07/06/2017 5566 Pechnik (Moscow) Boiler: A fireplace with a water circuit, which many call a thermofireplace or a water heating unit, is a design that looks like standard hearths. Such boilers operate on classic solid fuel (wood), which, if necessary, can be replaced with purchased eurowood or briquettes.

A fireplace boiler with a water circuit can be installed in a private or country house, as well as in some apartments in which there are associated conditions and the ability to install not only the main part of the structure, but also all additional elements, such as a chimney pipe.

Design Features

The unusual design of the firebox

is the main distinguishing feature of a fireplace with a water circuit. A heat exchanger is built into it. Modern manufacturers (Hark, Supra, Schmid, etc.) offer both completely finished fireplaces with a water circuit, and separate fireboxes with a heat exchanger, on the basis of which you can build a fireplace of the configuration you need.

Two main types of construction

providing heating with a fireplace:

- a contour of tubes sealed inside the side walls of the firebox or laid along their outer surface. Leads for water are made at the upper ends of the tube.

- “water jacket” in the form of a heat exchanger tank that is filled with water. One of the walls of the tank is the wall of the firebox. Such a jacket can cover the arch or only one wall of the firebox, but sometimes it is made “U”-shaped (that is, it covers all three side walls). The firebox is connected to the heating system through terminals at the bottom and top of the tank.

Interior use

Do not forget that the key point in the name of the device is the word “fireplace”. This means that in addition to its technical qualities, it primarily serves as part of the interior. Various design options provide the opportunity to choose a model to suit any room decor.

Cast iron stoves and fireplaces are equipped with a heat-resistant glass door. It's easy to watch the flames through this glass, and it's also part of the slow-burning technology. Cast iron options are the most optimal in terms of performance and finish.

Some ready-made models do not require additional finishing, since they are covered with a layer of ceramics. The buyer only has to decide on the color of the fireplace. However, there are also options that will have to be additionally lined. This makes it possible to complete the decoration in the same spirit as the style of the room. Ceramics, artificial stone, and brickwork decor are excellent.

The presence of a circuit in the fireplace does not prevent the creation of different types of models according to the installation method. Due to its dimensions, a corner fireplace is suitable for a small room in a country house. This arrangement not only saves space, but also creates the illusion of increasing it. The corner model hides the transition boundary between the walls, so the eye is not “clung” to the dimensions and the room is externally assessed as a large space.

Double circuit

Some models are equipped with it.

These circuits are completely independent: one serves the heating system, and the second circuit heats water for domestic needs; it can be connected to a hot water system and use the water for bathing or showering and washing dishes.

The second circuit requires a storage tank.

The design feature is such that water in the second circuit (as well as in the heating circuit) must circulate. Otherwise, it will quickly overheat, turn into steam and the pressure will simply burst the pipes. To prevent this from happening, it is necessary to provide a storage tank into which heated water will flow. And ensure a constant supply of new water from the water supply system. Thus, hot water enters the DHW system from the storage tank. That is, unlike heating radiators, it remains warm even after the fireplace is turned off.

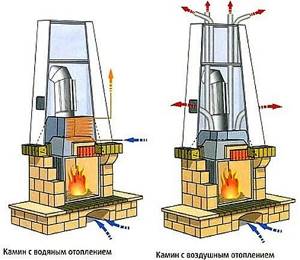

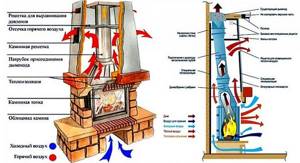

Features of air exchange

As already noted, air circulation is carried out naturally or under the influence of a fan.

During natural circulation, hot air rushes to those areas of the room that are located next to the fireplace. First, the heated air rises up the vertical channel, after which it enters the distribution channels and is carried into the home. Circulation occurs only in vertical channels, so the length of horizontal ones is reduced to a minimum. Note that an overly complex system of smoke channels can cause difficulties in operating the fireplace, which can only be avoided if there is sufficient draft force. The draft force, in turn, directly depends on the temperature difference between cold and hot air and on the sufficient height of the chimney.

The advantages of this heating method

- Auxiliary or backup heating method.

A fireplace equipped with a firebox with a water circuit is convenient to use “on the fly” - in addition to the main heating system using a boiler. - Providing hot water.

A fireplace with a water circuit is convenient to use for heating water in an autonomous water supply. - Atmospheric.

Despite all its functionality, such a device remains externally a beautiful and romantic fireplace, near which it is so pleasant to sit in the evening.

Types of systems

Fireplace inserts with a heat exchanger can be equipped with one of the following systems:

| System name | Detailed description |

| Open | Fireplace stoves for cottages with an open type heat exchanger are characterized by the presence of a built-in coil, through which water, in turn, circulates. These processes are typical for open fireboxes, and for smooth operation, it is necessary to install a special expansion tank (on the attic floor, in the basement or in the attic). |

| Closed

| Fireplace stoves with a heat exchanger for a closed type dacha are characterized by pre-heating of water in a combustion compartment built into the structure. Liquid circulation occurs through an installed pump. Before flowing through the general system, the water must be heated to 90 degrees. After complete cooling, the water returns to its original location. In this case, a special tank with a membrane is used. |

Due to its design features, a heat exchanger for a fireplace can have one of the following types of device:

- Internal. A water reservoir is installed in the combustion chamber or furnace coil.

- External. The reservoir is placed around the chimney pipe.

Advice: if your house has a small area or you need periodic heating of the premises, we recommend choosing an open system, the price of which is quite low compared to closed-type models. For large apartments, fireplaces with the function of forced circulation of liquids and are of a completely closed type are suitable.

It is interesting to know: this category of heating units can have both standard functionality and perform exclusively the heating function, or have additional built-in elements.

Models can be equipped with a hob or oven. For example, a fireplace stove with a stove and a heat exchanger is not only a fairly powerful unit, but also a means for cooking and heating water that can replace a gas or electric stove.

Flaws:

- Limited operating time:

heating with a fireplace is possible only while it is lit and the walls of the heat exchanger are heated. The fireplace went out - the batteries immediately cooled down. The heat stays somewhat longer in the storage tank of the hot water supply system. - Inability to work autonomously.

Fireplace with water circuit. Like any other fireplace, you need to light it, add wood and monitor it while it burns. - In Russian winter conditions, it is ineffective

- a fireplace with a water circuit is more of an auxiliary device for heating the house in early spring and late autumn. There are certain restrictions on the power of the device. However, a firebox with a power of about 15 kW is capable of heating a house with an area of 100-130 m². But in winter it must work continuously.

Typical diagrams for connecting a fireplace to a heating system

Gravitational convection.

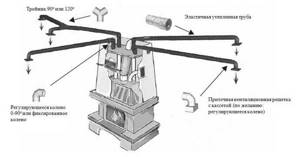

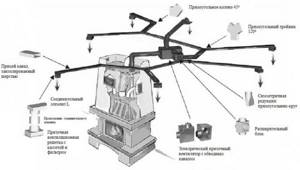

To maximize the efficiency of the fireplace and effectively distribute the heat generated in its combustion chamber throughout the house, it is necessary to integrate the fireplace into the heating circuit of the house (in the case of a fireplace in a water jacket). Fireplaces with air ducts require special design of heating elements.

The air heating scheme of a fireplace depends on the area of the serviced area. So, gravity wiring is suitable if the area of the room that needs heating is very small. The length of the air ducts should not exceed 3 m in length. In this case, the air heated by the fireplace will rise through the channels, displacing cold air at the ends of the pipes.

Forced convection.

This circuit is completely energy-independent, easy to design, install and use. Requirements for its installation: the length of the air ducts should not exceed 5 m, the pipe itself should be level with a minimum number of turns. The structural material of the pipes should be fireproof aluminum capable of withstanding temperatures of 250°C. Thermal insulation of the air duct housing is mandatory.

A circuit with forced air movement, although more expensive to implement, compared to its gravitational counterpart, allows you to heat a larger area of the room. At the same time, the efficiency of the system will not be affected by the complex layout of the house. In addition to air ducts, this circuit is equipped with elements of supply ventilation (as the main driving mechanism of warm air), connecting nodes and corners, and various elements for controlling directional air flows.

Review of popular models

There are many models of stoves and fireplaces on the market from different manufacturers, and it is easy for a buyer who is planning to buy them to get confused in the characteristics and descriptions of these devices. Below is an overview of the most popular models, according to reviews from Russian consumers.

AQUA stoves and fireplaces

The line of fireplace stoves with a water circuit from the META company is represented by the Angara, Pechora, Varta models, which differ in thermal power, shape and appearance, as well as installation method.

The AQUA hangar with a water circuit has the following characteristics:

- heating power emitted by the stove during combustion is 13-16 kW;

- heating power of the connected heating system - 5-7 kW;

- steel heat exchanger;

- wall-mounted version;

- the side walls are lined with ceramics;

- panoramic heat-resistant glass;

- outlet diameter of the smoke pipe is 150 mm.

Pechora AQUA differs from Ankara in the shape of the body - it is made in the form of a compressed prism. The power of the furnace is 13 kW, the heating system is up to 5 kW.

Warta AQUA is equipped with a hob. A special feature of AQUA fireplace stoves with a water circuit from the META company is the ability to connect only to systems with forced circulation.

Fireplace stoves Bavaria

Eco-fireplace Bavaria in a wall-mounted version with a thermal power of 12 kW is equipped with a 6 kW heat exchanger, which can be connected to a system with any type of circulation. The connection diagram is shown in the figure.

Corner fireplace model Bavaria

Advantages of Bavaria stoves:

- firebox made of heat-resistant steel 6 mm, lined with fireclay;

- cast iron heat-resistant grates;

- heat-resistant panoramic door glass with a self-cleaning system;

- long burning mode available;

- the smoke pipe is located at the rear, which allows the use of Bavaria stoves with chimneys of any type;

- the side surfaces of all Bavaria models are lined with tiles in different colors;

- the stoves are equipped with a hob, which makes them universal;

- simple design and detailed instructions allow you to buy and install these models yourself.

Consumer reviews from Bavaria fireplaces speak of their convenience and efficiency both when used for constant combustion and for periodic heating of country houses.

Installation of a fireplace with air heating

Designing and installing a fireplace with an air heating system is not easy and quite labor-intensive. However, based on the recommendations of professionals, it is possible to implement the installation yourself.

Before starting installation, prepare the tools and materials:

- — laser level and tape measure;

- - shovel;

- - grinder and drill;

- - hammer;

- - chisel;

- - protractor;

- — red brick M-150 and fireproof;

- — mortar for masonry;

- — material for pouring the foundation;

- — boards for making formwork;

- — reinforcing mesh;

- — thick-walled pipes;

- — ventilation pipes;

- — flexible pipes;

- -foil;

- -fans depending on the number of rooms.

Choosing a place for the future fireplace

Even if you want the fireplace to be the main element in the design, you must first be guided by practical considerations. It is best to place the fireplace in a corner, this will ensure the optimal length of the air channels and the highest quality air circulation. This will heat the maximum area of all rooms in the house.

Conditions for choosing a water fireplace

Materials

Most furnaces are made of structural steel. Its thickness should be optimal (from 3 to 6 mm). However, all-cast iron stoves, although heavier, retain heat longer and will not burn out after a few years.

Individual parts made of cast iron, which is more resistant to heat, are also a plus. The use of cast iron extends the service life of the entire device

Pay attention to models with a cast iron firebox, grates and hob

Fireplace in the interior of the room

The lining of the firebox is another plus. This means that there is masonry inside the firebox. It is heat resistant and retains heat. Broken fireclay can be easily replaced.

Power

Calculated individually for each home. To the classic technique, when for 10 sq. m of area, 1 kW of energy is taken, you need to add a reserve for extreme cold, energy consumption for cooking, heating hot water (if any). In addition, the quality of thermal insulation of walls, floors, ceilings, the size and quality of glazing and doors plays a role.

The power of the unit largely depends on the size of its firebox and draft adjustment.

Chimney and firebox

The designs have a rear or top connection. With a rear connection, you can hide the chimney in the wall (convenient during the construction phase), and for a finished house, a top connection is suitable.

The size of the combustion chamber is the most important criterion!

Fireplace chimney

It shouldn't be small. Firstly, you will constantly have to struggle with firewood (they will need to be cut short). And secondly, a small load burns out quickly, you need to add fuel often, you won’t achieve much power.

Long burning

These stoves, of course, are not special “long” boilers; they won’t last 12 hours on one load! However, it is possible to slow down the process of fuel burning a little if the design provides for regulation of the oxygen supply (usually the gate is located in the door or chimney). After the fuel burns out, by shutting off the supply, it will be possible to receive heat from the cooling cast-iron body for another 1.5 - 2 hours.

Ease of use and care

The fireplace glass must be self-cleaning, otherwise the soot will prevent you from enjoying the fire. Periodically it should be additionally wiped.

Cleaning ash will be much more convenient in those models that are equipped with a special handle and rotating grate. When rotated, the ash falls into the ash box, which you simply need to pull out and empty. No scoops or buckets!

Fireplace with oven

The cooking plate may have one or two "cups"

Please note that a good stove-stove should not be high, otherwise the water will boil only when it is heated to maximum. It is better to choose a horizontal firebox, then the flame will heat the food very quickly

With closed “circles”, the heat is less. If you open the pan and place it over an open flame, the heat will be very fast, but the bottom of the pan will smoke.

You need to know that self-cleaning of the door means blowing on the glass, and in the long-burning mode, the oxygen supply is cut off (partially or completely) and soot appears on the glass. So something is a play of fire and the rapid burning of firewood, or savings in case of smoked glass.

Fuel selection

As a rule, the suitable type of fuel is indicated in the attached firebox data sheet. If you use traditional firewood, the size of the logs should not be more than five to ten centimeters. Hornbeam, beech, birch and oak wood is used as firewood; this is the best option. The recommended humidity should not be more (or less) than twenty percent. If you comply with all the requirements, the flame will be long and hot. You should not use coniferous trees; they contain resin, which can burn and cause smoke in the home. Among other things, conifers smoke and crack. Also, soft wood and overdried firewood are not an option; they burn quickly and do not provide the required amount of heat. A small amount of briquetted coal can be added to the firebox, but this must be specified in the instructions. Never use plastic products or flammable liquids for ignition or as fuel.

How to choose and what to pay attention to?

What qualities must a heating equipment have to become a reliable source of heat:

- Power. Varies with the size of the firebox and the dimensions of the stove. On average, a room of 10 m² requires 1 kW of power.

- Dimensions. Must fit into the installation room.

- Coolant volume. It consists of the volume of pipes and radiators, depending on the total length of the system and the number of batteries. Another 10% is added to the resulting value.

- Chimney section. The indicator is important for selecting suitable structural elements.

- Additional options. Cooking and heating food, easy glass cleaning, non-heating handles and other easy-to-use little things.

Installation of fireplaces with a water circuit

Different designs of stoves and fireplaces also require different designs of the built-in water circuit (heat exchanger).

Stoves and fireplaces

The optimal solid fuel device for heating a house using water heating can be a fireplace stove. It may be less efficient than a boiler, but it is more presentable and functional. In addition, it is quite possible to build it with your own hands.

We are talking about the construction of a brick stove-fireplace, in which the heat exchanger is also prepared independently (or with the help of a welder). The shape and size of the water circuit may vary. The installation location is also different: directly in the firebox, behind it or on the side.

The design of the heat exchanger must correspond to the functional purpose of the unit and ensure rapid and uniform heating of the coolant. Tubular models - coil and register - cope best with this. It is, of course, easier to make capacitive circuits from steel sheets.

If the heat exchanger is installed in the combustion chamber, then the thickness and grade of steel matters, since it will be exposed to open fire. For these purposes, it is better to use boiler steel with a thickness of 4 mm.

The water circuit can also be located in different ways in the firebox. If the fireplace stove is equipped with a hob, then the heat exchanger should not interfere with cooking.

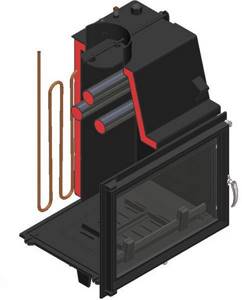

Fireplaces

A fireplace with a heating system will work with fireplace inserts in which a water circuit is installed. As in fireplace stoves, it can be tube, capacitive or combined, but with some features.

A spiral of copper tube bent in a special way is placed around the smoke collector. The selected shape allows you to quickly heat the coolant and maintain its parameters in the system. Circulation can occur by gravity or forced.

- Another type of pipe circuit is a “snake”, a pipe that is curved in several places, like a heated towel rail. Placed behind the wall of the smoke box.

- The combined version consists of two containers located on the sides of the smoke collector and connected by pipes. Since there is direct contact with flue gases, boiler steel is used. A very effective option, but not wear-resistant.

The simplest type is capacitive, also called “water jacket”, since the coolant is filled between the double walls of the housing. It is heated by the firebox casing, therefore it is the most inert.

Most fireplace inserts with a water circuit are made closed, but open ones are also found. In addition, fireplace inserts differ in appearance, power and connection diagram.

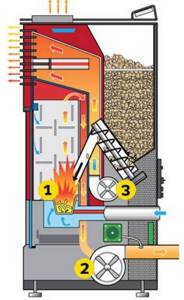

Pellet fireplaces

The solid fuel pellet fireplace stands apart in this category; it has also begun to be produced with a water circuit. Almost all of these units are of the same type: a closed firebox with a burner, a capacitive heat exchanger located behind the firebox, a pellet hopper, and a control unit.

Fuel is supplied automatically using a screw drive, the air is moved by one or two fans. An ash pit is also provided. Connection to the heating main, as in all fireplaces

Manufacturers are paying attention to the use of stainless steel pipes as chimneys, including do-it-yourself stainless steel chimneys

The big advantage of pellet fireplaces is the automation of the work process. You can load 15-20 kg of pellets into the bunker and this will be enough for one and a half to two days of burning at moderate mode. When operating at maximum power, the consumption will double.

Two bold minuses spoil the reputation of these devices. Firstly, for operation you cannot do without electricity, as is the case with conventional electric fireplaces. Secondly, it is necessary to clean the burner regularly, and if you add low-quality granules (a fairly common occurrence), it may stop working altogether.

DIY fireplace

The fireplaces discussed above represent factory-produced models. Is it possible to make a fireplace with water heating with your own hands? Many people have already done this - respect is due to them.

A description of how to build a brick fireplace yourself is in the article “Do-it-yourself fireplace: notes at the portal.” You can order a heat exchanger from a welder. Most likely, it will be a register of several rows of tubes spaced apart. The heat exchanger must be checked for the quality of welds. To do this, water is poured in, preferably under pressure.

Well, then the fireplace is built to the level of the smoke collector and a circuit is installed on the fireplace stove. The register tubes will be located in the cavity, and the housing will be laid down, leaving fittings for connection to the system.

It should be noted that such a fireplace is unprofitable for heating, but it will cope with the task of hot water supply.

Operating principle

If we consider the principle of operation of the device, it can be noted that heat is supplied by supplying warm air coming from the fireplace. In the hearth itself, the air is heated inside the structure between the fuel chamber, or it can be a cassette or liner, and directly the walls of the fireplace. To do this, a special air gap is created between the firebox and the lining during equipment execution. This is where the air accumulates and is then directed into the rooms through air ducts. Grilles in the ceiling and walls can be used as air ducts. Volatile combustion products are removed into the chimney without connecting with warm air. Warm air can circulate naturally or with the help of a fan. You can use air ducts, the action of which will be regulated, which will subsequently make it possible to evenly distribute air flows in the home and regulate the room temperature.

Main disadvantages

Like any thing, fireplaces with a water jacket have certain disadvantages:

- Difficulty connecting to an existing heating system. To install a fireplace, you need to provide cold water supply and drainage, as well as pipes for connection to the heating system. Therefore, it is necessary to think about using a fireplace at the construction stage. “Embedding” a fireplace into an existing system will be difficult and expensive.

- Price. For full operation of the fireplace, accompanying materials are required: heat exchanger, thermal protection, expansion tank, copper pipe, and so on. As a result, the total cost of a fireplace with a water circuit exceeds the cost of a conventional fireplace several times

Steam fireplaces for installation in an apartment

The installation of fireplaces in country houses and cottages began a long time ago, and they are represented by a huge number of models. However, ordinary electric fireplaces required a certain place, permission for installation, spending money on purchasing firewood, special care and a number of other points. Therefore, purchasing a steam fireplace not only eliminates the above difficulties, but also makes it possible to install this equipment even in an ordinary apartment. And this does not require an additional source of ventilation. A steam fireplace for an apartment is an ideal solution for obtaining warmth and a comfortable environment in the house. You can buy it in any specialized store.

The main advantage of a steam fireplace is that it replaces hot fire with safe steam. And all this is thanks to the presence of water in the device. The illusion of a flame is created by the play of small water droplets. The demand for steam fireplaces is increasing day by day, because in addition to functional equipment, the buyer receives a comfortable, stylish thing that can easily fit into a homey, cozy interior.

Installation and connection of the fireplace stove

In order to equip your house with a heating system using a thermo-fireplace, you need to acquire the following equipment:

- The device itself, which can be installed in a specially designated room or in one of the living rooms of the house.

- A container for coolant with a coil, mounted in the utility room.

- Pipes, radiators and hot water system components.

All these elements are connected according to an open or closed installation scheme. The difference between one or another installation plan is the type of expansion tank and its location.

When equipping a home with an open heating system, the force of gravity is applied. That is, from the expansion tank installed in the attic, water freely enters the heat exchanger, from where it is already heated by pipes and distributed throughout the house. To avoid some emergency situations, excess hot water is returned to the tank. The simplicity of this scheme is obvious. When using it, there is no need to install any additional electrical appliances that will facilitate the operation of the heating system. At the same time, it is not recommended to use such an installation plan for heating a large house. This is due to the fact that, first of all, the specific gravity of the heated water in the sections of the device is irretrievably lost due to the high hydraulic resistance of the pipes.

A closed heating system is considered more common. It uses a membrane expansion tank, from which water is directed to the heat exchanger built into the fireplace stove and heated to 80 degrees. Next, with the help of a circulation pump, the hot liquid enters the heating system through the storage boiler. There is a relationship between the cessation of heat transfer, which can lead to boiling of water, and the stoppage of the circulation pump due to the power being turned off.

Thanks to the presence of an auxiliary coil in the rear part of the firebox, overheating of the coolant can be prevented. To do this, if necessary, it should be filled with cold water. Such actions will help protect the fireplace system from an excessive increase in pressure inside it, which can lead to damage to the device. In addition, the water jacket is equipped with a thermal protection sensor that is triggered when the permissible temperature level is exceeded.

DIY steam fireplace assembly and installation

The steam fireplace is assembled according to the instructions included in the kit. You need to know that such fireplaces mainly consist of two main parts:

- fireboxes (hearths),

- decorative frame - portal.

I recommend: Question: How to insulate a cold floor in a house made of timber?

There are models with an open hearth that do not require the installation of a portal. But all the same, they are placed on something (something) and you will need to take care of setting up such a podium for an electric fireplace.

As for the podium, he's a big deal here. The main thing is that all internal parts are well installed inside and can be accessed when needed (fill the fireplace, change a lamp, etc.). The on/off system must also be accessible.

Steam electric fireplace portal

Setting up a portal for an electric fireplace with your own hands is a special task and you can simply buy a ready-made one, or build it yourself. We talked about this in → one of the articles on the site.

Portals can be angular or straight, made from various materials:

- tree,

- stone, including brick and decorative stones,

- gypsum, incl. plasterboard with facing.

Fantasy is almost limitless.

Selecting the right device

The task has been set and the decision has been made, but the worries do not end there. It is necessary to choose exactly the type of stove that can effectively cope with the main task of heating a house of this type and the entire living space. Don’t forget about efficiency, so you’ll have to stock up on knowledge about how water heating systems work.

When analyzing technical data, you will have to take into account some conditions for installing and operating the fireplace. Wall-mounted fireplace system

Wall-mounted fireplace system

The area of the room that will have to be heated. Any owner should know this indicator by heart. Otherwise, you will have to apply your knowledge of a school geometry course and calculate the area of the living space. At least approximately. It is known that the choice of boiler power depends on the area, so at the next stage you need to decide on this value. If you do not trust the seller’s advice, then choose the power according to the following statement: 1 kW can easily heat up to 10 m2 of area. Perform the rest of the related calculations yourself. Rated power is a parameter specified by the manufacturer. Russian-made stoves comply with the declared characteristics, as they undergo experimental tests. Be sure to consider the location and method of installing the fireplace. An external factor affects the design itself and even the principle of its operation. A corner fireplace cannot be installed along the wall. It is made in such a way that it fits perfectly into the corner of the room. Wall-mounted fireplaces usually have the shape of a rectangular parallelepiped and limit the choice only to the chimney design. There are wall-mounted versions, but here it is worth carefully considering the possibility of mounting, due to the large mass of the device. If the walls in the room are decorated with sheets of plasterboard, then this option is not for you. Functional. This is also an important question, because it is known that a fireplace can perform two functions simultaneously: heating and external decoration

If you are pursuing the goal of heating a country house profitably and efficiently, then focus on the technical parameters, and not on the appearance of the device.

Let's list a few more tips that will be useful when choosing a fireplace. The size of the firebox plays a big influence on the amount of heat generated. Wood-burning fireplaces have the largest firebox. This is due to the dimensions of the logs themselves. Therefore, you should not confuse or compare the sizes of furnace fireboxes with different types of fuel.

Modern device for heating the whole house

A heat exchanger is a unit where heat is transferred from metal to coolant. Naturally, the exchange rate depends on the thermal conductivity and heat capacity of the material. Cast iron has excellent qualities, it is quite durable and accumulates energy due to its heat capacity, but its large mass sharply reduces consumer demand. However, the cast iron heat exchange system still finds its buyer. A steel heat exchanger has qualities opposite to those described.

Gas fireplaces on a cylinder

When installing, the first thing you need to do is decide on the location of the fireplace, make a marking of where exactly the structure will be placed, and only then get down to business.

And although gas cylinder fireplaces are modern safe designs, precautions must be observed. There are certain rules for installing a gas fireplace that must be strictly followed.

There are certain rules for installing a gas fireplace that must be strictly followed.

Remember that by neglecting these rules, you risk not only your health, but also that of your loved ones.

After all, due to carelessness and negligence, a fire, explosion, or, at best, equipment damage can occur.

Basic Rules:

Review of popular fireplace stoves with a water circuit

Types of fireplace stoves according to design characteristics

Modern manufacturers produce water fireplaces for heating small houses and large rooms. Consumers prefer several options:

- Koza/K6, Kratki. Compact heating unit for a small house with adjustable flame intensity. The power is 8 kW, the firebox is made of cast iron.

- Bavaria Three glasses, EcoFireplace. A stove with an original design of a steel firebox glazed on three sides. The chimney is connected from above and from behind. A heater with secondary combustion mode can heat a room for about 6 hours.

- Professor Butakov, Termofor. Available with a door made of steel, cast iron with a window and a shielded convection pipe system. Suitable for equipping a warehouse, hangar for 1000 square meters. The efficiency is 80% due to the direction of air into the afterburning chamber by special jets.

- Happy Red, MBS. Stylish fireplace for a room of 45 m2. Made from steel and cast iron using a frame method. The firebox is framed with fireclay, and the temperature difference is smoothed out by a vermiculite chipper. Efficiency – 82%.

- PC-01, Vesuvius. A model with a hob will heat a house of 150 square meters. The firebox is heated by an electric fan, heat release during long-term combustion is 5 hours. The combustion intensity is regulated by the blower flap.

- Lava, Guca. The cast iron device with a heating area of 89 m2 is equipped with two regulators - in the firebox and in the ash pan. The chimney is connected at the rear or side.

All fireplace stoves are safe and equipped with operating instructions.

Main types

There are only two types of thermal fireplaces, the division into which is carried out based on the type of metal used for production.

Cast iron firebox

Cast iron has already become a classic in the fireplace industry: it performs well near open fire and high temperatures, but it expands excessively when temperatures rise and is highly brittle.

Fireplace stoves with a water circuit, made of cast iron, can be prefabricated or solidly cast. Prefabricated options made from several elements are much more common: during installation, it is enough to assemble the individual elements, connect them with bolts and seal the seams with a special sealant. But they also have disadvantages: due to the constant expansion and contraction of cast iron, the sealant loses its functions over time, and excess air enters the firebox. As a result, the combustion temperature of the wood in the firebox increases, destroying the walls of the fireplace. It will be impossible to repair damaged elements without disassembling the entire structure. True, such a firebox will last for almost 25-30 years.

Fireboxes cast with a one-piece cast iron structure are much stronger, last longer, but are also more expensive. Constant cycles of expansion and contraction have little effect on the state of solid-cast fireboxes. But if part of such a firebox is destroyed, it will have to be completely replaced.

Steel firebox

Steel fireboxes are made from special grades of steel that are not susceptible to the destructive effects of high temperatures. In addition, additional impurities will be included in the composition of such steel. So, the firebox itself is made of alloy steel, while the lining of its inner surface (lining) is made of fireclay (fire-resistant clay), ceramics, and cast iron. The smoke catcher, fire diffuser and deflector for such a firebox can be either steel or cast iron. The grate is always made only of cast iron.

Combined firebox

In a combined firebox both metals are present. For example, its outer casing can be made of steel, and its inner casing can be made of cast iron. This option is considered the most reliable: the steel body is made entirely welded and allows the firebox to be sealed throughout its entire service life; the inner body is already lined with various linings, creating various decorative effects and protecting the outer body from heat. Such a combined firebox can last up to 100 years, but it also costs slightly more than cast iron or metal.

The above types of fireplace stoves can be divided into subtypes based on their specific characteristics:

- By type of glass: with smooth (the cheapest option), trapezoidal and rounded glass.

- In terms of power: often stoves and fireplaces with a water circuit can produce thermal power from 7 to 18 kW. The most powerful fireplaces have a power of 24-30 kW.

- According to the furnace operating system: with a closed or open system. Fireplaces made for use in an open system have a wall thickness of 4 mm and can withstand one and a half atmospheres. For a closed system, ovens are made that can withstand 2.6 atmospheres and have a wall 6 mm thick. This is an extremely important point affecting safety, which must be taken into account when purchasing a fireplace.

Advantages of such systems

The presence of a heating duct in the fireplace makes it a full-fledged source of heat not only in its immediate location, but also in all the rooms provided in this case. Water heated in the heat exchanger serves to transport heat in the heating system and is used in the plumbing system.

Good to know: Designs of brick stoves and fireplaces, how to calculate it yourself, where to get a ready-made solution

A properly selected fireplace can heat a room and provide residents with hot water for various needs. The built-in heat exchanger in the fireplace does not change the main purpose of the device. The fireplace, as before, is a symbol of comfort, thanks to its characteristic design and the opportunity to spend time looking at the magical elements.

Adding functions to the fireplace leads to the fact that it turns into a universal life support device for autonomous existence in the house. The presence of a hob will open up all the cooking possibilities for the housewife. A fireplace with a contour is perfect for a summer house when, for example, during the heating season you have to spend a long time there.

The hob significantly expands the functionality of the device

Usage and operational capabilities

Fireplaces and stoves with a water circuit are intended for installation both in country houses and in private multi-storey buildings. Due to their high efficiency, such fireplaces can serve as the main source of heating. Also, the presence of a water jacket allows you to make a connection in such a way that the house has hot water and a boiler for its regular heating.

A fireplace stove with a water circuit does not depend on the availability of gas and electricity, and thus can be installed even in towns and villages, where interruptions and shutdowns of these resources often occur.

The main features and positive qualities of such installations include:

- Possibility of connection to almost any type of heating system;

- Wide range of prices, brands, models and manufacturers;

- To kindle and operate the structure, you need dried and prepared logs or purchased briquettes;

- The working process is fully streamlined, and the furnace itself can operate in an autonomous and economical mode;

- Each model has its own unique and inimitable style;

- For small rooms, you can choose a corner heating unit;

- Due to the presence of a heat exchanger and a water jacket, heating of the premises occurs very quickly and evenly.

This article presents a large number of photos of various models and installation schemes that will help you make a melting choice and determine the visual qualities of the hearth you need.

Principle of operation

Heating with a fireplace using this method is carried out according to the following principle:

- A fireplace for heating a house produces heating by heating air masses;

- An installation located between two rooms can heat several rooms at once;

- fireplaces for heating a house use an air circuit to warm up air masses after they enter the combustion hole;

- Heating occurs due to the presence of smoldering logs, coal or purchased briquettes with fuel in the hearth;

- The design of such a heating unit allows you to simultaneously heat the entire house, as well as promptly remove all combustion and decay products.

Direction of air flows using the example of a two-story house

The difference between a fireplace with an air circuit and a water jacket

How are the flows of cold and heated air masses directed?

Important: such heating fireplaces running on solid fuel can only be installed in private buildings. They require a chimney, and especially large devices made of brick may require the construction of an additional foundation.