To solve air exchange issues in private homes and industrial buildings, along with fans, devices are used that heat or cool the air that comes from the street. This helps improve the characteristics of the indoor microclimate and increase the level of comfort.

One of the economical and affordable devices is a water heater for fresh air ventilation, more familiar to residents of the northern regions. From our material you will learn about the operating principles and design features of equipment of this type. We will also talk in detail about several popular models of air heaters for ventilation.

Kinds

Heaters for supply ventilation are classified according to the type of heat source and can be water, steam and electric.

Water models

They are used in all types of ventilation systems and can be of two- or three-row design. The devices are installed in ventilation systems of rooms whose area exceeds 150 square meters. This type of heater is absolutely fireproof and least energy-consuming, due to the possibility of using water from the heating system as a coolant.

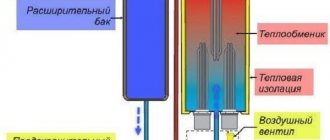

The principle of operation of water heaters is as follows: street air is taken in through air intake grilles and supplied through an air duct to coarse filters. There, the air masses are cleaned of dust, insects and small mechanical debris, and enter the heater. A copper heat exchanger is installed in the heater body, consisting of links arranged in a checkerboard pattern and equipped with aluminum plates. The plates significantly increase the heat transfer of the copper coil, which significantly increases the efficiency of the device. The coolant flowing through the coil can be water, antifreeze or a water-glycol solution.

Cold air flows passing through the heat exchanger take heat from metal surfaces and transfer it into the room. The use of water heaters makes it possible to heat air flows up to 100 degrees, which provides ample opportunities for their use in sports facilities, shopping centers, underground parking lots, warehouses and greenhouses.

Along with obvious advantages, water models have a number of disadvantages. The disadvantages of the devices include the risk of water freezing in pipes when temperatures drop sharply, and the inability to use heating in the summer when the heating system is not functioning.

Steam models

They are installed at industrial enterprises where it is possible to produce large amounts of steam for technical needs. Such air heaters are not used in domestic supply ventilation systems. Steam acts as a heat carrier for these installations, which explains the instant heating of passing flows and the high efficiency of steam heaters.

To prevent this from happening, all heat exchangers undergo a leak test during the production process. Tests are carried out using jets of cold air supplied under a pressure of 30 bar. The heat exchanger is placed in a tank with warm water.

Electric models

They are the simplest option for heaters and are installed in ventilation systems serving small spaces. Unlike water and steam heaters, an electric heater does not require the installation of additional communications. To connect them, it is enough to have a 220 V outlet nearby. The principle of operation of electric heaters is no different from the principle of operation of other heaters and consists in heating air masses passing through heating elements.

Even with a slight decrease in this indicator, the electric heating element overheats and breaks down. More expensive models are equipped with bimetallic thermal switches that turn off the element in case of obvious overheating.

The advantages of electric heaters are simple installation, no need for piping, and independence from the heating season. The disadvantages include high energy consumption and the inappropriateness of installation in powerful ventilation systems serving large spaces.

Differences in air heaters by tube type

Heating heaters may differ in the type of tubes used to transfer heat. The following models of such devices are distinguished:

- Smooth tube - products consist of a large number of thin hollow pipes.

- Plate devices have fins, which significantly increases their heat transfer.

- Bimetallic - such products use tubes made of copper and aluminum. Copper ones transfer heat, and collectors are made of aluminum.

Attention ! Caloriferous smooth-tube heating is the least efficient, but the cost of such products is noticeably lower.

Water heaters

Daikin ATXN25MB/ARXN25MB for RUB 34,500. DAIKIN inverter air conditioners. Installation from 7000 rub.

Water heat guns (water heater) are heating devices in which the heat source is hot water.

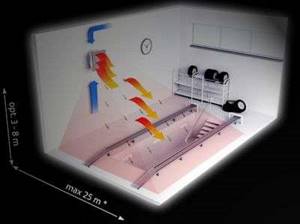

The principle of operation is simple: a powerful fan blows on the heat exchanger through which the hot water of the central heating system passes. Thus, the fan quickly and evenly distributes hot air throughout the heated room. Despite the use of hot water, a water heater with a fan is classified as an air heating device.

Advantages of air heating:

quickly achieving the set room temperature; low installation costs; low operating costs; high thermal performance.

The heating output of each model depends on the temperature of the water in the central water heating system. The higher the temperature of the water in the system, the greater the thermal power produced by the water heat gun. The maximum temperature of the coolant (water) is usually limited to 130ºС. Water heat guns are used for economical heating of large premises, such as:

exhibition pavilions and car shows; shopping and entertainment complexes; gyms and sports palaces; shops and hypermarkets; workshops and car services; farms and greenhouses; hangars and warehouses.

Water heaters are available for wall and ceiling mounting. To regulate the temperature in a heated room and save energy resources together with the air heating units themselves

VOLCANO fan heater VR series (VULCAN fan heater); water heat generator GALLETTI AREO series; water heat generator KROLL LH series; water heat generator Olefini fan heater and fan coil of the FH series (olefin heat gun on water); the units use special automation kits. To connect water heat guns, a water heater piping unit is usually used (circulation pump, automatic three-way valve, fittings and automation). The following water heat guns are best known on the Russian market:

If you want to place an order or have any questions, call our sales department on our multi-line phone number (495) 98-91091. Our managers will be happy to select water heaters or other types of heaters that are suitable for you and your premises in terms of type, power and cost. Due to the very large volume of material, we provide here information only on Galletti air heaters, but you can order olefini, kroll, general water heaters and volcano vr fan heaters from us.

Upon request, we will provide the information you need.

Features of water heaters - VOLCANO fan heaters:

VOLCANO MINI price 13800 rub.

.

Heating power 3-20 kW

VOLCANO VR1 price 18,300 rub.

.

Heating power 10-30 kW

VOLCANO VR2 price 20,900 rub.

.

Heating power 30-60 kW

- simple installation;

- modern design;

- low noise level;

- low weight of the structure;

- high equipment efficiency;

- resistance to corrosion processes;

- resistance to thermal influences;

- possibility of attaching Volcano using studs (not included);

- the flow direction of the VOLCANO VR fan heater can be changed during operation up to 180º (mounting console RUB 1,900 and flexible hose RUB 550 - options, not included);

Options:

- thermostat 2000 rub.;

- mounting console RUB 1,900;

- two-position valve with servo drive RUB 3,600;

- flexible hose 550 rub. (usually connect 2 pieces per Volcano);

- 5-stage fan speed control RUB 4,400.

Showing 1 to 99 of 99

They are made from steel and aluminum, which guarantees reliable operation for a long time.

They are installed in the air conditioning system and make the air coming from the street warm, which makes staying in the room comfortable.

They use hot water and high-pressure steam as a heat source, and because of this, their use is only possible in manufacturing plants.

Where to buy a water industrial fan heater in Moscow?

The equipment is highly safe. Today, devices of various capacities are successfully used for heating shopping malls, warehouses and production facilities, greenhouses, gyms, service stations, garages, and livestock farms. Even devices of not very high power and dimensions are capable of heating very large rooms due to their high performance. If necessary, water heaters in Moscow will help create entire heating systems. This will significantly reduce heating costs. The equipment is popular because it allows you to instantly create comfortable conditions and performs fast, targeted heating. The heating speed increases several times.

Today there are several types of heaters, and one of them is a ducted water heater for the supply ventilation system. Compared to their electric counterparts, thermal water heaters require significantly less electricity. However, if you intend to calculate and install them yourself, you should know that this will be somewhat more difficult to do than in the case of electrical appliances.

Connecting an electric heater

In electrical types, the main parameter is the power in kW; accordingly, it requires caution and compliance with safety precautions when connecting it. This option uses a control unit that is capable of controlling the room temperature

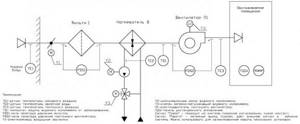

When the indoor temperature is below the set temperature, the heater automatically turns on. Using a thermostat, you can maintain the set temperature and be protected from heating the device over 140 degrees.

The way it works is that when the “Start” button is pressed, the engine and heater ventilation start. A thermal relay at a certain current is connected to the motor. In case of problems with ventilation, the thermal relay is triggered, after which the power circuit is opened.

When the heater fan is on, you can turn on the heating elements by closing the blocking contacts. The heating elements are turned on using the “Start” button. At this time, the intermediate starter is turned on, which activates a powerful starter, which turns on the heating elements through its contacts. For the fastest possible heating, all heaters turn on immediately.

- For fire protection, the circuit includes the following elements:

- Thermal relay that protects the engine when stopped;

- Protection against switching on without a fan;

- Thermal relay, which protects the heater housing from overheating. While the thermostat is activated, the fan will continue to operate and cool it down.

The circuit can be supplemented with a starter power-on indicator and an emergency indicator. In addition, it is advisable to install an automatic switch on the circuit that powers the heating elements, as well as a more powerful circuit breaker at the input of the device. Circuit breakers should not be installed on fans.

To control the heater, a control cabinet is installed, which should be located near the heater. The shorter the distance, the smaller the wire cross-section can be used.

What else do you need to know?

Thermal water heaters are installed with your own hands in supply ventilation systems and connected to central heating in moderate and cool rooms. For industrial, production and any other types of premises where a warm microclimate reigns, this technique is not used. This does not mean that this device will not work in such conditions - no, it, as in other places, will heat the air and cope with its functional “responsibilities” perfectly, but why heat the air where it is already warm. This is inappropriate and stupid.

Heating device design

The operating mode parameters of the device are specified in its passport, and in order for it to please you with faithful and long service, you need to take them into account. One of the advantages of a water heater with a fan for the ventilation system is that all the conditions for its normal and fruitful functioning exist in any room, including industrial ones - central heating is used everywhere

In addition, the calculation and installation of such equipment is convenient and simple.

One of the advantages of a water heater with a fan for a ventilation system is that all the conditions for its normal and fruitful functioning exist in any room, including industrial ones - central heating is used everywhere. In addition, the calculation and installation of such equipment is convenient and simple.

It can be installed both on the surface of the wall and ceiling. As for the material of manufacture, water heaters, or rather their body, are made of stainless steel. It can be painted in different colors, which allows you to choose the product to match the interior of the room.

By the way, an interesting fact - a thermal water heater can be used as a regular fan. This is important in hot rooms

Moreover, such a fan is characterized by an important feature - it is almost completely silent during operation. An important positive side is also operational safety

Based on the fact that this device requires a minimum of electrical energy (it is only needed to drive the fan), the risk of overvoltage is automatically eliminated, which indicates a high level of safety.

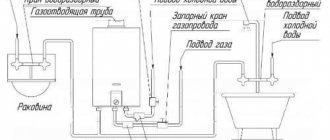

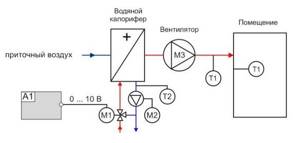

Connection diagram and control

Electric heaters must be connected in compliance with all safety requirements. The connection diagram for the electric heater is as follows: when you press the “Start” button, the engine starts and the heater ventilation is turned on. At the same time, the engine is equipped with a thermal relay, which, if there is a problem with the fan, instantly opens the circuit and turns off the electric heater. It is possible to turn on the heating elements separately from the fan by closing the blocking contacts. To ensure rapid heating, all heating elements are turned on simultaneously.

To increase the safety of the electric heater, the connection diagram includes an emergency indicator and a device that prevents the heating elements from turning on when the fan is turned off. In addition, experts recommend including automatic fuses in the circuit, which should be placed in the circuit together with the heating elements. But installing automatic machines on fans, on the contrary, is not recommended. The heater is controlled from a special cabinet located near the device. Moreover, the closer it is located, the smaller the cross-section of the wire connecting them can be.

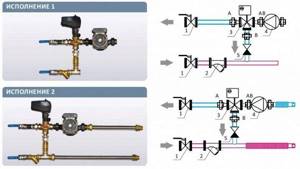

When choosing a water heater connection diagram, you need to focus on the placement of mixing units and units with automation. So, if these units are located to the left of the air valve, then a left-hand design is implied, and vice versa. For each version, the location of the connecting pipes corresponds to the air intake side with the installed valve.

There are a number of differences between left and right placement. So, with the right-hand version, the water supply tube is located at the bottom, and the “return” tube is located at the top. In left-sided circuits, the supply pipe enters from the top, and the outflow pipe is located at the bottom.

When installing a heater, it is necessary to install a piping unit necessary to monitor the performance of the device and protect it from freezing. Piping nodes are the reinforcement frames that regulate the flow of hot water into the heat exchanger. Piping of water heaters is done using two- or three-way valves, the choice of which depends on the type of heating system. Thus, in circuits heated by a gas boiler, it is recommended to install a three-pass model, while for systems with central heating, a two-pass model is sufficient.

Controlling a water heater involves regulating the thermal power of heating devices. This is made possible by the process of mixing hot and cold water, which is carried out using a three-way valve. When the temperature rises above a set value, the valve releases a small portion of cooled liquid into the heat exchanger, which is taken at the outlet.

In addition, the installation diagram of water heaters does not provide for the vertical arrangement of inlet and outlet pipes, as well as the location of the air intake at the top. Such requirements are due to the risk of snow getting into the air duct and melt water flowing into the automation. An important element of the connection diagram is the temperature sensor. To obtain correct readings, the sensor must be placed inside the air duct in the blowing section, and the length of the flat section must be at least 50 cm.

Advantages and disadvantages

The use of water heaters for heating has a number of advantages. The main one is energy efficiency. Spending a minimum of electricity (only on fan operation), they show a fairly high heat transfer coefficient.

Water heaters create strong temperature changes of the order of 70-100 degrees. Thanks to this, the required temperature regime in a room of any size is ensured very quickly.

You don’t need to spend a lot of money on purchasing and installing devices. Operation and maintenance are also cheap. The devices are universal, mounted on the ceiling or walls. Apart from centralized heating, no other systems are required for their operation.

The main disadvantage of such heaters is their large size. It is impossible to install bulky structures in an ordinary apartment. Finding more compact and lightweight models for everyday use is not easy.

Related Posts

- Supply ventilation steam heater piping

- How to choose and install an air valve for heating

- Connection diagrams for bimetallic radiators

- A supply of hot water that is always at hand: how does an electric water heater for heating work?

- How to make steam heating

- Split system with ultraviolet lamp for air purification

- Calculation of general and local ventilation of production premises

- Features and procedure for calculating exhaust and supply ventilation

- Radiators built into the floor: design

- Do-it-yourself air heating: everything about air heating systems

- Pros and cons of air distribution from the floor

- Hydroarrow: principle of operation, purpose and calculations

- Air-to-air heat pump and its prices

- Leningrad heating system for a private house

- Ventilation with heating

- Ventilation shaft in a multi-storey building

- Air exchange in residential premises: what you need to know for a comfortable life

- At what temperature of the coolant is the heating system turned off and turned on in an apartment building according to GOST

- What to do if the bottom of the battery is cold and the top is hot?

- How to make a dehumidifier with your own hands

- Pipe box

- Defrosting the sewer

- Economical heating of a private house and apartment

- How to glue fiberglass correctly?

- Installation and connection of the expansion tank

Read with this

- Supply ventilation steam heater piping

- How to choose and install an air valve for heating

- Connection diagrams for bimetallic radiators

- A supply of hot water that is always at hand: how does an electric water heater for heating work?

- How to make steam heating

- Split system with ultraviolet lamp for air purification

- Calculation of general and local ventilation of production premises

- Features and procedure for calculating exhaust and supply ventilation

- Radiators built into the floor: design

- Do-it-yourself air heating: everything about air heating systems

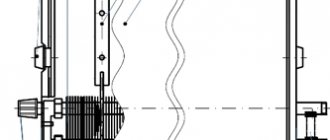

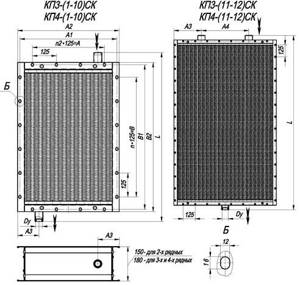

Overall and connection dimensions of KPSK steam heaters

| Overall dimensions, mm | KP3-1 | KP3-2 | KP3-3 | KP3-4 | KP3-5 | KP3-6 | KP3-7 | KP3-8 | KP3-9 | KP3-10 | KP3-11 | KP3-12 |

| KP4-1 | KP4-2 | KP4-3 | KP4-4 | KP4-5 | KP4-6 | KP4-7 | KP4-8 | KP4-9 | KP4-10 | KP4-11 | KP4-12 | |

| A | 250 | 250 | 250 | 250 | 250 | 375 | 375 | 375 | 375 | 375 | 875 | 1375 |

| A1±3 | 426 | 426 | 426 | 426 | 426 | 551 | 551 | 551 | 551 | 551 | 1050 | 1551 |

| A2 | 450 | 450 | 450 | 450 | 450 | 575 | 575 | 575 | 575 | 575 | 1075 | 1575 |

| A3 | 82,5 | 82,5 | 82,5 | 82,5 | 82,5 | 82,5 | 82,5 | 82,5 | 82,5 | 82,5 | 290 | 415 |

| A4 | — | — | — | — | — | — | — | — | — | — | 495 | 745 |

| B | 500 | 625 | 750 | 875 | 1125 | 500 | 625 | 750 | 875 | 1125 | 1625 | 1625 |

| B1±3 | 578 | 703 | 828 | 953 | 1203 | 578 | 703 | 828 | 953 | 1203 | 1703 | 1703 |

| B2 | 602 | 727 | 852 | 977 | 1227 | 602 | 727 | 852 | 977 | 1227 | 1727 | 1727 |

| L | 700 | 825 | 950 | 1075 | 1325 | 700 | 825 | 950 | 1510 | 1325 | 1825 | 1825 |

| Du | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 65 | 80 |

| n | 4 | 5 | 6 | 7 | 9 | 4 | 5 | 6 | 7 | 9 | 13 | 13 |

| n2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 7 | 11 |

| Vm3 | 0,057 | 0,067 | 0,077 | 0,122 | 0,107 | 0,072 | 0,8 | 0,093 | 0,106 | 0,132 | 0,343 | 0,503 |

Multi-channel telephone

Price and review of models

Water heaters for supply ventilation VNV or KSk, products of the group, are widely used. The units meet quality requirements. They have a wide range of models so that the buyer can select equipment for a ventilation system of any complexity and length. The pricing policy of the domestic company is relatively gentle:

- KSk 3-6 (2500 m3/h) Steel – 5.5 thousand rubles. Stainless steel – 15 thousand rubles.

- KSk 3-11 (16000 m3/h) Steel – 20 thousand rubles. Stainless steel – 48 thousand rubles.

- KSk 4-8 (4000 m3/h) Steel – 8 thousand rubles. Stainless steel – 21 thousand rubles.

- Galletti AREO 12 (power – 5.9-6.7 kW, capacity up to 790 m3/h, cooling capacity 3 kW). Price approx. 53 thousand rubles.

- KROLL LH 130 (power – 20 kW, capacity 1450 m3/h). Price approx. 60-77 thousand rubles.

- KSk 4-1 – 7-9 thousand rubles.

- FlowairLEOINOX 25S (power 10-25 kW, capacity 900-4400 m3/h). Price 64 thousand rubles.

Efficiency of using air heaters instead of heating radiators

The coolant circulating through water heating radiators transfers thermal energy to the surrounding air through thermal radiation, as well as through the upward movement of convection flows of heated air and the entry of cooled air from below.

The heater, in addition to these two passive methods of transferring thermal energy, drives air through a system of heated elements with a much larger area and intensively transfers heat to them. Assessing the efficiency of heaters and fans allows for a simple calculation of the cost of installed equipment for the same tasks.

For example, it is necessary to compare the cost of radiators and heaters for heating the showroom of a car dealership, taking into account compliance with SNIP standards.

The heating main is the same, the coolant is the same temperature, piping and installation can be ignored in a simplified calculation of the costs of the main equipment. For a simple calculation, we take the known norm of 1 kW per 10 m2 of heated area. A hall with an area of 50x20 = 1000 m2 requires a minimum of 1000/10 = 100 kW. Taking into account a margin of 15%, the calculated minimum required heating capacity of heating equipment is 115 kW.

When using radiators. We take one of the most common bimetallic radiators Rifar Base 500 x10 (10 sections), one such panel produces 2.04 kW. The minimum required number of radiators will be 115/2.04 = 57 pcs. It’s immediately worth considering that placing 57 radiators in such a room is unreasonable and practically impossible. If the price of a device for 10 sections is 7,000 rubles, the cost of purchasing radiators will be 57 * 7000 = 399,000 rubles.

When heating with air heaters. To heat a rectangular area in order to distribute heat evenly, we select from 5 Ballu BHP-W3-20-S water heaters with a capacity of 3200 m3/hour each with a similar total power: 25 * 5 = 125 kW. Equipment costs will be 22900*5 = 114,500 rubles.

The main area of application of air heaters is the organization of heating of rooms with large spaces for air movement:

- production workshops, hangars, warehouses;

- gyms, exhibition pavilions, shopping centers;

- agricultural farms, greenhouses.

Compact devices that allow you to quickly heat air from 70°C to 100°C, easily integrated into the overall automatic heating control system, are advisable to use in buildings with reliable access to coolant (water, steam, electricity).

The advantages of water heaters are:

- High profitability of use (low cost of equipment, high heat transfer, ease and low cost of installation, minimal operating costs).

- Fast air heating, ease of change and localization of heat flow (thermal curtains and oases).

- Reliable design, ease of automation and modern design.

- Safe to use even in high-risk buildings.

- Extremely compact dimensions with high heating output.

The disadvantages of these devices are related to the properties of the coolant:

- At temperatures below zero, the heater is easy to freeze. If water is not drained from the pipes in time, they can break if disconnected from the main line.

- When using water with a large amount of impurities, the device can also be damaged, so using it at home without filters and connecting it to a central system is impractical.

- It is worth noting that air heaters dry out the air greatly. When used, for example, in a showroom, humidifying climate control technology is required.

Operating rules and repair possibilities

The basic requirements for the operation and safety of the device are set out in the passport. They are aimed at eliminating emergency situations caused by exceeding the permissible temperature or pressure of the coolant, and avoiding a sharp increase in the temperature of the complex during the first start-up in the cold season. Particular attention should be paid to the risk of freezing of the device tubes in winter, which can lead to failure of the device. To repair devices, specialized organizations should be involved; independent intervention most often only increases the severity of the problem.

Design features of the device

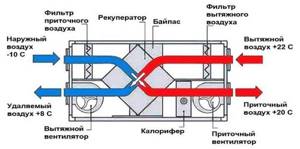

Main elements of supply ventilation

- Air intake grille. Acts as an aesthetic design and a barrier that protects debris particles in the supply air masses.

- Supply ventilation valve. Its purpose is to block the passage of cold air from outside in winter and hot air in summer. You can make it work automatically using an electric drive.

- Filters. Their purpose is to clean incoming air. I require replacement every 6 months.

- Water heater, electric heating elements - designed to heat incoming air masses.

- For rooms with a small area it is recommended to use ventilation systems with electric heating elements, for large spaces - a water heater.

Supply and exhaust ventilation elements

Additional items

- Fans.

- Diffusers (contribute to the distribution of air flow masses).

- Noise muffler.

- Recuperator.

The design of ventilation directly depends on the type and method of installation of the system. They come in passive and active action.

Passive ventilation systems.

This device is a supply ventilation valve. The scooping of street air masses occurs due to a pressure difference. In cold weather, the temperature difference contributes to the discharge; in warm periods, the exhaust fan assists. Regulation of such ventilation can be automatic or manual.

Automated regulation directly depends on:

- the flow rate of air masses passing through the ventilation;

- air humidity in the room.

The disadvantage of the system is that in winter, such ventilation for heating the house is not effective, since a large temperature difference is created.

On the wall

Refers to the passive type of supply ventilation. This installation has a compact box that is mounted on the wall. To control heating it is equipped with an LCD display and a control panel. The operating principle is to recuperate internal and external air masses. To heat the room, this device is placed near the heating radiator.

Active ventilation systems

Since in such systems it is possible to regulate the intensity of the fresh air supply, such ventilation systems are more in demand for heating and warming up the room.

According to the heating principle, such a supply heater can be water or electric.

Water heater

Powered by a heating system. The operating principle of this ventilation system is to circulate air through a system of channels and tubes, inside of which there is hot water or a special liquid. In this case, heating occurs in a heat exchanger built into the centralized heating system.

Electric heater.

The operating principle of the system is to convert electrical energy into heat using an electric heating element.

Breezer

This is a compact device, small in size for supply ventilation, with heating. To supply fresh air, this device is attached to the wall of the room.

Breezer Tion o2

Breather design tion o2:

- A duct consisting of an air intake and an air duct. This is a sealed and insulated tube through which the device draws air from the outside.

- Air delay valve. This element is an air gap. It is designed to prevent the outflow of warm air while the device is turned off.

- Filtration system. It consists of three filters that are installed in a certain sequence. The first two filters clean the air flow from visible contaminants. The third filter is a deep cleaning filter from bacteria and allergens. It purifies incoming air from various odors and exhaust gases.

- Fan for air supply from outside.

- Ceramic heater, which is equipped with climate control. Responsible for heating the air flow and automatic temperature regulation.

Teplomash TW and MW series

Water heaters Teplomash KEV TW/MW with a heat power range from 3.1 to 31 kW and an air capacity from 600 to 3000 m3/hour for TW; for MW heat power from 11.7 to 120 kW, air power from 3000 to 7000 m3/hour. Coolant temperature up to +150°C, operating ambient temperature: from -10°C to +40°C. The TW series is made in a metal case, and the MW series in a plastic case.

Cost: from 18,000 rub.

Water heater: operating principle and purpose

Water heaters are used to heat air in various rooms where there is no central heating. They are also intended for ventilation or air conditioning systems. This type of air heaters is climate control equipment that serves as a heat exchanger filled with an intermediate coolant. The coolant in this equipment is heated or hot water.

A steam heater differs from a water heater in that dry saturated steam serves as the coolant in the device. These are more advanced models of heaters, so the price of a heater of this class is much higher.

Operating principle of a heating coil: blue arrows - cold air, red arrows - warm air

Water air heater: features of the design and operation of the device

The water heater has a very high level of performance. This is possible thanks to the wide temperature range, ranging from 70 to 110°C. The temperature difference is created by the heater itself. The design of the device is a tubular metal body covered with rib plates.

The most common type of air heater is a water heater with perpendicular flow. It is used in various ventilation devices. In this case, the water moves opposite to the air flow, in a rectangular direction. As a result, water rises through the channels from bottom to top, air bubbles enter the top of the device, and are removed from there through special air vents.

In any water heater, a piping unit must be installed, which is a special component of the device responsible for supplying hot water to the heat exchanger.

The design of a water heater includes the following required parts:

- coolant circulation pump;

- three-way valve;

- structural reinforcement;

- Control block;

- a piping unit that controls the performance of the heater and prevents it from freezing.

Diagram of the structure of an electric heater

Heater: this is a device for heating air in different systems

Before you start choosing a device, you need to understand the very concept of what a heater is, as well as what types there are and what are the typical and functional features of each of them.

Air heaters are capable of heating both small and fairly spacious rooms.

Air heaters are used to heat air in various systems:

- heating;

- air conditioning;

- ventilation.

Heating in thermal equipment is carried out due to the reaction between chemically aggressive substances in the middle. That is why the classification of air heaters is based on the type of heat exchanger. The device can be water, steam, freon and electric. A water heater for heating is used as a heat exchanger with an intermediate coolant. A steam heater is used to heat air in heating systems.

If we classify air heaters according to thermal and aerodynamic characteristics, then the types of air heaters are divided into three-row and four-row. Based on the number of connecting sizes, heaters of individual models are divided into 7 numbers.

Steel pipes, which have a ribbed surface on the outside, serve as a coolant transporter in the middle of the heater. Due to this design, the area increases and, as a result, such piping of the heater increases the efficiency of heat transfer. In the middle of the tubes with fins, a heating or cooling element in the form of water, steam or freon is transported. Air currents flow outside, which heat or cool during contact with the pipes.

Volcano air heater structure: 1 - movable adjustable blades, 2 - built-in diffuser with fan, 3 - heating elements, 4 - warm air supply.

The general scheme is based on the following operating principle: the coolant has a high heat transfer coefficient when interacting with air flows. The rib trim on the device is metal plates that are simply mounted on tubes or wound like ribbons or wire.

Classic KSk-3 and KSk-4

Water heaters with thermal elements made of tubes with bimetallic and aluminum fins in a spiral-rolling manner. It is used to heat air with water at temperatures up to +190°C, supplied by circulation pumps under pressure up to 1.2 MPa (12 bar). The range of air productivity is from 2000 to 2500 m3/hour, for heat for KSk-3 - from 37 to 556.4 kW; for KSk-4 – from 43.4 to 648.1 kW. The main advantage is the affordable price due to its simple design, domestic production and simple appearance.

Cost: from 9,000 rub.

Sources

- https://VentingInfo.ru/oborudovanie/kalorifer

- https://klimatlab.com/ventilyaciya/kondicionirovanie/kalorifer-vodyanoj-dlya-pritochnoy.html

- https://GradusPlus.com/radiatory-otopleniya/vidy/kalorifery/

- https://stroy-podskazka.ru/ventilyaciya/pritochnaja-kalorifer/

- https://www.tproekt.com/kalorifery-otopleniya/

- https://sovet-ingenera.com/vent/oborud/kalorifer-vodyanoj-dlya-pritochnoj-ventilyacii.html

Share link:

- Click to share on Twitter (Opens in new window)

- Click here to share content on Facebook. (Opens in a new window)

Heating of influent masses using recirculation

Ventilation with heating due to recirculation, speaking in general terms, works according to the following principle:

- air enters the house through the influx of the ventilation system;

- after a certain period of time, it enters the exhaust system, where part of the incoming air masses is removed outside the house;

- the remaining air enters the mixing chamber.

In the mixing compartment, fresh air is mixed with “exhaust” air, thus heating cold wind masses (if the system in the control settings is set to air heating mode, and not vice versa). Next, the air flow is directed to the heater or air conditioner, then through the ventilation ducts into the house.

Types of coolants

Four methods of heating devices should be distinguished. Often the main raw materials are:

- 1. fire;

- 2. water;

- 3. steam;

- 4. electricity.

Water-based heating is advantageous due to its low cost. Minimal funds are required to maintain the device. The installation of equipment can cause significant difficulties, so it will not be possible to use it in a city apartment. Heat exchangers of this type quickly produce the desired temperature.

Electric models are wall-mounted or mounted. They are flat structures and can be installed on the floor in the desired location. The body of such devices resembles a radiator. The models are equipped with diverter plates, wings, and aerodynamic inserts.

The duct device heats the air due to hot water, air or steam circulating inside the device. Devices of this type are installed in ventilation ducts; they are produced in rectangular or round shapes.

Heating of premises with a water heater with a fan

1.1

Principle of operation

The essence of the operation of a water device is similar to a domestic heat heater. The air is heated in the same range and for the same amount of time. Only the function of an electric spiral in such an installation is performed by a set of metal tubes. They are necessary for the movement of water and heat transfer to the room. The liquid is part of the heating system and does not require additional heating.

The process of heating water in the structure looks like this:

- 1. The water is heated to the required temperature (up to +180 degrees) and enters the heat exchanger from the pipes. The latter device looks like a structure made of small steel, aluminum, bimetallic or copper tubes.

- 2. As the air passes through these elements, it heats up.

- 3. The fan included in the device distributes air masses throughout the room and promotes their reverse movement towards the device.

The standard water heater device is a mixture of a fan, a heat exchanger and a convector. It is allowed to be used in industrial premises. In cottages, it is permissible to use this system provided that the correct piping and installation of a modern ventilation device are observed.

Water and electric heater for fresh air ventilation

1.2

Advantages and disadvantages

A particularly cost-effective heating method for large enterprises with their own heat supply system is the use of heaters for fresh air ventilation. Among the obvious advantages are:

- 1. Ease of installation work.

- 2. Fast heating of the room.

- 3. Safety during operation.

- 4. Allows adjustment of temperature and air flow force.

- 5. Original design of the device.

The main costs are borne by the owner of the premises only at the time of purchase of the equipment. During the period of use of the unit, its owner will not suffer large material losses. The final price of the finished structure depends on the technical characteristics and configuration.

The main disadvantage is the impossibility of using hot air heating in city apartments. Only electrical devices are used in such premises. It is also prohibited to install these devices in rooms with temperatures below 0 degrees.

Automation for controlling the supply ventilation system