Types of Baswool mineral wool

According to the existing classification of materials used in construction, Baswool brand mineral wool (also called basalt insulation) belongs to products made of stone, glass and slag. Accordingly, these materials are used in its production, and the types of mineral wool are called stone wool, glass wool and slag wool. Each type has its own characteristics:

- Stone wool is especially durable, can withstand any temperature - from low to high, and has increased resistance to vibration. It is produced in wide slabs - this adds convenience during its installation;

- Glass wool is an elastic material with low density and does not interact well with high temperatures. It is used in construction for insulating partitions in apartments and houses; it insulates well, but does not withstand physical stress well - therefore it is not used for insulating the facades of houses;

- Slag wool - has almost the same characteristics as stone mineral wool, and is used in the same cases.

The density of Baswool mineral wool can range from 30 to 180 kg per cubic meter. The density is selected based on the intended use of the insulation. To insulate the facade, mineral wool with a density of 135 kg/m3 is used. For the first layer in a roofing pie - from 100 kg/m3, for the top layer - from 175 kg/m3. When using single-layer thermal insulation, the permissible density is from 140 kg/m3.

Main types of Basvul mineral wool

Now you can begin to get acquainted in more detail with the range of such insulating materials.

Plates for thermal insulation of walls

Materials intended for thermal insulation of walls are produced in the following modifications.

- "Vent Facade".

- "Sandwich C"

- "Standard".

- "Facade".

- "Light."

All of them are produced in the form of slabs 120x60 centimeters with a thickness of 1 centimeter (the latter indicator varies). Let's look at the features of each modification.

Basvul Standard

A universal material that can be used not only for wall insulation. As a rule, it is used in wall structures consisting of several layers (for example, in double brickwork). Also, this option may well be suitable for frame buildings. Due to its low density and excellent thermal insulation qualities, it can also be used for insulating roof slopes. Below are the main parameters of the material.

Table. Characteristics of the heat insulator Standard

| Material parameters | Stated indicators |

| Density, kg/m3 | 50 / 70 |

| Compressibility limit % no more | 10 |

| Thermal conductivity coefficient, VT/(m*K) | Within 0.035 / 0.038 |

| Thermal conductivity coefficient, VT/(m*K), under operating conditions A and B | Within 0.042 / 0.045 |

| Vapor permeability, mg/(m*h*Pa), minimum | 0,3 |

| Water absorption by mass, kg/m2, no more | 1 |

| Water absorption by volume, %, no more | 1,5 |

| Content of organic binders by weight, %, maximum | 3 |

| Range of produced slab thicknesses, mm | 30/200 |

| Average price from the manufacturer, rub – Basvul Standard 50 | 2260 |

| Average price from the manufacturer, rub – Basvul Standard 60 | 2685 |

| Average price from the manufacturer, rub – Basvul Standard 70 | 3135 |

As for prices, here they are indicated from the manufacturer, but transport costs are not taken into account.

Baswool Light

The following insulation, Basvul, can also be used on almost all construction sites (subject to certain conditions, of course). The density of such material is minimal, as is the weight. Because of this, low strength.

Light modification slabs can be used:

- for insulating internal partitions and frame-type walls;

- for insulating pitched roofs;

- for insulation of floors, ceilings between floors;

- for insulation in brickwork consisting of several layers;

- for ventilated facades.

Table. Characteristics of Light insulator

| Material parameters | Stated indicators |

| Density, kg/m3 | 30 / 45 |

| Compressibility limit % no more | 30 |

| Thermal conductivity coefficient, VT/(m*K) | Within 0.035 / 0.038 |

| Thermal conductivity coefficient, VT/(m*K), under operating conditions A and B | Within 0.043 / 0.046 |

| Vapor permeability, mg/(m*h*Pa), minimum | 0,3 |

| Water absorption by mass, kg/m2, no more | 1 |

| Water absorption by volume, %, no more | 2 |

| Content of organic binders by weight, %, maximum | 2,5 |

| Range of produced slab thicknesses, mm | 40/200 |

| Average price from the manufacturer, rub – Basvul Light 30 | 1645 |

| Average price from the manufacturer, rub – Basvul Light 35 | 1810 |

| Average price from the manufacturer, rub — Basvul Light 45 | 2035 |

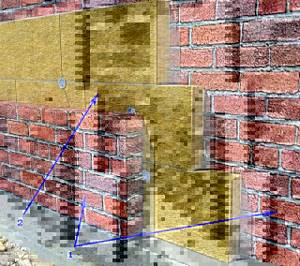

Vent Facade

There is no need to explain what this insulator is intended for - everything is said in its name. With its help, main walls are insulated from the outside for subsequent finishing using ventilated facade technology. The material is dense and therefore resistant to moisture, but during installation it is still recommended to take care of the waterproofing layer.

Table. Characteristics of heat insulator Vent Facade

| Material parameters | Stated indicators |

| Density, kg/m3 | 80 or 90 |

| Compressive strength (at 10% strain) | 10/12 |

| Delamination strength, kPa, not less | 4 |

| Thermal conductivity coefficient, VT/(m*K), under operating conditions A and B | Within 0.035 / 0.038 |

| Vapor permeability, mg/(m*h*Pa), minimum | 0,3 |

| Water absorption by mass, kg/m2, no more | 1 |

| Water absorption by volume, %, no more | 1,5 |

| Content of organic binders by weight, %, maximum | 3,5 |

| Range of produced slab thicknesses, mm | 60/160 |

| Average price from the manufacturer, rub – Basvul Facade 80 | 3540 |

| Average price from the manufacturer, rub – Basvul Facade 90 | 3970 |

Baswul Facade

Material with high density and enhanced strength characteristics. Attached to the walls using mortar for subsequent application of a layer of plaster. That is, such insulation is used for a “wet facade”, which means that during production it is treated with a hydrophobic agent.

Table. Characteristics of heat insulator Facade

| Material parameters | Stated indicators |

| Density, kg/m3 | 80 or 90 |

| Compressive strength (at 10% strain) | 10/12 |

| Delamination strength, kPa, not less | 4 |

| Thermal conductivity coefficient, VT/(m*K), under operating conditions A and B | Within 0.035 / 0.038 |

| Vapor permeability, mg/(m*h*Pa), minimum | 0,3 |

| Water absorption by mass, kg/m2, no more | 1 |

| Water absorption by volume, %, no more | 1,5 |

| Content of organic binders by weight, %, maximum | 3,5 |

| Range of produced slab thicknesses, mm | 60/160 |

| Average price from the manufacturer, rub – Basvul Facade 80 | 3540 |

| Average price from the manufacturer, rub – Basvul Facade 90 | 3970 |

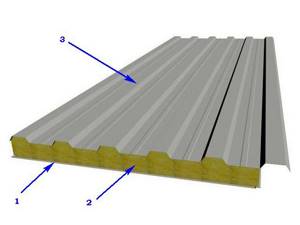

Modification Sandwich C

In most cases, such insulation is purchased by companies specializing in the production of sandwich panels. Obviously, in this case, it is the strength of the material that is important, because it is designed for use in harsh operating conditions.

Table. Characteristics of the heat insulator Sandwich C

| Material parameters | Stated indicators |

| Density, kg/m3 | 100 or 110 |

| Compressive strength (at 10% strain) | 60 |

| Delamination strength, kPa, not less | 100 |

| Thermal conductivity coefficient, VT/(m*K), under operating conditions A and B | Within 0.042 / 0.044 |

| Vapor permeability, mg/(m*h*Pa), minimum | 0,31 |

| Water absorption by mass, kg/m2, no more | 1 |

| Water absorption by volume, %, no more | 1,5 |

| Content of organic binders by weight, %, maximum | 4,5 |

| Range of produced slab thicknesses, mm | 100/200 |

| Average price from the manufacturer, rub – Basvul Sandwich C 100 | 4400 |

| Average price from the manufacturer, rub – Basvul Sandwich C 110 | 4840 |

Note! If desired, slabs of this material can be ordered in larger sizes than the standard 120x60 centimeters.

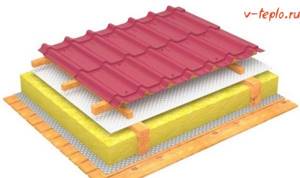

Plates for thermal insulation of roofs

We are talking about the Ruf line of insulating materials, which are mostly intended for flat roofs. If the roof is of a pitched type (or we are talking about residential attics), then it is preferable to use the Light modification by laying it between the rafters. Let's take a closer look at each of the representatives of the Ruf line.

Baswul Ruf

Used for sound and thermal insulation of flat roofs (in one layer). It is possible to lay a soft roof on top of the material or fill it with concrete. It is also worth noting the fact that the insulation is heavily treated with a hydrophobic agent.

Table. Characteristics of the thermal insulator Ruf

| Material parameters | Stated indicators |

| Density, kg/m3 | 140 or 170 |

| Compressive strength (at 10% strain) | 50 |

| Delamination strength, kPa, not less | 10 |

| Thermal conductivity coefficient, VT/(m*K), under operating conditions A and B | Within 0.038 / 0.04 |

| Vapor permeability, mg/(m*h*Pa), minimum | 0,31 |

| Water absorption by mass, kg/m2, no more | 1 |

| Water absorption by volume, %, no more | 1,5 |

| Content of organic binders by weight, %, maximum | 4,5 |

| Range of produced slab thicknesses, mm | 50/160 |

| Average price from the manufacturer, rub – Basvul Sandwich C 100 | 6170 |

| Average price from the manufacturer, rub – Basvul Sandwich C 110 | 7180 |

Modifications Ruf V and Ruf N

Each Basvul insulation (that is, N and B) is used together, comprehensively. They are intended for thermal insulation of the roof in two layers, followed by pouring concrete or laying soft roofing material.

It is quite obvious that “B” in this case means “Upper”, and “N”, respectively, “Lower”. The lower plates are less dense, but have greater thickness. The upper ones are more dense and durable, but have a slight thickness.

Table. Characteristics of the heat insulator Ruf N/V

| Material parameters | Stated indicators | |

| Basvul Ruf N | Basvul Ruf V | |

| Density, kg/m3 | 100 or 120 | 170 / 200 |

| Compressive strength (at 10% strain) | 35 | 60 |

| Delamination strength, kPa, not less | 7,5 | 15 |

| Thermal conductivity coefficient, VT/(m*K), under operating conditions A and B | Within 0.036 / 0.038 | Within 0.039 / 0.041 |

| Vapor permeability, mg/(m*h*Pa), minimum | 0,30 | 0,31 |

| Water absorption by mass, kg/m2, no more | 1 | 1 |

| Water absorption by volume, %, no more | 1,5 | 1,5 |

| Content of organic binders by weight, %, maximum | 4 | 4,5 |

| Average price from the manufacturer, rub – Basvul Ruf N 100 | 4415 | |

| Average price from the manufacturer, rub – Basvul Ruf N 110 | 4850 | |

| Average price from the manufacturer, rub – Basvul Ruf N 120 | 5790 | |

| Average price from the manufacturer, rub – Basvul Ruf V 170 | 7630 | |

| Average price from the manufacturer, rub – Basvul Ruf V 180 | 7980 | |

| Average price from the manufacturer, rub – Basvul Ruf V 190 | 8400 |

Modification Sandwich K

The scope of operation here is practically the same as that of Sandwich C, only in relation to roofing structures. The strength here must also, of course, be very high. The main technical data of the modification are given below.

Table. Characteristics of the heat insulator Sandwich K

| Material parameters | Stated indicators |

| Density, kg/m3 | 125/150 |

| Compressive strength (at 10% strain) | 100 |

| Delamination strength, kPa, not less | 100 |

| Thermal conductivity coefficient, VT/(m*K), under operating conditions A and B | Within 0.044 / 0.045 |

| Water absorption by mass, kg/m2, no more | 1 |

| Water absorption by volume, %, no more | 1,5 |

| Content of organic binders by weight, %, maximum | 4,5 |

| Range of produced slab thicknesses, mm | 100/120 |

Plates for thermal insulation of floors (interfloor ceilings)

As you know, most of the thermal energy leaves the room through the floor. Moreover, if the floor is cold, then walking on it will be uncomfortable, even if the room is heated quite well. And in order to insulate these building elements, the manufacturing company produces a specialized line of mineral wool.

The insulation of the Flor model range is characterized by quite high strength, therefore, it can be used when arranging a “warm floor”, laid with subsequent pouring of concrete, and also installed on overlapping slabs and soil. The material is also extremely resistant to moisture, which is why the penetration of water into the room from the outside is excluded in principle. Finally, installing such slabs is quite simple; even people who do not specialize in construction work can handle it.

The line itself consists of only two modifications:

- Flor modification;

- modification Flor P.

How are they different from each other? It turns out that these are exclusively technical parameters, which, in turn, depend on the operating conditions of the working surface. For example, Flor P mineral wool is designed for insulating floors that will be subject to significant mechanical loads (this includes, for example, industrial facilities). Basic technical data of the materials are given below.

Table. Characteristics of heat insulators Flor and Flor P

| Material parameters | Stated indicators | |

| Baswul Flor | Basvul Flor P | |

| Density, kg/m3 | 100 or 120 | 160 / 180 |

| Compressive strength (at 10% strain) | 25 | 50 |

| Delamination strength, kPa, not less | 7 | 15 |

| Thermal conductivity coefficient, VT/(m*K), under operating conditions A and B | Within 0.035 / 0.038 | Within 0.038 / 0.04 |

| Vapor permeability, mg/(m*h*Pa), minimum | 0,3 | 0,3 |

| Water absorption by mass, kg/m2, no more | 1 | 1 |

| Water absorption by volume, %, no more | 1,5 | 1,5 |

| Range of produced slab thicknesses, mm | 50/150 | 20/50 |

| Content of organic binders by weight, %, maximum | 4 | 4,5 |

| Average price from the manufacturer, rub – Basvul Ruf N 100 | 4520 | |

| Average price from the manufacturer, rub – Basvul Ruf N 110 | 5425 | |

| Average price from the manufacturer, rub – Basvul Ruf V 190 | 7265 |

It is also worth noting that if the floor is insulated by laying insulation between the joists, then Basvul Standard or Light insulation can be used for this.

Baswool mineral wool for heat and fire protection

We should also talk about the model range, the representatives of which combine the properties of insulating material and fire protection. We are now talking about the modifications Hit Protect and Fire Protect.

Note! These modifications are new on the domestic market, however, they have already gained considerable popularity among buyers and numerous positive reviews.

Using this material, you can reliably protect building structures, pipelines, ventilation ducts, various types of communications and tanks. The main technical data of this type of insulation is given below.

Table. Characteristics of thermal insulators for heat and fire protection

| Name of slabs Basvul | Material density, kg/m3 | Range of produced thicknesses, mm | Maximum operating temperature | Average price from the manufacturer, rub/m3 |

| Line Basvul Fire Project | ||||

| Fire Project 100 | 100 | 50/250 | 750C | 5060 |

| Fire Project 140 | 140 | 50/150 | 750 C | 7220 |

| Fire Project 180 | 180 | 40/100 | 900 C | 9060 |

| Baswool Heat Project line | ||||

| Heat Project 40 | 40 | 50/100 | 250C | 2100 |

| Heat Project 60 | 60 | 50/120 | 350C | 2950 |

| Heat Project 80 | 80 | 50/150 | 750 C | 4250 |

| Heat Project 90 | 90 | 50/120 | 250C | 4770 |

| HeatProject 100 | 100 | 50/120 | 750C | 4970 |

As a small conclusion

As a result, it is worth noting that Basvul insulation is an ideal option for insulating buildings for both residential and industrial purposes. In the video below you can find more information on this topic, as well as installation and operation features.

Detailed characteristics of the material

Basvul is a high-quality mineral wool made from basalt rocks. She is one of the brightest representatives in her segment.

Main features and differences from competitors

Popularity comes to a particular brand only if it has a considerable amount of advantages. The trend was confirmed this time too. Basvul is characterized by the following advantages:

- Variability of use. It can be used for both interior and exterior work (depending on the type).

- High temperature resistance, class NG (non-flammable substances). This is one of the few brands of mineral wool that can boast of this. Fire resistance is achieved due to the presence of stone fibers that prevent combustion.

- High noise absorption rate. When using insulation on the roof, it dampens up to 80% of noise and vibrations. As a result, no drops of rain or hail can be heard.

- Low (no more than 1%) water absorption coefficient. Therefore, this material can be used in rooms with high humidity (bath, kitchen, etc.).

- Absolute absence of shrinkage, even over time the wool does not deform.

- Relatively light weight.

- Absolute resistance to natural irritants: fungus, mold, etc. As a result, the material never rots, even in conditions of high humidity.

- Ease of installation. Basvul is sold in small rolls that are easy to roll and cut. Therefore, installation comes down to simple operations that anyone can handle with their own hands.

- As a consequence of the above advantages, the operational period is up to 50 years.

Moreover, the prices of this brand are significantly lower than those of foreign analogues (Knauf. RockWool, Isover, etc.) by an average of 20-30%. A competent pricing policy has become one of the main drivers of the success of this domestic manufacturer.

All known varieties

There are several types of Basvul thermal insulation, which differ in basic technical characteristics. For clarity, all data is presented in table form.

| Characteristic | Type of insulation | ||||

| Light | Standard | Facade | Vent. Facade | Rufus | |

| Density (kg/m3) | 35-45 | 50-60 | 140-160 | 80-90 | 110-190 |

| Thermal conductivity index (W/m*C) | 0,35-0,4 | ||||

| Vapor permeability (m*h*Pa) | 0,3-0,31 | ||||

| Water absorption (% of volume) | 1-1,5 | ||||

| Flammability class | NG (non-flammable material) | ||||

| Organic content (%) | 2,5 | 3 | 4,5 | 3,5 | 4-4,5 |

The technical characteristics presented above are regulated by TU 5762-001-80015406-2010. The product is certified. More detailed information can be obtained here - https://www.baswool.ru/assets/images/promotion/baswool.pdf

Mineral wool Baswool (Basvul) Standard 50 (1200x600x50)

Wall insulation BASWOOL Standard has found wide application in the construction of industrial, administrative and residential buildings. It is made from raw materials of natural origin. The main purpose of insulation is thermal insulation of walls built from small-piece materials.

Advantages of BASWOOL Standard boards:

- high technical characteristics - the material has low thermal conductivity (0.035-0.038 W/(m*K)), significant density (50-70 kg/m3) and practically does not absorb moisture (no more than 1.5% by volume); — minimal loads on the structure — BASWOOL Standard is lightweight;

— safety — the insulation is resistant to fire, no harmful substances are released from its surface. The packaging complies with GOST.

Application area:

In civil engineering, as unloaded heat and sound insulation of enclosing structures of all types of buildings: - middle thermal insulation layer in walls, partially or completely made of small-piece material;

— thermal insulation of frame walls, including external ones with various types of finishes, including siding.

Package:

BASWOOL STANDARD heat and sound insulating boards are packaged in accordance with the requirements of GOST 25880 and TU 5762-001-80015406-2010 in polyethylene shrink film, in packs. For ease of transportation and storage, transport packages are formed from packaged heat and sound insulating boards.

Physical and mechanical properties:

| Index | Standard |

| Density, kg/m3 | 50 |

| Compressibility, % no more | 10 |

| Thermal conductivity at 10 0 C, W/(m*K), no more | 0.035 |

| Thermal conductivity at 25 0 C, W/(m*K), no more | 0.038 |

| Thermal conductivity under operating conditions A, W/(m*K), no more | 0.042 |

| Thermal conductivity under operating conditions B, W/(m*K), no more | 0.045 |

| Vapor permeability, mg/(m*h*Pa) not less | 0.3 |

| Water absorption by mass, kg/m2, no more | 1.0 |

| Water absorption by volume, %, no more | 1.5 |

| Content of organic substances by weight, %, no more | 3.0 |

| Flammability degree | NG |

Overall dimensions of the plates:

| Length, mm | Width, mm | Thickness, mm | Quantity per pack, m3 | Cost of a pack, rub | |

| 1200 | 600 | 50 | 6 | 0.2160 | 415,00 |

| 1200 | 600 | 60 | 6 | 0.2592 | 498,00 |

| 1200 | 600 | 70 | 6 | 0.3024 | 580,00 |

| 1200 | 600 | 80 | 4 | 0.2304 | 442,00 |

| 1200 | 600 | 90 | 4 | 0.2592 | 498,00 |

| 1200 | 600 | 100 | 4 | 0.4320 | 830,00 |

| 1200 | 600 | 110 | 4 | 0.3168 | 607,00 |

| 1200 | 600 | 120 | 2 | 0.1728 | 330,00 |

| 1200 | 600 | 130 | 2 | 0.1872 | 360,00 |

| 1200 | 600 | 140 | 2 | 0.2016 | 386,00 |

| 1200 | 600 | 150 | 2 | 0.2160 | 415,00 |

| 1200 | 600 | 160 | 2 | 0.2304 | 442,00 |

| 1200 | 600 | 170 | 2 | 0.2448 | 470,00 |

| 1200 | 600 | 180 | 2 | 0.2592 | 498,00 |

| 1200 | 600 | 190 | 2 | 0.2736 | 524,00 |

| 1200 | 600 | 200 | 2 | 0.4320 | 830,00 |

What are the varieties?

Each insulation product has a wide selection of models used in different areas of insulation. The same can be said about Basvul.

Baswool Light 45

The parameters and features of Basvul Light 45 allow it to be used for insulating frame walls, interior plasterboard partitions, roofs, interfloor slabs, and attics. You can also insulate floors with it by laying it between the joists.

It is produced in slabs with a density of 30-50 kg/m 3. There are different models of Light insulation 30, 35, 45. The number indicates the density of the material.

Roof thermal insulation

Baswool Facade

It is produced in slabs with a density of 110-160 kg/m 3. This building material is used for façade insulation, followed by plastering and decorative finishing. Speaking about the properties of Basvul Facade, we can note the thermal conductivity of 0.036-0.040 W/(m*K), peel strength 15-21 kPa (the indicator depends on the density, the higher it is, the greater the peel strength).

Baswool Vent Facade

It is produced in slabs with a density of 80, 90 kg/m 3.

These two models have compressive strengths of 17 and 20 kPa, respectively. Layer peel strength is 6.8 kPa. Water absorption by volume is 1.5%. Corresponding to the entire model range.

Basvul Vent Facade is considered non-flammable and prevents the spread of fire.

Thermal insulation of the facade

Baswool Standard

This model is available in slabs of different densities - 50, 60, 70 kg/m3. It is used as a layer in a wall made of small-piece material. It is used for frame insulation indoors and outside the building. The Baswool facade insulation standard does not require plastering of the slabs. This option is intended before finishing with siding.

Basvul Standard absorbs no more than 1.5% moisture (volume percentage). The thickness of the slabs varies from 3 to 20 cm.

Frame insulation

Baswool Flor

It is manufactured for floor insulation. It can be laid under the screed of a floating structure. It is also used for heated floors. Basvul Flor has soundproofing qualities. Density - 100-120 kg/m3.

BASWOOL STANDARD

To main > BASWOOL > BASWOOL STANDARDBASWOOL STANDARD

Minslab BASWOOL STANDARD is a modern insulation material made from basalt mineral wool. Minslab BASWOOL STANDARD is designed for thermal insulation and sound insulation in residential and industrial construction. The BASWOOL STANDARD minislab is lightweight and is a non-flammable material. BASWOOL STANDARD insulation is produced in the form of hydrophobized slabs with a width of 0.5 and 0.6 m, a length of 1 and 1.2 m, and a slab thickness from 3 to 20 cm. All BASWOOL STANDARD mineral wool slabs are wrapped in polyethylene shrink film (according to TU TU 5762-001-80015406-2010 and GOST 25880) and are packaged in packs.

Properties of minislab BASWOOL STANDARD

- low thermal conductivity

- good sound absorption

- high density

- vapor permeability

- hydrophobicity

- chemical resistance

- non-flammability

- increased density

Application of BASWOOL STANDARD mini-slabs

Minslab BASWOOL STANDARD is widely used as non-load-bearing sound insulation and thermal insulation of enclosing structures and in the construction of facades of all types of structures and buildings in civil engineering. BASWOOL STANDARD mineral wool boards are used for thermal insulation and sound insulation of internal and external frame walls with various types of finishes (plywood, plasterboard, tile materials, siding, etc.). BASWOOL STANDARD mineral wool boards are also widely used as a middle insulation layer in walls that are fully or partially made of small-piece building material (it is recommended to use boards with a density of 60-70 kg/m3). Also, BASWOOL STANDARD mineral wool boards are often used as an external insulating layer for two-layer thermal insulation, when installing a system of external thermal insulation of facades with a ventilated gap (it is recommended to use boards with a density of 80-90 kg/m3).

For the convenience of transporting the material to the site and further storage there, BASWOOL STANDARD mineral wool boards are formed into transport packages.

Price list, prices for thermal insulation BASWOOL STANDARD

Technical characteristics of mini-slabs BASWOOL STANDARD

Name

| Meaning | |

| Length, mm | 1000,1200 |

| Width, mm | 500,600 |

| Thickness, mm | 30÷200 |

| Density, kg/m3 | 60…90 |

| Compressibility, % no more | 10 |

| Thermal conductivity at 10 0 C, W/(m*K), no more | 0,035 |

| Thermal conductivity at 25 0 C, W/(m*K), no more | 0,038 |

| Thermal conductivity under operating conditions A, W/(m*K), no more | 0,042 |

| Thermal conductivity under operating conditions B, W/(m*K), no more | 0,045 |

| Vapor permeability, mg/(m*h*Pa) not less | 0,3 |

| Water absorption by mass, kg/m2, no more | 1,0 |

| Water absorption by volume, %, no more | 1,5 |

| Content of organic substances by weight, %, no more | 3,0 |

| Flammability degree | NG |

What is Baswul?

Baswool insulation

Stone wool is made from basalt rocks. To obtain this fiber, raw materials are processed at temperatures above 1000°C. The individual parts are held together with organic resins. Basvul is produced at a modern plant in Blagoveshchensk near Ufa. The first batches of insulation were released in the summer of 2011.

This basalt wool is used in the processing of private buildings, outbuildings, as well as industrial institutions. The price is affordable, so even those who do not have the means to use expensive building materials can carry out thermal insulation work using this insulation.

Features of mineral wool slabs under the Baswool brand

Mineral wool slabs are made from natural raw materials (basalt rocks) using a synthetic binder. However, the quality of the latter is so high, and the production technology is so strictly observed that the finished material is safe for humans.

Basalt insulation has high strength, durability, and a special structure that causes its low thermal conductivity. Basvul slabs do not support combustion at temperatures up to 1000°C, and do not deform under the influence of fire. They can act as a sound-absorbing material and an additional waterproofing layer. Insulation materials are not attractive to fungi, rodents, harmful microorganisms, and insects.

Types and characteristics of Baswool insulation

Basvul stone wool with high density.

Basvul insulation is manufactured at, which is located near the capital of Bashkortostan, the city of Ufa. The company produces various thermal insulation materials:

- glass wool;

- stone wool;

- extruded polystyrene foam;

- fire protection

All products are manufactured using the latest Slovenian-made equipment. Baswool insulation is used for all thermal insulation work, both in civil and industrial facilities. Mineral wool insulation has gained the most popularity.

Thanks to the fairly democratic pricing policy of the management of the Agidel LLC holding, the cost of the product in the retail network is more than moderate. At the same time, there is plenty to choose from in the Basvul insulation line. Conventionally, all materials can be divided into groups:

- for roofing;

- for horizontal floors;

- for walls.

Different operating conditions are undoubtedly taken into account in the characteristics of each material.

Scope of application

Basvul insulation materials are used in private construction, in the construction of multi-storey residential buildings and industrial facilities. Basalt slabs are used to insulate walls using frame technology, when installing ventilated facades and insulating structures using the wet method.

The scope of application depends on the density of the mineral wool. Rigid slabs are recommended for areas with high loads - flat roofs, facades, floors. Lightweight insulation materials are suitable for heat and sound insulation of frame partitions, attic floors, and pitched roofs.

Basvul mineral wool, what’s so warm about it?

Stone or mineral slabs in their name do not carry heat, but if you pay attention to the fibrous structure of the material, it immediately becomes clear that heat is retained in it perfectly!

Buying Basvul insulation is an excellent solution for a private one-story house or for commercial construction. For this purpose, the material has a whole list of advantages, the main of which are:

- Environmental friendliness: fiber for boards is obtained from molten basalt rocks;

- Durability: the service life of the insulation exceeds 50 years;

- Hydrophobic impregnation: water absorption even with complete immersion is no more than 1.0 kg/m3;

- Non-flammable material: does not smoke on an open fire and prevents the spread of fire;

- Low thermal conductivity: heating up to 750 degrees on one side of the stove will feel like a comfortable 20 degrees on the opposite side;

- Thermal insulation with Basvul slabs supports the natural breathing of the house, removing excess moisture through the walls.

To maintain thermal insulation properties, it is recommended to use wind and vapor barriers, which will maintain moisture removal and protect the mineral wool. The springy material Baswool fits perfectly into the frame of guide profiles, covers the surface and is fixed even in steep areas.

The light weight and high economic performance of Basvul insulation, the price of which is significantly lower than that of foreign analogues with similar characteristics, makes the domestic manufacturer one of the sales leaders. In terms of performance characteristics, Penoplex brand polystyrene foam can be compared with Baswool stone wool.

Baswool mineral wool for walls

Stone wool is used indoors and outdoors.

In the line of thermal insulation materials for walls, it produces the following types of insulation:

- Light;

- Standard;

- Ventilated façade;

- Facade;

- Sandwich S.

The main difference between all these materials is their density, which cannot but affect thermal conductivity. The higher the density of the material, the worse it works as thermal insulation. Basful Standard has a density of 70 kg/m. cube, while Ventfacade is already 90 kg/m. cube The heaviest and densest material is Baswool Facade mineral wool, which weighs 160 kg/m. cube This is necessary so that it is possible to implement insulation of external walls using the wet facade method.

Sandwich C is used in the production of insulating panels for walls. Compared to Sandwich K (for the roof), it has a lower density, which is 110 kg/m. cube This is quite enough, since the load on the walls is much less than on the roof.

Thermal insulation of walls

You can insulate walls using Basvul insulation in one of the following ways:

- on a metal or wooden frame;

- using fastening brackets;

- using a basement cornice.

Work can be performed outside and inside the house.

Frame method

Wall insulation begins with the installation of a metal frame. The insulation is placed inside the frame and secured with special glue or dowels.

Then a vapor barrier is installed, for example, foil film, and the wall is sheathed with plasterboard. After this, the necessary finishing work is carried out.

Universal insulation - from floor to roof

Baswool universal mineral wool boards are widely used for thermal insulation:

- interfloor ceilings, floors along logs;

- internal partitions;

- walls of frame buildings;

- pitched roofs (attic, attic).

The following names belong to the category of universal insulation: Ecorock 30, Baswool Light 35, Baswool Light 45. They are united not only by the scope of application, but also by average technical characteristics.

- The thermal conductivity coefficient at 10°C is 0.035-0.037 W/m·K. At a temperature of 25°C it increases to 0.038-0.039 W/m·K.

- Density – 30-45 kg/m3. These are relatively low values.

- Water absorption does not exceed 2%.

All Basvul universal insulation materials are lightweight and resistant to chemicals. They are presented on the company’s official website, where you can buy them after reading the characteristics in more detail.

Description and main characteristics

Baswool mineral wool is produced by Agidel LLC, one of the leaders in the production of thermal insulation materials. The insulation described in the article can be used for insulation:

- walls;

- roofs;

- floor (interfloor ceilings).

The material can be used equally effectively both in private construction and in the construction of industrial facilities. It is made from molten rock - basalt - at a temperature of a thousand degrees. It is thanks to this production technology that the insulation received its exceptional characteristics. Let's look at them.

- The weight of this heat insulator can vary between 25 and 225 kilograms per cubic meter.

- The moisture absorption rate does not exceed 1 percent of the total weight, as well as 2 percent of its volume.

- Thermal conductivity, as a rule, does not exceed 0.038 Watt/m*K.

- Basvul has high vapor permeability - at least 0.3 milligrams/(h*m*Pa).

- The standard dimensions of insulation boards are as follows (WxLxH) - 600x1200x30-200 millimeters.

- Finally, in terms of its flammability it belongs to class A1.

Now let’s take a look at the advantages of Baswool heat insulation and how exactly it differs from competing insulation materials.

Strengths of Basvul heat insulator

As we noted above, the basalt wool described in the article has numerous advantages, thanks to which it has gained enormous popularity. Let's consider the advantages of insulation in more detail.

- It has excellent noise and thermal insulation properties.

- It weighs little, which means installation is not particularly difficult.

- The vapor permeability of the insulation is quite high, and therefore the most comfortable microclimate is maintained in the insulated room.

- The material is easy to install.

- It is environmentally friendly, and despite the fact that its service life is practically unlimited.

- During the entire period of operation in buildings, neither the dimensions nor the properties of the material change.

- Insulation shrinkage is minimal.

- Finally, it is hygroscopic.

Special thermal insulation - types and features

Special thermal insulation is intended for insulation of individual structures. It is developed taking into account operating conditions and possible load.

Thermal insulation Basvul for flat roofing

A flat roof experiences much greater loads than a pitched roof. For this reason, it requires thermal insulation with increased compressive strength and density. This is exactly what the manufacturer produces under the Baswool brand.

- Baswool RUF. Designed for single-layer insulation under a cement screed or without it. Material density is 140 or 160 kg/m3, strength is 50 and 60 kPa.

- Baswool RUF N – mineral wool boards with low thermal conductivity for the bottom layer of thermal insulation. Their density is 100-120 kg/m3, strength is 35-45 kPa.

- Baswool RUF V is the top layer of insulation when installing two-layer insulation. It has the highest density in the presented line - 170-190 kg/m3 and strength - 65-80 kPa.

All three types of basalt slabs are characterized by reduced water absorption - no more than 1.5%.

Basalt slabs for floor insulation

High-quality floor insulation not only reduces heat loss, but also creates a comfortable microclimate in the room. For effective thermal insulation, you need especially durable, moisture-resistant, dense slabs with increased noise absorption.

Baswool offers the consumer two types of materials with suitable characteristics: Baswool Floor, Baswool Floor P. They are designed for constructing various floors:

- "floating";

- warm;

- under the screed along a layer of thermal insulation;

- interfloor ceilings;

- over an unheated basement.

Please note: Basvul Flor P insulation can withstand much greater loads than Basvul Flor. It can even be used to insulate floors in industrial premises

Specifications:

- Baswool Floor has a density of at least 100 kg/m3 and a strength of at least 30 kPa. The thermal conductivity coefficient at 10°C does not exceed 0.035 W/m·K, and at 25°C – 0.037 W/m·K.

- Baswool Floor P can withstand a load of 160-180 kg per 1 m3 with a compressive strength of 50-55 kPa. The thermal conductivity coefficient, depending on the temperature regime, ranges from 0.037-0.040 W/m·K.

Heat and sound insulation floor slabs are resistant to moisture and shrinkage.

Thermal insulation of external walls (facade)

The manufacturer's product range includes several types of mineral wool slabs for insulating external walls.

- Basvul Facade is designed for single-layer thermal insulation of facades for their subsequent plastering. It has increased density (110-160 kg/m3), strength, low water absorption (less than 1%).

- Basvul Vent Facade is suitable for installing a ventilation façade. Most often it is used as external insulation with two-layer thermal insulation. The density of such mineral wool slabs can be 80 or 90 kg/m3, which is marked accordingly in the form of a number. Their water absorption does not exceed 1.5%, and the thermal conductivity coefficient at 10°C is maximum at 0.035 W/m K.

- Basvul Standard slabs with a density of 50, 60 and 70 kg/m3 are an option for insulating frame external walls and facades under small-piece finishing materials. This can be siding, block house, etc. The thermal conductivity coefficient, vapor permeability and water absorption are the same as those of Basvul Vent Facade.

The roof, walls, and floors have a large area, so without proper insulation, heat loss through them can be large. Baswool thermal insulation helps to effectively prevent them by creating a comfortable microclimate inside the building.

Popular types of Baswool insulation

Minvata Basvul is a heat-insulating material based on basalt rocks. The brand's products are manufactured at a plant with modern automated lines. The fibers are of high quality; their chaotic weave provides numerous air cavities. The Baswool brand offers materials for all types of insulation:

Light

Light series insulation materials have the lowest density and lowest price. This is a budget option for thermal insulation of unloaded areas of the building. The manufacturer produces 3 types of slabs, their markings indicate the density. Baswool Light 45 insulation materials are recommended for thermal insulation of floors and roofs; Light 35 is best installed in an attic or attic. Basalt wool with a density of 30 kg/cubic. m are used for interior partitions.

Rufus

Ruf basalt slabs are high-density roofing insulation materials. They are installed with single-layer roof insulation. Material density 140-160 kg/cub.m. Modifications marked “H” and “B” are intended for installation on a flat roof as a bottom and top layer. The products have a compressive strength in the range of 35-80 kPa. Long-term operation of the roofing pie is ensured by a record density reaching 190 kg/cubic meter. m. Another positive feature of roofing insulation is low water absorption - 1.5%.

Facade

The use of basalt slabs to insulate the facade of a building allows you to maintain a favorable microclimate without additional heating costs. The line of insulation for external walls includes:

- The façade is made of rigid basalt sheets with a density of 110-160 kg/cu.m. m, intended for plaster.

- Vent Facade is an insulation material with increased hydrophobization, used in the installation of ventilated facades. Mineral wool does not experience increased loads, so its density does not exceed 90 kg/m3. m.

A significant wall area leads to heat loss due to insufficient insulation of the enclosing structures. Basvul is an insulation material that quickly and reliably cuts off the cold from the interior.

Sandwich

Multilayer insulation construction is in demand in the production of sandwich panels for frame houses. Two types of products are available:

- Sandwich C - the outer layer of the wall panels is a metal sheet; slabs with a density of 100-110 kg/cubic meter are used as insulation. m.

- Sandwich K - roofing panels require the use of a material with a high density - 120-140 kg / cubic meter. m. The outer covering of the structure is made of painted metal.

The boards are protected from moisture by water-repellent impregnation. The material is used in the construction of administrative and commercial buildings, kiosks, garages. Sandwich panels with basalt wool have a fire safety certificate.

Flor

High-quality floor insulation will be provided by the Baswool thermal insulation of the Flor series. Durable slabs are used under screed, as part of a “floating” floor, to insulate floors. Basalt wool can reduce the level of noise penetrating between floors. The material is not afraid of moisture; it is used for flooring on the ground. The mechanical strength of the insulation is due to its high density. The Flor modification has 100-120 kg/cubic meter. m, Flor P – 160-180 kg/cu.m. m. The use of mineral wool significantly reduces heat loss. It is recommended when installing a heated floor system.

Standard

Universal insulation for insulating wall structures. It is widely used as a middle layer in well masonry. Standard slabs are characterized by an average density of 50-7 kg/cubic meter. m. Many air layers ensure a minimum thermal conductivity. The material significantly reduces noise penetration. Basalt wool does not deform during operation. It can be laid under exterior siding.

Ecorock

The Baswool Ecorock series are lightweight mineral wool slabs designed for insulation of pitched roofs, attic floors and joist floors. The material has the lowest density among manufactured products. A minimum amount of binder ensures safe use inside residential buildings.

Standard

Sandwich

Ecorock

Insulation of floors (floors)

All work begins with dismantling the floor covering. If the floor covering is going to be reused, it must be removed very carefully. In this case, it is advisable to mark with chalk where a particular fragment lay.

Leveling the base

The floor surface must be leveled. This will greatly facilitate the subsequent steps and increase the comfort of being in the room. Most often the screed is poured. However, with minor fluctuations in the surface, you can resort to other methods of leveling the base, depending on the type of floor, as well as financial capabilities.

If the base has not been properly prepared, cracks and crevices may form in it during subsequent use. As a result, the floor will be cold.

Laying vapor barrier and installing logs

After leveling the base, a layer of vapor barrier is laid. The material should be selected taking into account the operating characteristics of a particular room. Laying must be done with an overlap on the walls. The overlap should be proportional to the size of the joists.

The installation of the logs should be carried out taking into account the uniformity of the applied load. The optimal distance is considered to be about 90 cm. When choosing the size of the log, you should focus on the total area of the room and the size of the heat-insulating material used. The logs must be securely fastened in the selected places.

Installation of insulation

Mineral wool should be cut according to the size of the grooves formed between the joists and placed in the available space. The thermal insulation material should fit very tightly to the joists. The presence of gaps is unacceptable. To do this, each piece of insulation should be taken a centimeter wider than the width of the groove.

Waterproofing, finished floor

Waterproofing is laid on the insulation layer. Its characteristics must be fully consistent with the characteristics of the room for which it is purchased.

Installation of a finished floor begins with attaching a durable material to the joists that can absorb and evenly distribute the load. For this purpose, you can purchase regular boards, as well as special drywall, plywood, chipboard or fiberboard. The selected coating is laid on top of it.

Description and main characteristics

Baswool mineral wool is produced by Agidel LLC, one of the leaders in the production of thermal insulation materials. The insulation described in the article can be used for insulation:

The material can be used equally effectively both in private construction and in the construction of industrial facilities. It is made from molten rock - basalt - at a temperature of a thousand degrees. It is thanks to this production technology that the insulation received its exceptional characteristics. Let's look at them.

- The weight of this heat insulator can vary between 25 and 225 kilograms per cubic meter.

- The moisture absorption rate does not exceed 1 percent of the total weight, as well as 2 percent of its volume.

- Thermal conductivity, as a rule, does not exceed 0.038 Watt/m*K.

- Basvul has high vapor permeability - at least 0.3 milligrams/(h*m*Pa).

- The standard dimensions of insulation boards are as follows (WxLxH) - 600x1200x30-200 millimeters.

- Finally, in terms of its flammability it belongs to class A1.

Now let’s take a look at the advantages of Baswool heat insulation and how exactly it differs from competing insulation materials.

Strengths of Basvul heat insulator

As we noted above, the basalt wool described in the article has numerous advantages, thanks to which it has gained enormous popularity. Let's consider the advantages of insulation in more detail.

- It has excellent noise and thermal insulation properties.

- It weighs little, which means installation is not particularly difficult.

- The vapor permeability of the insulation is quite high, and therefore the most comfortable microclimate is maintained in the insulated room.

- The material is easy to install.

- It is environmentally friendly, and despite the fact that its service life is practically unlimited.

- During the entire period of operation in buildings, neither the dimensions nor the properties of the material change.

- Insulation shrinkage is minimal.

- Finally, it is hygroscopic.

In addition, Basvul insulation is a representative of the class of non-combustible materials; it fully complies with all fire safety standards and can even be used as fire protection in appropriate fences.

Note! The manufacturing company produces and sells a fairly wide range of mineral wool slabs for insulation, from the lightest (about 25 kilograms per cubic meter) to the heavy ones (up to 225 kilograms). Video – Basalt wool Basvul

Video – Basalt wool Basvul

Thanks to the characteristics listed above, Basvul compares favorably with other thermal insulation materials. The table below shows the comparative characteristics of the described insulation and its closest “competitors,” that is, EPS and polystyrene foam.

Table. Comparison of insulation materials

Parameter name

Thermal insulator

Baswul

Styrofoam

Extruded polystyrene foam

Among the many thermal insulation materials, mineral wool products have an advantage when it comes to fire safety issues. One of them is Baswul. It is used when performing a variety of types of thermal insulation work. There are different types of this building material: Basvul Light, Standard, Flor P, ECOROCK, Basvul Vent Facade, as well as others, the technical characteristics of which indicate high quality products.

Production of insulation

Basvul insulation is a representative of high quality basalt materials. Its production is carried out at the company’s own sites from basalt ore. In particular, the entire process occurs by melting the material and stretching it into fibrous fragments. Subsequently, these parts are connected to each other using special binders, which ensures the strength of the product and high performance characteristics.

In addition, Basvul insulation, the technical characteristics of which fully comply with all state standards, has a number of advantages, in particular:

1. — Low level of thermal conductivity of the material. This parameter is due to the structure of the material, which consists of fibrous fragments.

2. — The material is non-flammable and therefore can be used to ensure fire safety.

3. — Basvul basalt insulation provides a high level of sound insulation, absorbing up to 80% of noise.

4. — High moisture resistance of the material, which is due to the use of hydrophobic enzymes in the production.

5. In addition, the material is made from environmentally friendly materials, without the use of toxic additives, therefore it is not harmful to the body and can be used to insulate any buildings.

Due to these advantages, insulation has gained great popularity and recognition among consumers, and today it is used in all areas of construction.

Insulation sizes and types of materials

This insulation is presented in a large number of varieties, and is classified according to several factors, in particular:

1. — By thickness.

2. — By density.

Depending on its thickness it can be divided into:

1. - Thin, from 50 to 100 millimeters.

2. - Medium from 10 to 150mm.

3. - And thick up to 200 mm.

Depending on their density, they can be made in variations: 30, 35, 45, 50, 60, 70, 80, 90, 110, 120, 140 kilograms per square meter (km/m3).

Thus, Basvul insulation, the sizes of which are quite varied, can be used for various purposes due to its characteristics.

Characteristics of the material "Basvul Facade"

Increasingly recently, consumers are choosing Basvul products. Facade insulation can be used for thermal insulation of external walls, onto which decorative plasters are subsequently applied. Standard sheets are limited to a thickness of 4 to 16 cm, and the density varies between 135–175 kg/m3. Compressive strength is equivalent to 45 kPa, water absorption is minimal and does not reach 1%. The content of organic substances is less than 4.5%. Due to the fact that the material is not flammable, it can be used in reconstructed or new industrial and civil facilities.

Types of thermal insulation Basvul Ruf

“Basvul” - insulation, the characteristics of which are presented in the article, is offered for sale in the “Basvul Roof” variety. According to buyers, this thermal insulation is used when installing low-slope or flat roofs. The thickness of the sheets can vary from 5 to 16 cm, while the density varies from 40 to 170 kg/m3. Consumers emphasize that thermal conductivity, depending on temperature, can reach 0.04 W/m K. Water absorption by volume for this variety does not exceed 1.5%. You may also be interested in the strength, which remains at 50 kPa. There are two types of this thermal insulation: the first is used for arranging the lower, and the second – for the upper double layer.

Advantages and disadvantages

This building material can be used for facades and interior work.

Different sizes of insulation allow you to choose products of exactly the thickness that is necessary for the purpose of high-quality insulation.

Application in various areas of insulation

- Non-flammability - it is completely fireproof.

- High level of sound insulation.

- Good vapor permeability.

- Environmentally friendly. During operation, such material will not cause harm to residents of the house that is insulated with it.

- The material does not rot and is also not susceptible to beetles and microbes.

- It has a long service life - 40 years.

- Easy to install.

- Has low water absorption. Since moisture has a detrimental effect on insulation, this factor is important.

- As with any mineral wool, contact with water is undesirable. Although this model is hygroscopic, it should still be protected from rain and high humidity. This means that when performing facade work, it is necessary to begin plastering the surface (for wet facades) as early as possible. For ventilation facades, the wool should be covered if rain is expected.

- When performing installation work, you must provide yourself with all the necessary personal protective equipment. You need to work in gloves, glasses, and a respirator. Clothes must have long sleeves.

What is Baswul?

Stone wool is made from basalt rocks. To obtain this fiber, raw materials are processed at temperatures above 1000°C. The individual parts are held together with organic resins. Basvul is produced at a modern plant in Blagoveshchensk near Ufa. The first batches of insulation were released in the summer of 2011.

This basalt wool is used in the processing of private buildings, outbuildings, as well as industrial institutions. The price is affordable, so even those who do not have the means to use expensive building materials can carry out thermal insulation work using this insulation.

Basalt insulation Baswool for roofing

The slabs may fall out of their seats under their own weight. They need to be further secured.

Basvul roofing basalt insulation, according to reviews, has proven itself well if all installation work was carried out according to technology. It is available in slabs:

- RUF;

- RUF N;

- RUF V;

- Light;

- Sandwich K.

Based on reviews that confirm the characteristics declared by the manufacturer, Baswool RUF insulation can be installed under a screed. This allows for a fairly high density of 120-140 kg/m. cube and compressive strength 60 kPa. Its main purpose is insulation in one layer, the thickness varies from 50 to 200 mm. Like any stone wool, it allows steam to pass through (at least 0.3 mg/m*h*Pa). At the same time, it almost does not absorb moisture, the value is only 1.5% per day, lambda 0.037-0.04 W/mK.

Baswool RUF N insulation, technical characteristics:

- density 100-120 kg/m. cube;

- compressive strength maximum 45 kPa;

- lambda 0.036-0.038 W/mK;

- does not burn.

The level of vapor permeability and water absorption is the same as that of the previous material. This insulation is used as the first layer of a thermal insulation cake. Material thickness from 40 to 200 mm. It can also be installed under a thin protective screed.

Basalt insulation Baswool RUF V is laid as a second layer on RUF N. The density of this material is 170-190 kg/m. cube, which makes it more resistant to mechanical stress. It is much stronger in compression than the bottom layer, this value is 80 kPa. The increased density is reflected in thermal conductivity, lambda is 0.038-0.041 W/mK. Thermal insulation thickness is from 30 to 50 mm.

Thermal insulation Basvul Light has a low density of 30 kg/m. cube Thanks to this, the thermal conductivity of the material is only 0.037 W/mK, which is quite good for stone wool. This material is more susceptible to moisture absorption (2% per day), so it must be protected with vapor barrier films or other materials that prevent air circulation. The material can also be used to insulate horizontal ceilings and walls.

Mineral wool Baswool Sandwich K is used for the production of roofing panels, where the insulation on both sides is covered with metal (tin). Density 140 kg/m. cube and a compressive strength of 110 kPa are enough to make the products strong. At the same time, this material cannot boast of low thermal conductivity, lambda 0.042-0.045 W/mK.

Material Specifications

Given the location of the application of mineral wool, the description of its technical characteristics will vary. Below are the main parameters:

- Density - from 25 to 225 kg/m3.

- The thermal conductivity index ranges from 0.035 to 0.042 W/(m*K).

- Flammability class - A1. This level is assigned to those subspecies that are not susceptible to fire, that is, they stop the spread of fire.

- Vapor permeability is about 0.3 mg/(m*h*Pa).

- Moisture absorption - no more than 1% of weight, no more than 2% of the total volume.

Technical characteristics of Baswool basalt wool

- High strength: this quality is due to the source material (stone) for the production of stone wool, and allows the use of this thermal insulation in any building structures. Despite its high strength, Basvul basalt wool is easy to cut, which speeds up and simplifies all work.

- Fire resistance: high resistance to fire and elevated temperatures.

- Thermal insulation: reliably insulates rooms from thermal influences, guaranteeing high energy saving rates.

- Noise insulation: creates comfortable indoor conditions due to a special fibrous structure with a chaotic arrangement of fibers.

- Good vapor permeability: effectively removes moisture from building structures and maintains an optimal indoor microclimate.

- High moisture-repellent qualities: mineral wool is ideally hydrophobic and is not affected by living organisms, as it is made from a material not suitable for their habitat and nutrition.

- Elasticity, plasticity and resistance to mechanical stress, therefore it is used when carrying out work of any level of complexity.

Baswool basalt wool fills the entire insulated space without the formation of cold bridges due to the large number of air capsules (a kind of mini-thermoses) in its structure, located between the fibers of the material. Dimensions and shape are maintained over a long service life.

The Baurex company is the official dealer of the Baswool plant, so you can buy basalt wool from us cheaper than in other stores.

Related Posts

- Isover thermal insulation overview

- The best stone wool insulation - a review of manufacturers and brands

- Mineral wool, its characteristics and insulation composition

- Izovol

- Choosing non-flammable insulation for walls and ceilings: tips and tricks

- Subtleties of attic floor insulation

- Foil insulation: types, properties and possibilities of use

- Ecover insulation: pros and cons

- Insulating the attic from the inside if the roof is already covered: step-by-step instructions

- Technolight

- Types of roll insulation and the distinctive features of each of them. roll insulation for walls: choosing the best thermal insulation special thermal insulation coating

- Properties and types of dowel mushrooms for fastening insulation

- TechnoNIKOL

- Insulation of a veranda in a wooden house

- Thermal insulation pierced mineral wool mats: material properties

- What's better

- Aluminum foil for bath insulation

- Choosing insulation for a frame house

- Insulation of a house made of 150x150 timber from the outside

- How to properly insulate a wooden house with mineral wool

- Ecowool as insulation: pros and cons

- Insulation of facades. insulation for exterior walls of a house

- Insulating the attic with foam plastic

- Hydro-vapor barrier “isospan b”. characteristics and instructions where and how to use insulating material

- Insulation of a concrete floor in an apartment

Read with this

- Isover thermal insulation overview

- The best stone wool insulation - a review of manufacturers and brands

- Mineral wool, its characteristics and insulation composition

- Izovol

- Choosing non-flammable insulation for walls and ceilings: tips and tricks

- Subtleties of attic floor insulation

- Foil insulation: types, properties and possibilities of use

- Ecover insulation: pros and cons

- Insulating the attic from the inside if the roof is already covered: step-by-step instructions

- Technolight