Other faults

Also, malfunctions of the water heater can be caused by the following reasons:

Ignition system failure

In speakers without an igniter (electronic ignition), the spark is generated by the batteries; perhaps they have run out.

The battery capacity is not always enough for a year, as the manufacturer promises. In other models, a spark is produced by a piezoelectric element triggered by a turbine installed in the water supply.

If the water pressure is weak, such an ignition device will not work.

When buying a column, you need to pay attention to the minimum water pressure that it requires for normal operation. In columns with an igniter, the latter can become clogged: its flame becomes weak, sometimes yellow (this is how the lack of air in the gas-air mixture manifests itself). As a result, it either cannot ignite the main burner at all, or does this after a large volume of gas has entered, as a result of which the column ignites with a characteristic bang

After cleaning the igniter the situation returns to normal.

As a result, it either cannot ignite the main burner at all, or does this after a large volume of gas has entered, as a result of which the column ignites with a characteristic bang. After cleaning the igniter the situation returns to normal.

In columns with an igniter, the latter can become clogged: its flame becomes weak, sometimes yellow (this is how the lack of air in the gas-air mixture manifests itself). As a result, it either cannot ignite the main burner at all, or does this after a large volume of gas has entered, as a result of which the column ignites with a characteristic bang. After cleaning the igniter the situation returns to normal.

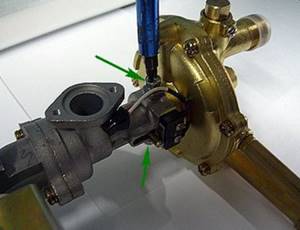

The membrane of the water unit has exhausted its resource

This element, made of a polymer material, must have sufficient elasticity, but over time it loses it, becoming rigid, and may even crack. It can also become overgrown with lime deposits.

Accordingly, the column will stop turning on, even if the user opens the tap completely.

The membrane must be inspected and if its condition is truly unsatisfactory, it must be replaced.

Control module board burnt out

This often happens with imported speakers, which are very sensitive to the quality of the power supply. They should be connected through a stabilizer.

It is also useful to know that smart speakers with electronics should not be turned off at night.

Water unit malfunction

Most often, geyser repairs are made due to a faulty water block. Its work is that, under the influence of liquid pressure, the membrane located inside it, arching, transmits movement to the rod, and it then moves the pusher of the gas unit. As a result, the spring valve opens and the electrical power supply to the control module is turned on. Therefore, if the water unit is faulty, the device will not start.

A broken water block can be determined by external signs.

.

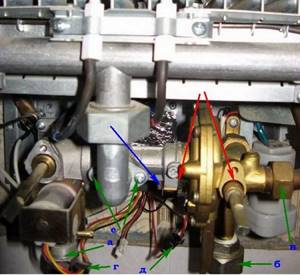

If you notice even one sign, the unit will need to be removed and repaired. The water unit can only be removed together with the gas module, since they are a single structure. You can do this in the following way:

- after you have made sure that the gas valve on the pipe is in the closed state, you can disconnect the supply hose (a);

- similarly, when the water supply is turned off, the nut on the water block pipe (b) is unscrewed;

- then, using a wrench, you need to unscrew the nut that connects the water block to the heat exchanger (c);

- disconnect the terminal block (d) on the conductors connecting the solenoid valve to the control module;

- wires (d) going to the switch are disconnected in the same way;

- using a screwdriver, you need to unscrew the 2 screws (e) attaching the pipe to the water-gas unit, through which fuel is supplied to the burner manifold;

- After unscrewing the fasteners, the entire assembly can be easily removed from the device.

Repairing a Neva 3208 gas water heater due to a faulty “frog” is similar and intuitive, although the internal appearance of the unit is slightly different. The Neva 4511 gas water heater can be disassembled in the same way, and repairing it yourself is quite feasible.

a Chinese gas water heater repaired?

, the size of the water node is always surprising. It is quite small in size, and to disassemble the “frog” you only need to unscrew 4 screws.

Control of water temperature in gas. column

I really like spending time in the bathroom, I even really like it. There’s nothing better than taking a beer, fried dumplings, an iPad, and drinking while lying in hot water. But this idyll is disrupted by a terrible creature, and its name is “Geyser”.

The essence of the problem:

Our house is old, the pipelines are also old, and the pressure in the water riser is simply disgusting.

If you turn on the water from the tap and set the column to 40 degrees, it will give you 40 degrees... but not for long. As soon as you turn on the shower, the temperature will skyrocket to 50, or even higher. Also, the rise depends on the day of the week (on weekends, the water temperature graph with the column setting unchanged looks like a visualization of some dubstep).

The reason is simple, when you turn on the shower because... The diameter of the shower hose is smaller than the diameter of the pipe, which means that less water passes through the heat exchanger in the column with the same flame. Accordingly, the water heats up more. The same effect is observed on weekends when everyone takes water procedures and the pressure in the general system drops even more; this effect can also be observed from anything up to the phase of the moon and the position of Saturn.

I hatched a plan for revenge for a very long time, but since I am very far from circuit design, I just couldn’t decide. But then the hour of reckoning came and I made up my mind.

Let's go©

So I needed: - Arduino Uno - a simple servo drive - wires, resistors and other small things - a cat that constantly steals these very small things

My speaker is Oasis 20RG

What prompted me to create the device is that the column shows the current water temperature, which means there is a sensor that can be read.

As you can see from the photo, the left knob is responsible for the height of the flame, it controls the temperature, and we will turn it.

I ordered all the stuff on the website amperka.ru, yes, from ebay it would have been many times cheaper and would have cost a penny. But the thirst for revenge could not wait.

So, after removing the front panel, a temperature sensor was discovered at the hot water outlet

which is a regular thermistor. By connecting it to a voltage divider and plugging the data into the analog input, I received an analog value, which was converted into temperature through simple manipulations and the map function.

In fact, I suffered for a long time here because I completely forgot Jeremy Bloom’s video tutorial about voltage dividers, but after watching it again I quickly grasped everything, there was little left to do.

I got the temperature, all that remains is to place the servo and come up with a mechanic that will turn the stud handle.

The servo was placed clearly under the stud

I was thinking about how to secure it, first I drilled holes for fastening, but the metal of the column turned out to be stronger than the metal of the bolts on which the threads were instantly eaten away. An irreplaceable material was taken - nylon ties. It was firmly fixed.

Then I got stuck, I don’t know what came over me, but I couldn’t figure out how to mechanically connect the servo with the pin; the idea of a rocker arm was spinning in my head, but it never materialized. Thank God the Q&A suggested, in the end a rocker arm of the same length as on the servo was cut out of PCB and glued to the stud. The rods were made of flexible wire (later replaced).

Next, I made it so that when the column is turned on, the whole process is turned on; there is no need to try to increase the temperature when the column is turned off. To do this, I monitor the power wire of the screen (which only works when the speaker is on) for voltage. And if it is there, I start the process.

I also wrote the so-called “warm-up” - the controller waits 10 seconds after turning on the speaker and only then starts working. This is done so that the heat exchanger has time to heat up.

As a result, an alpha version of the controller was born (sorry for the bad video, more will be better):

After a couple of tests, the following bugs were noticed:

Well, firstly, there is an obvious bug with the rods, they are soft and not stretched, so there is a play that prevents the temperature from being set quickly. A piece of copper wire was found in the bins and with some simple manipulations the work rods were made.

We measure:

Happened:

The next bug was that the temperature sensor suddenly showed 20 degrees less, but after a few seconds it returned to normal. I spent a long time catching this and eventually realized what was going on. I powered the sensor from the 3.3V output on the Arduino, I don’t know why, but these same 3.3 jumped, thereby changing the sensor readings. After powering the sensor from 5V everything became normal.

The result was a beta test:

Unfortunately, I don’t know how to combine two videos into one, so: Arduino logs:

Servo with new rods:

Well, that’s basically all, below is a listing of the program. After writing the article, the program was tweaked a little more in order to configure it for the fastest possible temperature equalization.

Listing:

#include int termalPin=A5; int enablePin=8; int ledPin=7; int temp; int lastTemp=0; boolean enabled=false; static int minAngle=5; static int maxAngle=100; static int needTemp=40; Servo myservo; void setup() { //turn on the series Serial.begin(9600); //set pin modes pinMode(enablePin,INPUT); pinMode(ledPin,OUTPUT); } void loop() { //map sensor readings to temperature temp = map(analogRead(termalPin),800,635,31,51); if(digitalRead(enablePin)==HIGH) { //the column is enabled if(!enabled) { //if it was not enabled before //attach the servo myservo.attach(9); //put it in the middle myservo.write(50); Serial.println("WARMING UP BOILER."); //wait for the column to warm up delay(10000); Serial.println("BOILER READY!"); } //let's go enabled=true; //light the LED digitalWrite(ledPin,HIGH); Serial.print("BOILER ONLINE. CURRENT TEMP: "); Serial.print(temp); Serial.println("C"); //look at the temperature and where to turn it if(temp>needTemp) decTemp(); if(temp

Elimination of traction disorders

To test traction, try using an ordinary match. Bring it to the chimney and determine if there is a draft, then the flame will deviate towards the chimney.

If there is no draft, the gas water heater will not light and users will not receive hot water. Many dispensers are equipped with draft sensors, and if they show insufficient draft, ignition will be impossible. Situations are possible when the flame lights up and immediately goes out - this is due to the fact that the combustion products simply have nowhere to go, they remain in the combustion chamber, and the flame goes out due to lack of oxygen. Lack of draft will require an inspection of the flue gas collector and the chimney itself. If there are blockages here, they can interfere with the normal passage of combustion products. The column perceives this as a lack of traction and does not allow the gas to ignite (or the gas goes out immediately after turning on). Unfortunately, you will be able to independently check only the part of the chimney that is visible before entering the wall - further work must be carried out by specialists. If the house is private, you can try to figure out the chimney yourself.

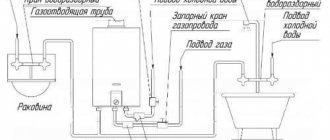

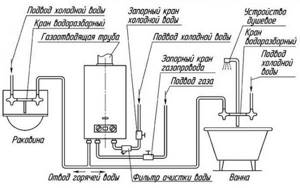

Internal organization

The diagram above shows the design of a typical gas water heater, which is also typical for Oasis columns.

Let's look further at how the most common type of brand's flow-through chimney model with automatic ignition works.

When the tap is opened, water is supplied through the inlet pipe into the water-gas unit, which turns on the ignition and gas supply. As soon as it ignites, a signal is sent from the flame sensor to the electronic unit to stop sparking.

Next, the water passes through a coil rigidly fixed to a heat exchanger, which is heated by burning gas. The coil transfers heat to the flowing water coming out.

When the tap closes, the water-gas unit turns off the gas supply. The combustion stops and the column goes into standby mode for the water tap to open.

An important condition for the normal and safe operation of the column is the removal of combustion products through the ventilation chimney. If the hood is missing or insufficient, the draft sensor is triggered and the column is turned off.

An overheating sensor is responsible for timely shutdown of the column when the maximum temperature is reached. It is an important element of the column, providing protection against overheating

Maintaining the required temperature regime is an equally important condition for fire safety and long service life of the column.

Overheating negatively affects the condition of all elements, primarily the heat exchanger, which leads to their premature failure.

Eliminating other column faults

Most often, you may encounter a situation where the column does not initially ignite a flame. First you need to determine what exactly led to this. After all, the problem may not be in the heat exchanger at all, but, for example, in dead batteries. Therefore, it is impossible to do without diagnostics. Moreover, some breakdowns can be fixed by yourself, and in some cases you will have to call a specialist from the gas service.

External inspection of the water heater

Competent diagnostics will allow you to quickly carry out repairs on your own.

It is not recommended to carry out independent repairs if the geyser is under warranty. The service department can remove the device from warranty service.

There are a number of basic steps that should be performed before you go to examine the inside of a water heating device:

- Replacing the battery and cleaning the power contacts.

- Checking the chimney draft and the presence of pressure in the cold water supply system.

- Checking the fuse (for turbocharged speakers). You can flip the plug in the switch to change the phase location - this is important for imported models, since they are quite sensitive to this.

- Cleaning the strainer. This is a dirt trap that can be found on the pipe supplying cold water. Often the mesh is a structural component of the water unit.

- Observe the ignition electrodes. To do this, just open the hot water tap, after which sparks should form. If the camera is closed, then you can listen to the body. Characteristic sounds like the clicking of charges should be heard.

The above steps may not always help. Then you have to look inside the speaker, for which you have to remove the housing.

Each geyser repair should begin with checking the batteries and cleaning the contacts if they are oxidized. You also need to inspect and clean the igniter. There are speaker models that have a small window for access to the electrodes, which can be cleaned with a brush

Troubleshooting inside the column

If an external inspection and replacing the batteries did not help, then you can start troubleshooting directly inside the device.

To do this, you need to remove the water heater casing and check the main components one by one. It is better to perform all actions with an assistant. He should be asked to open the hot water, and he himself should monitor the movements of the rod. The responsibility of this element is to act on the pressure plate in order to move it away from the microswitch button.

If the pusher does not perform any movements, then there is a 100% probability that the problem lies in the water block. If this problem occurs, it is necessary to disassemble the unit to clean and change the membrane in it.

Also, the rod can press on the plate, but the button will remain pressed. In this case, it is necessary to check the water regulator for scale. It should be found and cleaned.

If all of the above elements operate in normal mode, the button is pressed, but no sparks are formed, then in this situation the microswitch itself may be the culprit. To make sure of this, you need to disconnect its connectors and clamp the two terminals with a screwdriver. If sparks immediately begin to form in this case, then the switch is faulty and should be replaced.

It is necessary to check by shorting the connector that is connected to the pulse unit. The microswitch plug should not be touched in this case.

The solenoid valve may also fail, causing no gas to flow. To do this, you should check each of the sensors in the circuit by short circuiting one by one. You can also use a multimeter to test.

Condensate in a gas water heater - what to do

In this case, the problem is more serious. Most likely there is a leak in the heater. Occurs under the influence of small microcracks. Initially, perspiration appears on the body and internal parts of the speaker. Subsequently, condensation begins to drip from the gas water heater.

A heater (radiator, coil or heat exchanger) consists of pipes with fins. When exposed to direct fire, the metal will burn out over time. Thinning pipe walls lead to leaks and condensation. The malfunction must be corrected immediately. Replacing the radiator or soldering the damaged area will help get rid of condensation.

Soldering is performed in the following way:

Condensation in a gas column can form due to every microcrack and deformation. Soldering is used to treat each damaged area.

It happens that condensation forms only on the cold water pipe, and the problem usually arises in new turbocharged boilers. While the water heater is under warranty, it should be replaced immediately. There should be no condensation in a working column.

A gas water heater or gas heater is a metal body with two pipes attached to it, supplying cold water for heating and gas.

A gas water heater has several components:

- Radiator;

- Gas supply pipe;

- Burner;

- Igniter.

Cold water supplied through the pipe puts pressure on the membrane that releases the gas. When it begins to flow into the burner, it is ignited by the igniter, which heats the heat exchanger, through which warm water flows to the tap.

The igniter can be with piezoelectric, manual or electronic ignition. The gas is automatically ignited when the water tap is opened.

Standards for installation and connection of the Mora column

The basic requirements are listed in the technical data sheet of the device and the operating manual. Violations made during installation lead to refusal of warranty service for the boiler. Requirements:

- The connection must be carried out by qualified specialists with the appropriate license and work permit. After installation, a report is drawn up (the form is in the device passport) and a stamp is placed indicating that the water heater is put into operation.

- A coarse filter is installed on the supply pipeline; in some cases, at low pressure, a booster pump is connected.

- The column must not be installed in rooms with high humidity (bathroom, toilet), directly above a gas stove or refrigerator.

- The room used for the boiler room must comply with the standards described in SP and SNiP.

Maintenance of Mora Top geysers should be carried out at intervals of at least 1-2 years. Independent or unqualified repairs lead to removal of the water heater from the warranty, which lasts 3 years from the date of commissioning. Repairing a Mora gas water heater with your own hands will inevitably lead to a refusal of free service. If a breakdown occurs after the warranty expires, call a gas technician. It is better not to try to repair the water heater yourself.

Common breakdowns and troubleshooting of the Mora gas water heater:

- The main burner does not turn on - the reason is dead batteries, poor water pressure, lack of sufficient oxygen in the room.

- Presence of a leak - the rubber membrane of the water reducer has broken, corrosion has corroded the heat exchanger (a copper coil is installed on the Mohr column, there will be a green coating in the place of leaks).

For supplying hot water and heating a private home, the most popular equipment is a gas water heater. It is available to almost everyone and does not require large expenses. But it is necessary to choose quality equipment. After all, a comfortable atmosphere in the house and safety depend on this. In this article we will consider all the advantages and disadvantages, as well as the features of the Mohr gas water heater.

Lights up but goes out

Let's consider several moments when the column fades out some time after ignition and what ways there are to solve this problem:

One of the reasons is insufficient draft due to the lack of air movement inside the room where the device is located.

Checking the traction force

This happens when windows and doors are tightly closed. For this reason, the protective relay overheats and the overheating sensor is triggered.

You can eliminate it by opening a window or vent, creating a draft in the room. A gas heater burns a very large amount of oxygen during operation, so it requires a constant supply of fresh air to operate.

The second reason for the column to fade out may be the insufficient time of holding the ignition button. It should be held for at least 20 seconds; if held for less time, the column will go out.

A malfunction of the combustion products exhaust sensor is the next point. To check the sensor, you need to ring it by connecting two terminals. Normally, the resistance should show infinity. If the reading is different, the sensor will have to be replaced.

Strong cold water pressure and low hot water pressure - this situation also often causes the water heater to fade. This happens when you use hot water and open a cold tap. To eliminate this problem, you need to adjust the water supply in such a way that you do not have to open cold water in order to dilute the hot one. In addition, this is incorrect operation of the device and can lead to damage to the heater.

High water pressure can lead to attenuation. This problem is especially typical for the Lux Eco model, which is designed to work with low water pressure. In this case, the strong pressure of the flow bends the membrane of the water unit, the membrane moves the rod in the gas supply. It is necessary to adjust the gas supply or, if possible, adjust the water pressure.

The temperature sensor has activated, protecting the device from overheating.

Column temperature sensor Vector

The heater works for some time after ignition, then goes out again. If you try to turn on the device right away, there will be no result. After some time, about 25 minutes, the burner lights up, but then goes out again. The problem is that the sensor is too sensitive. In this case, only replacing it will help.

Poor contact between thermocouple and solenoid valve.

If the thermocouple is working, you need to clean the contacts and the automation unit.

The design of the igniter itself (device for generating an electric spark). The electrode is mounted in such a way that the spark hits the comb, which is welded to the edge of the gas burner at a distance of about 12 mm from its outlet. Provided that the gas supply is adjusted to low water pressure, the gas leaves the burner in a small volume and at a low speed.

Taking into account the fact that a small reverse draft is almost always formed inside the system, a weak level of gas goes down under the pressure of this draft, not reaching the spark. This situation can be corrected by bending the electrode from the comb to a level at which the spark does not fall on the comb, but through the gas exactly in the center of the burner. After performing such manipulations, the device almost always lights up, ignition is fast, stable and soft.

The formation of holes between the gas exhaust pipe, the connecting pipes of the gas exhaust device and the chimney, between individual sections of the gas exhaust pipe. Determined visually, to eliminate it, it is necessary to seal the gaps with self-adhesive heat-resistant tape or other materials that are resistant to high temperatures.

Peculiarities

High consumer demand and popularity of Oasis geysers are due to a number of undeniable advantages of these devices:

- The high safety of using the units is explained by the presence of protective sensors that turn off the device in emergency situations.

- The ability to provide stable heating of the coolant, regardless of pressure drops in the water supply system, makes the operation of the dispensers simple and comfortable.

- The location of the main module away from the hot water pipe increases the safety of the device and protects important structural components from overheating.

- The presence of a mesh filter protects the system of pipes and pipes from clogging and rust accumulation.

- Economical fuel consumption is due to the presence of “Winter-Summer” modes. This allows you to automatically regulate the fuel supply and significantly save on water heating.

- The presence of a heat-resistant alloy in the radiator eliminates the formation of scale on the internal walls of the device.

- High efficiency rates and long service life distinguish Oasis speakers from other devices available in this price category.

- The presence in the product line of turbocharged models capable of forcibly removing gas combustion products. They allow you to use the water heater without installing a chimney and make its operation even safer.

- The modern and aesthetic design allows you to install speakers in kitchens and bathrooms without the risk of spoiling their appearance.

- All Oasis models are equipped with a liquid crystal screen and a control panel, which makes using the device simple and convenient.

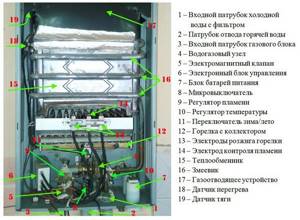

Oasis geyser device (with diagram)

The internal part of standard hot water gas equipment is presented:

- plate heat exchanger with a water tube;

- gas burners;

- exhaust gas collector;

- piezoelectric element or automatic electric ignition.

The electronics are powered through batteries, from the mains, or using a miniature built-in turbogenerator. The water temperature control in budget models is carried out by a water reducer or so-called frog, and in more complex and modern models - automatically via electronics.

Gas boilers are characterized by the presence of an open or closed combustion chamber, and the difference between models of the first type is represented by the intake of air masses directly from the room.

Exhaust gases are removed naturally through a chimney system, or using forced ventilation and a coaxial chimney.

The components and main components of flow-through gas equipment that require competent maintenance and explain the principle of operation are listed in the diagram.

Modern gas water heating equipment Oasis is equipped with protective automatic gas supply shutoff

Modern water heating equipment is characterized by the presence of protective automation, represented by flame control and a traction sensor, which allows you to shut off the gas supply automatically.

How to connect and configure

Gas water heating equipment is installed in the kitchen or any other non-residential but heated room in accordance with the gasification project and in accordance with the basic requirements of gas supply organizations:

- water heating equipment is connected to a chimney system that has good and stable draft;

- It is prohibited to install equipment above any open flame sources or heating devices;

- before installation, permission from gas service specialists to install equipment must be obtained;

- installation of the unit is carried out by the operating organization of the gas industry or other licensed companies;

- installation is carried out on non-flammable coatings, including brick, concrete and ceramic tiles with mandatory insulation with galvanized sheets and BTK;

- the protective layer of insulation should protrude beyond the body by at least 10 cm along the entire perimeter;

- the column is suspended using brackets attached to the wall, supplied with the gas equipment;

- all shut-off valves in the form of water supply to the gas supply to the unit are located in an easily accessible place;

- a filter system is installed in front of the water heating equipment to purify the water supplied for heating;

- to connect to the water supply, pipes or flexible hoses are used with an internal diameter of 13–14 mm or more.

Below is a standard connection diagram for a gas boiler.

Connected gas equipment must be registered

After installation and until it is put into operation, the water heater must be registered with the gas service.

Mixing cold water in the mixer

Many people, instead of adjusting the degree of heating on the gas water heater itself, mercilessly torment the mixer. If you open the cold water too much, the lit column will simply go out. If at that moment it was not burning, then it will certainly not catch fire. Make it a rule to turn on the hot water supply first, and only then the cold water supply. It’s best to adjust the degree of heating using the appropriate controls.

You also need to remember that intensive mixing of cold water is not welcomed by the developers of geysers - this can lead to their damage.

Leakage of threaded connections

Sometimes water drips from the gas water heater due to leaking threaded connections. In the places where they are located, manufacturers use American nuts (flare nuts).

To seal them, rubber gaskets are used, which, when exposed to high temperatures, lose their elasticity, become hard and allow water to pass through.

To troubleshoot you will need:

- Turn off the water (there is a special tap on the tube through which cold water is supplied to the column);

- Unscrew the threaded connection with an adjustable wrench (it will be easier to unscrew if the connection is slightly heated);

- Take out the old rubber gasket and carefully inspect the threads.

If the thread is not damaged, then you just need to replace the gasket with a new one and tighten the connection with a wrench. If there are defects on the American thread, the union nut will need to be replaced.

The best option would be modern silicone gaskets. They are more durable than rubber seals and provide better sealing. Instead of one gasket, you can use two in one place of the threaded connection.

Causes of problems and DIY repairs

The use of geysers, however, like any other equipment, is accompanied by malfunctions, frequent or rare. At the same time, there are some malfunctions that can only be eliminated by specialists who have the necessary knowledge and permission to do so. But there are also some that can be easily eliminated with your own hands, so we will consider them.

Video - sensor malfunction

Video - repair of a Chinese gas water heater

- The most “popular” type of failure is that it simply does not turn on. If it has an electronic ignition, then you can easily solve a similar problem - just check the batteries and, if necessary, replace them with new ones. Often, such troubles overtake the owners a year after purchase, since the batteries last only that long.

- Also, when using a gas water heater, it may happen that the water in it does not warm up or warms up, but not well enough. Often the cause of such problems is the water node, or more precisely, its defect. As a result, the membrane stops responding to changes in pressure in the water supply system. And if this membrane stops stretching under the pressure of water, then, as a result, the gas valve will not open, or it will open, but not completely. To solve this problem, you must know at least in general terms the structure of the geyser, because the defect can be of several types. If salt deposits have accumulated.

- If the system is clogged.

- If cracks have formed, etc.

To fix this problem, you must first disconnect the column from the gas supply, then clean the water unit and check the membrane.

If the internal elements of the device are covered with soot or dirt, this can also lead to failure. To solve this problem, you must remove the outer casing of the device, then clean each of the elements using a vacuum cleaner. The next sign that the gas water heater has stopped working correctly may be that the burner goes out immediately after turning on. This happens because the ventilation duct is clogged. Modern models of geysers are equipped with special sensors for such cases, which will inform the owner if there is no draft. After this, the gas supply should be turned off immediately. Next, the chimney should be checked. To do this, the plug is dismantled and everything that has accumulated there is removed.

Important! You can check the draft of a chimney in the old “old-fashioned” way: bring a lit match to it. If the fire on the match deviates in the direction of the chimney, then everything is fine with it

If this does not happen, then it needs complete cleaning.

It is for this reason that the gas water heater should be inspected annually - this is the only way it will work correctly.

We also recommend that you familiarize yourself with the basic requirements

Water flow problem

Often the column does not light up when the water is turned on due to a decrease in water flow. With such a malfunction in the tap, the stream of water when turned on is observed to be very thin and weak. There is a feeling that the gas water heater is faulty in appearance. This happens with absolutely any brand: Neva, Oasis, Bosch.

A decrease in water flow can occur:

- Abruptly, the loss of performance disappears instantly.

- Gradually, with a noticeable decrease in the performance of the gas water heater;

A sharp loss of performance of a geyser can occur in connection with street work. During this time, the street water supply may be repaired. Accordingly, the overall pressure of cold water everywhere will be sharply reduced. The owner can easily skip this moment and look for the cause in the gas water heater, disassembling it. The reason lies on the surface, but a person gets confused and looks for it in something completely different.

Also, the water pressure in a gas water heater may gradually decrease due to simple contamination of the aerator intended for the mixer. To eliminate the cause of the malfunction related to the aerator in the faucet itself, it is necessary to remove it and clean it.

This is a standard aerator that is installed on the faucet. Try cleaning it

Owners who have a mesh filter at the inlet should also not forget about it and periodically clean it.

Coarse filter. It is installed to supply cold water to the column. Clean it too

The filter flask can also cause a gradual decrease in water pressure in the gas water heater

You should not forget about this and, first of all, if the wick of the gas water heater does not ignite, pay attention to it. If you miss the reason that lies on the surface, there is a risk of investing money in unnecessary diagnostics or repair of the gas water heater.

Repair and diagnostics of the gas water heater are not appropriate in this case.

Two filters for water purification in flasks. They can also get clogged

There is another case associated with a lack of water pressure when the gas water heater is turned on. This happens due to mechanical clogging of the hose. Scale was found in the hose, and it blocked the path of water. The scale could have come from the heat exchanger.

Main types of faults

You can fix a malfunction in a gas water heater by turning to specialists for help or doing it yourself. But still, when working with such equipment, it is necessary to know the safety measures, as well as their strict adherence.

IMPORTANT! Otherwise, independent repair of a gas water heater is fraught with HUMAN SACRIFICES.

List of breakdowns found in geysers:

- The igniter does not light;

- The pilot light goes out;

- There is a pipe leaking in the radiator;

- Water is leaking at the connections.

Preparing for replacement

To change the membrane in a gas water heater, first of all, you should shut off the water at the inlet to the water heater or in the entire apartment. After this, the gas valve closes and the hot water tap opens. You should open the tap that is located lowest in the apartment, usually it is in the bathroom. Then all the water from the system will drain and will not interfere with repairs.

To replace the membrane, we will need Phillips and flat-head screwdrivers, 24 and 19 wrenches, a new membrane or a repair kit.

Before removing the casing, remove all the handles from the front side and disconnect the wires from the display, if present. In some speakers, the housing is additionally secured with screws that are located at the bottom and top of the speaker, under the adjustment knobs or decorative trims. The casing is also secured with simple latches.

Radiator leak

Hot water appears thanks to the existing heat exchanger. The heat exchanger radiator consists of metal pipes and plates located close to each other. The plates come into direct contact with the fire, due to which soot appears on them during operation.

Signs of soot accumulation include:

- The flame is yellow;

- When burning, the fire deviates to the side and heats the body (the flame should tend upward);

- Soot falls off the gas water heater;

- Even when operating at full power, the water heats up weakly.

To remove soot, you will need to remove the casing by unscrewing the bolts (latches) that secure it.

Important! To prevent soot from entering during disassembly of the column, it is necessary to cover the burner with a rag.

After the assembly is removed, it must be washed by placing it in a container with water for several hours to loosen the soot. This will make it easier to clean the space between the heat exchanger plates. For quality cleaning, it is recommended to use running water, a long-bristled brush and detergents. After drying, the radiator is put in place.

Green spots on the heat exchanger indicate existing cracks and holes.

If the geyser is leaking due to a failure of the heat exchanger radiator, then the actions should be as follows:

- The water supply pipes must be shut off to prevent water from entering the gas water heater. After which the hoses are disconnected and the remaining water is drained. The remaining liquid in the coil is removed with a pump or vacuum cleaner; you can try blowing the water out with your mouth using a hose. This must be done, since the remaining moisture absorbs heat during the soldering process, and it will not be possible to heat the metal to the desired temperature.

- Damaged areas (they are green) will need to be cleaned with sandpaper and degreased with a solvent, and then wiped dry.

- Crushed rosin or an aspirin tablet should be sprinkled on the work surface. Rosin and aspirin will serve as solder here.

- Using a soldering iron with a power of at least 100 W (since they will have to work at temperatures above 180 degrees), it is necessary to increase the solder to a height of approximately two millimeters. If the soldering is loose, this means that the working surface is not heated enough. You can additionally heat the soldering area with an iron or another soldering iron.

- Each through-hole fault will need to be soldered in a similar manner.

- After the soldering work is completed, you need to wait until the working surface has completely cooled and assemble the gas water heater.

- Before full operation, the equipment is started in test mode.