Maintenance and repair of ventilation heater

Like any device, the heater requires careful handling and some maintenance. If you do not follow the operating rules, then cracks may appear in the pipes transporting the coolant, which leads to leakage and, ultimately, loss of heat. If low-quality coolant is used, contamination of the heat exchanger pipes may occur.

If you comply with all operating conditions, you can avoid unwanted breakdowns. Then the main reason for preventive maintenance will be to clean the ventilation system from scale and other deposits. Such manipulations must be carried out regularly, since such obstacles reduce the thermal conductivity of the unit, and the costs of its operation, on the contrary, increase. Cleaning consists of regular flushing using special products containing reagents that kill bacteria that have settled in the system.

If the heat exchanger is nevertheless damaged, then you need to seek help from specialists who will carry out professional repairs of the equipment. Workers will find the leak, solder the pipes and, if necessary, replace plates and seals.

It should be noted that untimely cleaning of the ventilation system creates a fire hazard, which is caused by the accumulation of dust and dirt in the ducts.

For proper operation of the heater, it is necessary to clean it regularly.

Heaters are rightly considered one of the most popular heating equipment. When choosing a heater or air exchanger, you should take into account a number of parameters, in particular, the type of heat exchanger, the power of the device, pressure, temperature indicators inside the coolant, as well as at the inlet and outlet. The area of the room to be heated should also be taken into account.

- Disinfection mat for an apartment: 9 tips for choosing and using

- There is no zero on the 10 kilovolt lines - why and where can I get it from then?

What is it and what is it for?

A heater is a special device designed to provide heat exchange by heating the air flow by contacting it with a certain number of heating elements.

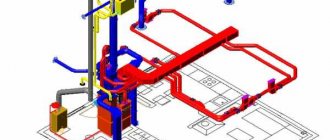

Such a unit is installed in ventilation systems both in combination with monoblock structures and in the form of separate modules.

How does the device work?

Depending on the heat source used, heaters are divided into water, electric and steam.

In the vast majority of cases, the heat transfer elements of air heaters are steel pipes with a finned surface. It is the fins that help increase the area and, accordingly, the efficiency of heat transfer. A heating or cooling coolant passes inside such pipes, and air flows pass outside, cooled or heated upon contact with the pipes.

The rib structure of the device consists of metal plates mounted on tubes, or a tape or thin wire wound on them.

The operating principle of air heaters is based on the fact that the coolant has a higher heat transfer coefficient in relation to air flows.

The energy efficiency of a heater depends on the heat transfer coefficient of the device at certain energy costs. In other words, the more heat the unit is capable of delivering at constant energy costs, the higher its efficiency.

The device is capable of significantly heating the air flows passing through it - raising their temperature by 70-110 degrees, so you can use the heater even at minimum temperatures (up to -25 degrees).

The heater can be installed according to two air exchange schemes - according to the principle of mixing recirculation and supply air, as well as in a closed air recirculation system. For forced or artificial ventilation systems, this condition is not relevant, since air is driven through the heater using duct fans.

How to choose a heater

Firstly, the device must be able to regulate operating modes using an external electrical signal from standard equipment. For example, a thermostat. The device in question is a conventional fan heater used as a heater. The unit only listens to the remote control and buttons. This is indoor equipment that can, for example, be mounted at the outlet of a ventilation duct. We believe that it is permissible to install such a device inside the tract. From the passport operating conditions it is clear that there will be no violations.

Water heaters KSk, KPSk seem to be more unpretentious and simple devices. There is no description on the dealer's website other than the radiator material, made of aluminum, as well as purely technical characteristics. It is not even clear whether a fan is installed inside the device. We will not advertise a product that is described disgustingly.

The devices are reviewed in detail on the website kalorifer.net, from which it becomes clear that the devices costing 5,000 rubles are an ordinary coil; there are no electronics inside. This is easy to install, but the device will reduce the performance of the recuperator in terms of air flow, which will require making adjustments or installing an additional fan. In this case, the proposed approach with KEV-25T3W2 does not look too primitive, eliminating the emerging difficulties. And the engine rotation speed can be changed externally. Additionally, ask the manufacturer.

We told you what a heater is and mentioned a couple of designs, simple and complex. Readers became aware of the varieties produced. For the case described in the article, a device is required that is controlled by a thermostat through devices that control the speed of an asynchronous motor. We hope that we have shown what to look for when buying a heater.

Of course, the device can also be used separately. Or equip rooms where heating is especially required, this will dramatically reduce costs and increase the efficiency of the system.

Mass air speed

3. Find the actual mass velocity for the selected one or more heaters. v (kg/m²•s) = G / f G - mass air flow, kg/hour; f is the area of the actual frontal section taken into account, m².

An example of selection and calculation of a KSk air heater. Step-3

Select a suitable KSk heater for heating 16,000 m³/hour from a temperature of -25°C to +23°C. The coolant is hot water with a schedule of 95°C at the inlet to the air heater, 60°C at the outlet. 3. The task is to find the actual mass velocity of the heat exchangers that we have selected. We accept KSk air heaters number 11 as the most suitable frontal cross-section for air passage (1,660 m²). Let's calculate all three models: two-row heater KSk 2-11, three-row KSk 3-11 and four-row KSk 4-11. v (kg/m²•s) = (20800/3600) / 1.660 = 3.48 kg/m²•s 20800 - mass air flow, kg/hour; 1.660 is the frontal cross-sectional area of KSk heaters taken into account, m². Since all three models have the same overall dimensions, the mass velocity in the frontal section of each air heater, regardless of the row, will have the same value.

Water heaters for fresh air ventilation

The main area of use of air heaters is buildings or premises in which, for various reasons, it is not possible to install radiators. For example, with large volumes of rooms, radiators simply cannot cope; on the contrary, it will be the most effective. The most rational location of water heaters is the supply ventilation line, since it is not practical to heat the exhaust flow.

In addition to heating, heating of the supply jet is actively used, used to preserve the existing heat in the room. If a fresh stream is transported through a long line of air ducts, then condensation will accumulate on them without heating the air, which will create a lot of operational problems. To solve all these issues, water air heaters are used.

Water air heater: operating principle and design

The most common type are. They replaced plate structures, which were less easy to maintain and required periodic maintenance in a rather labor-intensive manner.

View cart Add to cart / Details

View cart Details

View cart Details

View cart Add to cart / Details

Heater

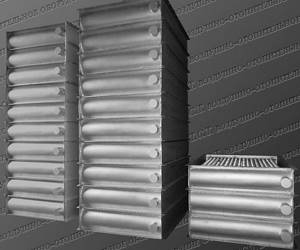

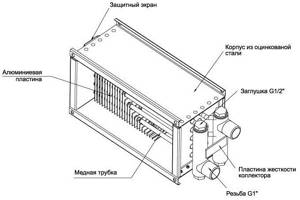

The main element of the heater is a steel tube, the outer surface of which is coated with aluminum fins. These fins serve as a heat-transfer surface, the total area of which is quite large. At the same time, the total outer diameter of the tubes (including fins) is 37 mm, and the tube itself is 16 mm, so the depth of the fins is relatively small and does not pose the risk of filling with dirt, dust or other foreign materials that reduce heat transfer. The distance between the fins is 2.8 mm, which allows you to retain heat even with intense airflow, making the device highly efficient.

Tubes

The tubes are installed in a flat rectangular frame in 2, 3 or 4 rows. The distance between the axes of the tubes promotes maximum heat transfer from their surface. The air flow is supplied using an axial or radial fan, it depends on the installation location of the device and the specifics of its operation.

Installation

To install the heater, the housing (frame) has several oblong mounting holes on flange mounts. With their help, devices can be installed in a system of air ducts, in openings or other supporting structures. Sometimes a separate installation is used when the device serves a room of a certain size and is not built into the overall heating or ventilation system.

Brief overview of modern models

To get an impression of the brands and models of water heaters, let’s look at several devices from different manufacturers.

No. 1 – KSK air heaters

Heaters KSK-3, produced at the company T.S.T.

The model range of domestically produced KSK water heaters includes 2/3/4-row devices that differ in performance and size

Specifications:

- coolant temperature at the inlet (outlet) – +150 °C (+70 °C);

- inlet air temperature – from -20 °C;

- working pressure – 1.2 MPa;

- maximum temperature – +190 °C;

- service life – 11 years;

- working resource – 13,200 hours.

External parts are made of carbon steel, heating elements are made of aluminum.

No. 2 – Volcano fan heaters

The Volcano mini water fan heater is a compact device from the Polish brand Volcano, characterized by practicality and ergonomic design. The air flow direction is adjusted using controlled blinds.

One Volcano mini fan heater is capable of generating as much heat as a dozen conventional bimetallic radiators made up of ten sections

Specifications:

- power within the range - 3-20 kW;

- maximum productivity – 2000 m³/h;

- heat exchanger type – double row;

- protection class – IP 44;

- maximum coolant temperature – 120 °C;

- maximum working pressure – 1.6 MPa;

- internal volume of the heat exchanger – 1.12 l;

- guide blinds.

Volcano water fan heaters are designed to heat the air in domestic and industrial premises using water coolant.

No. 3 – Galletti AREO air heaters

Galletti AREO heater made in Italy.

Galletti AREO water heaters are capable of both heating the premises being treated and cooling the space in hot weather

The models are equipped with a fan, a copper-aluminum heat exchanger and a drainage tray.

Specifications:

- power in heating mode – from 8 kW to 130 kW;

- power in cooling mode – from 3 kW to 40 kW;

- water temperature – + 7°C +95 °C;

- air temperature – from 10°C to + 40°C;

- working pressure – 10 bar;

- number of fan speeds – 2/3;

- electrical safety class – IP 55;

- motor protection.

In addition to the devices of the listed brands, on the market of heaters and water air heaters you can find models of the following brands: Teplomash, 2VV, Fraccaro, Yahtec, Tecnoclima, Kroll, Pakole, Innovent, Remko, Zilon.

Air heaters for air heating and ventilation

The heater is a duct type heater. The unit is always installed for its intended purpose in the ventilation or heating duct to heat the air. It is used as a wall convector. After the recuperator, the air is additionally heated; it is colder than room air. To achieve this result, a hot heater coil is inserted into the duct. Why do you need a fan - the coil is an obstacle to air flow. The recuperator is not designed to cope with ventilation alone, overcoming an unnecessary obstacle. The unit is assisted by a built-in heater fan.

Of course, the device turns on when necessary. In summer, hot water must be turned off to prevent heat from entering the room. It is better to install a valve controlled by a duct thermostat. It turns out that there is extra energy spent on overcoming the resistance of the heater, but the costs are offset by savings on heating

Please note that air from the toilet room (bathroom) is not included in the circulation path, otherwise the stream will exchange vapors on the recuperator membrane with the input flow, and the rooms of the building will be filled with a specific aroma

As a rule, a heater with a fan operates in several modes. Each is characterized by water flow, degree of cooling, air flow. There is the possibility of connecting to a European class central heating branch (60 ºС) and a special steam boiler at 150 ºС. For the above water heater with a fan, the solution looks like this:

The indicators are given for an input flow temperature of 15 ºС and maximum air flow (1200 cubic meters per hour), three in total:

- 600 cc m/h.

- 900 cubic m/h.

- 1200 cc m/h.

Remember, a water heater with a fan is an auxiliary equipment that does not work to create thrust, but accelerates the existing jet. Therefore, we expect that the practical air consumption will be slightly higher, even taking into account the convolutions of the ventilation tract.

Water heaters with a fan: characteristics and manufacturers

A water heater with a fan is one of the most economical and efficient devices used for heating air in hangars, warehouses, gyms, shopping, exhibition and concert halls, car service centers, and workshops. It is also used to heat greenhouses, farms and other spacious objects with a large area.

Such units also come in different designs depending on the intended placement. That is, there can be wall or ceiling heaters that can be easily installed in any room.

The main advantages of water heating coils are their energy efficiency and performance, which is manifested in the ability to both increase and cool the temperature in the room. At the same time, fan heaters are generally low-cost, since they consume little electricity and allow you to save on heating.

Electric fan heater with Flowair control panel

Both foreign and domestic brands specialize in the production of such air heaters, including Teplomash, Greers, Flowair and Volcano. A water heating coil with a fan is an excellent solution in most cases for heating large objects.

KSK air heaters are considered popular in the domestic market. Devices of this brand are compact and economical. The units are widely used in industry, as they do an excellent job of quickly heating air in large areas, while using a minimum of electricity. The devices are also used as a heat exchanger. They are a component in various units, heating, air conditioning and ventilation systems. The coolant in the KSK heater is hot water with a temperature of over 190°C.

Heating coils with fans: design and operation features

Heating coils with fans are available in six standard sizes. These are very popular heating products, therefore they have a wide range of models from many manufacturers. There are two-row and three-row models. Heater power from 10 to 60 kW allows you to select equipment for rooms of different sizes.

Interesting to know! Modern fan heaters are characterized by a low noise level, which at a five-meter distance from the unit when operating at full power does not exceed 55 dB. When the fan speed is reduced, the noise level is reduced to 30 dB.

The power of heaters varies between 10-60 kW

Such heaters are also called fan heaters or duct heaters; they are compact and lightweight. They are mounted on the ceiling or wall using special brackets.

For wear resistance, the unit body is made of polypropylene or galvanized steel, and the top is coated with enamel. Polypropylene is characterized by a high degree of resistance to mechanical damage and resistance to various gases and vapors. Therefore, the housing can withstand high temperatures and is resistant to corrosion and damage of various types.

Copper tubes are used to produce the heat exchanger, and aluminum plates are used for fins. They are mounted on the rear panel of the device, which greatly simplifies the installation of the device and improves its design.

The device is equipped with a silent axial fan with blades made of a special profile and bearings of the highest class that do not require lubrication. This device provides high performance with low power consumption. In addition, the air flow is adjustable within the operating range. Water from the central heating system serves as the coolant.

The units are produced in ceiling and wall versions. Due to the lightness of the mounting console, the unit can be rotated 180 degrees during operation.

Ceiling heating fan heater

Types of supply ventilation

These indoor air movement systems are classified according to a number of characteristics. According to the design of the ventilation network, the system is:

- Team

. When individual elements are connected using air ducts. - Monoblock supply ventilation

. In this option, most of the elements are combined in one housing.

According to the ventilation method, the supply system is divided into: local, complex and emergency. Based on the presence or absence of an air duct, the classification is:

- Ductless

. When fresh air enters the room through the supply opening. - Duct

. The supply occurs through an air duct system.

Ductless ventilation

The device ensures the injection of clean air into the room due to the operation of the supply unit, due to which the effect of an air curtain or oasis is formed in the intended area of the room. Ductless supply ventilation ensures the removal of contaminated air through a special hole or gap in the door and window. If you have a powerful fan that makes a lot of noise, it must be supplemented with a noise suppressor. Depending on the degree of complexity, supply ventilation is a device that is divided into three types:

- window valve

; - supply fan

; - Supply unit

.

In installations, a filter is installed to filter out impurities, and an air intake grille is installed to protect against debris. Supply and exhaust ventilation for an apartment can be equipped with a system for heating the incoming air; for this, a special element is used that prevents the temperature in the room from falling below a predetermined level. Each owner chooses one or another type for himself, depending on the final purpose of the acquisition and financial capabilities.

Duct ventilation

These devices are a set of air ducts that connect all rooms. What distinguishes them is the need for periodic maintenance to maintain quality of operation. Ducted supply ventilation has one drawback - a large network of air ducts that need to be hidden by the ceiling. This must be taken into account and installation done at the stage of renovation of the premises. The principle of operation of the system is simple - fresh air enters the room through the channels and with its flow displaces the exhaust air through the air intakes.

Often such forced ventilation is installed at large facilities, where heating requires large energy consumption. In order to lower them you can set:

- recuperator;

- water heater;

- VAV system.

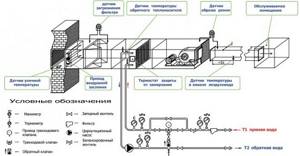

Connection

The supply of air masses can be carried out in one of two options:

- Left version: the mixing unit and automatic control are installed on the left side, water is supplied from the top, outflow is at the bottom.

- Right execution: the indicated mechanisms are on the right, the water supply tube is at the bottom, the “return” is at the top.

The tubes are placed on the side where the air valve is installed.

Water heaters are divided into 2 types according to the type of valve:

- two-way – when connected to a general heating supply;

- three-way – with a closed method of heat supply (for example, when connected to a boiler).

The type of valve is determined by the characteristics of the system supplying heat. These include:

- Type of system.

- Water temperature at the beginning of the process and during outflow.

- With central water supply, the difference between the pressure in the water supply and outflow pipes.

- When autonomous - the presence or absence of a pump installed on the inflow circuit.

The installation diagram must provide for the inadmissibility of installation in the following cases:

- with vertical pipe inlet and outlet;

- with top air intake.

Such restrictions are due to the possibility of snow masses entering the equipment inflow and further leakage of melt water into the electronic unit.

Place of installation of a duct heater for supply ventilation in the air exchange system (if there is a possibility of the temperature dropping below normal, it is obligatory to install an anti-freeze thermostat)

To avoid malfunctions of the automation unit, the temperature sensor must be located in the inside of the air blowing element at a distance of at least 0.5 m from the inflow mechanism.

What is a recuperator and a heater?

Let’s imagine that you not only need to make ventilation in the house, but also achieve compliance with two criteria:

- Forced air injection.

- Heating of premises if necessary.

The recuperator in combination with additional equipment meets the stated requirements. The purpose of measures for retrofitting buildings is:

- Reduce energy costs for heating by supplying the premises with fresh air from the street.

- Control humidity and conserve water vapor as much as possible.

- Monitor the operation of the ventilation system.

A lot of energy is wasted in winter. Reason: it’s cold outside, plus the ventilation takes the lion’s share into the chimney. What if you make the ventilation bring in heat? Look: if we take in cold air from the street, the volume needs to be heated, and there will be expenses for electricity and other energy resources. Let's reduce consumption: due to the energy of the air emitted into the street, taken when leaving the building.

The flow moves along the trajectory of a closed figure eight (infinity sign), giving off some of the heat to the air entering from outside. Through a special permeable membrane, a significant part of the steam enters the heated stream. The air becomes humid and does not dry the room. Let's talk about how a recuperator works and why a heater with a fan is needed.

In the indicated node there is a recuperator, closing the figure eight. Air from the street meets here in an exchanger with room air, but the jets are separated by area (length) by a membrane permeable to water. Under the influence of cold, moisture condenses along the fabric and, under the influence of gravity, begins to seep down to the dry cold stream from the street. As a result, the flow through the membrane simultaneously receives heat and is enriched with moisture (improves the immune system of residents, leaving the mucous membranes in a normal state). That's not all.

Fans are required for the system to function. As a rule, an exhaust one located in the heat exchanger housing. Two are allowed:

- at the room air inlet;

- at the fresh air outlet.

For every turn of the air duct, 10% of the power is lost. The total is divided between rooms and floors. The temperature is sometimes insufficient to maintain the microclimate. A single small recuperator cannot handle such a load. This is where a heater comes in handy.

Design features of the device

Main elements of supply ventilation

- Air intake grille. Acts as an aesthetic design and a barrier that protects debris particles in the supply air masses.

- Supply ventilation valve. Its purpose is to block the passage of cold air from outside in winter and hot air in summer. You can make it work automatically using an electric drive.

- Filters. Their purpose is to clean incoming air. I require replacement every 6 months.

- Water heater, electric heating elements - designed to heat incoming air masses.

- For rooms with a small area it is recommended to use ventilation systems with electric heating elements, for large spaces - a water heater.

Supply and exhaust ventilation elements

Additional items

- Fans.

- Diffusers (contribute to the distribution of air flow masses).

- Noise muffler.

- Recuperator.

The design of ventilation directly depends on the type and method of installation of the system. They come in passive and active action.

Passive ventilation systems.

This device is a supply ventilation valve. The scooping of street air masses occurs due to a pressure difference. In cold weather, the temperature difference contributes to the discharge; in warm periods, the exhaust fan assists. Regulation of such ventilation can be automatic or manual.

Automated regulation directly depends on:

- the flow rate of air masses passing through the ventilation;

- air humidity in the room.

The disadvantage of the system is that in winter, such ventilation for heating the house is not effective, since a large temperature difference is created.

On the wall

Refers to the passive type of supply ventilation. This installation has a compact box that is mounted on the wall. To control heating it is equipped with an LCD display and a control panel. The operating principle is to recuperate internal and external air masses. To heat the room, this device is placed near the heating radiator.

Active ventilation systems

Since in such systems it is possible to regulate the intensity of the fresh air supply, such ventilation systems are more in demand for heating and warming up the room.

According to the heating principle, such a supply heater can be water or electric.

Water heater

Powered by a heating system. The operating principle of this ventilation system is to circulate air through a system of channels and tubes, inside of which there is hot water or a special liquid. In this case, heating occurs in a heat exchanger built into the centralized heating system.

Electric heater.

The operating principle of the system is to convert electrical energy into heat using an electric heating element.

Breezer

This is a compact device, small in size for supply ventilation, with heating. To supply fresh air, this device is attached to the wall of the room.

Breezer Tion o2

Breather design tion o2:

- A duct consisting of an air intake and an air duct. This is a sealed and insulated tube through which the device draws air from the outside.

- Air delay valve. This element is an air gap. It is designed to prevent the outflow of warm air while the device is turned off.

- Filtration system. It consists of three filters that are installed in a certain sequence. The first two filters clean the air flow from visible contaminants. The third filter is a deep cleaning filter from bacteria and allergens. It purifies incoming air from various odors and exhaust gases.

- Fan for air supply from outside.

- Ceramic heater, which is equipped with climate control. Responsible for heating the air flow and automatic temperature regulation.

What else do you need to know?

Thermal water heaters are installed with your own hands in supply ventilation systems and connected to central heating in moderate and cool rooms. For industrial, production and any other types of premises where a warm microclimate reigns, this technique is not used. This does not mean that this device will not work in such conditions - no, it, as in other places, will heat the air and cope with its functional “responsibilities” perfectly, but why heat the air where it is already warm. This is inappropriate and stupid.

Heating device design

The operating mode parameters of the device are specified in its passport, and in order for it to please you with faithful and long service, you need to take them into account. One of the advantages of a water heater with a fan for the ventilation system is that all the conditions for its normal and fruitful functioning exist in any room, including industrial ones - central heating is used everywhere

In addition, the calculation and installation of such equipment is convenient and simple.

One of the advantages of a water heater with a fan for a ventilation system is that all the conditions for its normal and fruitful functioning exist in any room, including industrial ones - central heating is used everywhere. In addition, the calculation and installation of such equipment is convenient and simple.

It can be installed both on the surface of the wall and ceiling. As for the material of manufacture, water heaters, or rather their body, are made of stainless steel. It can be painted in different colors, which allows you to choose the product to match the interior of the room.

By the way, an interesting fact - a thermal water heater can be used as a regular fan. This is important in hot rooms

Moreover, such a fan is characterized by an important feature - it is almost completely silent during operation. An important positive side is also operational safety

Based on the fact that this device requires a minimum of electrical energy (it is only needed to drive the fan), the risk of overvoltage is automatically eliminated, which indicates a high level of safety.

Models and principles of operation of industrial air heaters

LLC T.S.T. produces six models of industrial heaters: water KSk and TVV (hot water coolant); steam KPSk and KP (coolant dry saturated steam); electrical SFO; The production of KFB industrial air heaters is carried out in two versions (with water and steam coolant). Below is brief information about all types of bimetallic spiral air heaters. More detailed information (technical characteristics, overall dimensions, operating parameters, drawings, photographs and tables) for each type of heat exchanger can be viewed by clicking on the link.

- Water heaters KSk

- Steam heaters KPSk

- TVV water heaters

- Steam heaters KP

Industrial heaters KSk (KPSk) manufactured by T.S.T. LLC designed for heating air in ventilation, air heating and air conditioning systems. The heat-dissipating elements are made of electric-welded steel or seamlessly drawn pipe 16×1.5 mm and aluminum rolled fins with a diameter of 39 mm. Finned heat exchangers KSk and KPSk are divided into twelve standard sizes and can have two, three or four rows of heating tubes along the direction of coolant movement.

Finned water heat exchanger KSk is a heating device in which the heating source is hot or superheated water. It is manufactured in a multi-pass design, which is achieved through partitions in the manifold covers. At the same time, the speed of water in the air heater increases, which leads to an increase in the intensity of heat transfer. The operating principle of the KSk industrial heater is that hot water coming from the central heating or hot water boiler circulates inside the heat exchanger tubes. The cold air flow, forced by the fan, passes through the interfin space of the heat-transfer elements, is heated and supplied to the room being served.

KPSK finned steam heat exchanger is a heating device in which the coolant is dry saturated or superheated steam. The air heater is made in a single-pass design. The coolant passes through all the tubes simultaneously, which implies very fast and uniform heating of the air flow throughout the entire cross-section of the heater. It is advisable to use heat exchangers of the KPSK series for industries that are connected to process steam pipelines. A steam boiler can also serve as a source of primary coolant.

Industrial heaters TVV (KP) manufactured by T.S.T. LLC designed for heating air in air conditioning and ventilation systems, air heating, and technological drying units. The heat-dissipating elements are made of straight-seam or seamless steel pipe 22×1.5 mm and aluminum rolled fins with a nominal diameter of 41 mm. TVV and KP finned heat exchangers are divided into seven standard sizes and are manufactured with three and four rows of heating tubes in the direction of coolant movement.

Increased cross-sectional area for coolant passage, expressed in the use of support tubes with a diameter of 22 mm, in contrast to other air heaters of the KSk (KPSk), KVS (KPS), KVB (KPB), VNV (VNP) types, which use heating elements with a diameter of 12 and 16 mm, provides a number of advantages. These include: lower hydraulic resistance of the heater, longer service life, preservation of stable thermal characteristics, the ability to operate at low temperatures of external supply air.

TVV air heater - the source of heat exchange is hot water flowing in the tubes. From the outside, these finned tubes are washed with air less heated than water. Air movement is created by a fan. As a result of heat exchange, the water in the heat exchanger tubes is gradually cooled, and the air is sequentially heated as it passes through the rows of finned tubes.

The gearbox air heater is a source of heat exchange - water vapor. Due to the existing temperature difference between the steam-condensate mixture and the air, heat transfer occurs, as a result of which the air heats up and the steam condenses.

Industrial heaters TVV (KP) are indispensable in poor operating conditions. This is the best choice for creating process heat in workplaces of industrial workshops, ventilating mine workings at mining and metallurgical enterprises in Siberia and the northern regions of the country.

Industrial heaters KFB-A manufactured by T.S.T. LLC - medium-sized air heaters that use steam and hot water to produce heat. KFB steam heaters differ from water heaters in that they are made in a single-pass design, installed with a vertical arrangement of heat exchange elements, steam passes through the tubes in parallel once. The coolant is supplied to the heating unit from above, and the water condensed from the exhaust steam is removed from below. The operating principle of multi-pass air heater models involves multiple sequential movements of water flow. KFB water heaters are installed with a horizontal arrangement of heat exchange elements; the coolant is supplied and removed from the side.

The technical qualities of this heat exchanger model with an increased cross-section for the passage of coolant are developed at a high level. In terms of overall dimensions and built-in design, the assembly and installation of several KFB thermal modules is the best option for assembling air heating units in areas with an estimated outside temperature for the cold period of the year below minus 30 degrees. Heat exchangers are divided into thirteen standard sizes. Air flow design of three A3 and four in-line A4. Air productivity range from 2000 to 18000 m3/hour, thermal power from 40 to 500 kW. KFB air heaters are widely used at various mining enterprises.

How do water heaters work?

Operating principles of water heaters and their installation

Heaters, as devices for heating premises, are divided into types: there are water, steam and electric heaters. In this article we will look at the operating principles of water heaters. The heater is covered with a metal casing with a ribbed surface. Water heaters operate on water, which, when heated, simultaneously heats the air passing through the heater. Such devices are quite compact and do not require complex installation or sufficient space. Heaters operating on water have a fairly high level of performance, thanks to a wide temperature range - from 70 to 100 degrees. And if you need to buy warm bed linen in Moscow for a comfortable and restful sleep, then a water heater will also suit you, which will maintain the desired temperature in the bedroom without high energy costs.

The maximum temperature of the heater water should not go beyond 180°C. By following this rule, you can greatly increase the service life of the device, as well as ensure its productive and uninterrupted operation. When using the heater, it is necessary to follow the operating instructions and also properly monitor all functions and operation of the heater. Otherwise, the water heater may deteriorate beyond repair.

Heated water from the central heating system passes through a heat exchanger, which is blown by a powerful fan. The latter evenly distributes heated air throughout the room. A water heater, despite the use of hot water, is considered an air heating device. The heater housing allows its installation in both vertical and horizontal positions.

The heating intensity is adjusted using two- or three-way valves, which are installed on the supply line. Heaters that are mounted on the wall are distinguished by a variety of models and are most often used compared to ceiling models. They can be used either as a single unit or in combination with several units that make up a reliable heating system.

This type of air heating is recommended for use in moderate, even cool climates. Of course, it will also work in a warm room, but this is not considered advisable. It is necessary, as far as possible, to adhere to the standard parameters of the water heater operating mode; they should not be below or exceed the permissible temperature threshold.

Advantages of water heaters

- The device is mounted both on the wall and on the ceiling.

- The water heater can be connected to the central heating system in any room.

- The case is made of stainless steel, and the enamel of different colors will suit almost any interior.

- During the hot season, the water heater turns from a heating device into a silent fan.

- It is safe to use due to the absence of overvoltage.

- Modern water heaters undergo numerous modernizations; for example, some models use a special nozzle as a thermal curtain.

Advantages of air heating:

- the set temperature is reached instantly

- installation does not require large expenses

- low cost of operation

- high heating output

- low weight of the structure

- corrosion resistance

- Possibility of fastening with studs

For each model, the thermal output depends, of course, on the temperature of the water leaving the central heating system: the higher the temperature, the greater the thermal output. These heat guns are also used for heating large rooms, but are distinguished by their energy-saving properties. They are installed for heating in places such as pavilions and car showrooms, gyms, shopping and entertainment centers, shops and supermarkets; car services, greenhouses, warehouses, hangars.

Operating principle and design features

Universal devices operating on water are installed in places with a well-established heat supply system. A simple but quite effective design solution allows you to heat air in the range from + 70 ° C to + 100 ° C and is relevant for hangars, gyms, supermarkets, greenhouses, warehouses, large pavilions - that is, large premises that require additional heating.

An example of using a VOLCANO air heater in a greenhouse. Heating is carried out by distributing warm air (water temperature - +90º C) using a fan and adjustable blinds

If you have ever used a household heat heater, you will easily understand the principle of operation of a water device. It also heats the air, but the role of an electric spiral enclosed in a small housing is played by a set of metal tubes through which the heated coolant circulates.

The heating process is as follows:

- hot water, heated to the required temperature (on average from + 80 ° C to + 180 ° C), from the heating pipes enters a heat exchanger consisting of small aluminum, steel, bimetallic or copper tubes;

- the tubes heat the air passing through the device;

- The built-in fan distributes heated air throughout the room and stimulates its movement in the opposite direction - towards the device.

There is no need to specially heat the water, since it is part of the heating system, so significant cost savings occur.

Design of a water duct heater type 60-35-2 made of galvanized steel, intended for ventilation and air conditioning systems. Typical duct size – 60 cm x 35 cm, row – 2, maximum operating pressure – 1.5 MPa, maximum coolant temperature – + 170 ºС

The design of a standard water heater is a hybrid of a heat exchanger, fan and convector. It is effective for heating large industrial premises, and, when choosing the right piping, also for cottages with a well-established ventilation system.

Efficiency of using air heaters instead of heating radiators

The coolant circulating through water heating radiators transfers thermal energy to the surrounding air through thermal radiation, as well as through the upward movement of convection flows of heated air and the entry of cooled air from below.

The heater, in addition to these two passive methods of transferring thermal energy, drives air through a system of heated elements with a much larger area and intensively transfers heat to them. Assessing the efficiency of heaters and fans allows for a simple calculation of the cost of installed equipment for the same tasks.

For example, it is necessary to compare the cost of radiators and heaters for heating the showroom of a car dealership, taking into account compliance with SNIP standards.

The heating main is the same, the coolant is the same temperature, piping and installation can be ignored in a simplified calculation of the costs of the main equipment. For a simple calculation, we take the known norm of 1 kW per 10 m2 of heated area. A hall with an area of 50x20 = 1000 m2 requires a minimum of 1000/10 = 100 kW. Taking into account a margin of 15%, the calculated minimum required heating capacity of heating equipment is 115 kW.

When using radiators. We take one of the most common bimetallic radiators Rifar Base 500 x10 (10 sections), one such panel produces 2.04 kW. The minimum required number of radiators will be 115/2.04 = 57 pcs. It’s immediately worth considering that placing 57 radiators in such a room is unreasonable and practically impossible. If the price of a device for 10 sections is 7,000 rubles, the cost of purchasing radiators will be 57 * 7000 = 399,000 rubles.

When heating with air heaters. To heat a rectangular area in order to distribute heat evenly, we select from 5 Ballu BHP-W3-20-S water heaters with a capacity of 3200 m3/hour each with a similar total power: 25 * 5 = 125 kW. Equipment costs will be 22900*5 = 114,500 rubles.

The main area of application of air heaters is the organization of heating of rooms with large spaces for air movement:

- production workshops, hangars, warehouses;

- gyms, exhibition pavilions, shopping centers;

- agricultural farms, greenhouses.

Compact devices that allow you to quickly heat air from 70°C to 100°C, easily integrated into the overall automatic heating control system, are advisable to use in buildings with reliable access to coolant (water, steam, electricity).

The advantages of water heaters are:

- High profitability of use (low cost of equipment, high heat transfer, ease and low cost of installation, minimal operating costs).

- Fast air heating, ease of change and localization of heat flow (thermal curtains and oases).

- Reliable design, ease of automation and modern design.

- Safe to use even in high-risk buildings.

- Extremely compact dimensions with high heating output.

The disadvantages of these devices are related to the properties of the coolant:

- At temperatures below zero, the heater is easy to freeze. If water is not drained from the pipes in time, they can break if disconnected from the main line.

- When using water with a large amount of impurities, the device can also be damaged, so using it at home without filters and connecting it to a central system is impractical.

- It is worth noting that air heaters dry out the air greatly. When used, for example, in a showroom, humidifying climate control technology is required.

Installation features

When installing a heater, its technical characteristics and the air exchange pattern in the room are taken into account. Among several installation options, the most popular is the one that ensures mixing of recirculated air with supply air flows.

If natural air exchange works well in the room, the device can be installed in the heating system directly at the air intake located in the basements of buildings. If there is supply ventilation, the equipment may be installed in any convenient location. To create a knot tie in this case you will need:

- heater;

- pump;

- ball valve;

- thermomanometer;

- stub;

- Mayevsky crane;

- detachable connection (in the form of a union nut);

- valve (three-way or two-way).

Today, ready-made models of strapping units in various designs are available for sale. Some of them, in addition to the main set of parts, contain balancing and check valves, as well as cleaning filters that prevent clogging and rapid equipment breakdown.

Industrial water heating heaters with a fan are very large, so their installation and connection are carried out by qualified specialists using the appropriate equipment. Devices intended for household use are much smaller and lighter, so you can handle their installation yourself. You just need to check in advance the strength of the ceiling or wall on which the heater will be mounted. Concrete and brick floors are characterized by the greatest strength, wooden floors have medium strength, and plasterboard structures have the minimum strength.

After choosing the optimal location, you can proceed to installation. First you need to secure a bracket with holes, which will hold the device body. Then hang the heater and connect the pipes and mixing unit (its partial installation can be carried out before installing the heater).

Insertion into the heating system is carried out by welding metal pipes or using connecting fittings. To avoid changing the position of the device, it is necessary to eliminate the load on the pipes, and replace rigid parts with flexible ones. In order to isolate the system and prevent leaks, it is recommended to treat the connections with sealant.

Strapping methods

The heater piping is a complex of devices and elements for regulating the supply of coolant to the device. It includes the following elements:

- Pump.

- Two or three way valve.

- Measuring instruments.

- Shut-off valves.

- Filter.

- Bypass.

Depending on the operating conditions, these elements can be located in close proximity to the device, or at a considerable distance from it. Based on the connection conditions, there are:

- Flexible harness. Mounted on control units located next to the device. The installation of such harnesses is considered easier, since it makes it possible to carry out all work on threaded connections, with virtually no need for welding.

- Rigid harness. Used on devices remote from control nodes and requiring strong communications.

Despite the difference in installation techniques, both types perform the same function - they provide setting and adjustment of the heater operating mode.

Types of heaters

There are several types of air heaters used in different areas and conditions.

Let's take a closer look at them:

Mermen

The most common group of devices, characterized by high efficiency, safety and ease of operation. They use hot water as a coolant, coming from the central heating network, hot water supply or from their own boiler. A water heater for fresh air ventilation is the most convenient and economical solution, allowing you to perform the assigned tasks with minimal maintenance or repair costs. The only drawback of the device is the need to connect to the coolant supply system, which creates certain difficulties at the installation stage and prevents quick transfer to another location.

Steam

Steam devices are complete analogues of water devices and in practice differ from them only in the type of coolant. The only difference between steam devices is the greater thickness of the tube walls - 2 mm versus 1.5 for water ones. This is due to the high pressure in the system, requiring reinforced channels for circulation. Otherwise, the devices are identical and have the same operating rules and requirements.

Electrical

An electric heater for supply ventilation does not require a coolant supply, since the heating source is electric current. Connecting such devices is much simpler, which makes them mobile and easy to use, but high energy costs limit the use of this group. Most often, they are installed for local heating when performing one-time work, and are used as emergency or temporary heat sources.

Installation recommendations

Experts advise adhering to the following recommendations when doing the installation yourself:

- The diagonal dimensions of the heater determine the distance to the bend of the channel, damper, and other elements of the system.

- In order for an air supply unit with a water heater to work effectively, it must be installed in rooms where the temperature is not lower than zero degrees. Because otherwise the heater may freeze.

- When starting installation, double check the integrity of the plates, tubes and other components.

- Connection using butt-welded flanges (or others, it all depends on the location) is considered the simplest solution for connecting a device to a pipeline.

- It is recommended to place direct-flow air exhaust valves in the highest sections of the supply and discharge manifolds.

- The connection of the heater to the ventilation components must be made using sealants at the joints. This will help prevent accidents in the future.

- You can also do the piping and connection of the water heater yourself, because this process cannot be called extremely complicated. But if you do not have experience in such work and you are not confident in your abilities, then it is better to entrust these activities to professionals.

Pros and cons of using

If the enterprise has its own heat supply system, the use of air heaters for supply ventilation of production premises is as cost-effective as possible.

A set of water fan heaters for servicing a warehouse. Air heaters with an air flow rate of 5200 m³/h and a coolant temperature of + 130 ºС heat the air and maintain the set temperature

Advantages of devices connected to a centralized system:

- simple installation, no different in complexity from installing heating pipes;

- rapid heating of a large room;

- safety of operation of all components;

- possibility of adjusting the flow of heated air;

- strict industrial design.

But the main advantage is the absence of regular financial investments - payment occurs only when purchasing new equipment.

Current prices for KSK bimetallic water heaters produced by Novosibirsk, which manufactures heating equipment. The final price depends on the basic configuration and technical characteristics

The main disadvantage is considered to be the impossibility of using water models in everyday life, especially in urban housing. An alternative is to use electrical appliances.

Another nuance concerns negative temperatures: the equipment must be installed in rooms where the minimum threshold does not fall below 0 °C.

There are practically no wearing parts in the design of the water heater. They rarely fail and require serious repairs, which should also be included in the “treasury” of equipment advantages

Operating rules and repair possibilities

The basic requirements for the operation and safety of the device are set out in the passport. They are aimed at eliminating emergency situations caused by exceeding the permissible temperature or pressure of the coolant, avoiding a sharp increase in the temperature of the complex during the first start-up in the cold season

Particular attention should be paid to the risk of freezing of the device tubes in winter, which can lead to failure of the device. Specialized organizations should be involved in repairing devices; independent intervention most often only increases the severity of the problem

Advantages and disadvantages

The use of water heaters for heating has a number of advantages. The main one is energy efficiency. Spending a minimum of electricity (only on fan operation), they show a fairly high heat transfer coefficient.

Water heaters create strong temperature changes of the order of 70-100 degrees. Thanks to this, the required temperature regime in a room of any size is ensured very quickly.

You don’t need to spend a lot of money on purchasing and installing devices. Operation and maintenance are also cheap. The devices are universal, mounted on the ceiling or walls. Apart from centralized heating, no other systems are required for their operation.

The main disadvantage of such heaters is their large size. It is impossible to install bulky structures in an ordinary apartment. Finding more compact and lightweight models for everyday use is not easy.

Related Posts

- Supply ventilation steam heater piping

- How to choose and install an air valve for heating

- Connection diagrams for bimetallic radiators

- A supply of hot water that is always at hand: how does an electric water heater for heating work?

- How to make steam heating

- Split system with ultraviolet lamp for air purification

- Calculation of general and local ventilation of production premises

- Features and procedure for calculating exhaust and supply ventilation

- Radiators built into the floor: design

- Do-it-yourself air heating: everything about air heating systems

- Pros and cons of air distribution from the floor

- Hydroarrow: principle of operation, purpose and calculations

- Air-to-air heat pump and its prices

- Leningrad heating system for a private house

- Ventilation with heating

- Ventilation shaft in a multi-storey building

- Air exchange in residential premises: what you need to know for a comfortable life

- At what temperature of the coolant is the heating system turned off and turned on in an apartment building according to GOST

- What to do if the bottom of the battery is cold and the top is hot?

- How to make a dehumidifier with your own hands

- Pipe box

- Defrosting the sewer

- Economical heating of a private house and apartment

- How to glue fiberglass correctly?

- Installation and connection of the expansion tank

Read with this

- Supply ventilation steam heater piping

- How to choose and install an air valve for heating

- Connection diagrams for bimetallic radiators

- A supply of hot water that is always at hand: how does an electric water heater for heating work?

- How to make steam heating

- Split system with ultraviolet lamp for air purification

- Calculation of general and local ventilation of production premises

- Features and procedure for calculating exhaust and supply ventilation

- Radiators built into the floor: design

- Do-it-yourself air heating: everything about air heating systems

Types of systems

Heated ventilation comes in several types; they are classified according to different criteria: heating method, mounting location, design, etc.

Central and individual ventilation

All types of ventilation can be divided into 2 main types: central and individual (compact, or breather).

Central ventilation is used when it is necessary to supply clean air to a large room. It has high performance.

It is used in industries and installed on general building ventilation systems. The air is heated from a water or electric heater; a recuperator is less often used. Such equipment is expensive.

Breathers are used for individual ventilation. These are compact devices that are installed in apartments and private houses. They are usually placed on the wall.

Installation is quick and takes no more than an hour. You can install such equipment in any home. The device has many settings, a climate control function, and a multi-stage cleaning system.

Active and passive ventilation

In this case, separation is used to regulate the supply of fresh air.

Passive designs do not have this feature. Air masses arrive due to the pressure difference between the room and the street.

The amount of air supplied depends on the speed of its movement, temperature differences and humidity levels. Most often, the device is mounted on a wall; it consists of a small box.

Active ventilation systems allow you to control the air supply. Outwardly, they are similar to passive ones, but the control unit allows you to regulate not only the temperature, but also the intensity of the flow.

By heating type

Supply ventilation may differ in the method of heating the air.

The following types of devices are distinguished:

- with recovery. In this case, the incoming air is heated by the outgoing air. Used in passive ventilation systems. Suitable for regions with warm winters, because with large temperature differences it is ineffective;

- with water heating. In this case, central heating or a boiler is used for heating. Allows significant savings on electricity;

- electric. Ventilation uses a heating element that runs on electricity. It heats the passing air to the desired temperature.

Other types

Devices are also divided according to the method of pumping air masses into natural and forced. In the second case, fans are used to supply them.

Devices are also divided by type of control. There are automatic devices that are controlled from a remote control or through an application on a smartphone. The second type is manual, the operation settings of which are set on a stationary control unit.

According to their design, they are divided into monoblock and mounting ones. The first ones consist of one block installed at the entrance to the ventilation duct. They are used when installing an air inlet in a wall or window frame.

The devices have low performance and are suitable for small rooms. Mounting devices consist of many elements.

They are used in the arrangement of central ventilation. Their power is enough to supply multi-storey buildings and production workshops with fresh air.