What kind of noise is there?

What noise can be heard in the apartment? Most often, a peaceful rest at home is disturbed by external and internal noise. External noise includes sounds coming from the street: cars passing nearby, children walking in the yard, barking dogs, loud conversations of passers-by. Installing high-quality double-glazed windows on your windows will help you cope with these types of noise.

The situation with indoor noise is more complicated. These include directly: the sounds of a moving elevator, slamming entrance doors, voices heard on the landing - as well as intra-apartment and intra-room sounds. They represent noise from the movement of neighbors: slamming doors in an adjacent apartment, stomping feet, loud conversations or loud TV sound.

You can combat the latest types of noise using soundproofing of the reproductive system. The very design of multi-storey buildings contributes to the spread of sounds between apartments. All the walls and ceilings of the house are interconnected, so they transmit sounds between apartments quite quickly. This type of noise is called structural noise, since shock vibrations are transmitted from one part of the building to another.

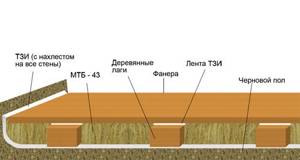

General soundproofing scheme for a wooden floor.

Structural noise can be successfully dealt with: it is almost impossible to get rid of it completely, but it is quite possible to drown it out as much as possible. Why is floor soundproofing so important? The floor in an apartment in a multi-storey building is a concrete covering or wooden flooring - a horizontal surface that perfectly distributes extraneous sounds. By soundproofing your floor, you can forget about most extraneous sounds.

Final sealing of joints between foam boards

In fact, at this point the installation process of the penoplex layer can be considered complete; all that remains is to resolve the issue of finishing. Such a ceiling can be plastered using reinforcement using fiberglass mesh. Another option is to cover it with decorative panels or “sew up” it with plasterboard, on which any finishing can be done.

It would seem that everything is simple and logical. It becomes even unclear why such an accessible method is not widely used?

But it turns out that the whole point is that such ceiling cladding with penoplex has nothing to do with high-quality sound insulation. To understand this, it is worth taking a closer look at the physics of sound transmission in a multi-story building and the properties of the material itself.

Why shouldn't this be done anyway?

An inquisitive apartment owner should not limit himself to the first recommendations he comes across. A “walk” through the forums of specialists in construction matters can bring much more benefit, and here an unexpected “surprise” may await you. Almost all experienced craftsmen call this method of soundproofing absolutely ineffective, “hacky”, which not only does not bring the desired silence to the apartment, but can even aggravate the situation. You can understand this yourself by delving deeper into the problem.

How does sound travel in high-rise buildings?

Noise propagates in a multi-storey building in two main ways.

- Airborne noise is transmitted by air vibrations. This is the normal range of sounds audible to the human ear - conversations, turned on TVs or audio centers, playing musical instruments, and the like. The penetration of such noise through ceilings is not so pronounced, since the air needs to “swing” a massive membrane, which in this case is played by a slab, which, in turn, transmits these vibrations further.

However, such a disturbing factor may still exist. Often such problems are solved simply by “administrative” methods - you can try to come to an amicable agreement with your neighbors on mutual observance of the required silence regime. By the way, it is in this matter that the location of the apartments does not matter at all - sound waves travel in all directions, and those living above may suffer no less from the increased noise of the lower neighbors.

Features of noise propagation and protection against it

- Shock. It appears from hitting objects on the floor, when walking, moving furniture, tables and other household paraphernalia. Transmitted through walls and ceilings.

- Air. This is music from your neighbors, TV, screams and other sounds transmitted through the air. This type of noise first travels through the air, then comes into contact with the ceilings and penetrates through them, partially fading away. You will hear it through the walls and ceiling.

It is necessary to note three types of apartment buildings, which differ in the building materials used.

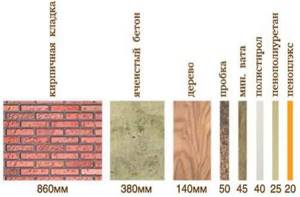

- Panel. The worst houses in terms of noise from neighbors. The thickness of the ceilings leaves much to be desired. It is recommended to carry out comprehensive noise protection using foam boards on the walls and ceiling.

- Brick. The walls in such houses are thicker than in panel houses, and they can dampen noise quite well. Often there is no need for additional sound insulation, but if there are particularly noisy neighbors above, certain measures are worth taking. Penoplex mounted on the ceiling is suitable for this.

- Monolithic frame. The thickness of the ceiling noticeably exceeds the thickness of the walls, which means that sound propagates through the partition. It is pointless to insulate the ceiling, but it is recommended to line the walls with penoplex.

Installation features

Many people think what is better to use for soundproofing the ceiling - penoplex or mineral wool.

Speaking of efficiency, the materials are quite close to each other. But the installation issue makes you look at the choice differently. This is because mineral wool provides a very complex structure, which is very problematic to install on your own:

- First, a hanging frame is installed to hold the mineral wool mats. Metal profiles are used for its manufacture;

- The frame is attached to the ceiling, which will require hangers;

- Next comes the line of cotton wool, all this is covered with plasterboard;

- The process is completed by performing standard finishing work.

If we talk about using penoplex, the installation sequence is as follows:

- The surface is cleaned of old plaster.

- It is additionally treated with antiseptics to prevent the appearance of fungus and mold.

- A layer of liquid waterproofing material is applied.

- A reinforcing mesh is fixed to the ceiling surface.

- Penoplex is installed on the mesh. To do this you will need good quality construction adhesive.

- The soundproofing is covered with gypsum board.

- Finishing work is carried out in accordance with your wishes and interior design features.

As practice shows, the use of penoplex is justified by many factors, ranging from its advantages to the relative ease of installation.

There is no need to hire specialists to protect your home from noise coming from neighbors if you decide to use extruded polystyrene. The material is financially affordable, easy to work with, and light in weight, so you can easily transport the required number of slabs in your own car.

Think carefully and evaluate the situation. Sometimes people do extra work by insulating those areas of the house where soundproofing does not provide the desired effect. Find out where most of the noise is coming from. Do not forget about such little things as the presence of cracks in the walls and ceiling, sockets through which an impressive part of the sounds passes.

Only an integrated approach to solving the problem allows you to achieve maximum effect at minimal cost. Both financial and physical.

How to avoid common mistakes and get the desired result

Polystyrene foam is an excellent material for insulating interior walls from extraneous sounds. However, you can also hear a negative opinion, to the point that no positive effect is observed or it is insignificant. Why do many craftsmen prefer to install polystyrene foam rather than mineral wool and similar materials? The answer is simple. Incorrect installation.

Indeed, basic errors when forming a soundproofing layer will not give the expected effect. When carrying out work, you must adhere to the main rule - do not leave cracks or gaps, ensuring a tight fit to the base and to individual parts of the structure.

An effective soundproofing layer will be obtained if the gaps between the parts of the foam are filled with polyurethane foam. A tight fit to the base will be ensured. The overall vibration-absorbing characteristics are improved. The method will save fasteners without compromising the strength properties of the sound insulation layer.

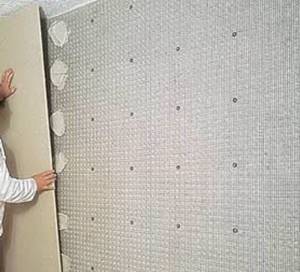

Very often, plaster is made over polystyrene foam. It is very convenient, practical and inexpensive. In order for the layer of building mixture to be firmly held and have the necessary strength characteristics, a reinforcing mesh is first fixed onto the prepared area. Most often this is a synthetic material, but you can also use a metal analogue made from small-section wire or a manufactured stamping method.

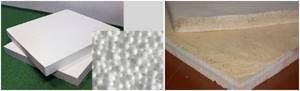

Foam plastic, its varieties and characteristics

Polystyrene foam is a large group of cellular materials made from plastics by foaming them. Almost all known polymer masses served as the basis for the production of modern types of foam plastic, and, depending on the source material, the final product differs in size and cell structure, density, strength, specific gravity, etc.

Foams are polyurethane, polyvinyl chloride, phenol-formaldehyde, urea-formaldehyde foams and polystyrene, differing in characteristics and, accordingly, areas of application.

According to the degree of rigidity, foam plastics are divided into:

- hard;

- semi-elastic;

- elastic.

The same type of foam can have varieties with varying degrees of rigidity and elasticity.

For heat and sound insulation, it is recommended to use rigid, thermosetting types of foam, which, after curing during manufacturing (polymerization), are not subject to softening due to increased temperature, for example, phenol-formaldehyde and polyurethane, extruded polystyrene foam (penoplex).

Thermoplastic types of foam (polystyrene, polyvinyl chloride) soften with each heating and then harden again when cooled, but this imposes additional restrictions on application.

Porous varieties (foam rubber of various types) are subject to shrinkage, are hygroscopic and therefore lose their insulating qualities over time.

It makes no sense to list the properties of all types of foam plastic, since they have many common characteristics that differ in numerical values, but knowing the properties that determine the use of these materials as insulators is necessary for their effective and safe use.

General advantages of rigid foam plastics used for heat and sound insulation:

- extremely low specific gravity (ease of transportation);

- high degree of heat and sound insulating properties, subject to operation in the temperature range acceptable for a particular type of material;

- ease of processing with mechanical tools;

- lack of toxicity when used without heating to the temperature of destruction (destruction);

- neutral to the effects of bacteria and does not contribute to their proliferation.

Disadvantages of rigid foams:

- low threshold for maximum application temperature;

- lack of resistance to a number of chemical compounds (solvents, nitro paints);

- porous surface, making cleaning difficult and favorable for the attachment of microorganisms;

- toxicity of most species when burned.

The surface requires mandatory priming with a special antiseptic composition

Priming is usually carried out with a roller, and in hard-to-reach places (in corners) - with a brush.

- After the surface is ready, you can attach slabs of extruded polystyrene foam - penoplex - to it.

The clear geometry of the slabs and the presence of special lamellas significantly simplify this process. To fix them to the ceiling, use one of the adhesives. This can be a dry construction mixture for a specific purpose - specifically for expanded polystyrene, or adhesive foams in plastic tubes, which are applied with a gun.

Sound insulation materials

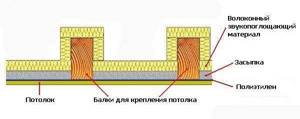

Ceiling soundproofing diagram.

Insulation of internal walls is necessary primarily to ensure that peace and quiet reign in the house. Therefore, when working on sound insulation, choose:

- extruded polystyrene foam;

- products based on basalt fiber;

- drywall;

- steel panels;

- plasterboard membranes;

- polyurethane foam materials;

- polystyrene insulation boards created by extrusion;

- rigid boards made of extruded polystyrene foam. In their production, polystyrene of the highest strength is used.

To install foam panels, they must first be cut. And this is not easy, since the foam crumbles when cutting. But there are several options thanks to which you can easily cut a piece of the required shape without deforming it.

To complicate the design and improve the soundproofing of the room, plasterboard is added to the base of foam boards as a frame. This method can achieve very good results.

Typically, the problem of increased noise transmission in domestic premises arises after unsuccessful repairs (redevelopment). Therefore, for sound insulation, it is imperative to carry out measuring work to establish the noise level. Such calculations will be done better by a specialist - an acoustician.

Will it help to soundproof walls and ceilings?

Initially, expanded polystyrene was used for repairs and foundation construction. The base of the building was protected from moisture and freezing.

Afterwards, penoplex began to be installed as insulation for building facades, balconies, and attics. Now the material is also used as a sound-absorbing material, due to its characteristics.

Scope of application of the material:

- Insulation of dachas and country houses, cottages.

- Insulation of balconies and soundproofing of apartments.

- Application in factories and hotels, churches.

Sound insulation is produced by various methods using different materials. Penoplex has good characteristics for creating silence in the room.

Why choose polystyrene foam for soundproofing your home?

To soundproof rooms, a wide range of products with the necessary qualities are used. If certain conditions are met, identical results can be achieved in all cases.

The answer to the question why polystyrene foam is so popular among both craftsmen and users will be its following qualities:

- affordable price. In comparison with other types of soundproofing materials, polystyrene foam is not only competitive, but is among the top materials in this area;

- ease of installation. The dimensions of the sheets allow you to form the required dimensions of the parts from which the soundproofing layer is mounted. Processing foam plastic is not difficult. It cuts easily with a knife;

- ecological and sanitary-hygienic cleanliness. There has been much debate over these characteristics, but studies have shown that the volatiles emitted are not in sufficient concentration to cause harm to human health. Exceptional cases of allergic reactions are caused by individual intolerance and are extremely rare. Fears about foam soundproofing are clearly overblown;

- long service life. The material is not susceptible to infection by mold, fungi and other microorganisms;

- stability of geometric dimensions. The coefficient of dynamic change in dimensions is extremely small and does not depend on humidity and non-critical temperature fluctuations;

- good sound insulation properties. The porous structure of the foam effectively dampens vibrations. Proper installation will reduce household noise to the required level.

The functional characteristics of polystyrene foam necessary for the implementation of a housing soundproofing project can be supplemented with a number of related qualities. Light weight makes transportation easy. It can be stored for a long time in unheated and utility rooms without compromising the quality of the product.

Among the disadvantages, there is a relatively low melting point of polystyrene foam, which actually has no practical significance:

- simple foam softens at 140° C;

- epoxy at 170° C;

- polyurethane foams soften at temperatures above 230° C.

Anti-foam is added to construction foam, which blocks the combustion process. The material itself does not support fire for more than 4 seconds. After which it goes out. But in the case of an open fire nearby, the process continues.

Soundproofing with carpet.

Soundproofing with a carpet on the wall is another favorite myth of people in our country. Everyone remembers the carpets hanging on the wall of their grandparents. The carpet on the wall acted as a decoration for the room, like a painting. Carpets showed prosperity and wealth in the house and were passed on by inheritance. The carpet also helped save on wallpaper, which was in short supply in the past; behind the carpet there was no need to glue wallpaper or update it. By the way, the same thing happened with the traditional furniture wall covering the entire wall. The soft carpet is more pleasant to the touch compared to the oil paint commonly used at the time.

Despite all the advantages of carpets, they cannot be considered effective sound insulation: the voices of neighbors cannot be eliminated by a carpet on the wall; they can only be muffled a little. Because carpets are fleecy, they absorb sound to a certain extent, but not very effectively and mainly at high frequencies (which are not a problem anyway). Again, what should you do if there is interference from above, hang the carpet on the ceiling? Using carpets you can reduce the echo in the room and remove the echo. This technique is often used in recording studios and even in ordinary apartments to create comfortable acoustics.

Noise insulation with polystyrene foam: disadvantages of the method

The main drawback of the master is considered to be the percentage of fire. In a fire, penoplex emits toxic smoke. Penoplex is not used as a soundproofing material in wooden houses and buildings. The material cannot remove moisture from a wooden structure. Subsequently, a fungus appears on the tree; the tree does not “breathe.”

Penoplex sound insulation dampens impact noise worse. These are repair and restoration work, construction. A smaller percentage of sound suppression from neighbors is a minus.

And also a minus - it requires skill and time.

Penoplex is a unique building material that combines several functions:

- thermal insulation – saving on electricity, heating costs;

- sound insulation – comfortable rest after a working day;

- smooth surface - even when carrying out plastering and puttying work, there is no need to waste time on leveling.

The disadvantages of the material are minor; during installation, the craftsmen do not mention fire safety or do not emphasize that penoplex will make the room completely quiet.

Reviews of sound insulation made of polystyrene foam

Buyers who have tried Penoplex in action note the light weight but large volume of the panels. The mats take up a lot of space in the room, but are easy to cut and, if desired, quickly transported to the next room. If soundproofing is installed correctly, your home can be finished in one day. The work does not require special tools or special skills; all steps can be easily completed with your own hands.

According to reviews of Penoplex sound insulation, the material does an excellent job of thermal insulation of floors. It is a good layer between other layers, together with them forming an impeccable coating that completely retains heat in the house. Carpets, runners, and other coverings are no longer needed, since the floors are warm and your feet do not freeze when in contact with them.

Features of the use of some materials

To isolate yourself from the noise coming from neighbors, it is recommended to use various modern materials. You should focus on the height of the ceilings and the overall dimensions of the houses. Thin ceiling sound insulation is used in an apartment or house with low ceilings.

Mineral wool

This material is chosen by many owners of houses and apartments to prevent the spread of sounds by neighbors. Advantages of this material:

- Good insulation properties;

- Simplified installation;

- Low cost.

How to soundproof a ceiling using mineral wool? It is used when soundproofing ceilings under plasterboard. Mineral wool also requires a metal frame. The material is available in the form of rolls or mats. When making frame gratings, the size of the material is correlated. To fit tightly to the ceiling, the mineral wool must fit tightly under the frame elements. To do this, the distance between the applied slats is less than the width of the wool.

The disadvantage of the material is that it is not resistant to moisture, so many additionally use hydro- and vapor barrier films when arranging the ceiling.

Expanded polystyrene, foam plastic, penoplex

These materials are among the budget options for blocking noise coming from neighbors. They are characterized by a foamed plastic structure. In a private home, these materials are used for insulation.

When using penoplex on a frameless basis, more funds are required due to the higher cost of the material.

A common drawback when using these materials to isolate ceiling noise in an apartment with your own hands is the release of harmful substances.

After fixing the penoplex to the ceiling surface, finishing occurs. It can be done by plastering or cladding. For the latter method, you can use panels to cover the ceiling of the house or plasterboard sheets. In wooden houses, gypsum boards are often used.

Wood and cork based materials

Materials made from wood are considered modern. They are fibreboards. Some can be impregnated with some composition, for example, paraffin.

There are numerous varieties of such panels, which may contain a layer of aluminum foil and a decorative surface. Elements such as penoplex are attached, that is, using the frameless method.

Another type of these materials is cork sound insulation. The main advantage of cork is the small thickness of the slab.

Cork ceiling panels must be used in combination with other materials to achieve the required effect of blocking the spread of noise from a neighbor, especially in panel houses, therefore the scheme for using cork consists of the following steps:

- Fastening the frame to the ceiling;

- Laying soundproofing material;

- Placing drywall on the frame;

- Covering the plasterboard layer with cork.

After installing the cork layer, you should choose a finishing method. You can purchase a decorative cork and then finish it with varnish. Another option is to putty the cork surface and wallpaper the ceiling. Also, this method is used to soundproof the ceiling in an apartment under a suspended ceiling.

Cork material also has many other advantages:

- Made from ecological natural raw materials;

- Low thermal conductivity;

- High absorption of high-frequency waves;

- Moisture resistance;

- Thin layer.

Along with many advantages, this method requires large investments. The price of the material is high. You also need to purchase special glue, which is expensive.

Acoustic panels

Such panels are made from materials that have sound absorption and sound insulation properties. The most popular representatives of the group are Armstrong ceilings. These good materials are based on mineral fiber. The top is lined with a decorative coating. The advantage of this type is the absence of final finishing of the ceiling surface.

Penoplex - scope

The scope of application, thanks to its valuable positive characteristics, is quite wide. It is suitable for indoor and outdoor sound insulation and insulation:

- dacha;

- apartments;

- cottages;

- factories;

- hotels;

- churches.

At the initial stage of construction, this material is used to insulate the foundation. Thanks to this, there is no need to deepen the structure much, since the soil freezes less. The foundation receives additional moisture protection, which extends its service life.

In any region, polyester foam is used to insulate balconies, roofs, walls, attics, and walls. Polyesterol can be used even in baths and saunas, due to its low water and vapor absorption. In basements, you can lay the slabs on a gravel surface, just level it.

It is worth noting: the slabs are sold in different thicknesses from 2 centimeters to 10, and you can choose based on your needs and capabilities.

Soundproofing measures

It is required to take a comprehensive approach to reducing noise in an apartment, following certain rules for performing the soundproofing procedure. Several sequential actions must be taken:

- To soundproof floors, it is recommended to use extruded polystyrene foam with a certain compressive strength, since this surface will be constantly subject to intense loads and mechanical stress.

- There are several ways to soundproof walls. This procedure can be carried out indoors or outdoors.

- Ceiling insulation through the use of insulation boards is used when it is impossible to install a suspended version.

Penoplex is great for sound protection. The consumer has the opportunity to purchase material of various thicknesses. Penoplex can be securely fastened to insulated surfaces and is characterized by high strength and resistance to mechanical stress, thanks to which it can withstand a load of 400 kilograms. This property makes this sound-proofing material indispensable in floor finishing.

Sound insulation of walls

The use of penoplex in soundproofing walls is combined with thermal insulation. As for the external method, the walls are faced with a ventilated facade. In this case, it is better to entrust the work to specialists. You can make internal insulation yourself. It is carried out in several stages:

- material is cut;

- walls are marked for installation of slabs;

- using an adhesive solution, foam boards are glued;

- disc dowels are used to secure the slabs;

- Aluminum tape is applied at the junction of the plates; polyurethane foam can also be used here;

- the surface of the slabs must be plastered;

- final finishing work of the walls.

Soundproofing the floor

If you plan to install penoplex in an old apartment, you will need to open up the old wooden floor and dismantle the joists. If your apartment is located on the ground floor, then under the floor there is probably an insulating pad made of glass wool, which also needs to be removed. Only after these preparatory works can you begin laying soundproofing material.

The stages of the work are as follows:

- prepare the surface and material;

- we mount the frame so that the cells have the same size as the slab;

- we install slabs;

- seal the joints;

- We install plywood or another base on the surface of the frame;

- We install the finishing flooring on the floor.

Installation of penoplex on the ceiling

Soundproofing the ceiling may be required if neighbors upstairs annoy you with their stomping. Since there is no load on the ceiling that is typical for the floor, the material can be glued. Work order:

- you need to clean the ceiling from the old coating and prime it well;

- we attach the plates to the adhesive solution and secure them with dowels;

- joints must be sealed using polyurethane foam;

- apply a layer of plaster and wait for it to dry;

- The ceiling is puttyed and the finishing coat is applied.

Using the soundproofing material in question, you can achieve the desired result. Penoplex is an inexpensive material, thanks to which you can not only prevent extraneous sounds from entering your apartment, but also prevent neighbors from eavesdropping on your personal life.

To learn what material is best to use for sound insulation, see the video below.

Using car sound insulation in apartments

This misconception is similar to the previous myth about thin structures. The argument usually given is: “It works in machines!” Indeed, car soundproofing materials are quite thin (usually only a few millimeters thick) and actually work: cars become noticeably quieter! There is a great temptation to use similar materials for the apartment: soundproofing the ceiling, walls and floor.

However, what works in cars will not work in an apartment. The reason is simple: in a car, noise is created by a vibrating sheet of metal less than a millimeter thick, and in an apartment the source of noise is a massive thick wall or ceiling 15–20 cm thick (or even more).

And the mechanisms for dealing with noise from a thin sheet of metal and from a thick massive wall are fundamentally different! If in the first case it is enough to simply dampen the metal with any viscous membrane (the mass and thickness of which is several times greater than the similar parameters of the metal), then in apartments the sound insulation can only be increased with multilayer cladding, and this is a certain thickness.

Features of decorative finishing for soundproofing with foam plastic

Many questions arise when finishing a soundproofed wall. For example, is it possible to glue wallpaper onto foam plastic? How to install drywall? Will the tiles stick securely if the tiles are glued to foam plastic? Any job can be done, but whether the result will satisfy you is a big question. To successfully complete finishing work, you need to understand the principle of working with foam plastic.

The material is quite soft and subject to deformation under physical influence, even minor. Having created a reinforcing layer on the surface, you can use absolutely any finishing material.

If you need to glue tiles in a room, then doing it directly onto the foam is impractical. In this case, it would be wise to first make a layer of plaster or install drywall, and then glue the tiles to your health; they will last as long as a concrete or brick wall. The same principle should be applied when wallpapering.

Moreover, the glue for this type of work is water-soluble and you will have to wait a long time for it to dry, since it cannot be absorbed into the synthetic mass. First the reinforcing, leveling compound, and then the wallpaper. If all operations are done correctly, the performance characteristics of the surface will not be affected, but the noise in the apartment will be reduced.

One of the persistent misconceptions is that any materials with a closed-cell structure, such as cork, various foam plastics, polyethylenes, polyurethanes, etc., can improve the acoustic properties of airborne noise protection (conversation, TV, vacuum cleaner, etc.). However, if you cover a wall or ceiling shared with a neighbor with such material, you will not get the expected effect, although its technical characteristics promise a sound insulation effect of up to 15-20 dB. And even if you increase the layer thickness to 50 mm, you will only waste a lot of money, but you are unlikely to achieve sound comfort.

The fact is that these materials are not intended to improve the acoustics of rooms in general, but to insulate from impact noise (steps, impacts of objects falling on the floor, etc.).

Soundproofing of partitions

To clarify the effect of the filling material of the partitions on their sound insulation, a study was carried out on the insulation of airborne noise of a frame-sheathing partition made of plasterboard sheets with the air gap filled with extruded polystyrene foam.

It should be noted that when using relatively rigid materials such as polystyrene foam, phenolic-resol foam, etc. as filling for frame-sheathing partitions. sound insulation is seriously inferior to partitions filled with porous-fibre materials, such as mineral wool or fiberglass mats and slabs.

In addition, heat and sound insulation are very closely related, since most insulation materials (mineral wool) are also sound insulators. True, specialized sound-absorbing materials from the same raw materials are produced using slightly different technology and are more efficient than conventional insulation.

Soundproofing the floor

Acoustic tests of samples of extruded polystyrene foam have shown that, according to the values of the dynamic characteristics, they belong to the class of soundproofing cushioning materials.

The use of soundproofing gaskets made from the specified material with a thickness of 20-30 mm in floating screed structures with a surface density of the slab of at least 100 kg/m2 provides an index for improving impact noise insulation by the floor ΔLnw = 21 dB, which in most real cases makes it possible to meet regulatory requirements requirements for impact noise insulation.

Increasing the thickness of the layer of extruded polystyrene foam from 20 mm to 30 mm and higher seems impractical and unjustified economically due to the rather high values of the dynamic modulus of elasticity of the specified material (the values of the indices for reducing the level of impact noise under the ceiling almost coincide with each other).

The most interesting for practical use may be a combined design of a soundproofing layer, consisting of a layer of extruded polystyrene foam no more than 20 mm thick and a layer of geotextile base laid between the EPS layer and the load-bearing floor slab. This design of a floating screed, as established as a result of laboratory measurements, allows us to provide an index for improving the insulation of impact noise by the floor ΔLnw = 28 dB.

Features of installing penoplex on walls: recommendations from experts

Among modern insulation materials used to improve the thermal insulation properties of building walls, the greatest interest among consumers.

Manufacturers produce two main types, each of which is intended for a specific installation location . One of them is intended for insulating the walls of a house from the outside, and the other will be an excellent material for internal thermal insulation of premises.

Consumers who have little understanding of the nuances associated with the quality of thermal insulation materials sometimes call this insulation foam, unknowingly making a mistake .

If you compare these materials to the touch, they will really be similar. And in appearance they resemble each other. However, if you look at the materials in cross-section, their differences will immediately be visible .

When cut, penoplex looks like a monolithic material. It is immediately clear that one of its properties is strength. Polystyrene foam, consisting of bubbles that are not held together too tightly, cannot be called durable - it breaks easily when bent. However, it can easily withstand significant pressure.

It is important to know that for high-quality insulation of the walls of a building, you need not only high-quality insulation, but also strict adherence to the technology of its fastening.

Methods for attaching penoplex to walls

When installing penoplex panels, they are fastened with a special compound designed for its fastening.

After placing the panel coated with an adhesive composition on the insulated surface, additional fastening of the material is carried out using dowels.

Penoplex adhesive is selected depending on the specifics of the work, the type of finishing (external or internal), as well as the type of room.

If the insulation is installed in rooms with high humidity, it is better to use a polyurethane adhesive. When choosing an adhesive, it is necessary to take into account the material of the base of the walls on which the penoplex will be glued.

Types of glue for penoplex

To select the correct adhesive when purchasing it, you should be guided by its technical characteristics. All their parameters are indicated in the instructions provided by the manufacturer complete with the glue packaging.

The instructions must contain the following information about the adhesive material :

- temperature parameters required when working with glue and operation;

- air humidity indicators;

- type of base on which insulation will be carried out.

These characteristics will determine how well the penoplex will be fixed to the insulated surface.

Depending on the base used to prepare adhesives, they are divided into several groups. Each of them is best used in certain conditions:

- mineral (contains cement) and gypsum adhesives are used when working on dry surfaces. It can also be used in damp spaces, but in this case the composition must be prepared for use in small portions. At high humidity, the composition hardens quickly;

- waterproofing adhesives (made from bitumen) are used only for external work. Due to the presence of properties harmful to human health, the use of such adhesives in enclosed spaces is prohibited;

- polyurethane and polymer composite compositions are universal adhesives.

It should be borne in mind that it is customary to carry out indoor insulation with penoplex in the warm season so that ventilation is possible. All glue compositions, until they are completely dry, have an unpleasant, corrosive odor .

Attention! The adhesive for penoplex should not contain organic solvents! They quickly destroy the insulation. Acetone, gasoline, kerosene, white spirit and toluene - these substances should not be in adhesives for penoplex.

The developers of this insulation recommend working only with adhesives made on a cement, polyurethane or acrylic base.

Selecting adhesive for installation

When purchasing an adhesive composition for working with penoplex, some consumers believe that the more expensive the glue is, the better the work will be done. This is not entirely true.

It often happens that the purchased glue has properties that are not necessary. For example, if finishing with penoplex is done indoors, then there is no point in buying an adhesive composition with frost-resistant additives included in it, overpaying a substantial amount for properties that are useless in this case.

For this reason, when choosing glue, you should carefully study the attached instructions, having previously decided on the characteristics of the premises and the quality of the wall surfaces where the insulation will be carried out.

Most often, consumers purchase the following brands of adhesives :

- ATLAS STOPTER K-20 kley - made on a mineral basis, optimal consumption 4.5 kg per square meter. meter, the cost of a bag of dry mixture is from 310 rubles.

- "T-Avangard-K" - designed for surfaces that require waterproofing, consumption 5 kg per square meter. meter, bag (25 kg) costs 270 rubles.

- Polyurethane adhesive "TITAN" - for reinforced concrete surfaces, per 1 sq. meter takes a tube of glue with a volume of 750 ml, costing from 405 rubles.

Consumers who do not have experience in gluing penoplex should purchase the adhesive with a reserve , since its actual consumption will be significantly greater than that specified in the instructions.

Not long ago, manufacturers developed a new composition for installing penoplex - adhesive foam . It perfectly connects penoplex with any surfaces, as well as with each other.

A high-quality composition for installing insulation is liquid nails , however, the cost of this glue is quite high.

Additional mounting methods

To increase the strength of the installation of insulation, dowels are used together with the use of an adhesive composition.

In their design, they resemble nails with wide heads. They are made of metal or plastic .

To attach insulation to building facades, only metal dowels are used; plastic products are used only for indoor work. The use of dowels significantly improves the quality of installation of penoplex, but the need to drill holes for their installation violates the tightness of its sheets.

are used as an additional fastening element . This is a very reliable mount. Some manufacturers complete with foam sheets and supply the number of self-tapping screws required for their fastening. However, just like dowels, they violate the tightness of the insulation.

SOUND INSULATION AND SOUND INSULATION MATERIALS Find out how to make your life quieter

Soundproofing walls

Perhaps the best protection from the noise of neighbors in the apartment, the optimal selection of materials and, as a result, the best overall price. Reviews from our clients are our best recommendations.

Ceiling soundproofing

Installing a ceiling soundproofing solution with your own hands requires special care, because the slightest miscalculation in installation will negate all efforts.

Soundproofing the floor

The main solution that allows you to effectively soundproof the floor in an apartment is to install a “floating floor” system under the screed. But as with everything related to noise protection, there are subtleties here.

Scope of application?

Apartments and private houses, office premises and bars - there are various options for soundproofing any premises, and we will help you choose yours

How to order?

Call or simply go to the feedback form and our managers will help you decide on materials, place an order and delivery.

Ready solutions

Our specialists have developed standard solutions for each of the common types of problems. You can familiarize yourself with the options we offer.

Company mission and benefits

Our mission is to provide the client with a comprehensive solution for soundproofing premises. Whether it’s a bedroom or a study, a meeting room or a manager’s office in an office, a workshop or a utility room in a country house – it doesn’t matter, the goal is a solution that is as comfortable as possible for everyone

Working with the customer

The client is our key value, because we have the same desires: quality, short deadlines, reasonable pricing policy

Prices from the manufacturer

Direct contracts with leading manufacturers and importers allow us to maintain optimal price levels.