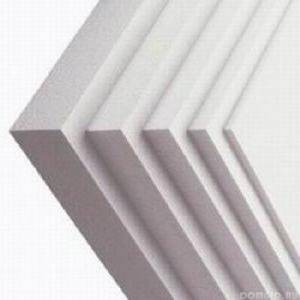

Expanded polystyrene foam

The main materials for the production of polystyrene foam are:

Table of physical and technical characteristics of polystyrene foam.

- polystyrene;

- polyethylene;

- polyvinyl chloride;

- polyurethane;

- polypropylene;

- phenolic, epoxy, urea, silicone resins.

Production involves heating, thermal expansion and molding of polystyrene granules. Due to the fact that the slabs consist of 90% air, this material is considered one of the best insulation materials. Expanded polystyrene boards have different thicknesses.

This material is very popular when insulating the facade or foundation of a house. One of the main positive aspects of polystyrene foam is its low price. In addition, polystyrene foam boards are lightweight, but at the same time have excellent strength and durability characteristics.

Installation is not difficult. Expanded polystyrene is a hygroscopic material. That is, even if exposure to moisture occurs, the foam will not lose its thermal insulation properties.

Scheme of building insulation with mineral wool and polystyrene foam.

But, along with all the advantages, polystyrene also has disadvantages. Speaking about which is better, polystyrene foam or mineral wool, it is necessary to note the advantage of mineral wool over polystyrene foam in sound insulation properties. Polystyrene foam does not have the same soundproofing properties as mineral wool. Foam plastic, compared to mineral wool, has a much lower vapor permeability coefficient. Foam plastic is deformed at t +60°C. Organic solvents destroy the material, meaning it is not resistant to such organic liquids. In construction, it is used only for insulating residential premises; industrial buildings and high-rise buildings (above 30 m) are not insulated with polystyrene. The biggest disadvantage of polystyrene foam is its susceptibility to flame. Expanded polystyrene boards, when ignited, go out on their own, unless, of course, the requirements of the standard are violated during production.

Mineral wool

Mineral wool is a fibrous material. By melting rocks, metallurgical slags and various mixtures, manufacturers obtain mineral wool. It is precisely because rocks are used that the material is of high quality and has good performance and long-lasting properties.

Table of properties of mineral wool.

There is also a blast furnace production of mineral wool. It is obtained from slag, but it is not suitable for thermal insulation of large industrial premises. It is used only for insulating residential buildings or apartment walls.

The positive aspects of mineral wool include the following:

- fire resistance;

- sustainability;

- no deformation;

- vapor permeability and resistance to moisture penetration;

- excellent sound insulation;

- anti-corrosion properties;

- high thermal resistance;

- easy installation;

- durability.

Mineral wool has good fire resistance because non-flammable silicate melts of igneous rocks are used in its production. High temperatures do not cause deformation processes, and mineral wool is not destroyed. Experts recommend insulating rooms where various flammable substances are planned to be insulated only with mineral wool slabs. The material prevents the spread of fire and the source of ignition in case of fire.

The figure shows that the greatest heat loss occurs through the walls, so they should be insulated.

When the question is what is best to choose for insulating a room, warehouse or residential building, you should not forget that if there is a mouse in a private house that has access to sheets of foam plastic, then most likely the rodent will ruin the material in several places. This will never happen with mineral wool: rodents are not able to damage even a centimeter of this durable and strong material. Mineral wool has high biological and chemical resistance to various chemicals. Mineral wool is resistant to temperature changes, sunlight and moisture. Having insulated his house with these materials, the owner will definitely not worry about mold or mildew ever appearing on the walls.

Mineral wool is not capable of deforming after shrinkage of the house.

The performance properties of polystyrene foam are good, but sometimes it happens that it begins to let in cold air at the joints. By using mineral wool, the occurrence of “cold” cracks is excluded.

Due to the fact that mineral wool is non-hygroscopic, there is no penetration of moisture into the room or onto the walls. Before installing mineral wool, the sheets must be treated with a water-repellent agent, because the water absorption of this material is very low.

When building any room, the level of humidity inside the building is very important. In order to remove water vapor and condensate, it is necessary that the heat-insulating material have good vapor permeability properties. Mineral wool is just the material that has a high vapor permeability rate.

Mineral wool has high thermal resistance. This means that it has the ability to resist external changes and maintain a certain temperature in the room. Different geometries and directions of mineral wool fibers have different thermal conductivity. Randomly directed fibers are considered ideal.

Comparison of materials by thickness

Mineral wool has excellent sound insulation. Polystyrene foam also prevents the penetration of sound waves, but mineral wool has a much higher ability.

Mineral wool has high strength and is an anti-corrosion material. When metal objects come into contact with cotton wool, corrosion is guaranteed not to occur.

Mineral wool is an environmentally friendly material and does not affect human health. Of course, cotton wool releases some substances, but they are absolutely not harmful to humans.

Installation of mineral wool is not difficult at all. The material is easy to cut with a regular knife or hacksaw and easily takes the shape of any surface.

Mineral wool is a durable and strong material that will last for hundreds of years if installed correctly. During production, basalt stone is added to mineral wool - this explains its long performance properties.

The only drawback of mineral wool is the cost. If we compare what is cheaper, mineral wool or polystyrene foam, then, of course, foam plastic will win.

Return to contents

Why choose polystyrene foam for soundproofing your home?

To soundproof rooms, a wide range of products with the necessary qualities are used. If certain conditions are met, identical results can be achieved in all cases.

The answer to the question why polystyrene foam is so popular among both craftsmen and users will be its following qualities:

- affordable price. In comparison with other types of soundproofing materials, polystyrene foam is not only competitive, but is among the top materials in this area;

- ease of installation. The dimensions of the sheets allow you to form the required dimensions of the parts from which the soundproofing layer is mounted. Processing foam plastic is not difficult. It cuts easily with a knife;

- ecological and sanitary-hygienic cleanliness. There has been much debate over these characteristics, but studies have shown that the volatiles emitted are not in sufficient concentration to cause harm to human health. Exceptional cases of allergic reactions are caused by individual intolerance and are extremely rare. Fears about foam soundproofing are clearly overblown;

- long service life. The material is not susceptible to infection by mold, fungi and other microorganisms;

- stability of geometric dimensions. The coefficient of dynamic change in dimensions is extremely small and does not depend on humidity and non-critical temperature fluctuations;

- good sound insulation properties. The porous structure of the foam effectively dampens vibrations. Proper installation will reduce household noise to the required level.

The functional characteristics of polystyrene foam necessary for the implementation of a housing soundproofing project can be supplemented with a number of related qualities. Light weight makes transportation easy. It can be stored for a long time in unheated and utility rooms without compromising the quality of the product.

Among the disadvantages, there is a relatively low melting point of polystyrene foam, which actually has no practical significance:

- simple foam softens at 140° C;

- epoxy at 170° C;

- polyurethane foams soften at temperatures above 230° C.

Anti-foam is added to construction foam, which blocks the combustion process. The material itself does not support fire for more than 4 seconds. After which it goes out. But in the case of an open fire nearby, the process continues.

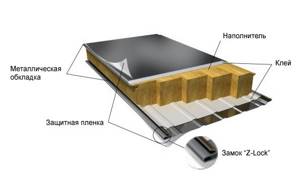

Sound insulation materials

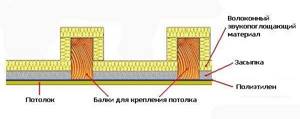

Ceiling soundproofing diagram.

Insulation of internal walls is necessary primarily to ensure that peace and quiet reign in the house. Therefore, when working on sound insulation, choose:

- extruded polystyrene foam;

- products based on basalt fiber;

- drywall;

- steel panels;

- plasterboard membranes;

- polyurethane foam materials;

- polystyrene insulation boards created by extrusion;

- rigid boards made of extruded polystyrene foam. In their production, polystyrene of the highest strength is used.

To install foam panels, they must first be cut. And this is not easy, since the foam crumbles when cutting. But there are several options thanks to which you can easily cut a piece of the required shape without deforming it.

To complicate the design and improve the soundproofing of the room, plasterboard is added to the base of foam boards as a frame. This method can achieve very good results.

Typically, the problem of increased noise transmission in domestic premises arises after unsuccessful repairs (redevelopment). Therefore, for sound insulation, it is imperative to carry out measuring work to establish the noise level. Such calculations will be done better by a specialist - an acoustician.

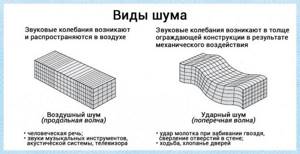

What kind of noise does polystyrene foam sound insulation protect against?

Negative reviews of foam sound insulation arise because people do not understand the differences between types of noise and between sound insulation and sound absorption, which is important. The noise may be as follows:

- Air. As the name suggests, these are sounds that are transmitted through the air without affecting the structure of the room (walls, floor, ceiling). Airborne noise seems to seep through barriers, but does not interact with them. Classic examples: the sounds of a working TV, music or neighbors talking behind the wall.

- Shock. As unpleasant as airborne noise can be, long-term exposure to impact is worse because it creates such vibrations that it can cause severe headaches. And all because impact noise creates a point load on the building structure, especially on the ceilings in apartments of multi-storey buildings. Typical impact noise comes from loud stomping noises, as well as objects falling on the floor.

- Structural. This view is also created by the interaction of a noise source with the building structure, but in a different way: tangentially. Most of us encounter this type almost every day: a working drill, furniture or other objects moving on the floor are typical examples of structural sounds.

You should choose the material based on what type of noise you want to protect against. Extruded polystyrene foam (penoplex) is excellent for impact protection, has good structural damping properties, but is useless against airborne ones. However, in practice, sound insulation in a city apartment must be made not from one, but from several materials to achieve the desired effect, and the work must be performed by professionals who know how to properly combine these materials. Thus, brick and plasterboard have soundproofing properties, reflecting airborne noise, and foam plastic and mineral wool are sound absorbers that work against impact. The right combination of these materials can combat any type of noise, including structural noise.

Characteristics of foam plastic

Polystyrene is one of the few that is not capable of releasing substances harmful to the human body. Expanded polystyrene is a type of plastic that, when burned, emits vapors identical to wood. Thanks to manufacturing technology, this material has the property of quickly fading. Water is not capable of destroying it, much less causing the proliferation of microorganisms. Therefore, polystyrene may come into contact with food. Expanded polystyrene can come into excellent contact with asphalt mixtures, fertilizers, paints, and soap.

It has been proven that the external environment does not destroy the composition of polystyrene foam. But water wears away stones. Therefore, excessively long exposure to ultraviolet radiation can significantly reduce its resistance to moisture and air currents. It would be best to cover the foam structure with a special material.

Thanks to the perfection of technology, a fire retardant was introduced into the composition of the foam. Due to this, he gained the ability to resist fire for 4 seconds. A sheet of polystyrene foam 3 cm thick can protect the room to a fairly good extent. If you increase the foam layer, you can achieve a very high level of noise absorption. The insulation is made from several sheets of expanded polystyrene, sealing the outer layer with a rigid facing material. This design can absorb almost 100% of noise.

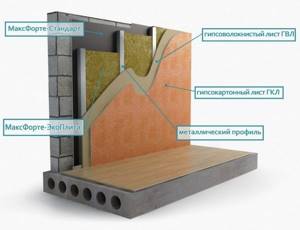

Wall soundproofing diagram.

But it is worth remembering that polystyrene foam is afraid of contact with chemical compounds (ethyl alcohol, acetone, white spirit, gasoline, kerosene). This is explained, first of all, by the structural features of the foam, which contains cells filled with air.

When using penoplex and expanded polystyrene in construction, a number of positive aspects can be highlighted. These include:

ease and ease of processing; use without additional precautions; non-susceptibility to deformation.

Ceilings, their sound insulation with penoplex

Soundproofing work requires an integrated approach, only then will everything be done efficiently and reliably.

- The surface of the ceiling is cleaned of plaster so that the working surface of the ceiling is better and of higher quality.

- To prevent mold and mildew from appearing over the years, the prepared ceiling should be treated with an antiseptic.

- Apply a layer of liquid waterproofing agent.

- The reinforcing mesh must be fixed to the ceiling surface.

- Using special glue, attach the penoplex to the fixed mesh.

- Next, cover everything with plasterboard, after which finishing work is carried out over the entire surface of the ceiling, depending on wishes and taste.

As you work, you should not forget about things like cracks on the surface of the ceiling, as well as where the most noise comes from. You may have to sew up not only the ceiling, but also the floor, and maybe the walls. Some surfaces may not provide the desired soundproofing effect, since extraneous sounds do not travel through them, and the work done will be unnecessary.

Experienced builders use penoplex foam with a specially shaped edge to work on heat and sound insulation. This feature of the material makes installation much easier, avoiding the formation of “cold bridges”, and sound insulation is more effective.

If you resort to the help of specialists who carry out work on insulation and soundproofing of the ceiling in 2 layers, then the price on average can be about 1800 rubles for a room up to 30m2. The cost of the work usually includes all necessary materials, delivery and loading and unloading operations.

The process of soundproofing structures

Properly installed thermal insulation using Penoplex allows you to create a reliable barrier to external noise, cold and moisture for several decades, leaving them behind the wall. Thanks to the tight joining of the slabs, it is possible to create a reliable thermal insulation environment for the enclosing structures. This increases the period of operation of the structure and its ability to withstand loads.

Features of soundproofing walls

Due to the small thickness of the slabs, Penoplex is suitable for covering walls and ceilings indoors. It slightly reduces the usable area, but at the same time creates an excellent sound insulation effect.

For Penoplex, it is necessary to take care of the evenness of the surface on which the material will be mounted. The base must be thoroughly cleaned of old layers, paints and flaking materials. Prime concrete walls with compounds containing quartz sand - they will improve the adhesion of the glue to the wall. For interior work, you don’t even need to install a frame—the slabs are attached directly to the base using glue.

- Apply markings on the wall for the installation of Penoplex.

- Use a utility knife to cut the slabs according to the dimensions of the walls.

- Prepare the glue according to the instructions - pour the mixture into water, mix with a mixer and leave for 10 minutes, then mix again.

- Using a spatula, apply the prepared glue to the surface of the foam board, covering 40-50% of its area.

- Fasten the material to the wall surface in the required order, trying to leave minimal gaps between the elements. The plate must be pressed tightly to the base, making light rotational movements.

- When the adhesive has hardened, secure the slabs with disc dowels.

- Tape the joints with aluminum tape. If the distances turn out to be voluminous, you can fill them with polyurethane foam.

- The top of Penoplex must be plastered using mesh or fiberglass.

Important! To insulate the facade, Penoplex is fixed to a frame made of a metal profile.

Soundproofing the floor

Penoplex laid on the floor will relieve residents from the noise of neighbors below and will additionally insulate the room. Even when combined with a concrete screed, the product will not create additional load on the floor and will not cause damage to the overall structure.

Penoplex insulation technology will depend on the base surface. If the apartment has an old wooden floor covering, it will have to be dismantled, the logs strengthened and stiffeners created. Then all the cracks are blown with foam and sealed with construction tape.

But most often Penoplex is combined with concrete floors under screed. Stages of work:

- Clean the surface from old coating, glue and mortar residues.

- Remove all dirt and dust, seal cracks and defects with putty or construction foam.

- Prime the surface of the concrete floor.

- Mark and cut the slabs taking into account protruding communications, pipes, etc.

- Pour a layer of sand or sand-cement mixture, about 1.5-2 cm thick, onto the concrete surface. The powder is done in stages, no more than for 2-3 slabs at a time.

- Lay Penoplex sheets on top of the embankment, lightly pressing them against the sand layer. Thus, the base is leveled and the mixture is distributed evenly.

- Cover the entire surface with insulation.

- Lay reinforcing mesh cards overlapping on top.

A concrete screed prepared using a certain technology from cement mortar is poured on top of the mesh.

Soundproofing ceilings

Insulating the ceiling in the room will eliminate temperature changes inside, which will prevent the formation of fungus and mold. The surface is prepared in the same way as in previous cases - it is necessary to get rid of the old coating, fill the voids and prime the ceiling.

Stages of insulation work:

- Prepare the adhesive composition.

- Cut the slabs into segments corresponding to the area and configuration of the ceiling.

- Apply a small amount of glue to each slab - in a continuous strip along the perimeter and several dots on the inner area.

- Press the part tightly against the surface of the ceiling, trying to press it into the base. Thus fill the entire surface of the ceiling.

Important! The insulated ceiling can be finished with plasterboard, decorative panels or a layer of plaster.

Properties of penoplex and expanded polystyrene

From everything stated earlier, we can conclude that this material is a fairly valuable and useful building material that has a number of positive qualities.

To all of the above properties you can add a few more:

- low weight, due to which the use of such insulation can significantly reduce costs during construction work, while saving money on the use of any special equipment and greatly reducing installation time;

- the material is quite easy to process. The fact is that working with some materials necessarily involves the use of various equipment: protective overalls, respirators, gloves and goggles. Polystyrenes are odorless, do not emit dust during processing and do not cause skin irritation;

- polystyrenes are resistant to biological influences and chemical environments; they are highly resistant to various substances: sea water, cement, various saline solutions and many others. They are not digestible by animals or microorganisms, and do not create a breeding ground for fungi or bacteria;

- transportation, storage, cutting and installation can be carried out without the use of special protective equipment;

- when pressed the materials are very durable;

- expanded polystyrene is breathable;

- penoplex and polystyrene have excellent energy saving indicators, for example, polystyrene foam, which is only 3 cm thick, is equivalent to 64 cm of brickwork, 123 cm of concrete and 11.3 cm of wood;

- Penoplex has very low breathability.

The most popular thermal insulation materials in today's construction are mineral wool and expanded polystyrene. Both materials have excellent characteristics and are recommended for thermal insulation work. You can hear the opinion that these materials are interchangeable, although experts recommend using mineral wool in the construction of roofs and ventilated facades, and expanded polystyrene for external insulation of walls. In order to choose the right material for a particular case, you should learn a little more about its positive qualities and disadvantages.

Content

- Expanded polystyrene, its advantages and disadvantages video video

- Mineral wool, what it is, its disadvantages and advantages video

- Let's summarize the comparison of materials - which is better: polystyrene foam or mineral wool?

- We take into account the scope of application

Foam plastic, its advantages and weaknesses

Polystyrene foam is rightfully considered the best of heat insulators; its 10 cm thick slab can replace, in terms of heat-shielding properties, 4 m of concrete, 1.5 m of hollow brick masonry, 0.9 m of expanded clay concrete, 0.6 m of aerated concrete and even 0.4 m of wood. It retains heat about one and a half times better than mineral wool.

The vapor permeability of expanded polystyrene can have different indicators, depending on its density. Low-density material allows steam to pass through in about the same way as cotton wool, while denser materials allow it to pass through with difficulty.

Sometimes you hear the opinion that polystyrene foam, when heated, releases styrene vapors into the environment that are harmful to humans. Modern research proves that this opinion is wrong; high-quality polystyrene foam is in fact absolutely harmless; it releases toxic substances in extremely small quantities that are not harmful to humans.

It is recommended that before purchasing the material, make sure that the residual styrene content is at the level of 0.01 - 0.05%.

Expanded polystyrene is a material with a long service life. The most durable, non-pressed foam grades have a service life of 10 to 40 years, extruded ones - up to 80.

Among the negative qualities of the material, one can note its selective ability for sound insulation and its tendency to flammability. The acoustic characteristics of a material depend on its structure, i.e. depending on the type of porosity: materials with closed porosity, such as polystyrene foam, extruded polyethylene, polyvinyl chloride foam, have the property of absorbing sounds whose frequency exceeds 1600 hertz, i.e. They will eliminate fan noise quite effectively, but will not at all affect the audibility of, for example, human steps. Foams with open porosity, such as polyurethane foam, perfectly absorb noise of any frequency, so they can be used as a soundproofing material.

As for fire safety, when burning polystyrene foam emits smoke that is toxic to humans. However, modern types, the basis of which is polystyrene foam, contain substances that not only prevent the possibility of fire, but also help extinguish the flame. The new generation includes self-extinguishing polystyrene foam of the SPB-S brand; it cannot be ignited by a spark, but it is still not protected from the harmful effects of fire.

Some problems can be caused by the very low, but still existing, ability of the material to absorb water. If a small amount of liquid enters the very small pores present inside during the freezing process, it can lead to the destruction of the internal structure of the foam. Moreover, pressed and non-pressed polystyrene foam is susceptible to such destructive effects of moisture.

It is recommended to use polystyrene foam boards only for installing external thermal insulation.

When considering which foam plastic is better, you should first of all subject to a thorough study of its qualitative characteristics and their compliance with the most important requirements that apply to a thermal insulation material in each specific case: thermal conductivity and noise absorption coefficients, hygroscopicity, flammability.

Mineral wool, what it is, its disadvantages and advantages

Mineral wool, which is actively used in construction, is of two types, they are determined by the raw materials used in production: glass wool is made from broken glass or quartz sand, by melting and blowing the raw material into thin fibers, the color of glass wool is light yellow; basalt wool is made by melting rocks breeds, its color can range from brownish-yellow to greenish.

It is difficult to say unequivocally which mineral wool is better; the characteristics of both types of material are almost identical, however, the basalt variety has a higher fire resistance coefficient, and glass wool has a lower specific gravity.

Both types of cotton wool owe all their positive qualities to the properties of igneous rocks or quartz sand. Mineral wool is a non-flammable material, its melting point is about +800 degrees C. At lower temperatures it does not change its properties and does not contribute to the spread of fire.

It has a high thermal insulation rate, second only to expanded polystyrene. But moistening the material can have a significant impact on its reduction, the reason for this is the high hygroscopicity of mineral wool. At the same time, the material is able to perfectly transmit steam through its fibrous structure. The advantages of mineral wool include its excellent sound absorption ability.

But this seemingly ideal material is also not without its drawbacks. The first of them is the large weight, which makes building structures heavier and creates certain problems during delivery to the construction site.

The environmental friendliness of the material is also somewhat problematic: the binder used in the manufacture of cotton wool can release a highly toxic component - formaldehyde, and its fibers themselves contain carcinogenic substances. Due to these factors, the use of mineral wool is permitted only when installing external thermal insulation.

Let's summarize the comparison of materials - which is better: polystyrene foam or mineral wool?

For greater clarity, let’s compare both types of thermal insulation materials according to their quality characteristics:

- In terms of thermal insulation characteristics, foam plastic is a confident leader, even in relation to mineral wool,

- Mineral wool has higher vapor permeability rates

- The hygroscopicity of polystyrene foam is lower; if installation technologies are followed, it can be used without problems in a humid environment; this cannot be said about mineral wool.

- the cost of polystyrene foam is lower than other thermal insulation materials

- the low weight of the foam simplifies its delivery and facilitates installation, the foam is easier to process, difficulties can only arise when processing the joints of the foam boards

- both materials are not suitable for interior work

- chemical resistance: mineral wool, unlike polystyrene foam, is not exposed to organic solvents

- Both materials do not promote the growth of bacteria or fungi on their surface.

We take into account the scope of application

From the above we can conclude that it is quite difficult to determine which is better: polystyrene foam or glass wool. Therefore, when choosing a material, one more very significant point should be taken into account: where exactly they will be used.

When constructing ventilated facades, it would be more rational to use mineral wool, but if the design of the walls involves plastering the surface after insulation, then the best option would be to use expanded polystyrene foam; the same material can be chosen for the construction of walls of a three-layer structure.

Mineral wool and polystyrene foam can be used in the assembly of various communication structures in modern buildings: ventilation, water supply and drainage, sewerage. This takes into account the possible influence of high temperatures and the possibility of the appearance of an aggressive chemical environment around the object. In high-risk areas, preference should be given to mineral wool, which has higher resistance to aggressive factors and high temperatures.

Author: Sergey and Svetlana Khudentsov

10

The use of penoplex for sound insulation

The material is produced in slabs with a thickness of 2 to 10 cm. For sound insulation, penoplex 5 cm thick is used. Installation is carried out on the floor, walls, ceiling, but it is not at all necessary to cover all these surfaces to avoid unnecessary costs. First you need to find out where the source of the annoying noise is: from above, below or from neighbors through the wall.

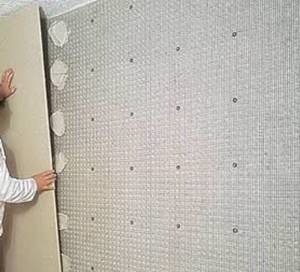

Soundproofing walls and ceilings

The principle of laying penoplex on walls and ceilings is similar. First you need to prepare the surface: clean it of the old layer of plaster, level it, treat it with an antiseptic, and prime it. Then the slabs are glued end-to-end without gaps onto a smooth surface, secured in several places for strength with special dowels with wide heads, the joints are treated with polyurethane foam and leveled. Then a layer of plaster is applied to the walls or ceiling, after it has dried, they are puttied, primed and then a finishing coat is applied or wallpaper is glued.

Soundproofing the floor

First of all, the old floor covering is removed and the logs are dismantled. If glass wool insulation was laid underneath them, then that must also be removed. Before laying the penoplex, it is necessary to assemble a wooden frame for the stiffeners with cells according to the size of the slabs. Treat all cracks with polyurethane foam and seal with special tape. Then install the slabs, insulate all joints with foam and tape. The next stage is the installation of a base made of plywood or other material. And only after this the finishing floor covering is laid.

Other questions on this topic

Hello! We will have 10 sq.m. of heated floor under the tiles. Workers say 3 cm of glue is needed for a heated floor. The remaining area for tiles is 70 sq.m. The workers say that at least 30 bags of Eunice Plus glue are needed and clearly hint that this will not be enough. In the Internet.

We wanted to lay tiles on the walls without seams (as in the photo) in the bathroom. But the workers claim that stitches are needed. Because the house is new and people will only make repairs and move in, but it has been standing like this for 6 years. But it will become heavier and may shrink and the entire tile may shrink.

The workers advise us to use Unis Plus (in red packets), is it worth taking? We will lay the tiles on the walls in the bathroom and the floor in the kitchen, bathroom, hallway

Please recommend adequate good builders. We are planning renovations in a 3-room apartment P44T in Moscow. All 3 rooms need repairs, 2 loggias need to be glazed and insulated. The rest of the premises have been renovated.

Good day. I’m going to make a warm balcony (I’m waiting for experts to glaze the balcony this week), after the glazing I’m going to “seal” the gaps between the bricks in the balcony parapet and after that I’ll invite “insulation specialists”. I don’t remember where in my head.

How to avoid common mistakes and get the desired result

Polystyrene foam is an excellent material for insulating interior walls from extraneous sounds. However, you can also hear a negative opinion, to the point that no positive effect is observed or it is insignificant. Why do many craftsmen prefer to install polystyrene foam rather than mineral wool and similar materials? The answer is simple. Incorrect installation.

Indeed, basic errors when forming a soundproofing layer will not give the expected effect. When carrying out work, you must adhere to the main rule - do not leave cracks or gaps, ensuring a tight fit to the base and to individual parts of the structure.

Very often, plaster is made over polystyrene foam. It is very convenient, practical and inexpensive. In order for the layer of building mixture to be firmly held and have the necessary strength characteristics, a reinforcing mesh is first fixed onto the prepared area. Most often this is a synthetic material, but you can also use a metal analogue made from small-section wire or a manufactured stamping method.

How to avoid mistakes

To achieve maximum effect, you must adhere to the following rules:

- To insulate the walls of a room, sound insulation from polystyrene foam is laid in rows, from bottom to top.

- Particular attention is paid to those areas that transmit sounds and cold the most.

- For better adhesion of Penoplex and the base, go over the mats with a needle roller or sandpaper.

- When attaching mats with dowels, calculate the length of the nails: add the actual difference in the fastening surface to the thickness of the glue and sheet, then add a couple of centimeters to the depth of the hole left for the dowel.

- The dowels are fastened in a checkerboard pattern touching each other.

- Penoplex products are reinforced with reinforced mesh, placing it on an adhesive layer. The glue is leveled with a spatula, completely immersing the mesh in it.

- The cracks/gaps are filled with foam without the slightest omission.

Penoplex sound insulation

This material is known to many as an effective heat insulator, but it also has other advantages, one of which is sound insulation.

Penoplex is considered the most popular in the construction market; it is made from extruded polystyrene. The strong walls of penoplex with insulated cells, filled with air, have an arbitrary shape, and this structural feature provides high strength. In the USA, penoplex foam began to be used as a building material more than 50 years ago. Penoplex has many positive characteristics, such as:

- Low water absorption

- Minimum thermal conductivity

- Low vapor permeability

- Flexural and compressive strength

- High level of sound insulation

It’s worth talking about this quality of penoplex in more detail. Given this characteristic of the material, it can be used to insulate any surface in the room. It can be called the most advantageous soundproofing material, since to work with it you do not need to have special tools or extensive work experience; all installation work can be easily done with your own hands.

When working with penoplex, it is necessary to lay it correctly, without leaving gaps, and foam the joints well. Even after years, the soundproofing qualities of the material do not decrease; for a maximum time it will also retain its other advantages. Penoplex will not rot, so the walls, floors or ceilings will be reliably protected from destruction.

Reviews of sound insulation made of polystyrene foam

Buyers who have tried Penoplex in action note the light weight but large volume of the panels. The mats take up a lot of space in the room, but are easy to cut and, if desired, quickly transported to the next room. If soundproofing is installed correctly, your home can be finished in one day. The work does not require special tools or special skills; all steps can be easily completed with your own hands.

According to reviews of Penoplex sound insulation, the material does an excellent job of thermal insulation of floors. It is a good layer between other layers, together with them forming an impeccable coating that completely retains heat in the house. Carpets, runners, and other coverings are no longer needed, since the floors are warm and your feet do not freeze when in contact with them.

Types of foam

The construction industry offers a significant range of products in this class. Foam grades reflect its origin and characteristics. There are two types of material. Pressed and non-pressed. It is not difficult to distinguish from. The first is a single porous body, and the second is produced by sintering ready-made granules, which is clearly visible visually. For sound insulation, preference is given to non-pressed soft foam. It effectively dampens vibrations and is easy to process.

In construction, the most popular types are the following, which indicate the following foam markings:

- PSB. Pressless foam plastic of several modifications. The last digit in the abbreviation means the strength class. For example, PSB-S-50 is the most durable material in this category. Used where mechanical strength is required. PSB-S-25 is a universal material widely used in construction for many purposes. The softest product is PSB-S-15. Due to excessive fragility and fragility, it is rarely used. It can become attractive solely because of its low price. If the letter F appears in the name, this means that the product can be used in facade work.

- PPU. Foamed mass based on polyurethane. One of the modifications is foam rubber. The material is elastic and very convenient to use, but its cost is quite high. For this reason it is used in limited quantities.

- PPE. The polyethylene base provides elasticity and wear resistance. This marking can be found in hardware stores on many products, but is rarely used for sound insulation.

- PVC. Polyvinyl chloride foam. It is distinguished by the absence of substances harmful to health. The environmental friendliness of the material, which manifests itself under normal operating conditions, is attractive, but danger arises during combustion. Exceeding the critical temperature leads to the destruction of structural bonds and the release of extremely dangerous hydrogen chloride, which, in combination with the liquid, begins to release hydrochloric acid. For the respiratory tract, the smoke emitted by PVC foam is very dangerous.

The most popular and widespread type of polystyrene foam is considered to be the material labeled PSB. Excellent performance combined with an affordable price make it attractive in all respects.

Types of noise

They are caused by different sources and have different acoustic effects on floors. The cause of airborne noise is the loud sound of musical equipment and instruments. Sound entering the ceilings provokes vibrations. These vibrations penetrate the room. In this case, the sound wave is dissipated and the sound spreads to the surrounding areas.

Impact noise is generated by mechanical impacts on partitions (drill, hammer, etc.). The entire force of impact noise is directed everywhere, where the sound indirectly penetrates. Vibrations can be felt if you put your ear to the wall. Due to the lack of sound insulation, it feels like the noise is spreading from the walls when the source is the apartment above you.

Advantages

There are a large number of advantages of the material in question. Consumers value it primarily because it repels water perfectly. This is one of its important positive characteristics. The value of this property is determined by the fact that such materials are very often used in conditions characterized by excessive humidity and temperature fluctuations, which lead to condensation.

It is important to consider that it is necessary to hide open sections of the material, since they differ in their ability to absorb moisture from closed cells. The following qualities should be highlighted as the main advantages:

- Thermal conductivity. This material is characterized by a low degree of thermal conductivity. Thanks to this property, combined with the ability to reject moisture, penoplex can be used on any object. It can be mounted not only on walls, but also in attics and basements.

- Low vapor permeability. Penoplex retains steam remarkably well, which is why it is compared to roofing felt. The material in question can be used for a long time. When used, it will withstand various external aggressive factors. Plates can survive a huge number of freezing and thawing cycles, while maintaining their original properties. Many manufacturers say that penoplex can be used for about 50 years. If this material is properly fastened, the service life can even be extended.

- Strength and other properties. The soundproofing material penoplex is characterized by good strength. This indicates that it is able to withstand intense loads and high pressure. This quality is due to the fact that the penoplex base contains small bubbles that prevent its compression. The use of slabs is characterized by simplicity. If necessary, they can be easily cut, and the material will not crumble. To carry out this procedure, you can use a regular knife.

Using penoplex as sound insulation can significantly reduce the amount of noise penetrating into the room. Consumers of this material claim that after this sound insulation, the room became much quieter and warmer. The cost of the material is affordable, which is an additional advantage. It shows itself remarkably in residential areas in soundproofing the ceiling. A definite advantage is that to work with penoplex it is not necessary to have certain skills in this area. Therefore, you can do sound insulation yourself, even with a suspended ceiling.

The soundproofing properties of the material have only positive reviews.

Basic options for floor soundproofing and work sequence

"Floating floor"

The floor is called “floating” because it is not fixed to the walls and floors, but rests on a soundproofing substrate under its own weight. To ensure high-quality sound insulation, soundproofing material is used as a separator over the entire surface of the screed. In such a substrate noise is dampened. Depending on the thickness of the noise-insulating material – from 4 to 20 mm – the “floating” floor reduces the impact noise level by 20-40 dB.

"Floating floor"

Sequence of work:

- If necessary, remove the old covering down to the floor slabs. If depressions and holes are found, seal them with a self-leveling mixture or cement-sand screed. The height of the layer is no more than 2 cm. The difference in height should not exceed 1 cm.

- Prime the surface.

- To prevent acoustic bridges, install temporary formwork made of plywood, thin boards or plasterboard along walls and partitions. Its height should be greater than the floating floor.

- Lay sound-absorbing material on the prepared base without cracks or gaps. To reduce waste, start laying from the corner. Glue the joints.

- Set up a self-supporting screed - cement-sand, expanded clay or dry: It is recommended to lay an oilcloth under the cement-sand screed, the edges of which are folded up and secured with tape to the formwork. Install beacons 1-1.5 cm high on it, and a reinforcing mesh on them. Lay guides made of metal profiles according to the level. Lay out the cement-sand mixture in a layer of at least 6 cm and level it. After drying, sand the surface.

- Instead of a concrete screed, you can use fine-grained expanded clay, this saves both time and money. Lay a sound-insulating material on the base of the floor - preferably hard, to avoid subsidence during operation, for example, membranes made of bituminous polymers or cork. Fill in expanded clay, compact and level it. Install chipboard or gypsum fiber boards on it with a gap of 1-2 cm. Check with a level. Glue the folds and secure them with self-tapping screws.

- To construct a dry screed, sheet materials are used - plywood, OSB boards, plasterboard or gypsum fiber sheets. They are laid in 2 layers. To avoid the appearance of acoustic bridges, the joints are shifted. The layers are glued together. If necessary, the surface is puttied and rubbed with waterproofing mastic.

Cement strainer

Sound insulation using screeds is effective and reliable, while being heavy. Due to the large load on the supporting structures, this method is not always suitable. The drying time for this screed is 1 month.

For soundproofing apartments, cement grades 150 and 200 are used. The ratio of cement and sand in the mixture is:

- for grade 150 – cement 400 1 part, sand – 3 parts;

- for grade 200 - cement 300 and sand - in equal parts.

Sequence of work:

- Install the beacons according to the level.

- Pour the solution in one layer, moving from the far corner of the room to the exit. Working width – up to 2 meters. Align with the rule. Use the freshly prepared solution within 1-1.5 hours. It is advisable to complete the screed installation work within 1 day. Screeding can be done on different days only where there are differences in floor height. In these cases, a 1-2 cm seam is left between the sections of the screed.

- To prevent the screed from drying out quickly and cracking, cover it with plastic wrap for 3-7 days.

- After 3 days, remove the beacons, prime their recesses and fill them with cement-sand mortar.

- In order for the screed to ripen better, cover it with sand or sawdust for 7-10 days and spill it with water.

- Then remove the sand or sawdust and leave the screed to dry for ~4 weeks.

Dry screed

Dry screed does not require drying. Sequence of work for its arrangement:

- Dry backfill, for example, fine-grained expanded clay, is laid out on the floor along the beacons and leveled using the rule.

- To evenly distribute the load, plasterboard or chipboard is laid on top with gaps of 1-2 cm.

- They are leveled and fixed with self-tapping screws.

Dry screed

ZIPS-Paul

When there is no time to make a classic “floating floor”, you can use quickly prefabricated ZIPS floor systems. The technology allows you to install soundproofing of the floor covering in 1 day without wet work. The premises can be used the next day.

The system consists of Vector and Module sandwich panels with a thickness of 4.5 and 7.5 cm, respectively. The kit also includes acoustic triplex Sandline with a thickness of 1.7 cm and a compensating layer of plywood with a thickness of 1.8 cm. The total thickness of the system is 5-11 cm, excluding the thickness of the final coating. Impact noise reduction index – 32-38 dB.

Wooden logs

A frame floor dampens vibration noise less well, but it isolates audio noise better and is more reliable. Procedure:

- Install rubber gaskets and logs with a cross section of 5*10 cm on the floor slabs. The distance between the logs is 30-40 cm.

- Place soundproofing material between the joists so that there is no empty space left.

- Lay boards or chipboard on top. Leave a 1 cm gap between the walls and the flooring.

- Apply the finishing coat.

The fastest and most cost-effective way to soundproof the floor in an apartment with your own hands is without a screed. To do this, a layer of noise-insulating material is laid on the floor slabs or self-leveling floor, and a finishing coating is placed on top. In this case, the effectiveness of sound insulation is reduced by 30-40%. An even simpler solution to the problem, but also even less effective, is to lay carpet on the floor.

Whatever floor soundproofing option you choose, it will not completely solve the problem of extraneous noise. To achieve a high-quality result, you need an integrated approach: you will also need to soundproof the walls and ceiling.

Features of decorative finishing for soundproofing with foam plastic

Many questions arise when finishing a soundproofed wall. For example, is it possible to glue wallpaper onto foam plastic? How to install drywall? Will the tiles stick securely if the tiles are glued to foam plastic? Any job can be done, but whether the result will satisfy you is a big question. To successfully complete finishing work, you need to understand the principle of working with foam plastic.

The material is quite soft and subject to deformation under physical influence, even minor. Having created a reinforcing layer on the surface, you can use absolutely any finishing material.

If you need to glue tiles in a room, then doing it directly onto the foam is impractical. In this case, it would be wise to first make a layer of plaster or install drywall, and then glue the tiles to your health; they will last as long as a concrete or brick wall. The same principle should be applied when wallpapering.

Moreover, the glue for this type of work is water-soluble and you will have to wait a long time for it to dry, since it cannot be absorbed into the synthetic mass. First the reinforcing, leveling compound, and then the wallpaper. If all operations are done correctly, the performance characteristics of the surface will not be affected, but the noise in the apartment will be reduced.

People, as a rule, do not think too often about sound insulation when building a house.

And indeed, when carrying out such complex processes, there is already something to pay attention to

A floor that is protected from noise loads by insulating with penoplex

But if a built house or a lived-in apartment is poorly protected from extraneous noise, then the problem of sound insulation will come first. Agree, it is unlikely that anyone will enjoy living in a house where sounds from the street or neighbors are constantly heard. We also recommend installing siding with insulation.

Working with foam plastic

Now let's talk about how to soundproof walls. To create sound insulation with foam plastic, special boards are used. These plates are made using 2 lead plates with a sheet of polystyrene foam sandwiched between them. It is worth noting that it cannot be an independent material for removing a noise source. Its effectiveness is manifested only in the vicinity of additional components.

In practice, closed cell foam is widely used. It is very good for soundproofing rooms with increased noise penetration. For example, this product is used in the construction of walls and partitions of motor ships. Closed foam with the addition of vinyl film becomes an ultra-resistant solution in the fight against noise. This material is used to lay the structures of ventilation and heating systems. Due to the high resistance of vinyl foam to negative natural phenomena, it is used for external insulation of walls. This innovative product is suitable for isolating reflected noise. For example, vinyl foam layers are widely used to insulate air conditioning systems and to absorb engine work in cars. Vinyl foam is good in shooting range structures because it cleans well and dries quickly.

Polystyrene foam is divided into various types of grades. The most common of them are:

Floor soundproofing diagram.

- PSB-S-50. Differs in versatility and hardness. It is used for internal and external sound insulation, for sound absorption of roofs and floors. It is used to cover the floors of refrigeration equipment and to insulate the underground in auto repair shops and garages. Widely used as coatings to protect subfloors from freezing.

- PSB-S-35. It is characterized by low cost. Soundproofing foam of this brand is applicable for insulating walls, foundations, and ceilings. Used in the manufacture of reinforced concrete panels, insulation of underground communications, to prevent soil shrinkage.

- PSB-S-25. This type of polystyrene foam boards is mainly used for insulation in domestic conditions.

- PSB-S-25F. The basis is the insulation of facades.

The foam is attached using various compounds and tools. These include:

- glue;

- special mastic;

- cement mortar;

- metal elements for installation.

Alternatively, the insulating structure can be installed directly on the wall: indoors or outdoors.

It is imperative that after the foam structure has been installed, it is necessary to begin facing work. To do this, some kind of base is laid on top of the polystyrene foam sheets, and then the surface is plastered. Insulation works can be covered with brickwork, tiles or other finishing materials.

The best option for sound absorption are PSB-S slabs, which are installed on the inner surface of the walls.

This manipulation will help achieve increased acoustic comfort and thermal insulation.

Soundproofing technology

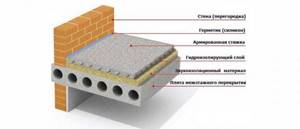

In order for as little noise as possible to penetrate into the room and more heat to be retained, special attention must be paid to the layer-by-layer arrangement of the floor. Sound insulation technology when laying Penoplex on the floor involves the formation of the following layers:

- concrete floor slab;

- insulation layer with Penoplex;

- waterproofing layer;

- reinforcing mesh;

- concrete screed;

- decorative flooring - ceramic tiles, linoleum, laminate, carpet.

In some cases, they opt for frame sound insulation made from wooden beams. The bars will serve as stiffeners and create a kind of cells, inside which prepared and cut Penoplex slabs will be installed.

Types of polystyrene foam sound insulation

Is it possible to soundproof with polystyrene foam? Penoplex and expanded polystyrene are the most popular soundproofing materials on the construction market. Both products are produced using polystyrene foam.

Penoplex is a derivative of expanded polystyrene. It makes excellent sound insulation.

Expanded polystyrene is an environmentally friendly, harmless, heat-resistant, soundproof material. Its quality characteristics have been known for a long time and are in great demand. This material is easy to use and economical.

Floor soundproofing diagram.

Another type of foam is polyurethane foam. The cells of this foam are of arbitrary shape with fairly strong walls. In this regard, very high strength of the foam is achieved. This type is flexible and has excellent thermal insulation. One of the disadvantages is destruction from penetrating ultraviolet radiation.

The next type of foam is polyethylene foam. This type is characterized by a high level of flexibility, increased strength and elasticity. Outwardly it looks like a translucent panel up to 2 cm thick. It is not used for the installation of soundproofing structures, but is good for packaging materials.

Soundproofing with foam plastic

Foam plastic is a popular material for soundproofing walls, ceilings, and floors. However, it makes sense to use it when the noise level from adjacent apartments is not prohibitive. If the neighboring decibels are off the charts, it is better to use special soundproofing materials. They are the most effective. But be prepared for the fact that it is expensive.

Soundproofing with polystyrene foam is a budget-friendly measure suitable for reducing the level of audibility under normal conditions. The main advantage of using expanded polystyrene is that you insulate the room at the same time.

Installation features

At the installation stage, the future characteristics of the soundproofing layer are laid down. The installation method is a key factor. Sound insulation will be satisfactory if there is an understanding of the processes taking place. This will allow you to most effectively protect your home from extraneous sounds and avoid mistakes.

To do this, it is necessary to consider all installation methods with an assessment of the final result:

- Fixation with glue. Convenient, economical and most effective installation method. If foam plastic is glued to concrete, brick, plaster, then the most complete fit is ensured. Vibrations in this case are damped well. Do not use adhesives

- Installation of foam plastic with fasteners. The method is good for external use. Often used for insulation and soundproofing of walls.

Inserting into the cells of the sheathing. A large number of individual elements creates risks for complete shelter. It is difficult to avoid gaps and cracks. Rigid metal profiles that transmit vibrations well also do not contribute to good sound insulation.

Options for soundproofing an apartment, taking into account the type of base

Soundproofing methods vary depending on the substrate. Soundproofing a concrete floor begins with laying soundproofing material. A layer of waterproofing is placed on top of it, after which the screed is poured. After it dries, the topcoat is laid and the baseboards are installed.

Soundproofing of a wooden floor is done using beams. Soundproofing material is laid on them, and logs are placed on top of it. Chipboard or boards are laid on top of the structure. A finishing coating is applied to them.