, you can line the stove. Homemade wood stoves should be placed in a place where a constant flow of air can be ensured.

Also make sure that flammable materials are not placed near the heating unit.

Preparing the base for the fireplace

The weight of the firebox and fireplace body is very large, so the base for it must be as strong and reliable as possible

It is especially important that this base does not have differences in height, otherwise the structure will settle unevenly and cracks will appear. In addition, the walls adjacent to the firebox should be made of non-combustible materials or sheathed with fire-resistant insulation and galvanized sheets

Cast iron fireplace insert

At the preparatory stage you will need:

- cement-sand mortar;

- brick;

- metal mesh for reinforcement;

- building level;

- trowel;

- insulation;

- waterproofing material;

- roulette.

Step 1. Marking for the fireplace

The area where the fireplace will be installed must be free and clean. The width and length of the fireplace are measured with a tape measure, and markings are drawn on the floor with chalk. If the load-bearing wall is made of wood, it is recommended to either cut out a section of it and replace it with brickwork, or lay an additional brick partition end-to-end.

Marking for the fireplace

If the second option is chosen, the partition should be installed on the same foundation as the firebox. This must be taken into account when marking the base in the floor and add masonry thickness around the perimeter. Lines are also drawn on the wall to indicate the width of the fireplace.

Step 2. Pouring the foundation

The area of the foundation should be larger than the area of the fireplace, so add 30-40 cm on each side. The depth of the foundation is approximately 50 cm; a thinner base will not withstand the load. If the floor in the house is made of boards, a fragment of the covering along with the joists is cut out according to the markings. Mix the cement mortar, then pour a small amount onto the prepared area. They are leveled, a reinforcing mesh is laid on top and filled with mortar again.

Fireplace foundation

You can make a brick foundation: red brick is laid out in several rows with obligatory bandaging until the base rises to the level of the finished floor. The surface of the foundation is checked with a level, leveling with a solution if necessary. When the solution dries well, the base is covered with waterproofing material.

Pouring the foundation for the fireplace

Step 3. Construction of the partition

The masonry is made of brick, aerated concrete or tongue-and-groove slabs - fire-resistant materials. There must be free space between the masonry and the firebox for warm air to escape. Do not lay bricks or blocks close to the pedestal and walls of the firebox. To connect the fire-resistant masonry to the load-bearing wall, metal rods are used, which are laid between the bricks and driven into the wall.

The finished brickwork is plastered with cement mortar or laid with mineral wool, and covered on top with foil material with the foil facing out. You can upholster the masonry with galvanized sheets. If the fireplace is mounted in a corner, the seam between the walls is sealed with a special sealant.

Step 3. Making a pedestal for the firebox

A U-shaped pedestal is laid out on the red brick floor. It consists of 3-4 rows, depending on the desired height of the fireplace. A mixture of clay and sand is used as a binding solution. To reduce the load on the floors, you can take aerated concrete blocks instead of bricks and then plaster them with cement mortar. Each row must be checked with a level; the bricks are adjusted using a rubber hammer. Excess solution is immediately removed with a trowel.

Making a pedestal for the firebox

Making a pedestal for the firebox

Steel corners are laid on the bricks of the fourth row so that they connect the opposite walls. The corners are placed at a distance of 15-15 cm with the protrusion upward. The bricks are placed on edge and grooves are sawed, then they are laid so that the protrusions of the corners fit tightly into the cuts. Only 2/3 of the top of the pedestal is laid with bricks, leaving the space near the wall free. Strengthen it all with a solution and level it. The surface must be perfectly horizontal.

Overlap

Overlap

Ready-made metal stoves

If you can’t make a stove to heat your home or cottage with your own hands, buy a ready-made device that will have no less productivity and functionality. The most popular manufacturers that produce wood stoves for individual use:

- Traforart - fireplaces of this production are equipped with elements that supply air from outside, as well as a secondary combustion function;

New TraforArt products

- Boley - produces models in both classic and high-tech styles. Many units are equipped with glass doors. The Boley stove can be lined with marble, granite, and various metal alloys;

Fireplace Boley Speciale Glashaard - Cheminees Philippe is a European manufacturer that produces fireplaces ranging from the simplest to the most interesting shapes in the avant-garde style;

Wide firebox from Cheminees Philippe - Fugar – produces metal stoves in the mid-price category. The most popular are hanging models or those with a central location;

Fireplace brand Fugar - Meta - have a fairly affordable price. The Meta oven is equipped with a glass-ceramic door, a spacious firebox, and some models have a hob.

Meta and fireplace stoves

Wood-burning stoves made of metal are an excellent solution for heating residential premises, even despite some disadvantages.

[ads-pc-2][ads-mob-2]

Installation

To install a metal stove in a bathhouse, you need to start by preparing a site for it. Such a stove weighs less than a brick stove; it does not require a foundation, but it has a greater fire hazard due to the high temperatures reached due to prolonged burning of wood.

The site for installing the furnace is prepared at least twice as large as the area occupied by the furnace itself, and consists of several layers located from bottom to top:

- asbestos coating;

- stainless steel;

- six-centimeter heat-resistant brick;

There is another option:

- we dig a shallow pit, maintaining the same proportion in terms of area;

- pour sand, crushed stone, compact it;

- fill it with cement mortar and wait for it to harden;

- We spread roofing felt as thermal insulation;

- We check the plane with a level, it is better to make a slight slope towards the drain;

- lay out two rows of red bricks.

To prevent fire, the stove should be placed no closer than one meter from walls and easily flammable objects. The walls around the stove are plastered, lined with bricks, sheathed with sheets of iron or mineralite, and a firewood storage area is separated. If the firebox is removed from the steam room, the opening is also protected from fire by non-combustible materials.

The location for creating the hole for installing the chimney must be provided during the construction of the bathhouse. Creating elbows in the chimney will cause soot to be deposited in such parts of the chimney, which will worsen the draft in the stove. If it is impossible to eliminate such places in the chimney, consider dismantling this area to clean it.

The chimney channel should be made of a double wall sandwich filled with basalt wool. As insulation, you can use a square water tank, which is installed in the ceiling.

Having installed the stove in place, we fill the heater with stones of basalt, river or sea pebbles, gabbro-diabase, soapstone, porphyriate, dunite, white quartz, crimson quartzite. It is better to choose flat stones and place them on the edge in the heater. Do not use stones with red veins or inclusions (this is iron), it is harmful to health when oxidized.

Rules of operation and care

A metal fireplace is quite easy to use and does not require special care. During operation, the main thing is to comply with fire safety measures - to avoid falling out of burning fuel, and so on. When servicing the fireplace, you must be careful not to touch the walls of the product. It is recommended to wear cloth gloves when loading fuel and opening the door.

To maintain the device, you need to regularly clean the firebox and chimney from soot. The overgrowing of the chimney with soot will worsen the natural draft - this can lead to smoke entering the room. Also, you should not wet clean the device - this will lead to increased corrosion and the fireplace will take on an unpresentable appearance.

Why should you choose a metal stove?

A metal fireplace stove is a very good alternative to a stone stove. In terms of heat transfer, it is in no way inferior and is quite capable of warming up one of the rooms. It all depends on the amount of firewood and the degree of preheating. Therefore, even on the coldest days, the stove will delight you with warmth and will not let anyone freeze. A metal fireplace can be made in the form of an elegant and noble design. It will easily fit into even the most sophisticated interior.

A metal fireplace looks no less noble than a stone one

The metal stove is a Japanese invention. As you know, the inhabitants of the Land of the Rising Sun are distinguished by wisdom, practicality and pragmatism, but, nevertheless, they know a lot about the noble design of premises. All these qualities are reflected in a metal fireplace.

Among the advantages of such a fireplace are lightness of design and portability. It is easy to install, move, dismantle. It weighs significantly less than a stone structure and does not require a heavy, durable and expensive foundation.

Another advantage of the fireplace is the combination of simplicity in operation with high efficiency. You can heat it even with a small amount of wood. It takes little time and fuel to warm up, since the metal heats up tens of times faster than brick. And at the same time it gives off a lot of heat, so it’s definitely enough to keep you warm in winter.

We advise you to read in more detail the article on our website, which shows rooms with a fireplace in photographs.

Unpretentiousness is another important advantage. Iron fireplaces are quite easy to clean and do not require any special care. It is enough to just clean them of soot, wet clean them and, if necessary, polish them regularly (for shine). For these purposes, you can use soda and citric acid. Of course, specialized stores also offer a wide range of fireplace care products.

The iron fireplace-stove can be easily transported and placed even in a bathhouse

Tip: Polishing with toothpaste will help eliminate severe darkening. It is better if it is bleaching.

We also recommend studying this topic:

We create a corner fireplace ourselves: a false fireplace in the interior

A corner fireplace will be a stylish and modern solution for the interior. Creating it with your own hands is real. Step-by-step instructions will help you in this endeavor. Let's look at the process in detail.

12937 0 0

There are not many disadvantages to a metal structure. The main ones are the rapid cooling of the furnace after the end of the combustion process and a high fire hazard. When loading firewood, carelessly touching a hot fireplace with your hand can cause burns. Therefore, it is necessary to work with the fireplace only with thick gloves.

Installation diagram and manufacturing stages

To make a fireplace with your own hands, follow the installation diagram. The drawing indicates the dimensions of future furnace elements. According to the drawing data, at the initial stage the main metal elements are cut. To do this, use a grinder. Using a gas cutter produces sheets with uneven edges - they will have to be finished with a grinder and leveled.

Installation begins with preparing the installation site. A metal fireplace does not require the construction of a foundation; it is enough to level the surface and insulate the floor surface from fire. Insulation is carried out in any case, regardless of the material of manufacture. This type of work is carried out because burning wood may fall out of the fireplace - this can damage the floor covering.

After this, the walls around the installation site are shielded. The best option is to lay ceramic tiles - they are easy to care for, and their surface can be easily washed off soot. The shielding material must have high fire resistance.

Next, a stand for the combustion chamber is made. It is welded from a channel or a metal corner. The frame is covered with a sheet of metal, and legs or supports are welded to it. The frame must be highly stable to prevent the fireplace from tipping over.

The next stage is the manufacture of the firebox and enclosing frame. The side, bottom and top sheets of the combustion chamber walls are welded together, and the end sheets (except for the front) are welded. Before this, one or two partitions of incomplete profile are welded in the upper part of the chamber. The stepwise pattern of smoke movement will reduce heat loss with flue gases. This increases the fuel efficiency and efficiency of a metal fireplace.

After the partitions, a grate is installed in the lower third - it will divide the chamber into a firebox and an ash pan. The grille is installed on corners welded to the side walls and should be easily removable for replacement and cleaning. A window for the door is cut in the front sheet, and the sheet is welded to the firebox. The door hinges are installed and the door is installed.

The finished structure is scalded with a steel screen. The screen will increase the inertness of the fireplace and protect it from the hot surfaces of the firebox. A hole for the chimney is cut in the upper part. Facing and decorative elements are installed (optional).