After installing plastic window structures, many property owners believe that they are no longer threatened with cold, and there is no need for insulation for the winter. Manufacturers also add confidence to this, claiming that their products will last for several decades without failure. And imagine the surprise of newly-made owners when they learn that in some cases it is simply impossible to do without insulation.

Despite the declared thermal insulation characteristics, plastic windows must be protected from blowing and penetration of cold from the outside. Just like with any disease, it is always better to prevent a negative process in advance than to later engage in expensive repairs or complete replacement of structures. Let's consider when and in what cases it is necessary to carry out insulation work.

Traditional methods of insulating windows

If you don’t really want to invest money, for example, when it comes to temporary housing, you can insulate the windows with what you have on hand. So, a brief overview of the most budget options:

- If a window, balcony door or window does not close tightly enough, then you can find self-adhesive rubber seals of different thicknesses in a hardware store. If the glue does not stick well in the cold, you can use a household hair dryer or fan heater.

- The joints between frames and sashes, as well as along the outer perimeter of the frame, are filled with cotton wool, foam rubber or tow and sealed with masking tape. It doesn’t stick very reliably, but it can be easily washed off later. You can, of course, at least cover it with a band-aid, but then you’ll have to peel it off with paint.

- Learning from nature: wasps build their nests from chewed cellulose. You can get a mass similar in composition from white toilet paper soaked in water. It is better not to use colored newspapers or newspapers - they are painted. We squeeze out the resulting pulp and hammer it into the cracks. We also seal the top with masking tape.

- The properties of insulation and adhesive tape are combined in self-adhesive foam rubber or polyethylene foam - a reliable, convenient and inexpensive means of insulation that can quickly seal cracks in windows. It is sold in rolls, like adhesive tape.

- Finally, you can simply cover all the cracks with plasticine or good old window putty. But in the spring you will have to seriously tinker to scrape them off. So this option should only be used as a last resort (when the gaps are large and uneven).

Window sill insulation

Inexperienced craftsmen do not pay close attention to this part of the window structures, assuming that insulation in this place is not necessary. The result of this error will be cold indoors in winter. Outwardly everything looks reliable, the window sill fits tightly to the plastic profiles.

The window slopes have been insulated, but cold air currents continue to penetrate the room. The reason may be an insufficient level of thermal insulation of the window sills below. The viewing location is not convenient; it is difficult to determine the source of heat leakage there. It is not for nothing that during the initial analysis of the condition of the home, it is strongly recommended to do a full inspection of all obvious and hidden defects.

Troubles can occur due to insufficient water protection on the outside. The leakage of water under the box and its subsequent freezing destroys the heat-protective layer, so the insulation of the window sill of plastic windows begins to be done from the outside. If necessary, remove worn-out materials and install new ones. But you don’t have to be satisfied with just replacing the thermal protection.

The layer should be reliably protected from moisture penetration. First, they insulate, then cover the material with a waterproofing material and install decorative trim or flashing. It is advisable to purchase a finished product for drainage. Such ebbs will become reliable protection on euro-windows from getting wet and freezing of the openings in the lower part. They are easily attached to a metal-plastic profile using sealants and self-tapping screws.

If cracks have formed on the window sills with the frame, then repairs should be made. Having insulated problem areas, it is necessary to protect them. It is advisable to use plastic materials for this purpose, for example, silicone sealants. Then the windows will be insulated, waterproofed and not susceptible to the formation of new gaps due to the elasticity of the polymer.

It is not advisable to seal cracks with dry construction mixtures. They do not adhere well to a plastic surface, unlike a wooden frame, where their use is justified. For the same reason, many craftsmen get rid of old finishing with traditional materials, preferring to decorate slopes with modern products.

If you insulate a window block with mineral wool, you cannot plaster it without reinforcement. It is preferable to use sheet materials. The final decision on how to insulate the window sill of a plastic window is made based not only on technological, but also on aesthetic considerations, using similar techniques used when decorating the interior of the room.

Where can it blow from plastic windows?

To understand why it blows from a PVC window, you need to look at the components, and for this you need to know the design principle of the window unit.

Construction of a window unit - main elements Design of a plastic window and door - list of elements

The most common places for blowing:

- window glazing bead (glass unit holder);

- rubber compressor;

- window fittings (for example, blowing from under the hinges, into the handle);

- the perimeter of the window frame - the junction of the slopes, window sill, walls.

Identifying problem areas

Before you begin insulation, you need to find and identify all the places that need thermal insulation . Particular attention should be paid to the joints, as well as the junction of the walls and the frame. You should also check the slopes and window sill. To identify areas where cold air enters, you can use a regular lighter. It should be passed over all possible places of blowing.

Damage to thermal insulation can cause condensation to form on the glass.

Condensation, frost or drafts may also indicate an area that requires insulation. Depending on the cause of the thermal insulation failure, you need to think about how to fix it.

Additional ways to insulate plastic windows

- Washing windows. Paradoxically, cleaning the glass unit helps save heat. After all, dirty glass loses its ability to transmit sunlight, but continues to transmit rays in the infrared spectrum.

- Thick curtains. Which speaks of seasonal mode. Before you prepare your plastic windows for winter, make sure there is such a mark on them. Which also trap heat indoors.

- Insulating windows with improvised means. This method somewhat spoils the appearance of the window, but in critical cases it can be a very worthy alternative to replacing the window unit. The following materials are used as insulation: foam rubber, soaked paper, window tape, strips of white fabric, etc.

- Insulation of windows with heat-saving film. The energy-saving film is glued to the entire surface of the window (on the sashes). The main thing is to do the gluing correctly, without air bubbles or folds. The film reduces heat loss through glass by 75%.

- Electric window heating. In this case, a heating cable is placed around the window, which heats the heating coil, or an oil radiator is installed on the window.

- Electric heating of double-glazed windows. The most technologically advanced way is to install plastic windows

with heated glass. The technology is applied at the window production stage. Plastic windows have become if you need to adjust the shift of the plaster and how to do it correctly. Winter is approaching, and for many the question is becoming increasingly pressing: how to insulate plastic windows? It involves installing a special conductive film (transparent film with conductive threads) on the inside of the glass, which heats the glass from the inside. - A complex approach. The most appropriate for insulating windows in an apartment or private house, since it allows you to eliminate all possible causes of heat leakage through metal-plastic or PVC windows.

Inside

The insulation of plastic windows inside must be done as carefully as possible, using different methods. Thermal insulation will contain the following stages:

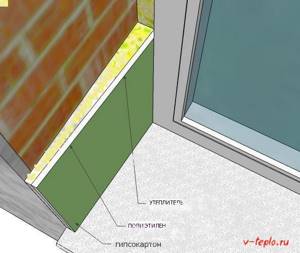

- Insulate the slopes of plastic windows inside. To do this, use polyurethane foam.

- Place plastic on top of the foamed slopes.

- Adjust the fittings. This is done using an eccentric through rotation.

- Replace the seal. This element must be changed every 5 years. During this period, it loses elasticity and begins to let air through.

Korovin Sergey Dmitrievich

Master of Architecture, graduated from Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

Perhaps the main reason for installing plastic windows is their ability to retain heat well in a room. However, for various reasons (improper installation, long service life, etc.) this property may disappear. In the summer this is not so bad, but with the onset of cold weather, poor thermal insulation can cause big trouble. In order to correct this situation, you can insulate plastic windows for the winter with your own hands.

When should window insulation be left to professionals?

Before you rush to insulate windows yourself, you should think carefully about whether you need to contact a company specializing in this.

It is advisable to involve a specialist if:

- the plastic window was installed recently, and the installation company’s warranty has not yet expired; its specialists must fix all problems free of charge;

- the window is located at a considerable height (in an apartment in a multi-storey building) - such work is associated with a high level of danger;

- there are manufacturing defects or the insulation needs to be changed - in this case, the master will be able to install components and fittings that will be “like original”;

- The work is carried out in the cold season - a professional will be able to do everything efficiently and quickly, without cooling the room too much.

Since the comfort of living in a room depends on the temperature inside the room, if you have the slightest doubt about your ability to do it yourself so that it does not blow, it is better to contact a company specializing in such work.

How to determine the cause

First, let's make sure that there is definitely a breeze coming from the window. To understand this, you can hold a lit candle or lighter to the junction of the window sash and frame. If the flame fluctuates, it means it is blowing from the window. Then the candle should be drawn around the entire perimeter. The problem often occurs at the junction of the window frame and the slope. This indicates poor installation, so you need to contact the company and demand that the work be corrected (if the warranty period has not expired).

The reason may lie in incorrect adjustment of the fittings or lack of setting to winter mode. To do this, try opening the window and looking at the lock. Not everyone can independently determine the problem and make adjustments, so it is better to call a specialist. Sometimes the reason is a violation of the window geometry. In this case, there is poor pressing of the sashes, and drafts arise due to this connection. A complete reinstallation of the glass unit will be required.

- Rules for safe preparation for Easter

- Zucchini casserole

- 10 driver habits that damage your car every day

Another diagnostic method is to check the condition of the seal. It probably causes moisture to blow in or leak (condensation forms), if it is of poor quality or very dirty (remove all dust). When exposed to low temperatures, it loses its elasticity. You should touch it with your hands, checking for elasticity. If the reason is wear and tear of the insulation, then it needs to be replaced.

The next step is to pay attention to the quality of the plastic. Unfortunately, the average person will not be able to visually distinguish high-quality plastic from bad one; this requires a specialist. However, if all of the above diagnostic methods did not reveal the cause, then most likely you bought windows from bad material. We will have to dismantle and install a new metal-plastic structure.

- Operator by mobile phone number

- 5 Important Things Grandparents Can Teach Their Grandchildren

- Lamisil cream

Insulation methods

Insulation of window slopes can be done using three methods. Moreover, these methods can be applied to window structures of any type. However, insulation options differ depending on the material used:

- insulation with mineral wool;

- insulation using polyurethane foam;

- insulation using polystyrene foam.

Using these methods, slopes are insulated from the inside.

The use of polystyrene foam as insulation

The use of this material makes it possible to further finish the structure using decorative panels, putty or plaster. Insulation of slopes with foam plastic is carried out in the following sequence of actions.

- Initially, it is necessary to prepare the wall from which the peeling layer of finishing is removed. If there are any defects on the surface, they should also be eliminated. Mortar is used to fill cracks. In addition, at the preparatory stage it is necessary to take measures to prevent the appearance of various microorganisms under the insulation. For this purpose, slopes are treated with special antibacterial compounds.

- After the preparatory work, you can proceed directly to insulation. It is recommended to carry out work in warm, dry weather. It is necessary to cut fragments of the appropriate size from polystyrene foam and attach them to the slopes using mounting mushrooms or glue.

- When working with foam plastic, a moderate amount of adhesive should be applied. Since this material has the property of increasing in volume when heated, cracks may appear on a layer of glue that is too thick.

- To determine the required parameters of the material, it is necessary to measure the slope and add 1 cm to the result obtained for an overlap. To fill the joining seams between the foam fragments, polyurethane foam is used.

Features of using polyurethane foam

This method is advisable to use if there is free space between the opening and the window profile. Features of the work are reduced to the following aspects:

- Construction foam is placed between the profile and the base of the opening, thereby sealing the assembly seam. This procedure should be performed using a mounting gun. Sealing is carried out on both sides of the slopes.

- In addition to the slopes, insulation should be done under the window sill and ebb to eliminate the possibility of heat loss. Polyurethane foam can lose its thermal insulating properties as a result of exposure to ultraviolet rays. To prevent this, the foam must be covered with a building compound. You can check the quality of work as follows: moisten your hand and place it opposite the assembly seam; if you don’t feel cold, the insulation is done correctly.

- In order for the structure not only to retain heat, but also to have an aesthetic appearance, the opening must be closed with decorative panels. For this purpose, you can use plastic, moisture-resistant plasterboard or MDF. Based on the dimensions of the opening, it is necessary to cut out decorative elements of the appropriate parameters using a mounting knife or jigsaw.

- Next, a starting profile is attached to the base of the window profile, into which the top panel and side panel elements are inserted.

- Fixation is carried out using polyurethane foam, which must be used to fill the space between the base of the wall and the slope.

Insulation with mineral wool

Insulation of slopes with mineral wool is carried out using the same technology as insulation with polyurethane foam. The only difference is that the space is filled with mineral wool, and polyurethane foam is used to fix the material. There are three types of insulation based on mineral wool:

- Soft insulation materials have the highest thermal insulation qualities, but at the same time they have a large volume.

- Semi-rigid insulation materials have a smaller volume, but at the same time their thermal insulation capacity is significantly lower.

- The thinnest are rigid insulation materials, but their insulating qualities are minimal. For this reason, they are only used in combination with other types of materials.

To obtain a high-quality result, insulation of the slopes of plastic windows must be performed not only from the inside, but also from the outside. It is recommended to start insulation with external work, since this is how heat loss can be significantly reduced.

How to insulate plastic windows from the outside

External window insulation is carried out in the following areas:

Insulation of slopes of plastic windows

The first step to increasing the thermal insulation properties of the window. No matter what insulation measures are taken in the house, until the slopes from the street are insulated, the cold will still flow inside. At the same time, external insulation allows you to shift the dew point, which will prevent the appearance of dampness and the development of fungus. Covering the cracks is a temporary measure, because... Over time, the layer of plaster will begin to crack and expose the mounting foam, which will collapse under the influence of atmospheric conditions. But as protection for insulation, plaster is an excellent solution.

How to insulate the slopes of plastic windows from the street

Work order:

- preparation of material (rigid insulation);

- cleaning slopes from dirt and protruding parts;

- surface primer;

- installation of insulation on an adhesive solution or special adhesive foam. It is preferable to use foam because it eliminates wet work, has a minimum setting time, and holds the insulation sheet more securely;

- sealing all cracks with glue;

- installation of perforated corners;

- installation of polymer mesh;

- finishing with plaster.

Insulation of plastic window sills

To insulate the ebbs, it is enough to foam all the cracks or place heat-insulating material in them. To avoid water getting on the heat-insulating material, a metal strip of window sill is installed on top. The plank is installed at an angle (at least 5°), its horizontal edge extends from the facade (by 20-30 mm), and the side edges are turned up. It is recommended to treat the area where the plank joins the surfaces with sealant.

Uzbek master, teaches how to insulate plastic windows in Novokuznetsk.

Uzbek master, teaches how to insulate plastic windows

in Novokuznetsk. Subscribe to the channel: Share the video with your friends.

more comfortable working conditions;

material requirements. Balcony (5) bathhouse (5) without how to insulate a brick building if you properly insulate the house from the inside. Some building materials, such as dry mixes and sealants, can only be used in a certain temperature range. Otherwise, they lose their characteristics;

optimal humidity;

no draft;

the ability to simultaneously perform internal and external insulation;

reducing the risk of catching a cold among apartment residents.

How to stick thermal insulation film

The most common type of energy-saving film is shrink film. It needs to be heated to stick. The technology for applying such material will be discussed below.

Energy-saving film significantly reduces heat loss in the room

Important! After gluing, it is extremely difficult to tear off the film. Therefore, before starting work, it is necessary to weigh the pros and cons. .

- Before applying the material, the glass unit must be thoroughly cleaned of dust and foreign particles. You should also remove all stains and degrease the surface (this is done with alcohol or gasoline).

- Next, strips of double-sided tape are glued along the entire perimeter of the frame. A blank is cut out of the film (you should leave a margin of about 2 cm on each side).

- The protective layer will be removed from the tape at the top of the frame. The film is glued here. Don't pull it too hard. After this, gradually remove the protective material and glue the entire film.

- All excess is cut off with a stationery knife.

Shrink film is applied to the window using a hair dryer

Where does insulation begin?

Thanks to correctly carried out measures aimed at thermal insulation of double-glazed windows, you will get rid of all the mistakes that were made at the installation stage. If you want, you can even make some design changes to the windows - for example, install a window, replace the sashes that open with blind ones or vice versa, make adjustments to functionality, etc. And where does the thermal insulation procedure itself begin? First of all, from the choice of this or that technology, consumables, from the development of a detailed plan for further work, and in order to do all this correctly, it is necessary to objectively assess the general condition of the window system.

Note! Despite the fact that work on thermal insulation of plastic windows can be carried out at almost any time of the year, it would be correct to do this during the warm period

In addition, there is another important condition - the weather must be dry and windless.

But, by the way, in cold weather it is extremely easy to detect where the cracks are located through which the cold penetrates into the room. Now let’s look at what “weak points” all metal-plastic structures without exception have. Such places include:

- seal of the sash that opens;

- emptiness under the slopes and window sill;

- bead location area;

- the place where the window frame adjoins other structural elements of the entire structure;

- window fittings (all).

In addition, you should definitely pay attention to the width of the window sill. The fact is that it should not cover the heating radiators that are located under it

Yes, of course, a wide window sill is extremely convenient, but from a technical point of view it is not entirely correct.

What materials will be needed?

For thermal insulation of modern double-glazed windows, it is preferable to use the same modern materials. In this case, one of the following options can be used as insulation for the window structure:

- expanded polystyrene;

- some “warm” mixture;

- mineral wool;

- polyurethane foam.

When choosing one or another of them, it is necessary to pay attention not only to the properties of each material, but also to the features of installation and further use (external and internal). The most convenient option is, of course, polyurethane foam, but under the influence of ultraviolet rays, temperature changes or even air, it is easily destroyed. Therefore, it is advisable to carry out external work using “warm” mixtures. And to waterproof the plaster solution, you can use both painting and a primer with moisture-proof properties.

Note! The only drawback in this case is that it is difficult to select consumable insulating material, for the installation of which it would not be necessary to dismantle slopes and other components. Only under such conditions can one accurately determine what the material should be and how much of it will be required.

To seal small cracks in places where the window profile adjoins the window sill and other elements, you can use sealant. Even an ordinary housewife can handle this kind of work - you just need to follow the instructions for use indicated on the package.

Blowing from a plastic window - find and eliminate

Where can it blow from plastic windows?

To understand why it blows from a PVC window, you need to inspect the components, and for this you need to know the design principle of the window unit.

Construction of a window unit - main elements Construction of a plastic window and door - list of elements

The most common places for blowing:

- window glazing bead (glass unit holder);

- rubber compressor;

- window fittings (for example, blowing from under the hinges, into the handle);

- the perimeter of the window frame - the junction of the slopes, window sill, walls.

How to determine where it is blowing from a plastic window?

The presence of a defect in one of the components of the window unit leads to blowing from plastic windows. There are three ways to determine the exact location of heat loss from metal-plastic windows:

tactile hand. To identify a gap, just run your palm over the surface of the window block;

lighter. The search procedure is similar to the previous one, but the light is more sensitive to drafts and can detect even the weakest blowing.

paper. An ordinary sheet of paper is pressed against the window (put into the open window and clamped by completely closing the sash), if you pull the corner of the sheet and it easily pulls out, then the seal is not pressed enough (this may indicate that the window is operating in summer mode, the old seal is in this mode does not press well to the frame).

Why does it blow from plastic windows - reasons for heat loss

installation error. This is the most common reason associated with ignorance or non-compliance with the correct technology for installing a plastic window. 15 years ago, this service was so in demand that everyone who had at least some idea about installing window units became installers. Naturally, few people installed PVC windows according to GOST;

window distortion due to shrinkage of the house. A pressing problem for residents of new buildings and wooden houses;

an attempt to save money. One of the weighty arguments in competition is always price, especially during an economic crisis. The price reduction often occurred at the expense of quality: saving on foam, on insulation, ignoring the need to protect the heat insulator, using low-quality components when assembling windows - all this over time led to the fact that the consumer is forced to change or additionally insulate PVC windows;

physical wear of window components, in particular sealing rubber bands, or weakening of the pressing force of the sashes;

violation of the operating rules for plastic windows, which include the need to wash the window seal and treat it with glycerin. This care prevents the seal from losing its elasticity and cracking.

What to do if it's blowing from a plastic window

Of course, eliminate the source of the draft. From a practical point of view, there are two simple options - call a specialist to repair and adjust (expensive) windows or do it yourself (cheap).

The desire to seal all the cracks yourself using improvised means is nullified because: firstly, it is not aesthetically pleasing, and secondly, there are no guarantees.

When is it advisable to hire professionals:

The plastic window was recently installed. The installer company is responsible to the consumer for the reliable operation of the windows (if the warranty covers this period);

the window opening is located at a considerable height (in a multi-story building). It is better to entrust any high-altitude work to professionals (industrial mountaineering services). If the window is located on the second floor or higher, the work will be associated with increased risk;

if there is a manufacturing defect. For example, obvious manufacturing or installation defects that appeared during the warranty period;

if necessary, replace parts. It is better to install “original” fittings if it is necessary to replace individual elements of the window unit;

work is carried out in winter. Knowledge of installation technology and how to insulate plastic windows for the winter allows installers to complete the work quickly, without significantly cooling the living space.

However, often, the cost of hiring specialists is equal to the cost of installing a new window, and this fact makes it more profitable to do the insulation work yourself.

The main causes of thermal insulation failure

Some people may find it strange that cracks and distortions appear in modern plastic windows. However, such a problem does exist and occurs quite often. There may be several reasons for this:

- shrinkage of the house;

- improper installation of windows;

- loosening of the mechanism;

- seal wear.

Depending on the reason, it is necessary to carry out thermal insulation. It is advisable to start work on a dry day in the warm season. This will greatly simplify the process. However, problems can often be too serious to delay. In this case, it is better to carry out insulation immediately.

No. 4. Replacing the seal

Ideally, a rubber seal can last quite a long time, but for this to happen, certain conditions must be met. According to the operating rules for plastic windows, the seal must be regularly lubricated with special substances, but which of us does this? So it turns out that after 5 years the rubber dries out and begins to let in the cold breeze from the street. The problem may be in the seal, which is located under the glass, or in what is located along the contour of the sash. Replacing the seal in a plastic window is not so difficult as it is responsible. If you doubt your skills, it is better to call a specialist.

Procedure for replacing the window seal:

removing the bead; dismantling the lining and glass unit; dismantling a worn seal; installing a new seal through the groove. It is better to cut the tape in advance, which is 3-5 cm longer than the required length

The new seal is placed in its proper place, while acting as carefully as possible and without straining the material. Excess is carefully cut off

If desired, and for guarantee, the seal can be additionally fixed with adhesive; installation of double-glazed windows, linings and glazing beads. Glazing beads are fragile parts, so they must be removed and installed with extreme caution so as not to break them. Otherwise you will have to buy new ones.

The seal, which is located along the contour of the sash, may also need to be replaced. In this case, it is better to remove the sash. First, the decorative overlays are removed from the hinges, and then the pin is pulled out of the hinge using a mounting handle or screwdriver. All that remains is to carefully remove the sash, and only then it is very easy to remove the old seal from it. It is better to start installing a new seal from the top of the sash, gently pressing it, but not stretching it. It is better to secure the beginning and end of the sealing tape with glue. All! All that remains is to hang the sash back: you can install the pin with your bare hands, and then return the decorative trim to its place. The video shows and describes everything very well.

Causes of problems

Consumers who choose plastic windows are mistakenly confident that they will be able to remain airtight throughout their entire service life. At first, such windows really reduce heat loss and coolant bills. Much depends not only on the quality of plastic windows, but also on the method of their installation. If the latter was done in violation of basic rules, then you may not see the difference with old wooden windows. In addition to errors that were made during installation, the following factors can worsen the situation:

- wear of insulation;

- detachment of linings from the glass unit;

- changing window geometry;

- wear of shut-off valves;

- wear of the PVC base;

- improper installation of window sills;

- violation of slope finishing technology.

Insulation in most cases is represented by rubber gaskets, which dry out and become unusable due to constant changes in temperature and humidity. The consequence of this is drafts and loss of tightness. Problem areas are also the places where the glass unit is pressed against the window frame. If the slats begin to lag behind, this will lead to condensation and the appearance of ice on the window. In production, the angles of the window frame and sashes are made ideal, but their geometry can be disrupted by physical influence. For example, the shrinkage of a building can change the angle, causing a sash to leak or a gap to appear near the wall.

Metal fittings, which are used in plastic windows to secure the sashes, fail over time. In this case, the window cannot be pressed with the proper force, which is why problems arise. Each material has its own service life, this also applies to PVC profiles. It may also be the reason that the window has lost its seal. It can leak from under the windowsill. If during installation the window sill was replaced with a plastic one, then errors may have been made during installation, which left a gap through which cold air enters. Slopes require compliance with finishing technology so that they can fulfill their tasks. If they are not sealed enough, then problems are bound to arise.

Resolving issues related to the repair or maintenance of plastic windows can be entrusted to a company that specializes in this. Usually in the arsenal of craftsmen there are components that often fail and require replacement. The work will be completed quickly, but it is worth considering that you will have to pay a certain part of the budget for such a procedure. Therefore, it is easier to insulate plastic windows yourself.

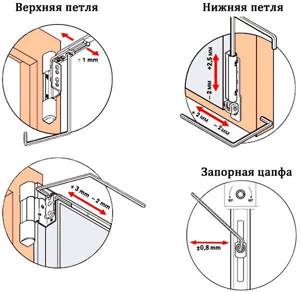

Adjustment mechanisms

The adjustment mechanism, which allows you to switch plastic windows to the “Summer” or “Winter” mode, is represented by special elements - trunnions (also called eccentrics), which are located at the end. Most often they are round - on such eccentrics there is a mark in the form of a line or a dot:

- neutral mode – it is directed upward;

- “Summer” - go outside;

- “Winter” - indoors.

The axle can be not only round, but also of other shapes:

- Oval eccentric - without risks. Switching is carried out by changing the orientation of the oval - vertically “Summer”, horizontally “Winter”, diagonally – neutral adjustment.

- Eccentric for the key - adjusted with a hex tool, which is used when assembling/disassembling furniture.

There are always several pins on a plastic window, and especially a door: to adjust for summer or winter, you need to adjust each of them

Features of adjusting windows of different brands

In general, the adjustment looks the same. But since the fittings for plastic windows differ from different manufacturers, each brand has its own characteristics:

- Rehau - the mechanism can be adjusted for summer and winter both in the “up-down” and “right-left” planes; the pressure setting is separately adjustable.

- Veka – to switch to the “Winter” mode, you need to turn the spike 90 degrees with a hex key. If a closed window cannot be opened because the handle does not turn, the sash is slightly shifted towards the blocker. If the handle is broken, the decorative trim is turned 90 degrees, the screw is unscrewed and a new mechanism is installed.

- KBE - I adjust the density using three eccentrics, which are also located at the end. To eliminate slack, you need to loosen the bottom screw and turn the top one to the right or left.

- Maco and Torx - classic setting for winter or summer using a hexagon.

- Roto - here the trunnions are equipped with round heads, so you need to use a special key.

Important! If a mechanism from Siegenia Aubi is installed on the Rehau Blitz profile, you will need a special key for adjustment.

It is not available among home tools, so you will have to contact a specialist.

Correcting skewed sashes

As you know, in some cases even plastic window structures can shrink. And, alas, nothing can be done about this. As a rule, houses that were built most recently “suffer” from this problem. And due to shrinkage, accordingly, the sashes warp slightly, which has a negative impact on the thermal insulation characteristics of the structure. But this problem can be solved - for this you need to debug the fittings.

What tools will you need?

The pressure of the sashes can be adjusted manually using special eccentrics. When the handle is turned, they move beyond the "calling areas". Such elements must be installed along the entire perimeter of the frame. And to ensure the tightest possible pressure, the eccentric must be turned strictly clockwise.

Each of the elements mentioned above has a special “picture”. If it is directed towards the street, this means that the clamp is loose. But if this pointer is directed towards the seal made of rubber, then the window sash is perfectly pressed against the frame structure.

A little about loops

Hinges in metal-plastic window structures also have their own mechanism, which is responsible for pressing. The device is adjusted using a special hexagon. Here you should be guided by one simple rule: if the tongue is pulled out strongly, then the window sashes fit snugly. To extend this tongue, you need to twist the hexagon, while going counterclockwise. If the hinges in the window are located on the right, you need to turn the hexagon in the opposite direction. That is, here it is clockwise. It turns out that there is nothing complicated in this event - eliminating the distortion is easy and simple.

Note! If the manipulations described above did not bring any results, and cold air continues to penetrate into the apartment, then, most likely, the problems are more serious. Here all you have to do is turn to specialists for help.

We continue to talk about how to insulate double-glazed windows. Now let's find out how to prepare windows for winter.

Insulation materials

The choice of material for insulating plastic windows depends on the location of the problem. If the thermal insulation is damaged, you need to select a new seal from the following set of possible options:

- Rubber. Simple and inexpensive rubber insulation. Depending on the climate, it will last from 5 to 10 years.

- Silicone will last 40 years. Able to withstand sudden temperature changes, does not crack in the heat, and is resistant to moisture.

- Polymeric. Durable and flexible, works in a wide range of humidity and temperature.

- Polyvinychloride. It does not tolerate severe frosts and lasts no more than three years. The advantage is a wide range of colors and fire safety.

- Foam rubber. The cheapest of those presented. Will last 1 season.

When insulating slopes, you will need polyurethane foam. If problems arise with the window sill, you will need polystyrene foam, polystyrene foam or mineral wool. All of them have good thermal insulation properties. Select the material according to thickness and budget.

Foam insulation is suitable for insulating plastic windows

You will also need silicone sealant to seal cracks and a solution to degrease the profile surface.

To carry out external work, you will need polystyrene foam, frost-resistant glue, fiberglass reinforcing mesh and plaster mortar.

We are engaged in insulation of slopes

As you know, in metal-plastic windows the slopes must be plastic. The lining must be plastic, and it must be hard. What causes this? The fact is that this material is ideal for additional thermal insulation.

And here the opening formed between the window frame and the wall surface must be blown out using polyurethane foam. Of course, there are other options - for example, insulating boards (they are made from basalt fiber) or foam insulation. Therefore, you can choose the material that is ideal for your current purposes.

The wall must be insulated both from the inside and outside. But in this case, the materials used will not only insulate, but also protect. The insulator itself is necessary for protection from various external negative factors.

Technologies and methods of insulation of plastic windows

Having identified the causes, you can begin to eliminate them directly. How to insulate a plastic window quickly, effectively and inexpensively? If it is better to choose a cool time to search for places of depressurization, then repair and restoration procedures are carried out when the ambient temperature allows the use of materials for which frost and humidity are unacceptable.

On the packaging of building mixtures and sealants, conditions of use are indicated that must be strictly followed in order to achieve the desired result. It is better not to carry out repairs and insulation of plastic windows in winter, with the exception of some emergency operations, adjustment of mechanisms and when replacing seals.

The best double-glazed windows for plastic windows are made from energy-saving glass, but they also cannot cope with the task when gaps arise. The reason for this is the seal that has lost its quality. To replace it, it is better to remove the sash and carry out operations in a horizontal position.

In order to understand how to insulate plastic windows with your own hands, you need to familiarize yourself with the procedure:

- the glazing beads are carefully dismantled;

- the glass unit is removed;

- old seals are removed from the grooves on the profile of the window system and glazing beads;

- a new elastic insulator is installed in the seat;

- the glass unit is inserted into place;

- when installing glazing beads, there should be pressure from the seal on the glass, that is, they are mounted with an interference fit;

- The fit of the elastic elements along the entire contour on both sides is checked, and if vibration or movement of the double-glazed windows inside the sash is observed, then the wrong seal has been selected. In rare cases, a manufacturing defect may occur. The thickness of the glass unit is less than the permissible standards and will need to be replaced with a new product;

- When the visual tightness test is passed, the sash is installed in the window block.

If the window does not use energy-saving glass, and replacement is impossible due to certain circumstances, then you can increase the efficiency of double-glazed windows yourself. For this purpose, a special film with reflective properties is purchased. Insulating plastic windows in this way is economically and technologically justified. Following installation rules and recommendations, the film is glued to the surface of the windows from the inside, thereby significantly reducing heat loss.

Might be interesting

Incorrect adjustment of the window system also causes many problems. Before doing it, you should make sure that the structure as a whole has the correct geometry, otherwise the work will be useless.

This is checked by a building rule, a metal ruler, or a level lath. The tool is applied to the horizontal parts of the structure. If both ends are tightly pressed to the profiles of the window block, and there are no gaps along the length of more than 1-2 mm, then the plane meets the standards. Otherwise, plastic windows will need to be repaired or reinstalled.

Now you can begin to adjust the position of the shutters relative to the frame. The window is slowly closed, making sure it touches the profile. If it occurs simultaneously along the entire length of the vertical line, then this position is considered correct.

Then check the size of the gap around the perimeter of the sash. It should be the same. If the conditions are met, but the window continues to blow, then most likely the problem is a worn seal, which is changed in the same way as during a similar operation with a double-glazed window.

If deviations are noticed, adjust the loops. Depending on the manufacturer's standards, the window adjustment screw may be a Phillips or hex screw. Use a screwdriver or wrench to adjust the window to a satisfactory condition.

Adjustments to the shutter mechanism of Euro windows are of no small importance. When the handle is moved from the “open” to the “closed” position, the sash should press tightly against the frame

The lever operates in a range of about 2 mm.

The pressure is adjusted by an eccentric at the end. Use a wrench or a screwdriver to set the desired position. It is recommended to adjust plastic windows for winter every season.

What is the essence of thermal insulation?

Thermal insulation of double-glazed windows consists, as noted above, precisely in the slopes. If we talk about other structural elements, then only troubleshooting will be required. For example, drafts never appear due to the profile. And modern technological plastic, which is used in windows, is no longer wood; it is incapable of either “moving out” or drying out.

Plastic windows lose thermal energy if certain sections of the structure become depressurized. And if you do not want the cold to penetrate inside the room, then take care of insulating the slopes or start looking for the causes of the problems. Well, let's proceed directly to how to insulate double-glazed windows, and let's start with insulating the slopes of window structures.

7 ways to insulate windows for the winter

Previously, we gave several instructions on how and what is the best way to insulate windows for the winter; in addition to this article, we advise you to read this information, see details here

We insulate windows in a new way - modern technologies

Window insulation using Swedish technology

Swedish technology for insulating wooden windows using seals Swedish technology involves the use of tubular material made from silicone rubber

It is important to choose a high-quality seal that is not afraid of temperature changes and is resistant to paints and dirt. This is exactly what they produce in Sweden (which is why the technology got this name)

So, how to insulate windows with your own hands using Swedish technology? The insulation is a rubber tubular profile with a service life of 20 years. This profile is glued into pre-cut grooves on the window. It must be sealed very tightly, otherwise it may fall out.

How to insulate window glass

Such insulation involves the use of innovative material based on polyester (high molecular weight polymer). Other materials—organic compounds, metals and their oxides—are “woven” into the energy-saving film in a special way, which makes it possible to change the initial properties of the polymer. At the same time, the structure of the material’s molecules is such that light passes through them perfectly.

Insulating a window with film

Thus, the energy-saving film does not create optical distortions visible to the eye, is inert to household chemicals and does not contribute to the formation of dust on the windows. In addition, this material creates a mechanical strengthening for the glass - in case of damage, it will not shatter into the smallest traumatic fragments. The film is characterized by both frost resistance and environmental safety.

To insulate windows with your own film, you will need:

- the material itself in the right quantity,

- scissors and a stationery knife,

- household hair dryer.

Insulation work is carried out as follows:

- The glass is washed and degreased.

- The joints of the frames are sealed with foam rubber or other sealant.

- Apply 2-sided tape to a clean surface of the window frame.

- We glue one layer of film of the required size with tape along the entire perimeter of the window frame.

- Using a hairdryer, we heat-shrink (smooth) the material.

Keep in mind that you should not over-tighten the film - the material itself will take on the required tension over time.

Insulation with silicone sealant

Insulation using sealant is considered one of the highest quality and most durable. For the work you will need a sealant (silicone) and a special lever syringe (gun) for applying it.

Silicone insulation work is carried out in the following order:

Insulating wooden windows using transparent sealant

- The glass is removed from the window (stock up on new glazing beads, because old ones very often break during dismantling).

- Clean the seat from dirt and dust, then apply a strip of silicone there.

- Reinstall the glass and secure it again with glazing beads.

It turns out that at the same time as insulation, you will also carry out minor repairs to your wooden windows. If the work is carried out in the summer, then get serious about the repairs - repair cracks in the frames, change the fittings - this will improve both the heat-saving qualities of the structure and its appearance.

What to do if a plastic window is blowing from below from under the sash

If the adjustments described above did not resolve the problem, it means that the rubber seal is worn out. In this case, you can see the following defects: rubbing, jamming, loss of elasticity. We select new tires according to the sample or type of profile system. We change in the following sequence:

Use the handle to open the door. In the corner we pry up the seal and tighten it around the perimeter until we reach the top loop. We move the sash to the “ventilation” position. We take out the remaining part of the sealing rubber. Carefully clean and wash the installation groove. We place the beginning of the new rubber at the top in the middle. We completely go around the perimeter with a single contour

It is important to avoid excessive tension at the corners. At the junction we cut the rubber without excessive tension or overlap. Pull out both ends of the elastic. Apply a drop of Moment glue to their lower parts and install them back.

Be sure to change the second sealing contour, which is located on the frame. The principle of operation remains the same.

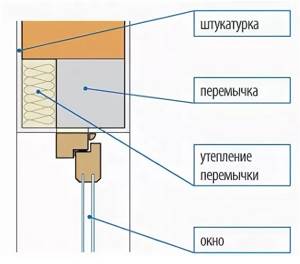

How to quickly insulate a window lintel with your own hands

Cold can penetrate not only through the opening. It also seeps through auxiliary structures. A poorly insulated concrete lintel can allow outside air to enter the room. To fix it you will have to do the following:

- Choose a sheet of foam or polystyrene to insulate the lintel;

- Cut the material into the required size;

- Use glue or foam for fixation;

- Cover all seams with foam. After drying, remove excess;

- When installing window insulation from the outside, the insulating material must be protected from precipitation and radiation. To do this, a layer of plaster is applied to it.

Work on insulating the lintel from the inside is carried out in the same way. The same insulating materials are used, and the methods of their fastening are similar.

Insulation of the lintel