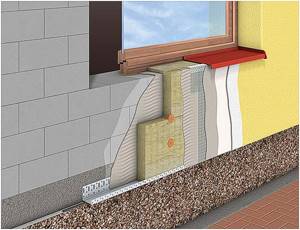

Why is it necessary to insulate a window sill?

Rice. 2. Insulating the window sill will eliminate drafts

Most Russians believe that the issue of room insulation can be solved by installing PVC windows. However, to effectively retain heat in a residential or office space, absolutely all elements of the window opening must be used. This is especially true for the window sill. It is this element of the window structure that is considered the most vulnerable. Therefore, if the temperature in the room drops, first of all, you should check the area where the window frame adjoins the window sill. If cold air comes from there, causing drafts, then residents urgently need to address the issue of insulating this particular window structure.

Required Tools

Rice. 3. Tools for insulating the window sill

To insulate plastic window sills, you may need the following tools:

- hammer;

- perforator;

- chisel;

- putty knife;

- building level;

- fine-toothed hacksaw with a hard and long blade;

- knife.

During installation and dismantling work, you may need a broom or a brush with stiff bristles, as well as a vacuum cleaner to clean the room.

Removing a plastic window sill

Rice. 4. The base for the window sill after dismantling

Insulation of PVC window sills always begins with their dismantling. To do this, it is common to use two main methods.

In the first case, the master must knock down the layer of plaster that is located under the slab structure as carefully as possible. The plaster must be knocked down to the very base of the wall. Due to this, the master will have open access to the base of the structure. Accordingly, he will be able to quickly detect all existing chips and cracks. Dismantling will also require breaking off the plaster at the contact points between the window sill and the slope.

To complete the dismantling work, it is necessary to cut off the layer of polyurethane foam that remains after installing this structure. The cut should be made as carefully as possible, since during the work the master can scratch the plastic. After completing all the processes described above, all that remains is to slowly pull the structure towards you and down. You should not make extremely large efforts to dismantle the PVC window sill, as there is a risk of damaging the plastic sheet.

The second dismantling method involves using a fine-toothed hacksaw. The blade of such a hacksaw should be hard and long. To dismantle the structure, a hacksaw is inserted under the blade, after which the cutting of the polyurethane foam begins. At the next stage of dismantling work, the sealant is cut on the sides of the slopes. After completing these operations, you can slowly and carefully remove the window sill by first lifting it up and then pulling it towards you.

After dismantling work, care must be taken to clean the window base. To do this, use a brush with stiff bristles and a regular household vacuum cleaner. After cleaning, you will be able to see all the existing cracks and chips that need to be sealed with foam or acrylic sealant.

Determining critical places

To effectively insulate plastic windows, you must first understand where the seal is broken. The only thing you can immediately remove from the list of suspects is the frame: multi-chamber plastic is a good heat insulator, it does not dry out, unlike wood.

Cold air can penetrate through the following structural elements:

- clamping elements that tend to loosen over time;

- a detached glazing bead that holds the glass unit in place;

- worn out seal;

- polyurethane foam, if it was applied in violation of technology;

- windowsill;

- slopes.

A double-glazed window rarely causes a violation of thermal insulation (the exception is its depressurization), but it can also be additionally insulated. “Extra” heat in winter will not hurt.

It is easy to identify leaky window elements - just run your palm along and across the entire structure, and you will feel that there is a decent amount of wind in some places. Some people recommend using a lighter for this purpose. If you light a flame and pass it around the perimeter of the window, maintaining a safe distance, it will tilt in those places where there is even a small draft. Be extremely careful with this method!

As a rule, work on insulating a plastic window can be done with your own hands. The exception is when it is necessary to insulate the slopes from the outside, and the apartment is located above the second floor. You need to be prepared that comprehensive insulation may be needed if several zones of warm air leaks are found, but first things first.

It is very important to find out exactly how cold air gets inside the room. To do this, you need to take a lighter and run it around the entire perimeter of the plastic window. Pay special attention to the places where the frame meets the wall. The window sill and slopes are also worth checking. If you don't have a lighter, use an open palm.

Important! Pay special attention to the fittings. Very often, domestic companies use low-quality components to save money.

Choosing material for window sill insulation

Rice. 5. The quality of window sill insulation will depend on the selected material

Most often, polyurethane foam is used to insulate PVC window sills. It can be used both to seal individual cracks and along the entire length of the base of the window frame. Better insulation can be obtained by using acrylic sealant. It is applied from a tube to all existing joints of the window sill with the frame.

Polyurethane foam

Rice. 6. Applying foam to insulate the window sill

To install a PVC window sill, it is necessary to cover its entire perimeter with mounting foam, which is a polyurethane foam sealant in aerosol packaging. Polyurethane foam is characterized by resistance to UV radiation and good adhesion.

The installation process involves drawing 2 intersecting lines in the center, which will simplify the process of adhesion of the slab to the base of the window. Next, all that remains is to attach the canvas to the base of the window opening. To check the evenness of the installation of the structure, you can use a building level.

When using polyurethane foam there is one very important nuance. This material tends to expand within 24 hours after application. Therefore, to prevent the window sill from moving, it is recommended to securely fix it for at least one day. For this purpose, you can use the most ordinary 3-liter jar of water. In addition, the use of polyurethane foam must be carried out in accordance with the strict requirements of the manufacturer indicated on the packaging of this product. In particular, the temperature regime of the surrounding space must be observed. Almost all manufacturers recommend using their products at an ambient temperature of at least 18 °C.

Acrylic sealant

Rice. 7. Acrylic sealant

An alternative to mounting foam is acrylic sealant. It is a non-toxic polymer material intended for both indoor and outdoor use. Among the main advantages of acrylic sealants are affordable cost, ease of use, high level of adhesion, paintability, resistance to ultraviolet radiation and fire safety.

The use of acrylic sealant allows you to obtain a better and more comprehensive seal. The sealant must be applied to small cracks and joints. During the application of sealant, excess may occur. In order to remove them, it is enough to use an ordinary spatula or rag. The base of the window opening should be treated with a primer. In some cases, putty is used to level the base, which should be applied in one layer, having previously aligned the beacons to the building level.

Installation of a plastic window sill

Rice. 8. Diagram of a standard PVC window sill

Once the surface of the window frame is ready, the process of installing the window sill begins. For this purpose, the canvas must be attached to the base of the window structure. To prepare wooden supports of the required thickness, measure the actual distance from the base to the bottom of the window slab. Wooden supports are necessary to ensure the design rigidity of the canvas during its operation. All external and internal dimensions can be measured with an ordinary tape measure.

After the plastic window sill is attached to the base, polyurethane foam or acrylic sealant is used. In order to avoid the formation of so-called “cold bridges”, it is necessary to close the joint between the inner surface of the PVC window sill and the mounting profile. Then, to better fix the wooden supports, polyurethane foam is used again. The last stage of installation is foaming the installed canvas and the external joint of the wall.

Price for work

You can install the canvas with your own hands, or you can turn to professionals for help. This type of work does not involve any particular difficulties. But you may not be able to handle the installation of artificial stone window sills yourself if you order products of designer shapes and non-standard sizes.

If you decide to entrust the work to specialists, an additional item will appear in your expense item. The cost of installing window sills is approximately 10-12% of the cost of the product itself.

The price of manufacturing the structure is determined after professional measurements.

The final cost of such a service as installing window sills includes the cost of preliminary work.

Each company in Moscow compiles its own price list. For example, it offers the following prices:

- preparation of grooves in the walls - 500 rub./piece;

- installation of slabs up to 500 mm wide - 2000 rub. for p/m;

- installation of canvases with a width of more than 500 mm - extra charge + 20%;

- fixation of radial bay window products (with gluing) - 2500 rub. for p/m.

If you are looking for artificial stone or cast marble from a manufacturer, we recommend visiting the company’s website. Below are the prices for their products:

Joint processing

Rice. 9. Finishing the slope in the “section”

In order to give the insulated window sill a finished look, the slopes are plastered. To do this, you can use either cement mortar or regular dry mixture, which can be applied with a spatula. After the mixture has dried, the final coating of the slope is carried out. To give the slope a finished look, the finishing coating is rubbed down with sandpaper. In order to ensure an aesthetically beautiful appearance, the plastered slopes can be painted, and the wallpaper peeled off during dismantling can be glued back.

How to insulate a plastic window sill from the inside

Rice. 10. Insulation of PVC window sill from the inside

Before proceeding with the internal insulation of a plastic window sill, it is necessary to determine its “weak point”. In other words, the master must understand where the draft is coming from. Most often, the greatest heat loss is observed at the joints between the plastic elements of the window and the window sill. “Weak spots” can also be cracks and cracks formed as a result of thermal factors and mechanical loads.

To seal existing cracks, you need to remove the old foam and apply sealant along the entire length of the base of the window frame. This material is able to penetrate deep into the gap and completely seal it.

Heat-saving film

Film for insulating plastic windows can significantly reduce heat loss in the house. However, in order for its application to have the desired effect, it is necessary to properly prepare the surface. In this case, you will need the following tools:

- stationery knife;

- hair dryer;

- scissors;

- scotch.

First, the surface must be cleaned of dust and dirt. Wipe the glass thoroughly (a layer of dirt and dust makes it difficult for sunlight to penetrate inside). To check the quality of cleaning, take the paper and press it across the glass; you should hear a distinct squeak.

The perimeter of the box is covered with double-sided tape. The edges of the film are separated with a stationery knife. Cut it with scissors to the size of the window and stick it on the previously attached tape. Take a hairdryer and blow warm air over the film. Burst the resulting swellings with the tip of a knife. This is the easiest and most inexpensive way to insulate platinum windows.

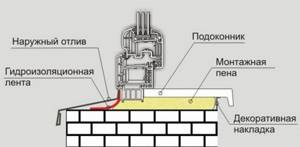

How to insulate a plastic window sill from the outside

Rice. 11. Insulating a plastic window sill from the outside will help get rid of drafts

External insulation of plastic window sills consists of finishing the ebb and window slopes on the street side. If these elements of a plastic window are not insulated, then the cold will seep into the room through the cracks at the joints of the window frame and the window sill. In addition, the lack of external insulation often leads to the development of mold on the lower surface of this structure.

For external insulation, it is not enough to use polyurethane foam and cover the cracks with plaster. It is not advisable to use these materials outdoors, since under the influence of negative environmental factors they will gradually begin to crack and collapse. Therefore, for external insulation, a material such as polystyrene foam is most often used. Sheets of this material should be glued to the surface of the outer slope using special glue. A reinforcement mesh must be attached to the top. To give a finished look, the slope should be plastered and, if necessary, painted in the desired color.

Setting the clamping mechanism

Over time, under the influence of mechanical and climatic factors, the sealing gum may lose volume. Because of this, air begins to penetrate into the room. Fortunately, to insulate plastic windows, it is not necessary to change the gasket. It is enough to adjust the clamping mechanism.

Important! If the gasket has completely deteriorated, it will have to be replaced.

To insulate plastic windows by adjusting the mechanism, you need to find protruding cylinders in the slots of the metal plugs. These are called trunnions and fit into hooks on the frame.

To insulate the frame, move the hooks to the desired position. Or adjust the trunnions. To change the position of the hook, you need to loosen the bolts. Moving towards the street increases the pressure, and towards the room decreases it. Here is a detailed video on how to insulate a plastic window yourself by adjusting the clamping mechanism:

How to insulate a plastic window sill on a balcony or loggia

Rice. 12. Scheme for insulating a window sill on a balcony or loggia

To insulate a window sill on a loggia or balcony, preliminary thermal insulation of the outer wall should be carried out. It is advisable to install the insulation from the outside, but this is almost impossible to do on loggias and balconies. Therefore, insulation in these rooms is usually carried out from the inside. Installing insulation will reduce heat loss on the balcony, thereby ensuring a comfortable microclimate throughout the living space.

Additionally, the PVC window sill itself can be thermally insulated. For this, polyurethane foam or acrylic sealant is used.

How to make a “warm” window installation yourself

The technology of insulating slopes with extruded polystyrene foam is excellent for an ordinary country house. But, installing windows in energy-efficient homes requires a more advanced option. The thermal characteristics of the wall-window assembly can be improved by using the so-called system. "warm" installation.

This could be EPPS, PIR board, foam glass. The technology for “warm” installation of a window with facing brickwork is as follows, you need:

- Insulate the upper, right and left slopes with EPS.

- The base under the window is also insulated with EPS. But first, in the thermal insulation, you need to make a rigid support under the frame (under plastic support pads/wedges) to transfer the load to the wall, which will be discussed below.

- Additionally protect the mounting foam - from the inside with a vapor barrier, and from the outside with a vapor-permeable moisture-UV and windproof sealing material .