Most of the goodies on the tables appear with the help of a natural gift - gas. Naturally, the owners of the house want blue fuel to enter the kitchen unnoticed, without destroying the harmony, integrity of design and style, which has been thought out for months. Meanwhile, utility networks are not a toy, you cannot joke with them, because in the pursuit of beauty you can lose the main thing - life. So, how and where should a gas pipe be installed in the kitchen: norms and rules for handling the system.

General standards

First, it’s worth finding out under what circumstances gas pipes are used in the kitchen. The use of blue fuel in such a room most often means installing a stove. It's time to familiarize yourself with the terms of use. So, remember the main postulates:

- gas stoves are allowed to be installed in kitchens with a height of 2.2 meters (if the ceiling in the room is sloped, then to install the stove you should choose a place where it reaches the established norm);

- the kitchen should be equipped with a window with a window so that during the day repair work can be carried out without artificial lighting, ventilating the room (the presence of a functioning ventilation duct is welcome);

- between the slab and the opposite wall there must certainly be a passage with a width of 1 meter;

- ceilings and walls made of materials prone to combustion, according to standards, must be covered with plaster;

- The stove can be used in kitchens separated from the corridor by a secure wall/partition and door;

- The installation of gas pipes in the kitchen should be done so that the distance between the walls and the stove is at least 7 centimeters;

- branching to the slab is allowed only at the level of the connecting fitting;

- the shut-off valve should be installed at a level of 1.5 meters from the floor and at a distance of 20 centimeters from the side of the stove;

- To install the stove, it is permissible to use a special (heat-resistant - from 120 degrees) flexible hose and do not forget to change it, based on the recommendations specified in the product data sheet.

The standards for handling mainly already installed pipes and devices connected to them are indicated. If you plan to change, move, or even cut the gas pipe in the kitchen, then move on.

Apartment standards

The gas pipeline is installed in the apartment according to a previously developed plan. But even before this, it is necessary to determine the operating conditions of the gas pipeline. So, if gas units operate in the kitchen, it will become a mandatory element for them. Its presence in the boiler room is the key to warmth throughout the house.

For the positions of the gas pipe in the kitchen and apartment, the standards are as follows:

- No installation in residential areas or ventilation shafts.

- Intersection with openings for windows and doors is unacceptable.

- Laying in hard-to-reach areas is prohibited. For example, behind designer decoration on the wall. Gas equipment must be provided with quick and easy access in case of malfunctions.

- The minimum distance of the gas pipe from the floor is 2 m.

- When using thin-walled pipes, the length of flexible communication components should not exceed 3 m. The density of connections of network elements is also of great importance.

- Installation is permitted only in those rooms where the minimum ceiling height is 220 cm. And these rooms must be well ventilated.

- The kitchen should not be provided with ventilation affecting the living areas.

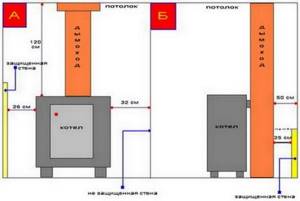

- Wall and ceiling surfaces close to gas appliances must have a special coating of non-combustible plaster. If there is no such coating on the wall, it must be insulated from gas appliances using a metal sheet. Its suitable density is 3 mm.

Pipeline requirements

What to do if the gas pipe in the kitchen is in the way, and you know for sure that you will not calm down until you move it? It’s natural to study the rules outlined below and change the network configuration without breaking the rules.

Installation rules

To remove a gas pipe in the kitchen or move it to another location, you need to know the following:

- Do not lay the pipeline through a door or window;

- It is prohibited to lead the gas system through the ventilation shaft;

- access to the pipes must always be open (you cannot know when an accident will occur or who will repair the breakdown, but this someone must accurately find where the pipeline is);

- the length of flexible network fragments should not exceed 3 meters;

- the distance between the floor and the system should be 2 meters;

- the rigidity of pipe joints is no less important than other standards;

- the pipeline requires painting;

- the places where the network intersects with the walls must have a special “packaging” in the form of a construction case.

This is important to know! And the most important rule: when working with a network transporting blue fuel, turn off the gas before starting the process!

Obtaining approval for gas pipeline replacement

Whether a transfer is possible or not can only be decided by authorized bodies, that is, the gas service of your city (district). Only a qualified specialist has the right to carry out any dismantling and installation work. Of course, pipes cannot be moved without approval.

Even such a simple step as cutting a pipe by 10 cm must be approved, since all work related to the gas pipeline falls into the risk category

The permit is issued in the following sequence:

- Find out the contact details of the gas service at the place of registration, contact specialists, explain the situation, and consult.

- You draw up an application (using a standard form) that will “launch” the approval process.

- Based on your application, a gas service representative will arrive at your home. The time will be confirmed in advance.

- The specialist performs an inspection, listens to wishes, and answers questions. Often at this stage it is necessary to change plans, since the desired transfer does not meet safety requirements (a preliminary study of the gas pipeline installation standards will eliminate this unpleasant moment).

- Approval of the final transfer scheme, drawing up an estimate. All documents are prepared by the organization providing the services. No work will be carried out without the consent of the property owner.

- If the transfer conditions are met, pay for the service using a receipt and agree on the start time of the work.

Read more: Adjustment of the pumping station principles and rules of adjustment

The approval procedure usually takes several days; it can drag on for a long period for only one reason: if the property owners and representatives of the gas service have not found a compromise solution.

Any factors that violate the installation standards for gas stoves (boilers, meters, water heaters) may cause refusal to move pipes.

It is not recommended to change anything yourself, even flexible eyeliner. All the more so, cutting, extending or moving pipes should be carried out by a representative of the gas service. However, knowing the sequence and some nuances of actions when working with pipes will not hurt the homeowner.

Usually a team of workers (most often 2 people) arrives within the next week after approval. By this point, it is already known which sections will be dismantled or extended, and whether additional equipment will be installed, for example, a geyser. Let's look at what else is worth considering.

Taking this opportunity, you can install a gas meter or completely replace outdated equipment. If additional installation is planned, workers must be notified in advance

All equipment used in the kitchen belongs to the owner of the apartment and is purchased at his expense, therefore, it is better to immediately ask what else needs to be purchased for moving appliances and working with pipes.

If we are talking about connecting a stove or oven, you will have to buy a bellows hose of a certain length. Installers bring metal pipes with them, their cost is included in the total payment for services.

To avoid any hiccups and for the work to proceed quickly, you need to free up space from excess furniture or other items. Anything that cannot be removed must be covered with thick, non-flammable material.

Most likely, when moving the pipe, you will need to cut off a piece of the old one and build a new one, but in a different direction. To do this, the master, using a special tool, removes unnecessary sections of pipes.

The qualifications of the craftsman authorized to move pipes are of great importance. Mechanics and electric welders undergo special training and certification, after which they receive the appropriate certificate

When dismantling the branch leading from the riser to the consumer, it is necessary to leave a small area on which the gas valve is attached. This horizontal piece of pipe cannot be removed or changed. The only exception is if the pipeline is damaged and requires complete replacement.

Sometimes residents of the top floors require the removal of a large piece of pipe that rises 1.8 m from the floor to the ceiling and then bends down 180°. It is strictly prohibited to cut the pipe and install a tap on the remaining section. The only way out is to weld the pipe so that the tap can be installed under the countertop, at a height of 0.75 m.

The transfer of pipes always follows the same pattern: they are moved parallel to the ceiling or walls, since diagonal and any crooked placement is prohibited. Consequently, most often the branch from the riser is lowered down, under the tabletop (rarely raised), or the vertical fragment is moved to the right/left.

A popular option for masking gas equipment: a faucet, which is easily accessible, is installed on a pipe passing below the countertop. A bellows hose is stretched from the tap to the device

When changing the direction of pipes, remember the following rules:

- internal gas distribution is an open system, all covering elements are camouflage in nature and should not be firmly fixed;

- It is prohibited to lay pipelines through ventilation ducts, as well as doors and windows;

- metal structures are predominantly used; flexible connections are allowed in equipment connection areas, but their length should not exceed 3 m;

- a rigid method of connecting pipes and hoses to pipes is used;

- Pipe transitions through walls/partitions are equipped with special adapters - sleeves.

Any work related to the transfer of pipes must begin with shutting off the gas. The organization providing the services is responsible for this.

According to SNiP standards, any changes in the position of pipes must occur by welding. Detachable connections between two sections are prohibited.

Threaded connections are used only when installing gas meters, household equipment and shut-off valves.

During the welding process, the worker must use only serviceable tools and use protective equipment: work clothes made of thick material, goggles (mask), gloves

Places burned by welding have an unpresentable appearance and also require protection against corrosion. After finishing the work, they must be treated with waterproof metal paint, matched to the color of the walls.

Before extending or moving a gas pipe, it is necessary to consider the option of installing a flexible transition. This is done using a bellows hose.

When choosing a flexible eyeliner, pay attention to its type. It is indicated in the technical specifications and is designated “fitting-nut”, “nut-nut”, “fitting-fitting”

Previously, rubber and rubber-fabric products were used, but the bellows turned out to be stronger than outdated materials. At its core, it is a metal or composite corrugation, but it has unique qualities.

For a long period of time, it maintains tightness and elasticity even under active mechanical stress. The structure of the shell is preserved even under high pressure of the transported medium or under constant mechanical stress.

The installation of bellows connectors is also carried out by a gas service worker. He connects boilers, columns, stoves and ovens in accordance with all the rules of the PUE and, if necessary, uses adapters and seals, for example, FUM tape.

They try to hide gas pipes in the kitchen behind decorative panels or furniture. Options for masking a pipeline are described in this article.

Video: moving a gas pipe

Why were the standards for the distance to buildings and objects from the gas pipe invented? Alas, we often neglect the norms of SNIP, especially in household plots and summer cottages. A particularly disdainful attitude towards the norms is if the threat of a fine is unlikely. But is it the fine?

The standards that specify the distance from the gas pipe are for our safety. Non-compliance or insufficient compliance can result in something worse than penalties. So is life really worth neglecting these indicators, even if it’s not entirely convenient?

Modern standards are suitable for the design of new gas supply systems, as well as the modernization of existing ones. According to them, the main gas outlets for domestic use do not exceed a pressure of 1.6 MPa. According to the same standards, gas supply is designed in dacha and cottage villages.

These standards are not suitable for gas supply systems of industrial organizations, for example, oil refining companies, ferrous metallurgy and others.

Composition of the gas supply system:

- external pipelines;

- internal;

- equipment and units for control, measurement, gas supply, and system maintenance.

Question about a private house

To lay a gas pipe in the kitchen of a private house, you also need to know the standards. To begin with, gasification here begins with notification of the local gas organization and the planned work. It provides a technological condition that determines the algorithm for constructing a gas pipeline. The technical issue is being resolved. A personal development for gasification of a certain area is created. Also, a warrant for the installation of a gas pipeline is issued by the traffic police.

If neighboring houses are already provided with gas, you only need to connect the pipes in a specific area to the main network. The working pressure factor is also important here. Its parameter in the main pipes determines the choice of pipes to pass into the house.

The preferred gas source determines the gas supply technology: centralized or autonomous.

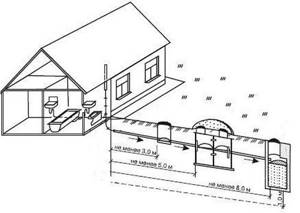

Gas pipelines can also run to private homes underground or above it.

And the standards for installing pipes to the kitchen in a private house are identical to the points in the housing issue.

Underground

The distance from the house to the gas pipe in the embankment cannot be less than 5 m. There are special provisions of SNIP, according to which the distance can be reduced by 50%, but they are regulated by the characteristics of the terrain and the passage of the gas pipeline. For example, laying pipes between houses, arches, in very limited areas, etc.

The distance to the gas pipe from the outer walls of the well, chambers or other equipment of utility networks should not be less than 30 cm. Laying must be carried out in compliance with technical requirements and conditions. Only this can be a guarantee of safety. By the way, this is why independent transfer or organization of the gas supply system is not allowed.

The distance to overhead communication lines, as well as electrical external networks, cannot be less than 2 meters. The same applies to the gap between the gas pipeline and heat transfer channels. The distance from the gas pipe to the fence, taking into account the underground laying of the pipeline in villages, must be at least 50 meters. SNIP provides for a reduction in the gap, but only if certain standards prescribed in the regulations are taken into account.

The depth of laying the gas pipeline must exceed 0.8 m for highways and roads with heavy passenger traffic and 0.6 m for roads with low traffic.

The question of camouflage

Is it possible to hide a gas pipe when there is no way to move it? It is possible and necessary. Special boxes are available for sale.

You can come up with your own plan on how to hide the gas pipe, and at the same time the counter in the kitchen.

If you have absolutely no idea how to do this effectively and harmoniously, look at the photo “How to hide gas pipes in the kitchen?”

Ground and above ground

Overhead wires are laid along the facades of buildings, on special supports made of materials that do not burn.

The laying location depends on the pressure of the gas pipeline:

- up to 0.6 MPa – wiring is allowed on shelves and trestles, as well as columns, supports and along the walls of industrial buildings;

- up to 0.3 MPa - it is allowed to lay on the walls of residential buildings and public buildings of at least the 3rd degree of fire resistance.

It is prohibited to lay gas pipelines of any pressure for the purpose of gas transit, according to SNIP:

- along the walls of kindergartens and schools, hospitals and companies that involve large crowds of people;

- for buildings in which the walls consist of panels and have metal cladding with polymer insulation;

- for buildings of categories “A” and “B”.

Standards for construction and installation work when creating a home gas network

The presence of a project for individual housing construction is not required, as it is stated in the Town Planning Code, and in PP No. 1314 it is stated that the GRO can only “check the gas consumption network installed by the applicant during the activities carried out by the contractor for connection before the actual start-up of gas.” That is, it is recommended to have a project, as in any construction, but not necessary; and even more so, its absence cannot be a reason for refusal of acceptance. As for the installation work itself, there is an updated version of SNiP 42-01-2002 - SP 62.13330.2011 with changes No. 1 and No. 2, “Gas distribution systems”.

In order not to copy a huge amount of information, there are a number of basic rules that must be strictly observed:

- When laying pipes through ceilings or enclosing structures, a sleeve sealed with elastic material is used.

- Pipe connections are not allowed at wiring points.

- For the intra-house network, only welded pipe connections are used; threaded fixation and flange connections are permissible only for connecting shut-off valves, specialized devices and flexible metallized hoses (diameter 10 mm) for the transition to gas-consuming equipment.

- All installed fittings must be accessible for maintenance.

- Inside the house, gas pipelines are mounted along the walls without slope, the risers are strictly vertical.

- The height from the floor to the gas pipes ranges from 220 mm for a flat ceiling and 200 mm for a sloped ceiling.

- The distance from the pipe to the wall is not less than half its diameter, but not more than 100 mm.

- Gas pipes should not cross any window or door openings or ventilation.

- The minimum distance from the main line to the electrical panel is 0.3 meters.

- There must be a minimum of 250 mm between the gas pipe and parallel electrical wiring if the cable is laid open, and at least 50 mm (from the edge of the pipe) if the wiring is hidden.

- When the main line and cable intersect, the distance between them must be at least 100 mm; laying without a gap is acceptable if the cable is covered with a wide rubber or ebonite sheath.

- If a gas pipeline crosses water, sewer or other pipes, the clear distance between them is at least 20 mm.

- For internal installation, the distance from the gas meter to the boiler or stove is at least 80 cm.

- Gas water heating equipment cannot be installed directly in the bathroom.

- The pipeline is attached either to detachable clamps (if the pipe diameter is up to 40 mm), or tightly to brackets or hangers (if the pipe diameter is more than 40 mm).