The development of technology has led to the replacement of classic wood stoves with boiler units. In addition to firewood and coal, gas, oil, diesel fuel and even electricity began to be used as fuel. Recently, energy for autonomous heating systems has been additionally obtained using solar panels and geothermal installations. Considering that hydrogen is an inexhaustible source of energy, you can try to assemble a hydrogen generator with your own hands to produce environmentally friendly fuel.

DIY hydrogen generator

The simplest electrolyzer

In order to make a simple hydrogen generator, enough knowledge of physics and chemistry at the level of high school.

Materials and tools

Stainless steel 03Х16Н15М3 size 500x500 mm. Any other grade of stainless steel can be used

Important: ordinary steel in water will be susceptible to corrosion. In addition, instead of water, it is possible to use an alkaline electrolyte, which is quite aggressive, especially when electric current passes through it

Under these conditions, ordinary steel will not last long.

A transparent polyethylene tube at least 1 m long and 8 mm in diameter. 2 bolts M6x150, washers and nuts. 3 herringbone fittings with an outer diameter of 8 mm. A plastic container with a lid with a capacity of at least 1.5 liters. Filter for purifying running water (you can use a filter from a washing machine). Water check valve. Silicone sealant. Grinder or hacksaw for metal. Wrenches for M6 bolts.

Manufacturing process

We cut the steel sheet so that we get 16 plates of the same size. In one of the corners of each plate you need to drill a hole for an M6 bolt. With the help of this hole, the plates will be fastened together, so the center of the hole in all plates must be on the same axis. In order to correctly connect the plates, it is necessary to cut off the corner in each plate, which is located on the side opposite the bolt hole. Install the plates on the bolts one by one according to the diagram, isolating the “+” and “-” plates from each other using a polyethylene tube and washers. If the plates are installed correctly, the cut corners will not allow the plates of different polarities to contact each other. After installing all the plates, the structure must be tightened with nuts

Important: after completing the assembly, you need to make sure that the different-pole plates are not connected to each other (ring the structure).

We fasten the resulting structure into a plastic box using washers and nuts, having previously drilled 2 holes for the “+” and “-“ bolts. To ensure the tightness of the hole, treat it with silicone sealant. Drill holes in the box cover and insert fittings

The holes must be treated with silicone sealant. It remains to check the performance of the resulting electrolyzer. To do this, fill the container with water up to the mounting bolts and close it with a lid. Then we put a polyethylene hose on one of the fittings and lower it into some container with water. Having connected a power source to the bolts, we observe the appearance of bubbles of released gas. In order to increase the amount of gas released, it is necessary to increase the current passing through the water. After checking the functionality of the device, you need to drain the water and fill the plastic container with alkaline electrolyte. This will allow you to obtain a significantly larger amount of gas released.

ATTENTION: when operating an electrolyzer, you must remember that the process of splitting water into oxygen and hydrogen is explosive. Therefore, certain safety regulations must be observed

Hydrogen water at home

Theoretically, you can create a hydrogen generator with your own hands at home. But for this you need to have special knowledge and have the appropriate equipment.

There are two options:

- Saturation is the process of enriching water with molecular oxygen. Based on the principle of producing carbonated drinks.

- Electrolysis is the process of passing current through a liquid medium. The essence of the technique is the reaction of water with metals.

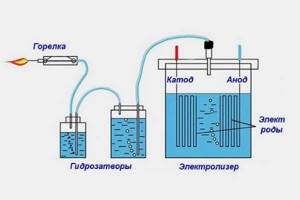

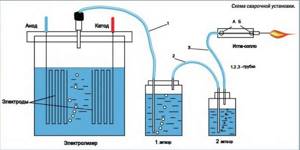

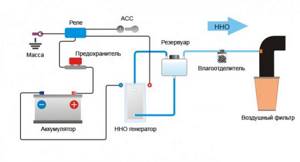

The operating principle of a home generator is shown in the image:

The simplest electrolyzer consists of:

- thick-walled container (reactor);

- metal electrodes connected to the electrical network;

- water seal;

- gas outlet tube;

- burners.

How to make a hydrogen generator:

- Immerse the metal electrodes in a container of water and apply voltage. The reaction will be improved by adding salt (or alkali, or acid) to the water.

- A reaction will occur as a result of which hydrogen will begin to be released near the cathode (minus), and oxygen will begin to be released near the anode (plus).

- The gases are mixed and enter a tube, through which they are then sent to a water seal (hydraulic seal). The purpose of the water seal is to prevent a flash in the reactor and to separate water vapor.

- Dangerous gas from the second container is transferred to the burner, where it burns out. As a result, water is formed.

Creating a hydrogen generator in practice goes like this:

- Prepare everything you need: 2 wide-necked glass bottles, caps for them, a dropper system, 20 screws, 2 flat wooden sticks, wires.

- Connect the wooden sticks with self-tapping screws with ends in different directions. Solder the heads of the screws and connect the wires to them. You will get improvised electrodes.

- Pull the tube from the dropper and the wire into the hole in the bottle cap. Seal with a glue gun.

- Place the electrodes in the container and screw on the lid.

- Pull the tubes from the dropper through 2 holes in the other lid. Pour water into the bottle and screw on the cap.

- Pour water with added salt into the reactor.

- Turn on the power source (DC, for example, car battery, AC adapter).

- As soon as bubbles appear, the reaction has begun. Adjust the voltage. Ignite the escaping gas.

For more information on how to make a hydrogen generator with your own hands, watch the video:

But is there any point in trying to create a water ionizer yourself when it’s easier and cheaper to buy a ready-made one?

Ideas for combining flooring in the kitchen

The combination of materials must be thought out before starting work, so that, taking into account the difference in thickness, a difference of the required magnitude can be made on the floor (during its preparation).

Tiles and laminate

These materials are perfectly combined in thickness and physical characteristics. Laminate flooring for the kitchen is selected with the highest degree of strength and moisture resistance. No matter how beautiful the glossy finish is, preference should be given to the option with a matte surface. It is easier to care for, and its textured structure will prevent it from slipping even on a wet floor. Laminate is not indifferent to moisture and grease, which is why it is used in the dining area.

Ceramic tiles are best suited for finishing the floor near the workplace. But not a slippery glossy one, but a matte one with a textured structure. There are so many colors and textures in the assortment that it will not be difficult to choose the ones that suit your kitchen decor. The combination of tiles and laminate with images of marble, limestone, oak, and beech looks impressive.

Tiles and linoleum

Ease of installation and low price have made linoleum popular for several decades. It is moisture-resistant, soft, silent, and can withstand cleaning agents without loss of appearance. A large selection of colors allows for a successful combination with other floor coverings, including tiles. Linoleum looks beautiful with an imitation of wooden or parquet flooring. The anti-slip coating improves grip on shoes, and a minimal number of joints makes the floor easier to clean.

Test results showed that the artificial material is no worse than natural linoleum in all respects, but costs less.

Linoleum and laminate

These materials complement each other perfectly, since service life, heat transfer, hygienic parameters and price differ slightly. If you choose linoleum with an imitation of a luxurious carpet, you can lay it in the recreation area. However, it is better to use it near the workplace, since it is not as picky about moisture as laminate, which will allow you to walk in the dining area even barefoot.

Tiles and parquet boards

These materials are not often used for combination, but in vain. Using parquet boards you can make your kitchen interior chic and comfortable. Valuable wood species are used for production.

Parquet boards are easy to install, but they are easily scratched and do not withstand moisture and detergents, so frequent washing is not recommended. However, in a dining area where there are no negative factors, it will look great, since no coating can compare with the warmth of natural wood.

Porcelain tiles and laminate

The combination of these materials will ensure the strength, durability and beauty of your kitchen floor. In terms of characteristics, porcelain tiles are similar to earthenware tiles, but have higher strength and can withstand even strong impacts. Its service life is indicated not in decades, but in centuries. Even the most aggressive detergents, much less water and grease, do not affect porcelain tiles. Therefore, it is ideal for the work area. Selecting the right shade when combined with laminate will not cause any difficulties, since there are any options in the color palette. They are approximately the same in thickness, which will make joining easier.

Porcelain tiles with a polished surface are not suitable for the kitchen, since they become slippery after liquid gets on them. Matte tiles do not have this defect, they do not lend themselves to abrasion and are easy to clean.

When purchasing, you need to pay attention to the presence of small technical holes on the back side. Their shape should be smooth and neat

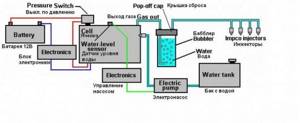

Homemade installation diagram

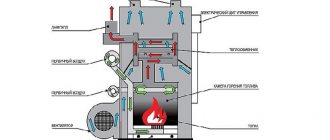

A lot of practical advice on this matter can be found in online communities of craftsmen and enthusiasts. In general, most of them come down to the idea that to build such a boiler with your own hands, you should adhere to a scheme that includes the following main parts:

Diagram of a hydrogen heating boiler

The electrolytic solution enters the electrolyzer, which produces gas, after which the products of this reaction are returned to the container. For reliability, it is recommended that the latter be made of alloy steel and equipped with a pressure relief valve. The resulting hydrogen is then directed through a protective block (a pair of bubblers) into the combustion chamber. The gas reacted here with oxygen forms useful heat. It enters the house heating system through a heat exchanger, and the moisture released in the chamber is returned through a separate channel to the container with electrolyte. Thus, part of the solution is self-replenishing due to recycling.

By adding standard automation elements typical for any heating boilers to the basic circuit described, you will get a working prototype.

Through trials and testing, it will be possible to bring it to a full replacement for other types of fuel devices. Or use it as an addition to an existing heating system at home.

Installation quality criteria

It is extremely difficult to assemble a high-quality, efficient and productive installation at home. For example, even if we take into account such a criterion as the metal from which the electrode plates or tubes are made, there is already a risk of encountering problems.

The durability of electrodes depends on the type of metal and its properties. You can, of course, use the same stainless steel, but the lifespan of such elements will be short.

A kind of parody of electrode plates for a hydrogen generator. The plates are taken from a conventional variable capacitor, which are made of aluminum. Such electrodes will be enough for exactly half an hour of operation even as part of a small experimental system

Installation dimensions also play a significant role. Calculations with high accuracy are required in relation to the required power, water quality and other parameters.

So, if the gap between the working electrodes is outside the calculated value, the hydrogen generator may not function at all. In the worst case, the power for which the calculation was made will turn out to be several times less.

Even the cross-section of the wire connecting the electrodes to the power source is important in the design of a hydrogen generator. True, this concerns the safe operation of the device. However, this design detail should also be taken into account in home installations.

Returning to the safe operation of the system, one should also not forget about the introduction of a so-called water seal into the design, which prevents the reverse movement of gas.

Despite a fairly impressive number of developments of homemade hydrogen generators, there is no really effective option yet. All models are inferior to factory equipment

Model selection criteria

A hydrogen boiler for a home must be selected taking into account the following criteria:

- the heating power must meet the requirements of the heating system and coolant used, and also take into account the area of the heated premises;

- the dimensions of the combustion chamber must be equipped with the required number of heat exchangers, allowing the organization of several heating circuits;

- the electrical network in the building must be able to withstand the power consumption of the boiler;

- all structural elements of the boiler must be made of high-quality materials and have a sufficient margin of strength and wear resistance;

- The protection unit must be certified and comply with safety standards.

Example of a hydrogen heating boiler

Methods for producing hydrogen

Hydrogen is a colorless and odorless gaseous element with a density of 1/14 relative to air. It is rarely found in a free state. Hydrogen is usually combined with other chemical elements: oxygen, carbon.

Hydrogen production for industrial needs and energy is carried out using several methods. The most popular are:

- electrolysis of water;

- concentration method;

- low temperature condensation;

- adsorption.

Hydrogen can be isolated not only from gas or water compounds. Hydrogen is produced by exposing wood and coal to high temperatures, as well as by processing biowaste.

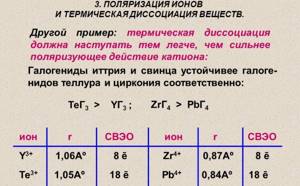

Atomic hydrogen for energy is produced using the method of thermal dissociation of a molecular substance on a wire made of platinum, tungsten or palladium. It is heated in a hydrogen environment under a pressure of less than 1.33 Pa. Radioactive elements are also used to produce hydrogen.

Electrolysis method

The simplest and most popular method of hydrogen separation is the electrolysis of water. It allows the production of almost pure hydrogen. Other advantages of this method are:

- availability of raw materials;

- obtaining the element under pressure;

- the ability to automate the process due to the absence of moving parts.

The procedure for splitting a liquid by electrolysis is the reverse of hydrogen combustion. Its essence is that under the influence of direct current, oxygen and hydrogen are released on electrodes immersed in an aqueous electrolyte solution.

An additional advantage is the production of by-products of industrial value. Thus, oxygen in large quantities is necessary for catalyzing technological processes in the energy sector, cleaning soil and water bodies, and recycling household waste. Heavy water produced by electrolysis is used in the energy sector in nuclear reactors.

Hydrogen production by concentration

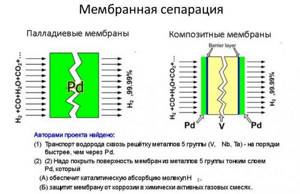

This method is based on isolating an element from gas mixtures containing it. Thus, the largest part of the substance produced in industrial volumes is extracted using steam reforming of methane. The hydrogen produced in this process is used in the energy sector, in the oil refining industry, the rocket industry, and also for the production of nitrogen fertilizers. The process of obtaining H2 is carried out in different ways:

- short cycle;

- cryogenic;

- membrane.

The latter method is considered the most effective and less expensive.

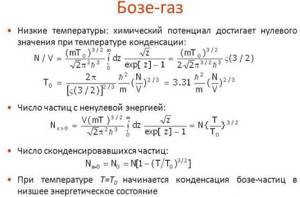

Condensation due to low temperatures

This technique for producing H2 involves intensely cooling gas compounds under pressure. As a result, they are transformed into a two-phase system, which is subsequently separated by a separator into a liquid component and a gas. Liquid media are used for cooling:

- water;

- liquefied ethane or propane;

- liquid ammonia.

This procedure is not as simple as it seems. It is not possible to cleanly separate hydrocarbon gases in one go. Some of the components will leave with the gas taken from the separation compartment, which is not economical. The problem can be solved by deep cooling of the raw materials before separation. But this requires a lot of energy.

Modern low-temperature condenser systems additionally include demethanization or deethanization columns. The gas phase is removed from the last separation stage, and the liquid is sent to the distillation column with a flow of raw gas after heat exchange.

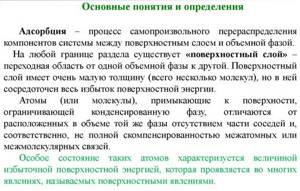

Adsorption method

During adsorption, adsorbents are used to release hydrogen - solid substances that absorb the necessary components of the gas mixture. Activated carbon, silicate gel, and zeolites are used as adsorbents. To carry out this process, special devices are used - cyclic adsorbers or molecular sieves. When implemented under pressure, this method allows recovery of 85% hydrogen.

If we compare adsorption with low-temperature condensation, we can note that the material and operational costs of the process are lower - on average, by 30 percent. The adsorption method produces hydrogen for energy and using solvents. This method allows for the extraction of 90 percent of H2 from the gas mixture and the production of a final product with a hydrogen concentration of up to 99.9%.

General structure of an electrolytic hydrogen generator

Using electrolysis (see the school curriculum for physics and chemistry), water is decomposed into hydrogen and oxygen.

The surface area of the electrodes must be large, so they are collected in packages (cells). By the way, the electrolyzer cannot be overheated above 65 ºС, otherwise the plates will have to be cleaned for a long time or even replaced

There is no need to separate the gases; the combustible mixture is sent to a heat generator, in which a reverse reaction occurs: hydrogen and oxygen reunite, again forming water.

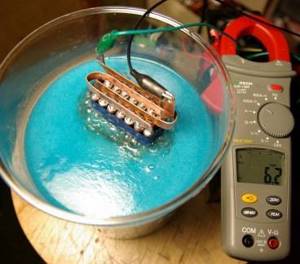

The simplest homemade hydrogen generator is a sealed container with electrodes immersed in liquid, a 12-volt power source.

There is a charge, the water is “gurgling”, Hydrogenium is gone

On the lid of the container there is a fitting for discharging a mixture of hydrogen and oxygen to the consumer (Brown’s gas, “explosive mixture”).

In addition to the fitting, it is advisable to have air vents on the lid

This container is the basis of a hydrogen generator for a car with a carburetor engine. The internal combustion engine runs on a mixture of gasoline and requires an additional storage device and battery. The case is durable, from a water filter, a simple installation created by “people's academicians”, called “AquaCar”, was offered in Ukraine for 1600 hryvnia in pre-revolutionary prices

A hydrogen generator for the home, also in a water filter housing. More efficient cylindrical electrodes are used here, and there is a pressure sensor. Bubbles are visible on the walls of the vessel - the coveted H2 and oxygen

But the point is not just to separate the “rattlers” from the water; it’s no wonder to do this. Gas must be obtained from raw materials in the maximum quantity, in a short time, while spending a minimum of energy. To increase efficiency, they use not ordinary electrodes made of copper or stainless steel, but products of complex shapes made of expensive alloys. The strength of the electric current must change during the reaction, accordingly, an electronic unit is needed.

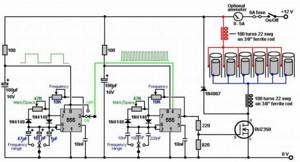

Version of the electronic unit of the miracle generator

Water is consumed, its level must be constantly maintained, and if this is not done manually, an automatic replenishment system will be needed. Finally, for electrolysis to occur with sufficient intensity, the water must contain a sufficient amount of dissolved salts; in soft water the reaction will be weak, and in distilled water it will be completely absent. This means that you cannot pour water from the tap: you will have to prepare it (the simplest option is a tablespoon of sodium hydroxide per 10 liters of water), which means additional tanks, pipelines, etc.

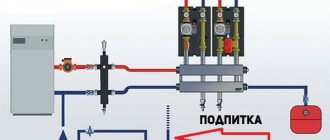

The figure shows a diagram of a hydrogen generator for a car, but the difference with a device for heating is only that the gas consumer is not the engine nozzles, but the boiler burner

But that's not all. The heat generator (boiler) consumes fuel unevenly, and also requires a certain pressure and humidity. In order for the fuel reactor + heat generator system to work interconnectedly and accurately, hydrogenium must first enter the dryer, then the compressor, which will pump it into the storage facility, where the required pressure must be maintained with the help of additional automation.

Features of a hydrogen generator

Based on the requirements and size of a private or municipal building, it is necessary to select a hydrogen burner with an optimal power level, adapted to the needs of a particular room. It should be noted that the maximum possible power rating of the generators is 6.

Hydrogen, rightfully recognized as the most economical type of fuel, can be produced in any quantity. A prerequisite for this is the availability of electrical energy and water.

The main task of the equipment is complete independent heating of premises. However, hydrogen-based installations can perfectly complement existing home heating systems. You just need to make sure that all elements of the heating system operate at low temperatures.

These units are also used to heat the room using heated floors, which are now easy to assemble with your own hands.

Operating principle of the device

The heat generation process is based on the electrolysis of water in a medium saturated with a catalyst. The main condition for the normal operation, as well as the safety of the generator, is that under such conditions, water does not decompose into oxygen and hydrogen, the combination of which can be explosive.

Modern generators work to produce Brown gas. This is a completely non-explosive substance of a brownish or green hue, also called water gas. After production and heating to 40 degrees, it immediately goes to the combustion chambers, and more specifically, to the heat exchanger. There it is mixed with air-fuel elements.

Hydrogen Generator Components

The main structural components of the simplest hydrogen unit are pipes and the boiler itself. Often no technical accessories or additional elements and devices are required anymore.

This also applies to components designed to remove combustion products. After all, as a result of the operation of the generator, only steam is released into the atmosphere: water, clean and completely safe.

Often, burners of this type have a modular design, each part of which has its own catalyst, which increases the overall efficiency of the system.

Regarding pipes for a hydrogen heating system. then it is advisable to use those whose diameter is in the range from 1 to 1.25 inches. Some deviations are allowed, but most often these particular ones are used to heat a house.

An important rule that should not be neglected when installing heating pipes is that each previous branch must be larger in diameter than the next one.

Advantages and disadvantages

Professionals highlight the following advantages of hydrogen heating:

Induction electric heating boiler and its diagram

- No fire. Thermal energy is generated during a chemical reaction that does not require combustion of any type of fuel.

- Consistency of temperature indicators. The coolant is maintained at a temperature of +40 C throughout the entire time the boiler is put into operation.

- Versatility of use. There are no restrictions for forming a system in any building.

- Practicality. The low temperature of the coolant guarantees no burns, and a home craftsman with minimal tool skills can install the heating circuit.

- Environmentally friendly. During operation, the device does not emit harmful gases, combustion products, waste particles and slag. The boiler emits neutral gas that does not pollute the atmosphere.

The scheme pays for itself in 3-3.5 years, provided it is used as a constant and main source of heat. The only alternative may be gas heating, but despite the cheapness of fuel, connecting to the main line is not always possible.

The disadvantages include the high explosiveness of hydrogen, so it is important to ensure all levels of safety when using raw materials and transporting fuel only in low-temperature conditions. It is precisely because of the difficulties in supplying hydrogen that such a heating scheme is used quite rarely today.

No. 8. Dining table style

It’s probably not worth even talking about the fact that the dining table should fit into the interior of the kitchen space. It is advised to choose a table and chairs at the very end of a kitchen renovation, when all the subtleties of the created interior are known. But it’s better to create a project for the future kitchen in advance, and choose the table that will fit in as best as possible. Kitchens made in a classic style will be complemented by wooden dining tables. Modern spaces will look great with a glass table and transparent plastic chairs.

Modern kitchens and studio kitchens today are often equipped with bar counters. They serve both as a space separator for the work area and the dining area, and as an additional surface where you can also have lunch or a snack.

Recommendations for operating a hydrogen boiler

- It is strictly prohibited to independently upgrade such equipment, even if you have a detailed and professional engineering drawing. This may contribute to the possibility of leakage of the hydrogen mixture from the generator into the open space, which is quite dangerous.

- It is recommended to install special temperature sensors inside the heat exchanger, this will make it possible to monitor the likely excess of the water heating temperature level.

- The burner design itself can include shut-off valves, which will be connected directly to the temperature sensor itself. It is also necessary to ensure normal cooling of the boiler.

- And finally, what needs to be emphasized is safety. It must be remembered that the mixture of hydrogen and oxygen was not called explosive for nothing. NHO is a dangerous chemical compound that can cause an explosion if handled carelessly. Follow safety rules and be extremely careful when experimenting with hydrogen.

If handled correctly, a hydrogen boiler can last not 15 years, as is usually expected, but 20 or even 30. However, remember that the greater the power of the boiler, the greater the electricity consumption!

Instructions: how to make a hydrogen generator with your own hands

To manufacture a fuel cell, we will take the most advanced “dry” electrolyzer circuit using electrodes in the form of stainless steel plates. The instructions below demonstrate the process of creating a hydrogen generator from “A” to “Z”, so it is better to follow the order of actions.

Dry type fuel cell diagram

Manufacturing of the fuel cell body. The side walls of the frame are plates of hardboard or plexiglass, cut to the size of the future generator. You need to understand that the size of the device directly affects its performance, however, the costs of obtaining HHO will be higher. For the manufacture of a fuel cell, the optimal dimensions of the device will be from 150x150 mm to 250x250 mm. A hole is drilled in each of the plates for the inlet (outlet) fitting for water. In addition, drilling will be required in the side wall for gas outlet and four holes in the corners to connect the reactor elements to each other.

Using an angle grinder, electrode plates are cut from a sheet of 316L stainless steel. Their dimensions should be 10–20 mm smaller than the dimensions of the side walls. In addition, when manufacturing each part, it is necessary to leave a small contact pad in one of the corners. This will be needed to connect the negative and positive electrodes into groups before connecting them to the supply voltage. In order to obtain a sufficient amount of HHO, the stainless steel must be treated with fine sandpaper on both sides. Two holes are drilled in each of the plates: with a drill with a diameter of 6 - 7 mm - to supply water into the space between the electrodes and with a thickness of 8 - 10 mm - to remove Brown's gas. Drilling points are calculated taking into account the installation locations of the corresponding inlet and outlet pipes.

They begin assembling the generator. To do this, water supply and gas outlet fittings are installed in the hardboard walls. The places where they are connected are carefully sealed using automotive or plumbing sealant.

After this, studs are installed in one of the transparent body parts, after which they begin laying the electrodes.

The stainless steel plates are separated from the side surfaces of the reactor using O-rings, which can be made of silicone, paronite or other material

It is only important that its thickness does not exceed 1 mm. The same parts are used as spacers between the plates

During the installation process, make sure that the contact pads of the negative and positive electrodes are grouped on different sides of the generator.

After laying the last plate, a sealing ring is installed, after which the generator is closed with a second hardboard wall, and the structure itself is fastened with washers and nuts. When performing this work, be sure to ensure that the tightening is uniform and that there are no distortions between the plates.

Using polyethylene hoses, the generator is connected to a container of water and a bubbler. The contact pads of the electrodes are connected to each other in any way, after which the power wires are connected to them.

The fuel cell is supplied with voltage from a PWM generator, after which the device is configured and adjusted to the maximum HHO gas output.

To obtain Brown's gas in quantities sufficient for heating or cooking, several hydrogen generators are installed, operating in parallel.

Conclusions and useful video on the topic

In the video below you will see an overview of a model of a gas boiler running on hydrogen fuel, produced by the famous Korean company DAEWOO.

Hydrogen is not without reason called the fuel of the future: this gas can become an almost limitless resource of cheap, environmentally friendly fuel that can be used in various installations.

A hydrogen fuel boiler, manufactured in a factory or independently, will allow you to create an autonomous heating system. This will help to significantly reduce payments in housing and communal services, and will solve the issue of maintaining a comfortable temperature in living rooms and utility rooms.

Sources

- https://otoplenie-doma.org/otoplenie-na-vodorode.html

- https://dizain-vannoy.ru/sistema-otopleniya/sistemy-otopleniya/vodorodnoe-induktsionnoe/otoplenie-na-vodorode.html

- https://teplodom1.ru/domotopl/286-toplivo-iz-vody-samoe-deshevoe.html

- https://www.tproekt.com/vodorodnyj-kotel-otoplenia-aponcy-uze-10-let-tak-topat-domiki/

- https://sovet-ingenera.com/otoplenie/kotly/vodorodnyj-kotel-otopleniya.html

- https://aqua-rmnt.com/otoplenie/generator-vodoroda-dlya-sistemy-otopleniya-sobiraem-dejstvuyushhuyu-ustanovku-svoimi-rukami.html

- https://dizain-vannoy.ru/sistema-otopleniya/oborudovanie/kotly/kotel-vodorodnyy.html

Related Posts

- Hydrogen heating boilers: why you should not choose a hydrogen fuel boiler for heating a private home, review and comparison of efficiency and economy, the best models and their prices

- Hair lightening

- Concept and operating principle of protective grounding

- DIY foam cutting

- How to build a children's sandbox with your own hands

- Benefits of using a duct extension for radiators

- How to glue fiberglass correctly?

- Dry Stream: photos and videos

- Mounting a mirror on the wall in various ways

- Making a stand for a drill with your own hands: instructions, drawings, video

- How long should a floor screed dry?

- Alabaster: what is it? how to divorce? where to apply?

- DIY wooden slide for winter - drawings

- Stages of renovating a children's room

- Options for making shelves for the garage with your own hands

- What and how to drill into the tiles so that they don’t crack?

- How to cut metal using a grinder

- Welding of aluminum and its alloys

- How to seal the joint between the bathtub and the wall? 8 popular options

- Making a drilling rig with your own hands

- Required profile for a plasterboard partition: 3 types

- Do-it-yourself insulation of walls with polystyrene foam - detailed instructions

- How to make water filters with your own hands?

- How to make a dollhouse with your own hands

- How to update old tiles in the bathroom

Read with this

- Hydrogen heating boilers: why you should not choose a hydrogen fuel boiler for heating a private home, review and comparison of efficiency and economy, the best models and their prices

- Hair lightening

- Concept and operating principle of protective grounding

- DIY foam cutting

- How to build a children's sandbox with your own hands

- Benefits of using a duct extension for radiators

- How to glue fiberglass correctly?

- Dry Stream: photos and videos

- Mounting a mirror on the wall in various ways

- Making a stand for a drill with your own hands: instructions, drawings, video

What is a hydrogen generator and how it works

Such a device is also called an electrolyzer and works due to the occurrence of two processes - physical and chemical. Representing several metal plates immersed in a container of distilled water, the electrolyzer is the most popular type of generator - it is a simple device that produces huge amounts of thermal energy.

The process looks like this: an electric current is passed through water between plates with different fields (anode - cathode), as a result of which distilled water is split into hydrogen and oxygen. If the area of the plates is large, then a lot of current passes, and the volume of gas released also increases.

The housing in which the electrolyser is immersed is equipped with terminals for connecting a power source (electric current) and a sleeve for gas outlet.

Comparison of a hydrogen boiler with other heating devices

As you know, an electric boiler is considered the most inefficient heating device, in other words, the cost of heat produced by this device will be the most expensive.

Comparison of heating using a heat pump with other methods.

Even the medieval scientist Paracelsus, during one of his experiments, noticed that when sulfuric acid comes into contact with ferrum, air bubbles are formed. In fact, it was hydrogen (but not air, as the scientist believed) - a light, colorless, odorless gas, which under certain conditions becomes explosive.

Hydrogen generators for heating can have different capacities

Nowadays, do-it-yourself heating with hydrogen is a very common thing. Indeed, hydrogen can be produced in almost unlimited quantities, the main thing is that there is water and electricity.

Chemical properties of H2

Is it profitable to heat a house with hydrogen?

Sellers of compact hydrogen generators convince buyers that heating a home with hydrogen is incredibly cheap. Supposedly this is even more profitable than heating with gas. They say that the water that is poured into the installation costs nothing, and they are silent about other costs. Such promises have a magical effect on some of our fellow citizens who love freebies. But let’s not be like Pinocchio and, before setting foot in the Land of Fools, let’s find out how much hydrogen heating at home actually costs.

The average selling price of natural gas for the population for heating and electricity generation is 4.76 rubles/m3. 1 m3 contains 0.712 kg. Accordingly, 1 kg of natural gas costs 6.68 rubles. The average calorific value of natural gas is 50,000 kJ/kg. For hydrogen it is much higher, 140,000 kJ/kg. That is, in order to obtain an amount of thermal energy equal to that generated by the combustion of 1 kg of hydrogen, 2.8 kg of natural gas will be required. Its cost is 13.32 rubles. Now let’s compare the cost of thermal energy obtained from burning 1 kg of hydrogen obtained in a good factory electrolyzer and from 2.8 kg of natural gas: 420 rubles versus 13.32. The difference is truly monstrous, 31.5 times! Even compared to the most expensive of traditional types of heating - electric, hydrogen cannot even come close to competing, it costs 4 times more! The electricity that will be spent on the operation of the electrolyzer is better used to operate heating electrical appliances; there will be much more benefit.

It is precisely these advertising technologies and methods of persuasion that sellers of installations for heating a home with hydrogen use in order to sell their useless goods at exorbitant prices.

As for the prospects for hydrogen energy, they exist, but success is associated with promising industrial technologies that have not yet been invented. Household hydrogen generators and hydrogen vehicles are definitely unprofitable at least for the next decades. Their very limited use in some countries is only possible thanks to significant government subsidies as part of experimental environmental programs.

What is needed to make a fuel cell at home

When starting to manufacture a hydrogen fuel cell, it is imperative to study the theory of the process of formation of detonating gas. This will give an understanding of what is happening in the generator and will help in setting up and operating the equipment. In addition, you will have to stock up on the necessary materials, most of which will be easy to find in the retail chain. As for the drawings and instructions, we will try to cover these issues in full.

Hydrogen generator design: diagrams and drawings

A homemade installation for producing Brown's gas consists of a reactor with installed electrodes, a PWM generator to power them, a water seal and connecting wires and hoses. Currently, there are several electrolyzer designs using plates or tubes as electrodes. In addition, you can find on the Internet an installation of so-called dry electrolysis. Unlike the traditional design, in such a device the plates are not installed in a container with water, but the liquid is supplied into the gap between the flat electrodes. Refusal of the traditional scheme makes it possible to significantly reduce the dimensions of the fuel cell.

Plasma boilers

Plasma type devices consist of:

- reactor. It is a steel container, at the bottom of which there is a copper plate with tungsten electrodes. They are drowned in plasma substance;

- pulse generator. It produces and transmits electrical impulses to the electrodes;

- heat exchanger. The steam generated inside the reactor enters it. This element is a cylindrical container with a coil. The latter is filled with coolant;

- catalyst. Inside it, the plasma restores its properties. It is connected to a heat exchanger;

- circulation pump. Located between the catalyst and the reactor. Its task is to distill plasma inside a heating boiler.

What else to consider

So, taking into account the above features of the design of boilers operating on hydrogen, as well as the known characteristics of this gas, to make similar equipment with your own hands, a number of important factors should be taken into account. They are:

In today's rapidly changing world, technology is constantly improving, and home climate control equipment is no exception. And although the use of hydrogen heating systems is not yet widespread, simplifying and reducing the cost of methods for separating this gas from compounds containing it can lead to truly limitless prospects for the use of such equipment.