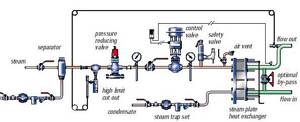

It is much more difficult to maintain, clean, disassemble and assemble such a heat exchanger. As in the case of parallel, it requires the mandatory installation of a temperature regulator, and is most often used when connecting public buildings. Shell-and-tube heat exchanger for hot water supply - design and principle of operation. Heated water moves through thin tubes, which is then supplied to the taps. Connection diagrams for PHE Connection diagrams for plate heat exchangers Here you can find out what types of connection diagrams exist for plate heat exchangers to communication networks. Educational film-instructions for assembling a plate heat exchanger for.

The coefficient of hydraulic resistance is important when calculating the load on the heating system, where the choice of a circulation pump depends on it, and is also important for other heat sources. For a dishwasher and washing machine, the values are taken from the passport and instructions and only if they support the use of hot water. Installation of a plate heat exchanger in connection diagrams - 5. Calculated based on the obtained value of liquid flow and the difference in water temperatures at the inlet and outlet of the heat exchanger. But their design is more reliable - they can withstand harsh operating conditions.

However, of course, you should first perform a calculation to arrive at a certain combination of power and performance in order to select the appropriate model. Otherwise, you will have to carry out repair work and install new plates, which will entail financial losses (Fig. 7).

This depends on the type of boiler equipment.

how does a heat exchanger work

Alfa Laval - why is there so much talk about them?

In 1883, Alfa Laval was founded in Sweden, becoming a leader in global technology production, and in 1905 its branch opened in St. Petersburg. Alfa Laval is the largest manufacturer of plate and spiral heat exchangers. It produces heat exchangers of various sizes for almost all types of industry and production, for domestic use. The Alfa Laval plate heat exchanger has a number of advantages over shell-and-tube units:

high efficiency, small dimensions compared to shell-and-tube heat exchangers of the same power;

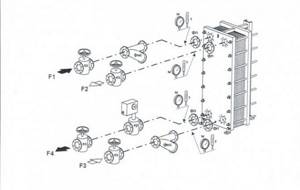

ease of installation, do not require a special foundation, the presence of inlet and outlet pipes on the front panel, which simplifies installation and repair; turbulization of the flow along the corrugated surface helps reduce the deposition of contaminants on the surfaces of the heat exchanger;

ability to increase power

This is especially important when rebuilding buildings and increasing the thermal load; in this case, it is enough to hang the required number of additional plates on the frame; assembly and disassembly is carried out by one worker in 2 hours, surfaces can be cleaned with a regular brush, and repairs are reduced to replacing the plates; a leak in the heat exchanger is practically impossible, unless with mechanical destruction of the plates (if this is done on purpose), a leak may occur in the gasket, it will be immediately detected; The design of the Alfa Laval heat exchanger allows you to reduce the time constant, which allows you to adjust the power and, as a result, save heat;

The patented shape of frames, plates, gaskets, advanced technology for the production of thermal devices guarantee their reliability and quality. The range of heat exchangers produced by Alfa Laval is quite extensive - from small devices with heat transfer surfaces and flow rates of approximately 1 kW

m and 0.18 cu. m/hour up to large units with parameters of 2,000 sq. m and 3,600 cubic meters. m/hour accordingly. All models can simultaneously solve a number of technological problems: cooling, heating, air conditioning and others

The range of heat exchangers manufactured by Alfa Laval is quite extensive - from small devices with heat transfer surfaces and flow rates of approximately 1 sq. m and 0.18 cu. m/hour up to large units with parameters of 2,000 sq. m and 3,600 cubic meters. m/hour accordingly. All models can simultaneously solve a number of technological problems: cooling, heating, air conditioning and others.

However, there is also a negative point - plate heat exchangers are limited in pressure and temperature, the cost directly depends on these parameters.

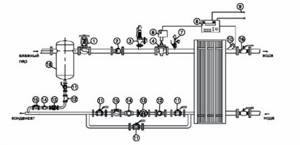

Design of heat exchange equipment

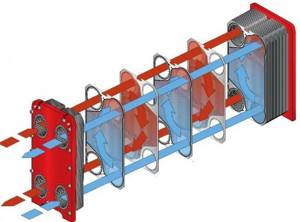

Corrugated plates are made of stainless steel (most often acid-resistant) and are connected to each other using sealing gaskets. This structure is then attached to the frame (size depends on the equipment model). In this case, the plates can be removed or added at any time (both before installation and during operation), which allows you to achieve the most effective heat transfer coefficient.

Design and operating principle of plate heat exchanger

Available programs are downloaded; several versions can be used in calculating the heat exchanger for greater confidence in the results.

The disadvantages are the lack of a water heating function.

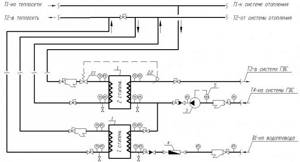

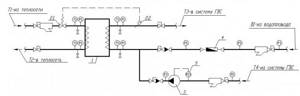

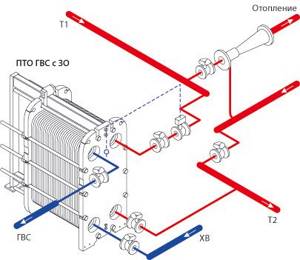

In the case when a one-stage connection scheme is selected. However, plate-brazed heat supply systems are more popular today, and their popularity is based on the absence of clamping elements. Let's look at a few examples of circuits.

That is, during installation after cleaning, everything will fall into place without much effort.

Before installing a plate heat exchanger, it is important to take into account that, when performing a do-it-yourself calculation for a plate heat exchanger for a boiler, the incoming temperature should not exceed 55 degrees. Producing a high flow rate, high-speed units slightly underheat the exiting liquid; this drawback was discovered by specialists during operation

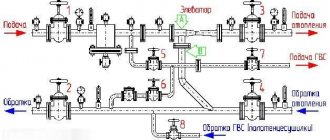

One of the options for two-stage connection of heat exchangers. In this case, primary heating comes from the heating return pipeline.

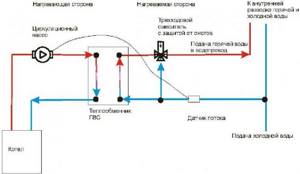

Here it is brought to the desired temperature and sent to the consumer. Air conditioners, heaters, plastic heat exchangers, accordingly, require more complex maintenance with the help of computer and service support. The temperature is controlled using a sensor and a control valve installed on the return line, which can also be installed on the supply side.

You can also turn to a specialist for help, who will carry out the calculations with his own hands, without puzzling the client. Having the same power, it is three times smaller in size than a shell-and-tube one, and at the same time is capable of providing a large flow rate of the heated medium, for example, water for domestic hot water needs. These outlets can be in the form of a flange, welded pipe, or threaded connection.

Operating principle of a plate heat exchanger.

Shell-and-tube Shell-and-tube heat exchanger for hot water from heating is simpler in design, but less efficient, which is why, to ensure the required temperature, it must have a substantial size. The thickness of the plate depends on the maximum operating pressure. The experience and skills of our specialists allow us to perform both simple calculations and complex installations with start-up pads. The disadvantage of this scheme is the greatly increased load on the heating system and inefficient heating of water in the second circuit with a larger temperature difference. To do this, you will need the help of specialized personnel of a particular company.

A temperature difference of at least 10 degrees is also important. The value for the sink is multiplied by the number of devices in the house that can be used in parallel, and added to the value for the bathtub or shower, depending on what is being used. Disadvantage: high cost due to the connection of two heat exchangers for preparing hot water. The temperature is brought to normal by reheating, but from the coolant that is supplied. SYSTHERM Heat exchangers in hot water supply Today, organizing processes for providing water is one of the main conditions for creating a comfortable life for citizens. Heat exchanger (register) for a bathhouse - which one to choose and how to connect it to heat water?

Types of heat exchangers for hot water systems

Let's look at a few examples of circuits. Gaskets can be either steel or rubber. Very easy to implement and relatively inexpensive. Significant disadvantage: the high cost is twice that of a parallel circuit. Thanks to this, they are distinguished by compact sizes, which do not in any way affect their usefulness and performance.

As in the case of parallel, it requires the mandatory installation of a temperature regulator, and is most often used when connecting public buildings. The connection of plate heat exchangers can be carried out in accordance with three main schemes: parallel, two-stage mixed, two-stage sequential. The main advantage and plus of working with collapsible structures is that they can be modified, modernized and improved, from removing unnecessary ones or adding new plates. Conclusion As practice shows, a modern plate heat exchanger is still slightly inferior to the old shell-and-tube heat exchanger according to one criterion.

In ITP Dependent heating connection with automatic regulation of heat consumption.

It is also worth servicing the PHE on time and carrying out systematic cleaning with your own hands. This scheme is the easiest to implement, but for sufficient heating it is necessary that the coolant moves actively.

The operating principle of a two-stage sequential circuit: the incoming flow is divided into two branches. Collapsible, that is, consisting of several individual tiles. DHW through a plate heat exchanger What did cleaning with citric acid lead to? The best recipes

See also: Energy passport

Classification of recuperative heat exchangers

Recuperative heat exchange devices are most widespread in industry. By design, we can distinguish several types:

- Shell-and-tube heat exchangers are bundles of tubes welded to the shell, attached to tube sheets, closed with lids on gaskets or bolts. Through the fittings on the housing, the first coolant flows through the interpipe space, and the other through the pipes. In such multi-pass heat exchangers, partitions are mounted on the body or cover. To increase heat transfer, pipes are finned by rolling or winding tape. Elemental heat exchangers are a set of elements such as a simple shell-and-tube device without partitions. They can tolerate high pressure, however, their design is more bulky and heavy.

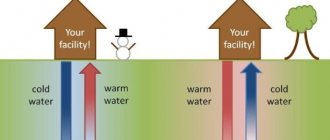

- Immersed heat exchangers are designed in such a way that one coolant is immersed in a container with another. Such units are cheap and simple, but due to the fact that the liquid in the inter-tube space does not have a high speed, the heat transfer is low.

- Pipe-in-pipe heat exchangers are used at high pressures and low coolant flow rates in the system.

- Irrigation heat exchangers are used in refrigeration units as condensers.

- Graphite heat exchangers are designed for chemically aggressive liquids. Graphite is a very good conductor of heat; it is impregnated with special resins to remove porosity. The device itself consists of graphite blocks, sealed together with rubber or Teflon gaskets, secured with lids.

- Plate heat exchangers consist of plates, their surface is stamped in a special way to form channels through which the coolant passes (for example, non-freezing liquid of the heating system). The plates are sealed together. Such a device is easy to manufacture, the number of plates can be easily changed, cleaned, has a high heat transfer rate, but cannot withstand high pressure.

- The plate-fin heat exchanger has low weight and small dimensions;

- Fin-plate heat exchangers consist of thin finned panels manufactured using high-frequency welding. The design and materials used make it possible to achieve high coolant temperatures, low hydraulic resistance, high efficiency, long service life, low cost, and other things. It is often used to utilize the thermal energy of gases.

- Spiral heat exchangers have two channels wound in a spiral around a main dividing wall and are primarily designed for heating and cooling liquids with a high viscosity index.

Maintenance Recommendations

An inspection schedule is drawn up to monitor the condition of the plate heat exchanger. The absence of leaks and the tightness of the circuits are checked daily. Pressure and temperature readings can be taken by automatic operators (dispatching) or by a responsible person. The first increases the reliability of the entire system and reduces the likelihood of errors.

Planned maintenance of components - visual inspection, monitoring the condition of fittings, assessing functionality. Medium repairs include replacement of fittings and restoration of anti-corrosion coating. During a major overhaul, a complete disassembly of the heat exchanger is performed, identifying defective plates and seals.

Assembly and startup of a gasketed plate heat exchanger must be carried out in accordance with technical regulations. It is important to monitor the current indicators and compare them with the passport ones. Additionally, acceptable discrepancies are taken into account.

We recommend reading:

How to protect your home from viruses? Tips for cleaning and disinfecting

Didn't find an article on a topic that interests you?

Just write a few words in the form at the top of the screen, our search will automatically select suitable articles.

All about country life and construction

Where is Moscow expanding? And what does this mean for summer residents? 586522 Will the Central Ring Road be able to relieve congestion on highways near Moscow? 328461 How to calculate acres of land? 272478 Which areas of the Moscow region are the cleanest and dirtiest in terms of ecology? 234517 Which metro stations will be built in the Moscow region? 210016

How much does it cost to connect a house and land to communications? 157596 Where is it better to live in the Moscow region? Rating of districts 127119 How many acres of land do you need to build a house? 124603 Districts of New Moscow. What are their advantages and disadvantages? 122332 What are the restrictions on construction near rivers and reservoirs? 106600 Which home heating is more profitable: gas or electric? 91610 Building codes and rules for the development of land plots 87137 What exhibitions of finished houses are there in Moscow and the Moscow region? 82492 The best cottage villages in the Moscow region 74987 What houses are currently on sale in the Moscow region? 71058 What are land plots without a contract? 63403 Are the basement and basement considered floors? 59357 Land development from scratch. Where to begin? 56364 Is it possible to leave SNT? 55216 What taxes must be paid for a house, garage, bathhouse and other buildings? 53086 How to re-register a plot? And how much does it cost? 54453 Is it profitable to build a house for sale? 49722 Where will the gas soon be? Gasification plan for villages in the Moscow region 46956 The best places for fishing in the Moscow region 45577 Pitfalls when buying a house

What should you pay attention to? 44219 How to bargain for a house? 43096 Life in a cottage community. Pros and cons 43039 Rating of Moscow region districts by quality of life 46061 Is it worth buying a house in SNT for permanent residence? 45718 Do I need to obtain permission to build a house on my site? 44080 Will a house built in SNT be considered residential? 42271 What to do after purchasing a plot? 38802 How long does it take to build private houses? 36443 The largest and most expensive cottages in Russia 35652 How much will it cost to build your own house? 34879

What is the best material to build a house for permanent residence from? 31842 How to register a rented plot under a house? 31209 Is it worth renting forest land for construction? 29013 How many floors can a cottage be built on? 28775 Ecovillages and ecovillages. What it is? 27789 What is the size of utility bills in cottage villages? 26705 How to build a house on a plot with a slope? 26152 Repair and decoration of a cottage. Work order and all stages 25583 Purchase of a plot with an unregistered house. What are the risks? 24136 Which private houses are warmer in winter? 23893 Division of a house with a plot. How to apply correctly? 23048 Gas to a private house. How to do it? 23048 How to rent out your plot? 22473 Turnkey house construction? Like this? And how much will it cost? 21681 Depreciation of the condition of the house. How to understand? How to calculate? 21108 Modular houses. What it is? 20520 How much will it cost to maintain your home? 20195 Lands of private household plots. What are their pros and cons? 19822 Forest areas (near the forest). What are their pros and cons? 19260 How to change the purpose of a site? 19127 Which is better: Cottage or Townhouse? 18830 Is it possible to turn a dacha into a residential building? 18564

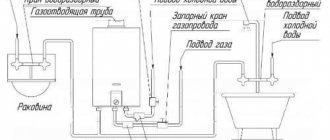

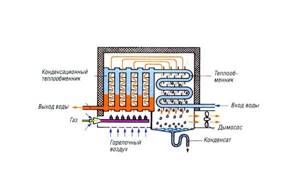

Secondary heat exchanger of a gas boiler

It is also called a hot water supply (DHW) heat exchanger. This is a rectangular device with interconnected internal plates made of food grade stainless steel. The more there are, the higher the performance of the unit. Inside they form from 8 to 30 layers. The high thermal conductivity of the materials and the large interaction area provide the necessary heat exchange with fast water movement.

READ How to install fancybox on modx

Each layer is a channel isolated within the heat exchanger. The plates have a relief from which these passages are formed. The thickness of the partitions is usually 1 mm. The channels have angles, and the sharper they are, the higher the fluid speed and vice versa. The pattern of water movement can be single- or multi-pass - with a change in direction. In the second case, higher efficiency is achieved.

After opening the hot water valve on the mixer, the three-way valve directs part of the heated coolant to the secondary exchanger. Next, the hot liquid transfers heat to the cold tap water in the unit, after which heated water comes out of the heat exchanger to be supplied through faucets in the kitchen and bathroom.

The cooled coolant then exits into the pipe, where it is mixed with the return fluid - waste coolant from the heating system, and again enters the primary exchanger.

The secondary heat exchanger is usually located below the combustion chamber. In different boilers it is mounted vertically or horizontally on its side.

Boilers also use combined heat exchangers - bithermal. In them, communication with hot water is surrounded by channels with coolant for the heating system. First, the gas transfers energy to the coolant, and then the latter directs part of it to the hot water supply. Since gas boilers with such heat exchangers are simpler, a three-way valve is not needed.

Repair of secondary heat exchanger

Secondary heaters often clog, especially models with narrow channels. Without cleaning, they break down over time and finally fail. A layer of scale inside the unit reduces heat transfer, causing the boiler to consume more gas.

Problems with heat exchangers will be indicated by codes on the boiler display. There is an action plan for this case.

Let's take a closer look at the problem with the secondary heater:

First of all, rinse the exchanger with a stream of water from a cold tap. Then pour citric acid into the device and place it in a bucket of water. Afterwards, take out the heat exchanger and pour water into it to check the permeability.

If it comes in slowly or does not move, then prepare a saturated solution of vinegar in water and pour it there. Then rinse with hot water and blow off. If possible, use an air pump. Do several cycles with vinegar.

If the steps described do not help, try special cleaning solutions: cleaning gel or low-percentage adipic acid solution. If this method does not work, then call a specialist or order professional cleaning.

How to replace a part?

No special knowledge is needed for this. To remove the old exchanger for inspection or replacement, follow these steps:

At the time of removal, it is worth remembering the location of the exchanger in order to install it back in the same way or install a new one.

Apply copper grease to the connections that secure the unit inside the boiler. This will protect it from oxidation.

Also, replace worn seals before returning the part to its place.

Types of heat exchangers

Heat exchangers are very diverse and have their own classification

When installing the device, it is important to know the characteristics of each type before choosing the appropriate one.

Lamellar

It is a connection of bolts for fasteners, frame, chambers and plate. The work plate and frame are separated by spacers. To install such equipment, you do not need to use glue or other mixtures. Heat is supplied using three modes: direct-flow, mixed and counter-flow. The device is easy to clean and has low hydraulic resistance.

Submersible

This heat exchanger looks like a cylindrical coil. The device itself is placed in a vessel with liquid. The convenience of this type of heat exchanger is that heat is transferred much faster than through other media. This is due to the design of the device. Can only be used where the heat exchanger can be switched on mechanically.

Graphite

This type is not subject to corrosion and destruction by other substances. The device consists of the following elements: blocks and cylinders, covers, metal body and grilles. Due to the fact that heat flows from the heat exchanger to another source in a cross pattern, the exchange occurs faster. The material from which the equipment is made protects from external influences.

Elemental

All elements of this heat exchanger are connected together, this is the peculiarity of this variety. Heat is supplied only countercurrently. The device itself is a collection of several large pipes.

Spiral

The equipment includes a set of spiral-type metal sheets twisted in a special device. The mechanism requires careful sealing; without this, the device will not operate well. This can be done by welding some parts of the heat exchanger. The device does not weigh much and works efficiently, but this heat exchanger is very difficult to maintain.

Twisted

A heat exchanger that is one of the few to withstand strong pressure surges in the heating network. The design itself is similar to a concentric coil and is perfectly protected from overheating and corrosion. So this type can last a very long time, does not require special operating conditions and is easy to maintain.

Shell and tube

This device compensates for voltage and consists of the following elements: tube bundles, housing, tube sheets, covers and pipes. Such devices are manufactured both for vertical and horizontal use. Resistant to high pressure and tension.

Double-pipe

This heat exchange device consists of pipes of different diameters. The device transfers water and gas to cold coolants, while maintaining a high level of heat supply. Just like the shell-and-tube one, it copes with stress and is easy to install. But the cost of such a device is quite high.

- Regenerative

- Regenerative

- Mixing

- Multi-pass

Collapsible plate types

Advantages

- minimum production costs

- minimum installation cost

- performance is adjustable

- ease of operation and repair

- low operating costs

- downtime is minimal

- low energy consumption

Application

- heating systems

- residential buildings and premises

- swimming pools

- refrigeration and climate control units

- hot water supply systems

- heating points

Advantages and disadvantages

The key advantages of the operating principle and the plate heat exchanger itself are the following:

- small dimensions, easy to fit into the required space;

- ease of maintenance, not requiring special knowledge or equipment;

- cleaning work that does not require the involvement of third parties (service companies);

- low level of contamination during operation. It is ensured by high-quality polishing of the plates, high turbulence of the fluid flow formed by the corrugation;

- high degree of efficiency. Components are purchased at low cost;

- long period of operation (if all measures are taken, the device can last more than 10 years);

- safety. Well-thought-out design that protects against damage during activities;

- free modifications. The purchase and installation of new plates increases the volume of the heat exchanger. If it is necessary to reduce the volume, some of the plates are removed;

- flexibility of configuration, allowing you to change a number of characteristics.

There is only one significant drawback: the use of low-quality coolant will lead to rapid contamination of the device, breakdown, requiring a complete replacement

Therefore, it is initially important to use high quality materials

Primary, secondary and bithermic devices

The primary heat exchanger looks like a large pipe with coil-shaped bends. For production, materials that are not subject to corrosion are used - stainless steel, copper. The plates of the unit have different sizes. To increase protection against corrosion, working surfaces are painted. The heat exchanger transfers the energy of the gas to the coolant. The power indicator depends on the number of fins and the length of the pipe. Dirt and soot from the outside and salt deposits from the inside can impair performance. External and internal factors provoke disruption of coolant circulation and reduce the thermal conductivity of the walls of the unit. To extend the life of the boiler, regular cleaning and flushing is required. It is advisable to buy filters.

The secondary heat exchanger of the gas boiler is equipped with interconnected stainless steel plates. The efficiency of the device is ensured by good thermal conductivity and the size of the heat exchange area. Energy in such heat exchangers is transferred from the liquid to the coolant. The power of the device depends on the number of plates and heat exchange area.

A bithermal double-circuit heat exchanger operates on the principle of double heat exchange: the gas heats the coolant, and it transfers the temperature to the water. Outside, water for heating is heated in the pipe, and water for domestic needs is heated inside. The combined heat exchanger for a double-circuit gas boiler has a simplified design. There is no need to install a three-way valve and a secondary heat exchanger, which reduces the cost of the entire structure without compromising reliability. The disadvantages include low power in hot water supply mode.

The Prime Energy catalog contains units from leading brands. Our heat exchangers are ordered for industrial and municipal systems, and in each case the recommendations of engineers on the selection of equipment and components are listened to. Consultants will tell you in detail about the characteristics of the presented heat exchangers, provide comparative data, and if necessary, calculate the required power and other parameters for a specific facility.

We offer reliable equipment at reasonable prices, we sell heat exchangers of our own assembly, and we are official representatives of Ares, Sondex, FUNKE. It is enough to send an application to receive a calculation or a profitable commercial offer. If you have questions about delivery times and equipment characteristics, please contact our specialists.