Geysers operate on the basis of natural and liquefied gas. Manufacturers of space heating devices equip boilers with a safety system. The occurrence of a breakdown or the threat of an emergency situation triggers the protection, after which the operation of the unit is blocked. The draft sensor of a floor-standing gas boiler (or mounted) can be located in various parts of the equipment. Before turning on the unit, it is important to make sure that it is in good working order and learn the operating principle of the gas boiler draft sensor.

Pneumatic relay with membrane (traction sensor) prevents an emergency situation

The principle of operation of the draft sensor in a gas water heater

A sensor is a bimetallic relay endowed with the ability to start and turn off the boiler burner. In the inner part of the element you can find a strip made of metal that reacts to temperature changes. The manufacturer sets it to 75-900 °C (in cases where natural fuel is used) or 75-1500 °C (for liquefied gas). In situations where there is a deterioration in draft in the chimney, the degree of flue gas concentration increases, against which the temperature increases. The main function of a gas boiler pneumatic relay is to control and transmit signals about changes in temperature to the control unit. After the signal reaches the block, it enters the gas valve area. The supply of liquefied or natural gas is cut off. The sensor can also be triggered in cases where there is a disturbance in the draft in the chimney, which leads combustion products to the street.

The draft sensor of the AOGV gas boiler prevents toxic fumes from entering the house.

In boilers with closed combustion chambers, products are removed through a coaxial channel using a fan. A pneumatic relay with a membrane acts as a sensor that responds not to changes in temperature conditions, but to changes in flow speed.

When the speed is within normal limits, the membrane appears bent. Contacts are closed. As soon as the flow rate weakens, the contacts begin to open. The membrane gradually straightens. The gas supply valve is closed.

Prices

Each brand produces boilers of a special design, so there is no need to talk about the universality of protective elements. If it is necessary to replace this controller, then you should look for a replacement from the same company as the gas unit itself. Moreover, it must fully comply with the performance characteristics.

Approximate cost of draft sensors for popular boiler models:

| Boiler series | Code/article | Suitable Models | price, rub. |

| Vaillant atmoTEC | 0020039083 | Pro VU200/3-5, 240/3-5, 280/3-5 and Plus VUW 200/3-3, 200/3-5, 240/3-3, 240/3-5, 280/3-3 , 200/3-5 | 1 900–3 200 |

| BAXI atmoMAIN | 600870 | DIGIT 240i, 24I BSE and 24I BSB | 1 200–1 800 |

| Vaillant turboTEC | 0020041905 | Pro VUW INT 202, 242, 282/3-3 and Plus VUW INT 202, 242, 282, 322, 362/3-5 | 2 400–3 100 |

| BAXI turboSLIM | 721890400 | 1.230 Fi, 1.300 Fi and 2.300 Fi | 2 800–3 400 |

As can be seen from the table, purchasing original parts will require quite a significant investment. However, it is not worth saving and buying a Chinese analogue: despite the fact that they are 5–10 times cheaper, they are of appropriate quality, which in the future may negatively affect the safe operation of the boiler.

Where is the draft sensor installed in gas boilers?

The design of the pneumatic relay may vary depending on the type of combustion chamber installed on the boiler by the manufacturer.

Cameras available for sale can be of two types:

- open combustion;

- closed combustion.

Each manufacturer is required to install a pneumatic relay with a membrane in gas appliances with an open combustion chamber. As a rule, the location for installing the sensor is located in the smoke eliminator area.

Important! As soon as the normal temperature inside the boiler rises, the supply of fuel to the column stops. The functions of the pneumatic relay in this case are similar to the operation of the overheating sensor. It is better to entrust the replacement of the pneumatic relay to a specialist

What does it look like and where is it located?

According to the gas safety rules PB 12-368-00, domestic heating boilers must be equipped with a draft sensor. The installation site, as a rule, is the smoke hood (located in the smoke extractor) or the free space between the ventilation duct and the unit body.

In atmospheric boilers, the draft sensor has a slightly different appearance.

It is worth paying attention that it cannot be attached closely to the surface of the flue. Paronite gaskets are used as a “separator”: this measure reduces the likelihood of contact heating, as well as creates a gap that will provide technical access to the flue opening and to the draft sensor.

How to install a gas boiler draft sensor

There are times when it is necessary to replace the draft sensor of a floor-standing gas boiler (or a wall-mounted one). The installation process of a pneumatic relay with a membrane is simple. It is enough to fix the regulator in the chosen place and connect it to the gas water heater. To correctly fix the temperature regime, it is important to position the control element, following the recommendations of experts:

- the minimum height from the floor surface reaches 150 cm;

- the maximum height from the floor is 170 cm.

Any heating appliances, household appliances, or climate control equipment that distort the temperature inside the gas appliance must be located at a distance of 100 cm. It is important to prevent the occurrence of drafts. Installing the boiler in a cold room is not permitted.

It is worth considering that the sensor should not be fixed too tightly to the body of the equipment. The installation is carried out on paronite gaskets, which helps reduce the heating of the sensor through contact with the column body and allows for a gap to be achieved between the hole in the flue area and the plane of the sensor.

It is important to make sure that the thermal relay contacts are firmly fixed to the housing. The presence of traces of oxidation on the device is unacceptable.

Step by step installation process:

- After the device has been fixed in the chosen location, you should begin laying the wire to the heat source, using hidden or open methods. One part of the end of the cable is connected to the contacts on which the COM and NO markings of the thermostat are displayed. In wireless versions, you can find the terminals in the relay block area.

- The front panel of the gas equipment must be removed, as it blocks access to the control board and connectors. The jumper located between the terminals is removed.

- The wires that come from the regulator contacts are connected to the freed terminals. Polarity is not necessary.

What does it look like and where is it located?

According to the gas safety rules PB 12-368-00, domestic heating boilers must be equipped with a draft sensor. The installation site, as a rule, is the smoke hood (located in the smoke extractor) or the free space between the ventilation duct and the unit body.

In atmospheric boilers, the draft sensor has a slightly different appearance.

It is worth paying attention that it cannot be attached closely to the surface of the flue. Paronite gaskets are used as a “separator”: this measure reduces the likelihood of contact heating, as well as creates a gap that will provide technical access to the flue opening and to the draft sensor.

How to check the draft sensor on a gas water heater

In some cases, during normal operation of the smoke removal system, the column may turn off. The cause of this phenomenon is a malfunction of the pneumatic relay with a membrane. In this situation, it is worth checking the traction sensor, the step-by-step process of which is described below:

- A mirror is placed in the area where the sensor is placed for 10-20 minutes.

- After the specified period of time, it is necessary to check whether it fogs up during operation.

- If the mirror does not fog up, you don’t have to worry, the device works. Fogging of the mirror indicates a breakdown. It is important to identify the cause of the malfunction as soon as possible and take measures to eliminate it.

To use the second method of checking the pneumatic relay, partially cover the chimney with a damper. In cases where the device is working fully, the boiler turns off.

You can also check the draft sensor of a gas boiler with a multimeter. After connecting the probes of the measuring device, you need to wait for the readings. In cases of normal switching, the multimeter needle will display the minimum resistance level. If the device does not respond, we can talk about a violation of the switching channel.

The reason for the operation of a pneumatic relay with a membrane may be a blockage in the chimney

Signs that replacement is needed

The sensor is an integral part of the gas system. Despite its high reliability, it may become unusable after a long period of use. It will need to be replaced sooner or later. What will happen if this is not done is described above.

The following signs may indicate the need to replace the controller:

- The installation is permanently switched off unless there is a fault in the output system.

- The heat generator operates at intervals of 20-30 minutes, after which it is deactivated and reactivated only after complete cooling.

If one of these signs appears, you should either call a repair service or check the sensor for serviceability yourself.

The operation of the gas boiler sensor in the heating system can be checked using one of the methods described below:

- It is necessary to install a mirror near the sensor mounting location. And if the boiler is in an active state and the glass surface fogs up, it means the sensor is faulty;

- If you close the damper of the exhaust system halfway, the boiler in operating mode should immediately turn off, since the traction force will be insufficient. If this does not happen, the sensor does not work correctly and needs to be replaced.

There is another, less accurate, but still quite effective way to check the health of the sensor. It is necessary to switch the boiler to hot water supply mode and open the water at full power. If in this case the heat generator turns off, then with a high degree of probability the sensor does not work. The accuracy of the verification method is 95%.

The boiler may turn off even if the controller is working properly. The issue may be a malfunction of other devices inside the boiler.

To solve any problem that arises, you must contact gas service specialists and under no circumstances try to fix the problem yourself.

How to disable the draft sensor in a gas boiler

Frequent activation of the traction sensor causes indignation. Property owners are beginning to look for ways to disable the regulator, but such actions are unacceptable because:

- systematic activation of the sensor indicates poor chimney draft, against which the fuel will not be able to burn out quickly and will begin to accumulate in the house;

- there is a risk that the situation is provoked by a backdraft indicator that has arisen against the background of the formation of an air plug (in this case, the exhaust gas, having reached the plug, returns back).

The formation of reverse draft occurs due to a lack of natural vacuum in the chimney area of the gas water heater. A similar problem occurs in boilers with an open combustion chamber. Disruption of the air flow does not allow carbon monoxide to escape, so it penetrates into the living space and becomes a cause of poisoning.

If necessary, you can still disable the sensor. For example, if it stops working and needs to be replaced. To do this, it will be enough to remove the communication wires with the thermocouple breaker and the solenoid valve from the circuit. However, when turning off the sensor, it is important to understand that this is a violation of safety regulations. In the event of an emergency, the unit will not shut down, but will continue to operate. There is no need to take risks; it is better to invite a specialist who will help eliminate the reason that triggers the sensor.

Operating rules

The safety of using a gas boiler depends not only on the serviceability of the sensor or its other components, but also on compliance with the operating rules of this installation.

The following operating requirements must be strictly observed:

- It is prohibited to install and dismantle a gas boiler yourself.

- You must not break the seal of the case, open it, or carry out independent repairs of the technical device.

- Materials and liquids that can easily ignite should not be stored near the boiler.

- Children should not be allowed into the gas installation.

- If the seal of the boiler or gas pipe is broken, it is necessary to immediately shut off the gas supply using a valve.

The sensor should also be used carefully:

- It should not be removed from the gas installation.

- You cannot repair or replace it yourself.

- If it malfunctions, the gas boiler must not be used. Violation of this rule may lead to dangerous consequences.

It is worth clearly understanding: if a malfunction occurs in the boiler, you need to shut off the gas supply and call a special repair team.

Of course, gas allows you to quickly heat up food or heat a room, but we must not forget that its use is a big responsibility. Responsibility for the lives, health and property of people.

Reasons for the operation of a gas boiler draft sensor

There are many reasons that can trigger the device. Among the main reasons leading to the disabling of the column, it is worth highlighting:

- Poor quality traction. Often the problem arises due to improper installation of the exhaust structure. Poor extraction of combustion products can cause poisoning of people living in a residential area.

- Backdraft, which occurs due to the formation of an air plug in the chimney area, which does not allow decay products to escape out. Quite often, a sharp change in temperature conditions leads to the formation of air jams.

- Blockage in the chimney area. Homeowners lacking experience believe that the pipe does not clog. But it is not so. Birds looking for a place to build a nest often choose a chimney. When a bird builds a nest, it can fall into a pipe, get stuck there and die. In addition to birds, clogs can be caused by leaves and soot deposits on the inner walls of the chimney. When it occurs, the intensity of traction decreases. The only solution to the problem is cleaning.

- Strong gusts of wind. If the pipe is positioned incorrectly, wind gets into it and blows out the burner. Triggering of the sensor causes the fuel supply to be cut off.

- Incorrect installation of equipment. An incorrect calculation of the dimensions of the chimney often provokes the burner to go out. It is recommended to measure the height of the chimney depending on how far the pipes are from the roof ridge. The head should be 60-70 cm higher than the ridge.

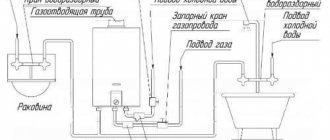

Before you start replacing the draft sensor, it is important to familiarize yourself with the design of the gas water heater

Functionality check

All of the above can be combined into one whole: the sensor is necessary in order to shut off the fuel supply in the event of a danger - such as a gas leak or poor removal of combustion products. If this is not done, then very sad consequences are possible.

Carbon monoxide poisoning has already been discussed more than once above. It very often leads to death, and it’s definitely not worth joking with. And if the burner suddenly goes out, but the gas continues to flow, sooner or later an explosion will occur. In general, it is clear that the sensor is vital.

But it can fully perform its functions only in good condition. It is common for any equipment to fail periodically. Failure of this part will not affect the external condition of the boiler in any way, so it is very important to regularly check the functionality of the element. Otherwise, you risk noticing the problem only when it is too late.

There are several methods for checking:

- attach a mirror to the area where the sensor is installed. During operation of the gas water heater, it should not fog up. If it remains clean, then everything is fine;

- partially block the exhaust pipe with the damper. In case of normal operation, the sensor should react instantly and turn off the boiler. For safety reasons, do not test for too long to avoid carbon monoxide poisoning.

If in both cases the testing showed that everything is in order, it means that the element being tested is ready at any time to react to an unforeseen situation and turn off the gas supply. But there is another type of problem - when the sensor is triggered just like that.