Using a Multimeter to Test the Boiler and Column Thermocouple

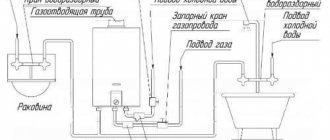

In private houses and apartments where gas is installed, in addition to kitchen stoves, gas boilers are often found to provide hot water supply and heating. Most heating and household gas appliances have a thermocouple in their design, which protects the device from overheating, which in turn ensures the safe operation of such equipment.

What is a thermocouple?

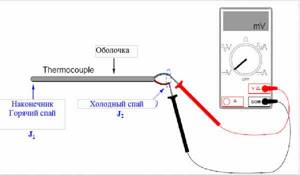

The thermocouple design includes two dissimilar conductors that are in direct contact with each other at one or more points (in rare cases, they are connected by compensation wires). When a temperature change occurs in the sensor area, voltage is created inside the device.

This ensures temperature control and overheating protection. Thermocouples can also be used to convert thermal energy into other types of energy, including electric current.

The main characteristics of a thermoelectric converter directly depend on the material from which they are made. Any temperature sensor made from two different metals will produce an electrical potential when exposed to temperature, but the response temperature will be different for each combination of metals. Due to this, thermocouples differ in their level of temperature control.

There are many types of thermostats, but their resistance to corrosion will be important. In those models of thermoelectric converters where the temperature sensor is located at a sufficient distance from the measuring device, expansion wiring is used in the design to connect them, thereby reducing the cost of the device.

Most thermocouples are standardized during production to a temperature standard of 0 degrees Celsius. Most manufacturers use electronic cold solder compensation technologies, which correct temperature differences at the device terminals.

Also, due to special electrical engineering, it is possible to minimize the deviation of other characteristics, which makes thermocouples more accurate and measurements as close to reality as possible.

Thermoelectric converters have become widespread in both household and industrial heating equipment. These simple yet useful devices can be found in the design of geyser, kitchen stove, industrial furnace, exhaust gas turbine, diesel engine, etc.

Thermocouple check

Sometimes it happens that a gas boiler stops working stably and there can be many reasons for this, but often the most common is a malfunction of the thermocouple. The first sign of a gas boiler malfunction is most often a problem with the button on the magnetic box, or rather, it does not lock while the boiler is operating. In most cases, owners of gas boilers in such a situation simply fix the button in the pressed position using adhesive tape or insulating tape. But, firstly, this solves the problem only temporarily, and secondly, this method can lead to unpredictable consequences, for example, complete failure of the gas boiler or an accident.

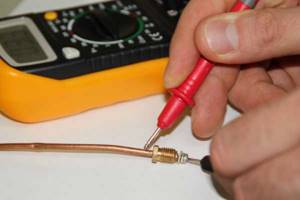

If such a problem with the button begins to appear, you should immediately take measures to eliminate it. First of all, you need to check the thermostat. There is a simple method to check a thermocouple with a multimeter:

- First, you need to disconnect the gas boiler from the electrical network and gas pipeline to ensure safety during repair work.

- At one end of the thermocouple there is a temperature sensor, and at the other end the thermocouple is attached to the solenoid valve using a nut.

- The nut is unscrewed from the valve, and the thermocouple is removed from the gas boiler.

- Next, you need to heat the thermoelectric converter sensor over a source of stable fire (for example, a gas burner on a stove or a candle). The sensor must be kept at a height of approximately 1 cm from the flame.

Attention! When the sensor heats up, the body of the thermoelectric converter can heat up to the middle. When heating the thermocouple, you should use gloves to protect your hands from burns.

Also, in cases where the voltage of the thermoelectric converter does not exceed 18 mV, it may still be operational. It is necessary to move the thermostat in the flame and measure it with multimeter probes again. The optimal electrical voltage value for stable operation of the solenoid valve is 20-25 mV. But even at 18 mV the valve can continue to operate without knocking out. The button will constantly turn off when the voltage value is less than 16-17 mV.

The most common type of thermocouple failure is burnout of the temperature sensor.

If, upon visual inspection, a deep black dent or hole (burnout) is visible on the surface of the sensor, then the thermoelectric converter must be replaced. Burnout of thermoelectric converters occurs in gas boilers of any manufacturer, which is normal practice in their operation.

Also, to increase the voltage in the thermocouple, and, consequently, increase the sensitivity of the solenoid valve, the igniter hole was specially further enlarged. This leads to an increase in voltage to 30 mV, but the service life of thermostats in such conditions is reduced.

Checking and replacing the temperature sensor

In the event of a breakdown, the device cannot be replaced. When a gas installation stops working correctly or does not ignite, this indicates a breakdown of the valve or thermoelectric converter. It’s easy to test its operation - one end needs to be connected to a temperature sensor. The other one needs to be heated, which can be done manually. A lighter is also suitable for this purpose.

If the device is working, the voltage will show on the multimeter around 50 mV. If spots, oxidation of areas are noticed, and the multimeter shows abnormal readings, the device is out of order and needs to be replaced.

You can replace it yourself. When choosing a device, you should take into account the boiler model, since the technical characteristics of both devices must match for acceptable and correct operation. Otherwise, the thermocouple may reduce its operating capabilities or even lose them.

How temperature is measured with a multimeter, how to check a temperature sensor with a tester

Multimeters are universal instruments for measuring various indicators of electrical equipment. Most often they are used for work by electricians, but sometimes they are used to measure temperature. This is possible if the device has the appropriate functions, or if it is possible to attach a microcircuit to it.

Basic moments

A multimeter is used as a thermometer if it is necessary to measure temperature in difficult conditions - an open flame, toxic substances, difficult access to an object, an object that is too hot.

Many multimeters have a built-in temperature measurement function. In this case, using the device is not difficult, since you do not have to make any changes to its design, you just need to figure out which mode to choose. Usually this mode is marked with the letters “temp”, and the multimeter comes with a thermocouple, which is a wire with a sensor. There are two sockets on the housing to connect a thermocouple.

Most testers are capable of working with temperatures ranging from -40 to 1000 degrees Celsius. If you have purchased an inexpensive multimeter, you should pay attention to which thermocouple is included. The fact is that most multimeters have fairly thin wires that can melt when exposed to temperatures above 250 °C. It is also necessary to pay attention to whether it is possible to measure the temperature of liquids or only gases.

If you are going to work with high temperatures, then it is better to replace the standard thermocouple with a special one, the design of which is designed for measurements in more difficult conditions.

For some devices, you will need to use a special adapter, since multimeters have single inputs, and a professional thermocouple has a miniature plug. After connecting the thermocouple, you must select the temperature measurement mode: it can be in degrees Celsius or Fahrenheit.

In order to find out what the temperature is, you need to touch the tip of the thermocouple to the object of interest. The data will immediately appear on the electronic display.

The duration of contact with the object is only 2-3 seconds; for accurate measurements, the contact must be tight. You can check if your multimeter is working correctly by comparing its readings with those of a thermometer. It is also important to monitor the polarity of the thermocouple connection.

No special mode

Is it possible to measure temperature with a multimeter that does not have a special mode for this? It turns out that this can really be done, but the device will need to be slightly upgraded. You need to purchase an LM-35 microcircuit, with its help the temperature readings will be converted into voltage, and the device will be able to recognize the data, but will indicate them in Volts. For example, 0.30 Volts will need to be understood as 30 degrees Celsius.

The use of a microcircuit does not require complex intervention in the design of the device and allows you to use any multimeter to measure temperature. In order for the chip to work, you will need:

- three wires that can be connected to the 10-ohm output of the device;

- a separate power source of at least 4 Volts, that is, 2 flat batteries.

If you need to measure not only positive, but also negative temperatures, you will also need to connect a reference voltage source.

The microcircuit itself is easy to connect. It has three connectors for positive and negative wires and an output sensor. This approach will allow you to transform any multimeter, making it more functional, while the design will be inexpensive.

Checking the temperature sensor with a tester

The question of how to check a temperature sensor with a tester is quite relevant for motorists. In order to carry out the necessary measurements, you can use any multimeter; in addition, you will need to remove the sensor itself and prepare a kettle of water. The sensor will need to be immersed in boiling water (the liquid temperature is always 100 °C). It is most convenient to secure the wires coming from the sensor with crocodile clips and connect them to the measuring device. After this, the multimeter must be set to current resistance measurement mode.

If the resistance readings of the sensor when exposed to a temperature of 100° do not exceed 210 Ohms, then the sensor can be safely changed, since its readings are incorrect. With such sensor resistance, you will encounter the fact that your car will boil regularly. By using a multimeter, you will eliminate the need to disassemble the cylinder head and carry out complex repairs, quickly identifying the cause of the problem at home. You can also choose the sensor that will display the data correctly.

Which device to choose

In principle, it is possible to measure temperature with any multimeter, but there are several important nuances. Before purchasing, you need to pay attention not only to the price, but also to the quality. It will be much more convenient if the multimeter is initially designed to measure different temperature ranges and has a special mode for this. Then you won’t have to modify it using additional devices.

The higher the functionality of the device, the more convenient and useful it is to use. It is better to purchase a device from a trusted store, since quite a lot of products from even well-known companies are counterfeited, not to mention unscrupulous manufacturers offering low-quality products. It is better to overpay a little, but have a guarantee of the reliability of the purchased tester.

Standard functions of the devices include the ability to measure voltage, resistance, DC and AC current.

Most models will allow you to ring the chain. The price often depends on what kind of display the tester has. If this is a regular screen with numbers, the device will cost less than an analogue with a full color display and the ability to control it.

The choice of multimeters is quite wide. You can always choose the right device based on functionality, price and quality. The device will become indispensable in many situations; it will help check not only the condition of wiring, but also many parts of various electrical appliances.

Types of Thermocouple

Due to the simple classification of application areas, three types of temperature sensors are used and found on the market:

The first (E) is made mainly from chromium and constant plates. It is very reliable, the factory marking of the developers is THKn. The operating temperature ranges from 0 to +600 degrees Celsius.

The second type (J) is similar to the first, but here chromium is replaced with iron. The functions are not inferior to type E, but the pricing policy for the manufacture of the device is much lower. Marking of manufacturers-developers - TZHK. The operating temperature range is from -100 to +1200 degrees Celsius.

principle of operation, how to check the device with a multimeter and how it works, what it is

The thermocouple for a gas boiler has a simple design, so it is quite easy to repair. A gas boiler is a complex structure that requires additional components. Particularly important in this device are the parts that control its operation and protect against overheating. One of the most important components of a gas boiler is a thermocouple. Let's figure out what it is and how to repair it yourself.

What is a thermocouple for a gas boiler

To understand how a thermocouple works, you must first determine what it is. Only in this case will you be able to change it in case of malfunction and check its operation.

The thermocouple is an element not only of a gas boiler, but also of a column. It is thanks to it that the safe operation of gas equipment is ensured.

You can find the answer to the question: “What is a thermocouple?” in special documentation. However, we offer you an explanation of the structure of this element in simple language.

What is a thermocouple:

- The thermocouple is a equipment monitoring device. It consists of two conductors of different types.

- The thermocouple conductors must be in contact with each other. Such contact is provided at one or two points of the device.

- Due to the different types of conductors in a thermocouple, when heated, they create a voltage between themselves. This voltage is taken into account during the operation of the gas boiler.

- It is thanks to the conductors and their characteristics that you do not have to use external excitation of the gas boiler. These parts can be powered autonomously.

Thus, the thermocouple is a temperature control sensor in the boiler. It has a very simple structure, which ensures its versatility.

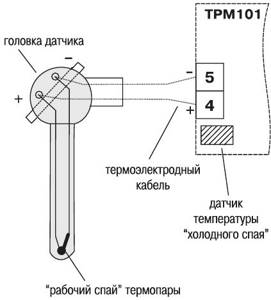

In order to measure temperature, temperature sensors are used - primary converters. Resistance thermometers and thermocouples are commonly used in industry. There are several types of thermocouples. The most common are chromel-alumel and chromel-copel. For measurements, a special thermocouple thermometer program is used.

— for long-term monitoring of temperature changes, the “Multi-channel recorder” program.

Posting sponsor P&G Articles on the topic “How to check a thermocouple” How to check the quality of a telephone line How to check a diode with a multimeter How to check an IR receiver

Source

Conclusions and useful video on the topic

The video below demonstrates the process of testing a thermocouple installed on one of the models of gas boilers.

The video explains in detail how to remove, check, change an important component of a gas water heater, without which the equipment actually remains operational only in uncontrolled mode, which is extremely dangerous for the end user:

Replacing the sensor yourself is possible. However, for this, the home craftsman must have plumbing skills and be able to use measuring instruments:

Thanks to the thermocouple, the ignition and heating process is automated, increasing the safety of the gas water heater and boiler. The material considered allows us not only to fully appreciate the technological significance of the thermocouple device in the design of gas-using equipment and to understand the structural intricacies of home boilers, but also, if necessary, to repair the equipment with your own hands. At the same time, it is important to remember the safety rules, and if you have doubts about your own abilities, it is better to turn to specialists.

Would you like to talk about your personal experience of testing the functionality of a thermocouple? Or do you have useful information on the topic of the article and would like to share your knowledge with other users? Write your comments, participate in discussions - the feedback form is located below.

Thermocouple Study

If the operation of the gas boiler is not stable, it is necessary to examine the condition of the thermocouple.

The first symptom of the problem is that while the device is operating, the button does not lock on the magnetic box.

In this case, you need to check the temperature sensor. There is an easy method for this:

- Disconnect the gas appliance from the network (electricity and gas).

- At one end of the thermocouple there is a special indicator. The second end of the thermocouple is connected to the EC (solenoid valve). Mounting method: nut.

- The nut must be unscrewed from the EC, then the thermocouple must be removed from the device.

- Heat the indicator over a stove or candle. Its distance from the heat source is 1-2 cm.

When the indicator heats up, the thermocouple body heats up to the middle. Protect your hands with gloves during this process.

Steps after heating the thermocouple:

- Use a multimeter. Place one of its probes on the body of the device. And the second one goes to the output contact.

- After about a minute, the multimeter will detect the voltage. If the readings vary in the range of 18-25 mV, then there are no problems with the thermal regulator. The problem lies in poor contact between the thermocouple and the EC.

If the readings do not reach 18 mV, the thermal converter may be working. To do this, move it in the flame. Measure the data again with the probes.

The optimal parameters are 20-25 mV. Even at 18 mV, the EC can function without failure. And the button turns itself off at 16-17 mV

Source

Gas control repair manual

If the gas on the stove goes out, then the problem may lie not only in the thermocouple. However, most often this is precisely the problem.

The main sign of problems with gas control is that after igniting the burner and releasing the handle or button to open the “blue fuel”, the flame immediately goes out. This occurs due to the valve closing, since the thermo-EMF to keep it open is absent or insufficient.

The reasons for the noise of gas stove burners are described in detail in the article, the useful information of which is worth reading.

Before purchasing a new thermocouple, you need to determine the reason for the poor operation of the existing device - perhaps the problem is loose contacts on the valve, then you just need to tighten them

You should independently check, repair and replace the thermocouple in a gas stove with your own hands only when the gas is completely shut off. First you need to close the valve on the cylinder with the gas mixture or the methane pipe, and only then begin any work. Also, do not forget about turning off the power supply if the design contains volatile devices.

The thermocouple tip is located directly next to the burner and gas fire. And in the oven you can find it near the flame divider in the upper part of the oven. This tip should be free of carbon deposits, mineral deposits and any damage.

If the working tip of the thermocouple sensor is covered with scale, it must be cleaned off with sandpaper. The more carbon deposits, the less heat reaches the thermocouple, and the less it accordingly creates an EMF. The resulting millivolts may simply not be enough to open the solenoid valve.

How to check before replacing?

The thermocouple usually has one tip for installation near the fire. But there are also options with two or three temperature control tips. They are usually used in ovens, but it all depends on the specific model of the stove.

Thermocouples with several working tips have a peculiarity - if only one of them is not heated or fails, the solenoid valve will be closed. Therefore, in order to accurately find the cause of the problems, such thermocouple devices will have to be checked especially carefully. Only one of the sensors may be faulty.

A working thermocouple for a gas stove, when heated over a candle, produces an EMF of the order of 15–20 mV after 20–30 seconds - if less, then the sensor must be changed

Another point is that the thermocouple conductors in the area up to the valve must be tensioned or dangling in the body of the plate. At the same time, their connection to the electromagnet must be rigid; a connector hanging “on my word of honor” is unacceptable here.

The devices in question are produced with lengths from 40 to 130 cm. You should choose a thermocouple gas monitoring device based on this indicator very carefully. On the one hand, the conductor wire should not be over-tensioned, and on the other hand, it should not lie on heated surfaces or dangle freely.

How to change the device?

Before replacing a damaged thermocouple in a gas stove, you should inspect the device for:

- the presence of carbon deposits on the working tip (if there is any, it must be cleaned off with sandpaper);

- no burnout of this tip (in this case, only complete replacement);

- the rigidity of the connection between the contacts of the thermocouple sensor and the valve (if necessary, tighten);

- serviceability of the thermocouple itself with the output of an EMF at a level of at least 15 mV when heating.

The device in question should only be replaced when it is definitely faulty. In many cases, to get a gas stove to work again, you can get by by cleaning the tip from carbon deposits and checking the contacts.

To replace the thermocouple, you will have to remove the front panel from the gas stove, and also lift the top cover with the burners on it

The working tip of the thermocouple is rigidly fixed near the burner or burner using a nut. If it cannot be unscrewed due to scale, then you should not put too much pressure on the key. This can only break the fastening. It is better to use a solvent first.

The second end of the thermocouple is attached to the solenoid valve using a threaded connector or two crimp contacts. Removing them doesn't seem difficult. The new thermocouple sensor is installed in a similar sequence - one end of it is attached near the burner, and the other to the electromagnet.

Why is a thermocouple needed in a gas boiler?

A thermocouple (also known as a thermoelectric thermometer) is a control and measuring module that, when heated, produces a low voltage, which is sufficient to hold the gas supply solenoid valve in the open position. In fact, a thermocouple is needed solely for safety reasons: as soon as for some reason (for example, due to reverse draft) combustion stops in the combustion chamber of the boiler, the thermocouple will not be able to keep the gas supply valve open, the fuel supply will stop, gas leaks into the premises will be prevented.

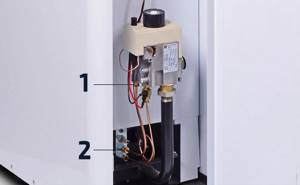

The photo shows the standard location of the thermocouple in a gas boiler. It can be identified by its copper tube.

In addition to gas boilers, thermoelectric sensors are used in household gas stoves, stoves, and water heaters. Therefore, when choosing, it is necessary to select a thermocouple specifically for gas boilers, or more precisely for a specific model of boiler unit or automation (usually the Italian automatic EuroSit 630 and its analogues).

How to replace a temperature sensor?

Most options for repairing (replacing) the thermocouple of a household geyser require dismantling this element from the equipment structure. Accordingly, a potential technician needs to be aware of how to remove and install the sensor. Let's look at how to replace a thermocouple in a gas boiler and what is needed for this.

The tool set is quite simple. Usually one or two open-end wrenches are required for a 14 (or 15) nut.

It is worth noting that, based on the specific boiler model, the size of the fastening nuts may differ, as well as the design of the thermocouple itself. On some models, the thermocouple is secured with screws.

Dismantling the control sensor on the gas water heater for subsequent performance testing. Depending on the boiler model, sensor mounting options may vary

Thus, the technician needs to free the sensor from the mounting screws, after which the structure is removed and can be repaired or replaced with a new one. Installation of the new element is carried out in the reverse order.

Are you having problems with your geyser thermocouple? In this case, we recommend that you read the repair and replacement manual.

Design and principle of operation

It is known that in a closed circuit, which consists of two conductors of different metals (for example, chromel and copel), a thermoelectromotive force (EMF) arises, provided that their hot and cold junctions have different temperatures (Seebeck effect). The value of the EMF depends on the materials of the conductors, the temperatures of their cold and hot junctions.

Typically, the voltage of a household thermocouple is in the range of 20-60 millivolts (mV), which is enough to open the gas valve, but, of course, not enough to operate complex automation and other modules that already require an electrical connection.

This is what a standard thermocouple looks like in the photo.

The module is not limited to a pair of junctions, but the thermocouple device is quite simple and understandable:

- The sleeve, inside of which there are thermoelectrodes with the “hot” junction of the conductors, is what is attached to the burner module of the boiler, next to the pilot burner (igniter).

- An extension cord, protected by a copper tube from external influence of electromagnetic fields, is used to connect the working part (hot junction) with the electromagnetic gas valve.

- A dielectric washer with a “cold” junction, it is this that is inserted into the socket of the gas solenoid valve.

Most often, thermocouples of domestic gas boilers use junctions made of chromel and alumel (TCA), chromel and copel (TCC), and iron and constantan (TLC). All alloys used, their markings and characteristics are listed in the table below.

| Thermocouple type (European classification) | Junction conductor materials | Russian markings | Temperature range, °C |

| K | chromel-alumel | THA | -200 – 1 300 |

| L | chromel-copel | THC | -200 – 850 |

| J | iron-constantan | TZHK | -100 – 1 200 |

| N | nikhrosil-nisil | TNN | -200 – 1 300 |

| T | copper-constantan | TMKn | -200 – 400 |

| E | chromel-constantan | THKn | 0 – 600 |

| S | platinum-rhodium-platinum | TPP10 | 0 – 1 700 |

How does a thermoelectric thermometer work as part of a gas boiler?

The operating principle of a thermocouple in a gas boiler is the same everywhere:

- First, a person mechanically opens the gas supply valve by holding the solenoid valve button for 15-30 seconds.

- Then the piezo ignition button is pressed once, a spark appears and the pilot burner lights up.

- The magnetic valve button is held down for another 30-60 seconds until the working junction of the thermocouple, located next to the igniter, heats up and produces the required voltage.

- After 30-60 seconds, the solenoid valve button is released, but combustion continues as the heated thermocouple produces enough voltage to hold the gas valve open. The boiler operates normally, without human intervention.

- Once combustion stops, the flame no longer heats the thermocouple, causing the voltage to be insufficient to hold the gas solenoid valve open and it closes, stopping the flow of gas.

How to choose a water softener for a gas boiler and extend the life of the heat exchanger

Connection and testing

The thermocouple must be connected using electrodes (wires) made of the same material as the thermocouple being connected.

Or metal wires can be used, which have characteristics similar to those of the electrodes on the thermocouple itself.

Before connecting thermocouples for heating boilers, it is important to strip the ends of the wires to remove oxides that affect the accuracy of the measurements. And during installation, it is important to ensure that the fuel outlet and supply pipes are lowered straight down.

If the thermocouple is broken, as a rule, it is no longer possible to restore it, so it is important to know how to check the thermocouple with a multimeter on a gas boiler.

The working thermocouple should operate after 10-30 seconds of heating

To check its functionality, just connect one end to a multimeter - a measuring sensor, and heat the other end using a gas burner or lighter.

A combined electrical measuring instrument, which can be digital and analog, combines several functions (at least the functions of a voltmeter, ohmmeter, ammeter). Multimeter

The working thermocouple should have a voltage around 50 mV.

If a thermocouple malfunction is confirmed, you can replace it yourself.

Instructions for diagnostics, repair and replacement

How to test a thermocouple for functionality

It is often possible to determine that the thermocouple is faulty even visually, without disassembling the boiler. During ignition, after releasing the solenoid valve button, it will not remain in the clamped position, since the solenoid valve does not receive the minimum required voltage. The valve will close and the gas supply will stop.

You can bypass the thermocouple by holding the button with a heavy object or taping it with tape, which is often done in practice. However, we strongly do not recommend doing this, because if the flame dies out, for example, when blown out by the wind, the supply will remain open, the gas will not be burned and will enter the room, which will cause an emergency. You can resort to such a bypass only temporarily, until the arrival of a specialist or a spare module, by constantly being at the boiler and monitoring the presence of a flame.

To ensure that it is working properly or malfunctioning, you should check the thermocouple with a multimeter (tester) set to mV or a voltmeter:

- Unscrew the nut securing the thermocouple in the socket of the electromagnetic gas valve.

- Remove the working part of the thermocouple from the cat.

- Now you need to heat the working part of the thermocouple so that it generates voltage. It is best to do this over a stove burner or a candle; the flame should tightly envelop the thermocouple.

- After heating the thermocouple (30-60 seconds), apply one tester probe to the thermocouple body, and the second to the output contact. It is better to carry out measurements within 40-60 seconds, without stopping heating the working junction.

A working thermocouple of a gas boiler should produce a voltage of 20 mV (0.02 V). Some models can output up to 50-60 mV. If the thermocouple produces less than 20 mV, this is guaranteed to indicate a malfunction. However, do not rush to repair or replace the module.

How and in what cases can it be restored?

The thermocouple is designed in such a way that any damage or contamination can reduce the voltage it produces below a critical level. A very common cause of malfunction is carbon deposits or a layer of soot on its working (heated) part. To restore the thermocouple, just clean it with a soft brush or cotton wool and alcohol, while avoiding scratches and other damage. After cleaning, it is worth checking the voltage again following the instructions above.

Oxidized contacts are also a common cause; they can be carefully treated with sandpaper. If the thermocouple has a deep black dent or hole due to burning, it is guaranteed to need to be replaced.

The procedure for replacing a thermocouple with a new one

Installing a new thermocouple is no different from the process of dismantling it: first, we fix the working part with the hot junction on the burner module, simply tightening the nut. In the same way we connect the dielectric washer to the gas valve socket.

The main point is to adjust the position of the thermocouple relative to the pilot burner, if necessary. The principle here is simple: the wick flame must completely wash the working part of the thermocouple.

The cost of a thermocouple depends on the model and the alloys used in it. On average, prices are in the range of 350-500 rubles. Below is a table of thermocouple prices for the most popular models of gas boilers.

Source

The need to use a thermocouple

With the proper equipment, there is a real opportunity to significantly reduce gas consumption. The thermocouple of a gas boiler is part

device that regulates and controls the operation of the machine and ensures that it

was not overheated. The design of the thermoelectric element is both simple and very reliable.

It is quite possible to make such an element yourself, but it is very important to calculate the measurements correctly, otherwise there may be an error, as a result, in temperatures, 1 degree Celsius will play an important role in the correct operation.

Thermocouple connection diagram

- Connecting a potentiometer or galvanometer directly to the conductors.

- Connection using compensation wires;

- Connection with ordinary copper wires to a thermocouple with a unified output.

Application

Thermocouples are used wherever temperature measurement in a process environment is required. They are used in automated control systems as temperature sensors. Thermocouple type TVR, which has an impressive thermoelectrode diameter, is indispensable where it is necessary to obtain data on very high temperatures, in particular in metallurgy.

Gas boilers, convectors, water heaters are also equipped with thermoelectric converters.

Advantages

Flaws

The disadvantages of the products are the following factors:

Due to the fact that problems associated with shortcomings can be solved, the use of thermocouples is more than justified.

How does gas control work?

Gas control (or, as more than 2 times fewer people write, gas control) of most, if not all gas stoves, works on the same principle: we have a thermocouple located near the corresponding burner. When the fire burns, it heats the thermocouple and it begins to produce electricity - only 30 millivolts, which are transmitted to the solenoid valve installed between the main gas line of the stove and the gas regulator of this burner, which is closed by default, but opens when the above voltage is applied to it .

In many modern stoves, for example, Gefest, where gas control is built into all burners, pressing the gas control knob itself opens the gas control valve, so after the gas ignites, the knob must be held down a little, and not released immediately, so that the thermocouple ignites The burner had time to heat up and the gas control valve began to be held in place by the current from it.

But the stove we have here is by no means new, even though it comes from the same factory:

The handles of the gas taps of the burners here turn without pressing, and the gas control here is installed only on the upper and lower burners of the oven, therefore, in order to light them on such a stove with a properly functioning gas control, we need:

- Turn the gas regulator in the oven to maximum (or set it to the “top burner” mode). In this case, gas should not flow.

- Light a match and bring it to the desired channel at the bottom of the oven or to the top burner.

- Press the red gas control button, which will open the gas supply valve, it will flow into the burner and it will light with a match.

- Keep the gas control button pressed until the thermocouple heats up and the solenoid valve “seizes” from the current it produces.

- Release the button, it will come back out, because... spring-loaded, and the gas will continue to burn as if nothing had happened.

Moreover, if you turn off the gas after that and immediately try to light it again, you no longer have to press the button: heating the thermocouple is enough for 10-15 seconds to hold the gas control valve open, after which it snaps back quite loudly, cutting off further gas supply.

Here is such a simple scheme. But what should you do if the gas control on your oven does not work as it should, the gas goes out spontaneously and you cannot bake or cook anything normally? Let's figure it out, let's move on to diagnostics!

Temperature measurement using thermocouple and AVR microcontroller

A thermocouple is a type of temperature sensor that can be used in measuring devices and automation systems. It has certain advantages: low cost, high accuracy, wide measurement range compared to thermistors and digital temperature sensor microcircuits, simplicity and reliability. However, the output voltage of the thermocouple is small and relative, and the circuit of the thermocouple meter is complex, since there are strict requirements for the precision amplification of the signal from the thermocouple and for the compensation circuit. To develop such devices, there are specialized microcircuits that integrate an analog signal conversion and processing circuit. Using these microcircuits, you can build a fairly compact temperature meter with a thermocouple as a sensor (Figure 1).

| Picture 1. | Appearance of a digital temperature meter with a thermocouple as a sensor. |

Operating principle of the boiler

The connection diagram of the thermoelectric sensor in various gas-using devices is approximately the same.

The measuring electrode is located in the area of action of the wick or the main burner, the conductor is connected to an electromagnet that opens the gas supply. How does a thermocouple work on floor-standing boilers of the AOGV type and similar devices:

- The user presses the button with one hand and forcibly opens the gas supply solenoid valve.

- With the second hand, the homeowner turns on the piezo ignition while holding the first key. The pilot lights up.

- According to the operating instructions, the button must be held for 5-30 seconds (depending on the model of the unit), during which the wick warms up the measuring electrode.

- A direct current appears in the electromagnet circuit, coming from the thermoelectrodes. The user releases the key, but the fuel supply does not stop - the valve now holds the thermocouple voltage.

If, for various reasons, the fire goes out, heating of the thermoelement ends, and the EMF disappears. The electromagnet will turn off, the spring will close the valve and block the path of fuel.

The thermocouple electrode is located next to the igniter on all water heaters.