Calculation of thermal loads for heating, methodology and calculation formula

Thermal loads of heating systems

- load on the heating supply structure;

- the load on the floor heating system, if it is planned to be installed in the house;

- load on the natural and/or forced ventilation system;

- load on the hot water supply system;

- load associated with various technological needs.

Calculation of heat loads

- degree of heat loss of external fences;

- power required to heat the coolant;

- the amount of thermal energy required to heat the air for forced ventilation;

- the heat needed to heat water in a bathhouse or swimming pool;

- possible further expansion of the heating system. This could be the creation of heating in the attic, attic, basement or in various extensions and buildings.

Methods for calculating thermal loads

- calculation of heat loss using aggregated indicators;

- determination of heat transfer from heating and ventilation equipment installed in the building;

- calculation of values taking into account various elements of enclosing structures, as well as additional losses associated with air heating.

Types of thermal loads for calculations

- Seasonal loads

having the following features:

– the presence of differences in the amount of thermal energy consumption in accordance with the climatic characteristics of the region where the house is located;

– change in the load on the heating system depending on the time of day. Since external fences have heat resistance, this parameter is considered insignificant;

– heat consumption of the ventilation system depending on the time of day.

- Constant thermal loads

. In most heating and hot water supply systems they are used throughout the year. For example, in the warm season, thermal energy consumption is reduced by about 30-35% compared to the winter period. - Dry heat

. It represents thermal radiation and convection heat exchange due to other similar devices. This parameter is determined using the temperature of a dry thermometer. It depends on many factors, including windows and doors, ventilation systems, various equipment, and air exchange occurring due to the presence of cracks in the walls and ceilings. The number of people present in the room is also taken into account. - Latent heat

. Formed as a result of the process of evaporation and condensation. Temperature is determined using a wet thermometer. In any room for its intended purpose, the humidity level is affected by:

– availability of technological or other equipment;

– flows of air masses penetrating through cracks and cracks in the building envelope.

Why do housing and communal services overestimate the amount of energy spent when paying for heating?

When making your own calculations, it is worth noting that housing and communal services slightly overestimate the standards for thermal energy consumption. The idea that they are trying to earn extra money from this is wrong. After all, the cost of 1 Gcal already includes maintenance, salaries, taxes, and additional profit. This “surcharge” is due to the fact that when hot liquid is transported through a pipeline in the cold season, it tends to cool down, that is, inevitable heat loss occurs.

In numbers it looks like this. According to regulations, the temperature of water in heating pipes must be at least +55 °C. And if we take into account that the minimum temperature of water in power systems is +5 °C, then it must be heated by 50 degrees. It turns out that 0.05 Gcal is used for each cubic meter. However, in order to compensate for heat loss, this coefficient is inflated to 0.059 Gcal.

Thermal load

One of the main factors influencing its value is the degree of insulation of the house. SNiP 02/23/2003, which regulates the thermal protection of buildings, normalizes this factor, deriving recommended values for the thermal resistance of building envelopes for each region of the country.

We will present two methods for performing calculations: for buildings that comply with SNiP 23-02-2003, and for houses with non-standardized thermal resistance.

Normalized thermal resistance

Instructions for calculating thermal power in this case look like this:

- The base value is 60 watts per 1 m3 of the total (including walls) volume of the house.

- For each window, an additional 100 watts of heat is added to this value. For each door leading to the street - 200 watts.

| Country region | Coefficient |

| Krasnodar, Yalta, Sochi | 0,7 — 0,9 |

| region and Moscow, St. Petersburg | 1,2 — 1,3 |

| Irkutsk, Khabarovsk | 1,5 — 1,6 |

| Chukotka, Yakutia | 1,8 — 2,0 |

As an example, let’s perform a calculation for a house measuring 12*12*6 meters with twelve windows and two doors to the street, located in Sevastopol (the average temperature in January is +3C).

- The heated quantity is 12*12*6=864 cubic meters.

- The basic thermal power is 864*60=51840 watts.

- Steam doors and Windows will increase it: 51840+(12*100)+(2*200)=53440.

- Only a mild climate due to the proximity of the sea will force us to use a regional coefficient of 0.7. 53440*0.7=37408 W. It is this value that we can focus on.

Non-standardized thermal resistance

What to do if the level of quality of home insulation is noticeably better or worse than recommended? In this case, to estimate the heat load, it is possible to use a formula of the form Q=V*Dt*K/860.

In it:

- Q is the cherished thermal power in kilowatts.

- V - heated quantity in cubic meters.

- Dt is the temperature difference between the house and the street. In most cases, the delta is taken between the recommended SNiP value for interior spaces (+18 - +22C) and the average minimum street temperature in the coldest month over the last couple of years.

| Description of the building | Insulation coefficient |

| 3 — 4 | Half-brick masonry, or plank walls, or corrugated sheets on a frame; single glazing |

| 2 — 2,9 | Brickwork, double glazing in wood frames |

| 1 — 1,9 | Laying one and a half bricks; single-glazed windows |

| 0,6 — 0,9 | External insulation with foam plastic or mineral wool; double-chamber energy-saving double-glazed windows |

Let's repeat the calculations for our house in Sevastopol, specifying that its walls are 40 cm thick masonry made of shell rock (porous sedimentary rock) without external finishing, and the glazing is made of single-chamber double-glazed windows.

- Let us take the insulation coefficient equal to 1.2.

- We calculated the number of houses earlier; it is equal to 864 m3.

- We will take the internal temperature to be equal to the recommended SNiP for regions with a lower peak temperature above -31C - +18 degrees. The widely recognized Internet encyclopedia will kindly advise you on the average minimum: it is equal to -0.4C.

- The calculation, therefore, will look like Q = 864 * (18 - -0.4) * 1.2 / 860 = 22.2 kW.

As you can easily notice, the calculation gave a result that differed from that taken using the first method by one and a half times. The circumstance, first of all, is that the average minimum used by us differs markedly from the full minimum (about -25C). An increase in the temperature delta by one and a half times will increase the estimated heat demand of the building by exactly the same amount.

Gigacalories

In calculating the amount of thermal energy acquired by a building or premises, along with kilowatt-hours, another value is used - gigacalorie. It corresponds to the amount of heat required to heat 1000 thousand kilograms of water by 1 degree at a pressure of 1 atmosphere.

How to convert kilowatts of thermal power into gigacalories of consumed heat? Everything is easy: one gigacalorie is equal to 1162.2 kWh. Thus, with a peak power of the heat source of 54 kW, the large hourly heating load will be 54/1162.2 = 0.046 Gcal*hour.

Room

How to calculate the heat requirement for a separate room? The same calculation schemes are used here as for the house as a whole, with only one amendment. If the room is adjacent to a heated room without its own heating devices, it is included in the calculation.

So, if a room measuring 4*5*3 meters is adjacent to a corridor measuring 1.2*4*3 meters, the thermal power of the heating device is calculated for a volume of 4*5*3+1.2*4*3=60+ 14.4=74.4 m3.

What to do if you need a very accurate calculation

Unfortunately, not every apartment can be considered standard. This applies even more to private residential buildings. The question arises: how to calculate the number of heating radiators, taking into account the individual conditions of their operation? To do this, you will need to take into account many different factors.

The peculiarity of this method is that when calculating the required amount of heat, a number of coefficients are used that take into account the characteristics of a particular room that can affect its ability to store or release thermal energy. The formula for calculations looks like this:

KT = 100W/sq.m. * P * K1 * K2 * K3 * K4 * K5 * K6 * K7. Where

KT - the amount of heat required for a specific room; P - room area, sq.m.; K1 - coefficient taking into account the glazing of window openings:

- for windows with conventional double glazing - 1.27;

- for windows with double glazing - 1.0;

- for windows with triple glazing - 0.85.

K2 - coefficient of thermal insulation of walls:

- low degree of thermal insulation - 1.27;

- good thermal insulation (two bricks or a layer of insulation) - 1.0;

- high degree of thermal insulation - 0.85.

K3 - ratio of window area to floor area in the room:

K4 is a coefficient that allows you to take into account the average air temperature in the coldest week of the year:

- for -35 degrees - 1.5;

- for -25 degrees - 1.3;

- for -20 degrees - 1.1;

- for -15 degrees - 0.9;

- for -10 degrees - 0.7.

K5 - adjusts the heat demand taking into account the number of external walls:

K6 - taking into account the type of room located above:

- cold attic - 1.0;

- heated attic - 0.9;

- heated living space - 0.8

K7 - coefficient taking into account the height of the ceilings:

This calculation of the number of heating radiators includes almost all the nuances and is based on a fairly accurate determination of the room’s need for thermal energy.

All that remains is to divide the obtained result by the heat transfer value of one section of the radiator and round the resulting result to a whole number.

Some manufacturers offer an easier way to get the answer. On their websites you can find a convenient calculator specifically designed to make these calculations. To use the program, you need to enter the required values in the appropriate fields, after which the exact result will be given. Or you can use special software.

When we got an apartment, we didn’t think about what kind of radiators we had and whether they suited our house. But over time, a replacement was required and they began to approach it from a scientific point of view. Since the power of the old radiators was clearly not enough. After all the calculations we came to the conclusion that 12 is enough. But you also need to take into account this point - if the TEC does not do its job well and the batteries are a little warm, then no amount will save you.

I liked the last formula for a more accurate calculation, but the coefficient K2 is not clear. How to determine the degree of thermal insulation of walls? For example, a 375mm thick wall made of GRAS foam block, is it low or medium? And if you add 100mm of dense construction foam to the outside of the wall, will it be high, or still medium?

Ok, the last formula seems to be good, windows are taken into account, but what if the room also has an external door? What if this is a garage with 3 windows 800*600 + door 205*85 + sectional garage doors 45mm thick with dimensions 3000*2400?

If you do it for yourself, I would increase the number of sections and install a regulator. And voila - we are already much less dependent on the whims of the thermal power plant.

Methods for determining load

First, let's explain the meaning of the term. Thermal load is the total amount of heat consumed by the heating system to heat the premises to the standard temperature in the coldest period. The value is calculated in energy units - kilowatts, kilocalories (less often - kilojoules) and is denoted in formulas by the Latin letter Q.

Knowing the heating load of a private house in general and the needs of each room in particular, it is not difficult to select a boiler, heaters and batteries of the water system according to power. How can you calculate this parameter:

- If the ceiling height does not reach 3 m, a larger calculation is made based on the area of heated rooms.

- For ceiling heights of 3 m or more, heat consumption is calculated based on the volume of the premises.

- Determination of heat loss through external fences and the cost of heating ventilation air in accordance with SNiP.

Photo of the building taken with a thermal imager

The first two calculation methods are based on the use of specific thermal characteristics in relation to the heated area or volume of the building. The algorithm is simple, used everywhere, but gives very approximate results and does not take into account the degree of insulation of the cottage.

Calculating thermal energy consumption according to SNiP, as design engineers do, is much more difficult. You will have to collect a lot of reference data and work hard on calculations, but the final numbers will reflect the real picture with 95% accuracy. We will try to simplify the methodology and make the calculation of the heating load as easy to understand as possible.

Characteristics of the object for calculation

A house with large double-glazed windows needs more intensive heating.

Thermal load on heating and heat loss in a house are not the same thing. There is no need to heat a technical building as intensively as residential premises. Before starting calculations, establish the following:

- The purpose of the object is a residential building, apartment, school, gym, store. Heating requirements vary.

- Architectural features include the size of window and balcony openings, the structure of the roof, the presence of attics and basements, the number of storeys in the building, etc.

- Temperature standards are different for living rooms and offices.

- Purpose of the room - this parameter is important for production facilities, since each workshop or even area requires a different temperature regime.

- Construction of external fences - external walls and roof.

- Level of maintenance - the presence of hot water supply reduces heat loss, intensive ventilation increases.

- The number of people constantly staying in the house, for example, affects temperature and humidity indicators.

- The number of coolant intake points - the more there are, the greater the heat loss.

- Other features - for example, the presence of a swimming pool, sauna, greenhouse or the number of hours when people are in the building.

Thermal load regulators

Programmable controller, temperature range - 5-50 C

Modern heating units and devices are provided with a set of different regulators, with the help of which you can change the thermal loads, thereby avoiding dips and surges in thermal energy in the system. Practice has shown that with the help of regulators it is possible not only to reduce loads, but also to bring the heating system to rational use of fuel. And this is a purely economic side of the issue. This especially applies to industrial facilities, where quite large fines have to be paid for excessive fuel consumption.

If you are not sure of the correctness of your calculations, then use the services of specialists.

Let's look at a couple more formulas that relate to different systems. For example, ventilation and hot water supply systems. Here you will need two formulas:

Qv.=qv.V(tn.-tv.) - this applies to ventilation. Here: tн. and tв - air temperature outside and inside qв. — specific indicator V — external volume of the building

Qgws.=0.042rv(tg.-tx.)Pgsr - for hot water supply, where

tg.-tx - temperature of hot and cold water r - water density c - ratio of maximum load to average, which is determined by GOST P - number of consumers Gav - average hot water consumption

Energy survey of the designed operating modes of the heat supply system

When designing, the heat supply system of JSC Termotron-zavod was designed for maximum loads.

The system was designed for 28 heat consumers. The peculiarity of the heat supply system is that part of the heat consumers is from the output of the boiler room to the main building of the plant. Next, the heat consumer is the main building of the plant, and then the rest of the consumers are located behind the main building of the plant. That is, the main building of the plant is an internal heat consumer and a transit of heat supply for the last group of heat load consumers.

The boiler room was designed for 3 DKVR 20-13 steam boilers, running on natural gas, and 2 PTVM-50 hot water boilers.

One of the most important stages in the design of heating networks was the determination of design heat loads.

The estimated heat consumption for heating each room can be determined in two ways:

- from the room heat balance equation;

- according to the specific heating characteristics of the building.

The design values of thermal loads were made according to aggregated indicators, based on the volume of buildings by texture.

The estimated heat consumption for heating the i-th production premises, kW, is determined by the formula:

, (1)

where: is the coefficient for taking into account the area where the enterprise is being built:

(2)

where is the specific heating characteristic of the building, W/(m3.K);

— volume of the building, m3;

— calculated air temperature in the working area, ;

— the estimated outside air temperature for calculating the heating load, for the city of Bryansk is -24.

The determination of the estimated heat consumption for heating for the premises of the enterprise was carried out according to the specific heating load (Table 1).

Table 1 Heat consumption for heating for all premises of the enterprise

| No. | Object name | Building volume, V, m3 | Specific heating characteristic q0, W/m3K | Coefficient e | Heat consumption for heating , kW |

| 1 | Dining room | 9894 | 0,33 | 1,07 | 146,58 |

| 2 | Painting Research Institute | 888 | 0,66 | 1,07 | 26,46 |

| 3 | Scientific research institute TEN | 13608 | 0,33 | 1,07 | 201,81 |

| 4 | Electrical assembly engines | 7123 | 0,4 | 1,07 | 128,043 |

| 5 | Model site | 105576 | 0,4 | 1,07 | 1897,8 |

| 6 | Painting department | 15090 | 0,64 | 1,07 | 434,01 |

| 7 | Galvanic department | 21208 | 0,64 | 1,07 | 609,98 |

| 8 | Procurement area | 28196 | 0,47 | 1,07 | 595,55 |

| 9 | Thermal section | 13075 | 0,47 | 1,07 | 276,17 |

| 10 | Compressor room | 3861 | 0,50 | 1,07 | 86,76 |

| 11 | Forced ventilation | 60000 | 0,50 | 1,07 | 1348,2 |

| 12 | HR department extension | 100 | 0,43 | 1,07 | 1,93 |

| 13 | Forced ventilation | 240000 | 0,50 | 1,07 | 5392,8 |

| 14 | Container shop | 15552 | 0,50 | 1,07 | 349,45 |

| 15 | Factory management | 3672 | 0,43 | 1,07 | 70,96 |

| 16 | Class | 180 | 0,43 | 1,07 | 3,48 |

| 17 | Technical department | 200 | 0,43 | 1,07 | 3,86 |

| 18 | Forced ventilation | 30000 | 0,50 | 1,07 | 674,1 |

| 19 | Sharpening area | 2000 | 0,50 | 1,07 | 44,94 |

| 20 | Garage - Lada and PC | 1089 | 0,70 | 1,07 | 34,26 |

| 21 | Foundry /L.M.K./ | 90201 | 0,29 | 1,07 | 1175,55 |

| 22 | Garage Research Institute | 4608 | 0,65 | 1,07 | 134,60 |

| 23 | Pumping station | 2625 | 0,50 | 1,07 | 58,98 |

| 24 | research institute | 44380 | 0,35 | 1,07 | 698,053 |

| 25 | West - Lada | 360 | 0,60 | 1,07 | 9,707 |

| 26 | Private enterprise "Kutepov" | 538,5 | 0,69 | 1,07 | 16,69 |

| 27 | Leskhozmash | 43154 | 0,34 | 1,07 | 659,37 |

| 28 | JSC K.P.D. Build | 3700 | 0,47 | 1,07 | 78,15 |

PLANT TOTAL:

The estimated heat consumption for heating of JSC Termotron-zavod is:

The total heat generation for the entire enterprise is:

Estimated heat losses for a plant are determined as the sum of the estimated heat consumption for heating the entire enterprise and the total heat releases, and are:

Heat load calculation

The need to comply with all safety and reliability standards is extremely important when designing facilities, but calculating the thermal load of the building is no less important.

Why do you need to calculate the thermal load when designing a building?

This operation will allow you to find out how much fuel the heating system needs to operate, correctly determine the heat source and calculate heat loss throughout the entire system. It’s worth noting right away that calculating the heat load for heating allows you to find out how much heat all heating devices provide. All this information allows you to save large sums in comparison with heating systems that were not calculated correctly.

First of all, it is worth deciding which heating objects should be calculated. Such objects include:

- General heating system;

- Underfloor heating (if available);

- Ventilation devices;

- Water heating system;

- Other objects that require connection to the heating system, for example, swimming pools.

In addition, the calculation of the heat load can be affected by the smallest objects and objects where heat loss is possible.

Calculation procedure

It should be noted that all calculations made must be performed in accordance with GOST and building codes. For all systems there is a general list of parameters that must be calculated. These parameters are:

- Heat loss on external fences. This parameter allows you to select the optimal temperature for each room;

- The amount of power that will go to the hot water supply system;

- If you need to install an additional ventilation system, then calculating the heat required to heat the air circulating in it is also required;

- If there is a pool or bathhouse, the amount of heat required to heat these objects is calculated;

- If it is planned to expand the heating system in the future, then a calculation of the thermal load of the building must also be carried out.

It is also extremely important to know how heat flows are distributed throughout the room for each heating object

The importance of this knowledge lies in the fact that it allows you to most accurately select the elements necessary for the heating system

Key points for each type of heat load

Builders share several types of loads. Each type has its own characteristics that need to be analyzed.

First of all, seasonal load is distinguished. Its peculiarity is that throughout the year, temperature conditions outside the premises change, and heat costs are calculated depending on the climatic conditions of the place where the building is located.

In second place is the calculation of the heat load for heating throughout the year. Since most domestic buildings are characterized by this particular load, changes throughout the year are not critical, but in the summer the load becomes less by about 30 percent.

There are two more parameters that must also be taken into account in the calculation - latent and dry heat. The first parameter characterizes heat loss due to condensation and other evaporation. Calculation for dry heat is carried out taking into account the number of windows, doors, parameters of the ventilation system and possible losses in the cracks of the walls.

Advantages of turning to professionals when calculating thermal loads

Of course, it is possible to calculate the thermal load yourself, but this is a big risk, since there is a high probability of making a mistake. Many different parameters, the need to take into account losses at all possible heating objects and the overall complexity of all calculations can scare off an inexperienced person. It is in such cases that the help of an experienced specialist is necessary. Our company is able to make the most accurate calculations and select the most optimal equipment in the shortest possible time, while the cost and quality will pleasantly please you.

Contact us for advice by calling the numbers listed on the website or online.

Factors influencing TN

loss. Heat loss is influenced by many factors:

- Foundation - the insulated version retains heat in the house, the non-insulated version allows up to 20% to pass through.

- Wall - porous concrete or wood concrete has a much lower throughput capacity than a brick wall. Red clay brick retains heat better than silicate brick. The thickness of the partition is also important: a wall made of brick 65 cm thick and foam concrete 25 cm thick have the same level of heat loss.

- Insulation – thermal insulation significantly changes the picture. External insulation with polyurethane foam - a sheet 25 mm thick - is equal in effectiveness to a second brick wall 65 cm thick. Cork finishing on the inside - a sheet 70 mm thick - replaces 25 cm of foam concrete. It is not for nothing that experts say that effective heating begins with proper insulation.

- The roof is a pitched structure and an insulated attic reduces losses. A flat roof made of reinforced concrete slabs transmits up to 15% of heat.

- The glazing area - the thermal conductivity of glass is very large. No matter how sealed the frames are, heat escapes through the glass. The more windows and the larger their area, the higher the thermal load on the building.

- Ventilation – the level of heat loss depends on the performance of the device and the frequency of use. The recovery system allows us to somewhat reduce losses.

- The difference between the temperature outside and inside the house - the greater it is, the higher the load.

- Heat distribution inside the building affects the performance for each room. The rooms inside the building cool down less: when calculating, the comfortable temperature here is considered to be +20 C. The end rooms cool down faster - the normal temperature here will be +22 C. In the kitchen, it is enough to heat the air to +18 C, since there are many other heat sources: the stove , oven, refrigerator.

When calculating the thermal load of an apartment building, the material, thickness and insulation of partitions and ceilings are taken into account.

Features of calculating thermal load

Air parameters, or more precisely, its temperature, are taken from GOSTs and SNiPs. Heat transfer coefficients are also selected here. By the way, the passport data of all types of equipment (boilers, heating radiators, etc.) must be taken into account.

What is usually included in a traditional heat load calculation?

- Firstly, the maximum flow of thermal energy emanating from heating devices (radiators).

- Secondly, the maximum heat consumption per 1 hour of operation of the heating system.

- Thirdly, the total heat costs for a certain period of time. Usually the seasonal period is calculated.

If all these calculations are compared and compared with the heat transfer area of the system as a whole, you will get a fairly accurate indicator of the efficiency of heating a house. But small deviations will also have to be taken into account. For example, reducing heat consumption at night. For industrial facilities, you will also have to take into account weekends and holidays.

Dependence of the degree of heat transfer on the connection method

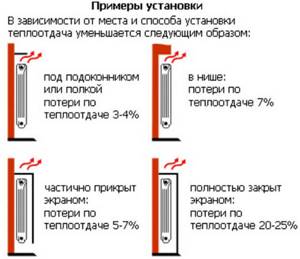

The heat transfer of heating radiators is affected not only by the material of manufacture and the temperature of the coolant circulating through the pipes, but also by the chosen option for connecting the device to the system:

- The connection is direct one way

. It is the most favorable in relation to the thermal power indicator. For this reason, the calculation of the heat transfer of a heating radiator is performed precisely with a direct connection. - Diagonal connection

. It is used if you plan to connect a radiator to the system in which the number of sections exceeds 12. This method allows you to minimize heat loss. - Bottom connection

. It is used when the battery is connected to a floor screed in which the heating system is hidden. As the calculation of the heat transfer of the radiator shows, with such a connection, the loss of thermal energy does not exceed 10%. - Single pipe connection

. The least profitable method in terms of thermal power. Heat transfer losses with a single-pipe connection most often reach 25 - 45%.

Sequence of calculation of heating systems

The stages of calculations for heating systems and heating equipment, regardless of the heated area and the number of circuits, are as follows:

- It is produced taking into account their thermal insulation properties to determine the amount of heat loss in winter.

- The volume and amount of heat required to heat it in the rooms is determined.

- The result of the thermal engineering calculation is the heat balance of the house or the required power of the heating system.

- Based on the results of drawing up a heat balance for each room, the standard sizes of heating devices are selected, and the type of radiators acceptable for the given case is determined. Then the devices must be placed in the rooms in areas of maximum heat loss.

- According to the selected heating system diagram (gravity or pump, single-pipe or two-pipe, riser, radiant or collector), the construction plans include piping and determination of the location of connections to radiators.

- In the process of hydraulic calculation, the diameters of each section of the heating system, coolant flow and pressure loss along the length of the pipelines due to friction are determined.

- Based on the results of hydraulic calculations, circulation pumps are selected.

- Depending on the circuit diagram of the heating system and the basic technical data of the system and the maximum operating pressure, the volume of the expansion tank is selected, which serves to compensate for the thermal expansion of the coolant.

- The type, number and power of heating boilers are selected, and a schematic diagram of the boiler room is drawn up with the placement of the main equipment and related systems.

Heating devices

Sectional radiators

In general, information about the heat flow per section can always be found on the manufacturer’s website.

If it is unknown, you can rely on the following approximate values:

- Cast iron section – 160 W.

- Bimetallic section – 180 W.

- Aluminum section – 200 W.

The aluminum radiator leads due to its high thermal conductivity and developed fins.

As always, there are a number of subtleties. When connecting a radiator with 10 or more sections to the side, the temperature spread between the sections closest to the supply and the end sections will be quite significant.

However: the effect will be nullified if the eyeliners are connected diagonally or from bottom to bottom.

In addition, usually manufacturers of heating devices indicate power for a very specific temperature delta between the radiator and the air, equal to 70 degrees. The dependence of the heat flow on Dt is linear: if the battery is 35 degrees hotter than the air, the thermal power of the battery will be exactly half the declared one.

Let's say, at an air temperature in the room of +20C and a coolant temperature of +55C, the power of a standard size aluminum section will be equal to 200/(70/35)=100 watts. In order to provide a power of 2 kW, you will need 2000/100 = 20 sections.

Registers

Homemade registers stand apart from the list of heating devices.

The photo shows a heating register.

Manufacturers, for obvious reasons, cannot indicate their thermal power; however, it is not difficult to calculate it yourself.

- For the first section of the register (a horizontal pipe of known dimensions), the power is equal to the product of its outer diameter and length in meters, the temperature delta between the coolant and air in degrees and a constant coefficient of 36.5356.

- For subsequent sections located in the rising flow of warm air, an additional coefficient of 0.9 is used.

Let's look at another example - let's calculate the heat flow value for a four-row register with a section diameter of 159 mm, a length of 4 meters and a temperature of 60 degrees in a room with an internal temperature of +20C.

- The temperature delta in our case is 60-20=40C.

- Convert the pipe diameter to meters. 159 mm = 0.159 m.

- We calculate the thermal power of the first section. Q = 0.159*4*40*36.5356 = 929.46 watts.

- For each subsequent section, the power will be equal to 929.46*0.9=836.5 W.

- The total power will be 929.46 + (836.5*3) = 3500 (rounded) watts.

How to calculate heat loss using aggregated indicators

To quickly determine the heat loss of a room, you can make an approximate calculation. In this work, one must rely on knowledge of the design features of the room:

• If you have a room with one outside wall and one window. then 1 kW of radiator power will be able to warm up 10 sq.m.

• If the room has two external walls and one window. then for 10 sq.m. you will need 1.2 kW.

• And if the room has two external walls with two windows. then for 10 sq.m. — 1.3 kW of energy.

Of course, with such conditional calculations, errors arise, therefore, to calculate the heating of a separate room with an electric, water or air system, it is necessary to make an accurate complete thermal calculation.

Today in country houses. As a rule, the role of a heat generator is played by a boiler, so calculating heating for a country house comes down to determining the power of the boiler.

If we take the heat input as 100%, then the heat loss will be the following indicators, which are also applicable for calculating the heating of greenhouses.

Heat loss:

• due to air exchange, including infiltration - 15%;

• through the external walls of the room - 35%;

• through window openings - 10%;

• through the roof of the building - 25%;

• through the floor - 15%.

A similar type of calculation for heating a country house. As a rule, it is based on the generally accepted formula:

Where

c is the heat capacity of air, equal to 1.2 kJ/(m3•°C);

tpr — supply air temperature, °C;

tв — room temperature, °C.

The temperature of the air supplied to the room is determined by the formula:

tpr=tn+Δt +0.001p

Where

tн—outdoor temperature, °C;

Δt—temperature change in the air heater, °C;

p is the total air pressure after the fan, Pa.

Depending on the type of radiators and the area of the room, you can make the following calculation for heating a country house:

• calculate the area of the room;

• take as a minimum - 100 watts to heat 1 sq. m. and for large heat losses in the room, add 10-20 watts per square meter;

• find out the required number of radiator sections. To do this, we divide the amount of watts for one room by the power of one section of batteries (for cast iron - 130 watts, for aluminum 150-200 watts (with a section height of 0.6 m)) and get the required number of sections;

• by calculating the power of the batteries for all rooms and adding them up, we get the required boiler power in watts (1 kW = 1000 W);

If the calculation of the heating of a country house is carried out incorrectly and the boiler’s power is not enough, then it will not be able to heat the house evenly.

Heating should be designed to ensure the design air temperature in the premises, taking into account: heat flow regularly coming from electrical appliances, lighting, technological equipment, communications, materials, people and other sources; at the same time, the heat flow entering the rooms and kitchens of residential buildings should be taken at least 10 W per 1 sq. m of floor.

Heat losses through the internal enclosing structures of premises may be ignored if the temperature difference in these premises is 3°C or less.

Further in the article, convenient tables are provided that allow you to easily and quickly calculate the heat loss of a designed or finished house, and select the necessary equipment for heating premises.

Determining the number of radiators for single-pipe systems

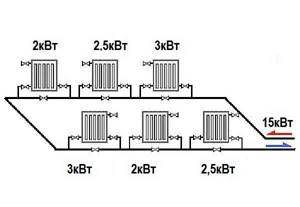

There is one more very important point: all of the above is true for a two-pipe heating system. when a coolant with the same temperature enters the input of each radiator. A single-pipe system is considered much more complex: there, increasingly colder water flows to each subsequent heating device. And if you want to calculate the number of radiators for a one-pipe system, you need to recalculate the temperature every time, and this is difficult and time-consuming. Which exit? One of the possibilities is to determine the power of the radiators as for a two-pipe system, and then, in proportion to the drop in thermal power, add sections to increase the heat transfer of the battery as a whole.

In a single-pipe system, increasingly colder water flows to each radiator

Let's explain with an example. The diagram shows a single-pipe heating system with six radiators. The number of batteries was determined for two-pipe wiring. Now we need to make an adjustment. For the first heating device everything remains the same. The second one receives coolant with a lower temperature. We determine the % drop in power and increase the number of sections by the corresponding value. In the picture it turns out like this: 15kW-3kW=12kW. We find the percentage: the temperature drop is 20%. Accordingly, to compensate, we increase the number of radiators: if 8 pieces were needed, there will be 20% more - 9 or 10 pieces. This is where knowing the room will come in handy: if it’s a bedroom or a children’s room, round up, if it’s a living room or other similar room, round down

You also take into account the location relative to the cardinal points: in the north you round up, in the south you round down.

In single-pipe systems, it is necessary to add sections to radiators located further along the branch

This method is clearly not ideal: after all, it turns out that the last battery in the branch will have to be simply enormous in size: judging by the diagram, a coolant with a specific heat capacity equal to its power is supplied to its input, and in practice it is unrealistic to remove all 100%. Therefore, usually when determining the power of a boiler for single-pipe systems, they take a certain reserve, install shut-off valves and connect radiators through a bypass so that the heat transfer can be adjusted and thus compensate for the drop in coolant temperature. One thing follows from all this: the number and/or size of radiators in a single-pipe system must be increased, and more and more sections must be installed as you move away from the beginning of the branch.

An approximate calculation of the number of sections of heating radiators is simple and quick. But clarification depending on all the features of the premises, size, type of connection and location requires attention and time. But you can definitely decide on the number of heating devices to create a comfortable atmosphere in winter.

Thermal load from heating water for domestic hot water supply

To determine this load, you can use the same simple formula, only now you need to calculate the thermal energy spent on heating the water. Its heat capacity is known and is 4.187 kJ/kg °C or 1.16 W/kg °C. Considering that a family of 4 people needs only 100 liters of water for 1 day, heated to 55 °C, we substitute these numbers into the formula and get:

QDHW = 1.16 W/kg °C x 100 kg x (55 – 10) °C = 5220 W or 5.2 kW of heat per day.

A unit of equipment power is always referred to 1 hour, and the resulting 5.2 kW is referred to a day. But we cannot divide this figure by 24, because we want to get hot water as soon as possible, and for this the boiler must have a power reserve. That is, this load must be added to the rest as is.

Related Posts

- Comparison of heating radiators by heat transfer

- Connecting and calculating a buffer tank to a solid fuel boiler

- Thermal power

- Economical heating of a private house and apartment

- Leningrad heating system for a private house

- Connection diagrams for bimetallic radiators

- Air-to-air heat pump and its prices

- How to make steam heating

- At what temperature of the coolant is the heating system turned off and turned on in an apartment building according to GOST

- How to correctly calculate the power of a gas boiler

- Calculation of materials for a frame house

- Calculation of space heating

- Do-it-yourself air heating: everything about air heating systems

- A supply of hot water that is always at hand: how does an electric water heater for heating work?

- Online calculation of the capacity of round and rectangular profile pipes

- How to make geothermal heating at home

- Calculation of the area of air ducts and fittings, aerodynamic and other indicators

- Hydroarrow: principle of operation, purpose and calculations

- What to do if the bottom of the battery is cold and the top is hot?

- Thermal accumulators for autonomous heating systems

- Subtleties of crimping a heating system

- Tichelmann loop

- Calculation of resistor resistance for LEDs: online calculator

- Do-it-yourself gas heater: options for the best homemade products

- GOST 25136-82 connection of pipelines. leak test methods

Read with this

- Comparison of heating radiators by heat transfer

- Connecting and calculating a buffer tank to a solid fuel boiler

- Thermal power

- Economical heating of a private house and apartment

- Leningrad heating system for a private house

- Connection diagrams for bimetallic radiators

- Air-to-air heat pump and its prices

- How to make steam heating

- At what temperature of the coolant is the heating system turned off and turned on in an apartment building according to GOST

- How to correctly calculate the power of a gas boiler

Simple area calculations

You can calculate the size of heating batteries for a specific room based on its area. This is the easiest way - to use plumbing standards, which stipulate that a thermal power of 100 W per hour is needed to heat 1 sq.m. We must remember that this method is used for rooms with standard ceiling heights (2.5-2.7 meters), and the result is somewhat inflated. In addition, it does not take into account such features as:

- number of windows and type of double-glazed windows on them;

- the number of external walls in the room;

- the thickness of the building walls and what material they are made of;

- type and thickness of insulation used;

- temperature range in a given climate zone.

The heat that radiators must provide to heat the room: the area should be multiplied by the thermal power (100 W). For example, for a room of 18 sq.m the following power of the heating battery is required:

18 sq.m x 100 W = 1800 W

That is, 1.8 kW of power is needed per hour to heat 18 square meters. This result must be divided by the amount of heat that the heating radiator section produces per hour. If the data in his passport indicates that this is 170 W, then the next stage of the calculation looks like this:

1800 W / 170 W = 10.59

This number must be rounded to the nearest whole number (usually rounded up) - it will be 11. That is, in order for the temperature in the room to be optimal during the heating season, it is necessary to install a heating radiator with 11 sections.

This method is only suitable for calculating the battery size in rooms with central heating, where the coolant temperature is not higher than 70 degrees Celsius.

There is a simpler method that can be used for normal apartment conditions in panel houses. This approximate calculation takes into account that one section is needed to heat 1.8 square meters of area. In other words, the area of the room must be divided by 1.8. For example, with an area of 25 sq.m., 14 parts are needed:

25 sq.m / 1.8 sq.m = 13.89

But this calculation method is unacceptable for a radiator of reduced or increased power (when the average output of one section varies from 120 to 200 W).

Calculation of heat supply standards in an apartment

In an apartment served by a utility company, the calculation of the heat load can be carried out exclusively upon the transfer of the house in order to track the SNIP indicators in the premises accepted for balance. In another case, this is done by the owner of the living space in order to calculate his own heat losses when it is cold outside and remove the disadvantages of insulation - use heat-insulating plaster, glue a heat insulator, install penofol on the ceilings and install metal-plastic windows with a profile with five chambers.

Calculating heat leaks for a utility for the purpose of opening a dispute is generally ineffective. The problem is that there are standards for heat loss. If, for example, the house is open, then the requirements are met. At the same time, heat supply devices comply with the requirements of SNIP. Replacing batteries and extracting more heat is prohibited, since heating devices are installed in accordance with approved building codes.

Methodology for calculating heat supply standards in a private home

Privatized houses are heated by independent systems, in which the load is calculated to meet the requirements of SNIP, and adjustments to the heating power are carried out together with work to reduce heat losses.

Calculations can be created manually using a simple formula or a calculator on the resource. The program helps to calculate the required power of the heating system and heat loss typical for winter. Calculations are performed for a specific thermal zone.