Operating principle and advantages

A boiler that does not have a chimney completely or has one, but is very simple, has a number of its own unique design features and a certain operating principle, which we will discuss later.

Since gas is used to operate such a heating unit, the main requirement is the presence of a cylinder connected to the device or the presence of an already installed gas line. Also, although the name suggests that such a boiler is chimneyless, it still has a chimney, but in comparison with other large, complex and massive systems it is very simple.

In order to make such a hearth even more useful and powerful, to heat a large house with it, you can connect it to heating radiators and thereby convert it into systems with a water circuit. Heating in this case will be carried out by circulating and heating cold water in the radiators of each room. In the same way, you can get hot water in the house.

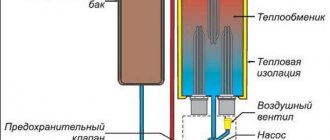

A double-circuit gas flueless boiler consists of the following elements:

- Gas lines or systems;

- A heat exchanger through which heated water moves and circulates;

- Return heating circuit;

- Through the input element, cold water enters the system;

- An output element that is used to remove and use already hot water for various domestic needs and purposes.

Such systems are complemented by two circuits at once, each of which is not connected to each other. This allows you to use them separately and for different needs. This variation can be supplemented with coolant, unlike single-circuit ones, which, at most, can be used to simultaneously heat and produce hot water using a device such as a boiler, which is purchased separately.

The most economical and budget-friendly variations are those that have a boiler with indirect heating, due to which closed local recirculation is formed. Thus, you can equip your home not just with hot water, but also get it heated to a certain temperature by simply opening the tap. The disadvantages include the bulkiness of such systems, due to which they will not fit into small houses and apartments. At the same time, the price of products manufactured by well-known and trusted brands is not always the lowest and most affordable.

Before you buy a chimneyless boiler, we recommend that you familiarize yourself in more detail with all its positive qualities and operational capabilities:

- Double-circuit variations of the modern model are distinguished by their average, and in some cases, quite miniature overall dimensions. Due to this, such a unit easily fits even in the smallest and most standard kitchen or in a specially designated utility room;

- The functionality of such centers is very large and varied. This is not just a heating device, but also the ability to connect to a water jacket to heat a large area. If you have a boiler, you can get water for domestic purposes;

- They are economical. The owner of the house can use such boiler equipment himself, as needed, thereby reducing resource consumption;

- Since double-circuit variations have a simple list of components, unlike single-circuit boiler systems, installation can be done with your own hands and without the help of a specialist.

The disadvantages of this variation are that it is not capable of performing several actions at the same time. For example, when performing the heating function, you will not be able to receive hot water. Also, water heating does not occur immediately, but gradually. Moreover, the smaller the size of the tank for filling and storing water, the less you will be able to provide your home or apartment with hot water

When using such a boiler, it is important to remember that, for example, when using water in the kitchen, it may not be enough for someone who is currently washing in the bathroom

Types of boilers without a chimney

Convection boilers

The operation of such a boiler is as follows: a burner is used to provide thermal energy to heat the water.

Due to the fact that part of the energy goes outside into the atmosphere through the chimney, such a system is irrational and cannot be called economical. Since the boiler is made of metal, you need to worry about its safety. When the boiler operates in a reduced mode, the temperature of the combustion products also decreases accordingly. When the temperature drops below 55 degrees, condensation of gases occurs, and such processes negatively affect metals, which can lead to repairs of the device and deterioration in its performance.

Such boilers should only be installed by professionals, since amateurish installation exacerbates the shortcomings of this system.

Condensing boilers

As is clear from the name, condensing chimneyless gas boilers operate using vapor condensation. A special feature of this boiler is its environmental friendliness, since when used with a low-temperature system, gas consumption is reduced. Other systems provide for combustion products to exit from smoke shafts, but in the case of a condensing boiler, a separate tube is used.

Such boilers provide for the formation of water vapor that heats up during operation. Such vapors remain on the heat exchanger. It is better to make heat exchangers from stainless steel to avoid corrosion. When vapors are released and heated, the hot water supply and heating system operates, as thermal energy is released.

In order for the system to operate smoothly and correctly, the temperature regime must be observed, that is, the temperature in the return pipeline must be below the dew point. Under such conditions, the condensation regime will be observed throughout the year.

Wall boilers

Wall-mounted chimneyless gas boilers can be considered mini-boiler rooms, because they are distinguished by simple operating principles and a convenient location that saves space.

In such a system, it is very important to rely on sensor readings and the position of the fluid thermostat to regulate the heat supply. After this, the pump supplies warm water to the heating circuit.

Also, wall-mounted boilers can have closed and open combustion chambers. The open ones have a chimney hood, and the closed ones have special fans.

When the system is suspended, protective functions are in effect. When there is no power, the system stops and resumes when it is turned on. Thus, in the absence of gas, the solenoid valve closes. Such a scheme is a guarantee of safety.

Also, the system can independently analyze its own work and diagnose it. A large number of faults can be identified only thanks to this function.

Floor standing boilers

The operation of floor-standing boilers is not too different from wall-mounted ones. This type of chimneyless gas boilers is used when there is a separate room in which the boiler can be placed (boiler rooms, boiler rooms), since they have large dimensions.

Such boilers have high power, which distinguishes them from their wall-mounted counterparts, and they are also much more reliable than any type, since they have a non-volatile system.

Unfortunately, the installation of such a boiler will cost a lot of money due to its dimensions, and you will also need permission from the gas service to install it.

Single-circuit boilers

Such boilers heat water only for hot water supply, without heating. Each single-circuit boiler is equipped with devices for the smooth operation of the boiler, and if not, they should be installed by a professional.

An important component is the volume of the boiler; it is used in different volumes depending on water consumption. Some boilers can reach up to 300 liters, but even such a boiler will not accommodate a fairly large bathroom for a large number of family members.

A single-circuit gas boiler will have to be installed in a separate room, since it has large dimensions and requires a considerable area. It is more convenient to use a wall-mounted single-circuit boiler to avoid occupying a large area.

This system provides uniformly heated water that can be used without restrictions.

Double-circuit boilers

As for the chimneyless double-circuit boiler, it acts on both the heating system and the hot water system. The process occurs in such a way that the heat exchanger heats cold water, influencing the movement of water through the systems, directing it to the central heating system, and then to the hot water system. It all depends on changing the valve position. But it is worth paying attention that while the hot water system is open, the heating will be turned off.

It is very important to choose the power of the system. If the consumer wants good water pressure, then it is worth choosing a boiler power from 28 kW. The minimum power is 10 kW (for shower) and 18 kW (for bathroom).

Installing such a boiler will not be difficult, since the system already contains all the necessary tools - shut-off valves, valve and tank. You just need to supply gas, water pipes and a pipe for removing combustion products.

A double-circuit gas boiler is considered quite economical, as it turns on when the need for hot water arises, unlike a single-circuit gas boiler

Manufacturers and brands

Equipment of this class is produced by all well-known European companies, as well as domestic enterprises. If we consider its cost in relation to wall and floor options, then it is distributed in the same way as for boilers with an open combustion chamber. Wall-mounted options are cheaper, while floor-mounted ones have the highest price.

If we compare between local and foreign models, then here too there is no particular difference between boilers with an open and closed combustion chamber. Imported samples still have the highest prices, and products from domestic manufacturers are almost 50% cheaper.

If we consider boiler models from one manufacturer, for example, the very popular Italian company Baxi. Then its gas flueless floor-standing units have a price of around 2000, and wall-mounted models - about 1000 euros. The cost of wall-mounted boilers with an open combustion chamber under the brand name of this company is about 700-800 euros.

But, despite the higher price, chimneyless boilers are in great demand, especially when equipping apartment heating systems in multi-storey buildings.

What is this equipment?

In terms of their purpose, chimneyless boilers are practically no different from conventional ones. They, like all other models, can be used for heating rooms and preparing hot water, but they have a slightly different combustion chamber. There are differences in the principle of operation.

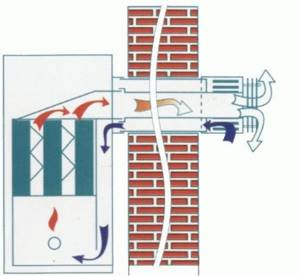

If the normal functioning of a conventional gas appliance requires the presence of a chimney and draft, then these models use a coaxial pipe to take in air and discharge exhaust gases.

Equipment of this type is designed for heating rooms up to 300 m² and can be connected to the system on one or both sides. Combustion products are removed from them through a coaxial pipe consisting of two elements. Gases are removed through the internal one, and air is supplied to the boiler through the external one.

They are very convenient not only structurally, but also because they are fireproof. Hot combustion products are isolated from the walls of the building by cold air coming from the street.

Another advantage is that the boiler does not require draft and air flow; these operations are performed forcibly, using a fan built into the device.

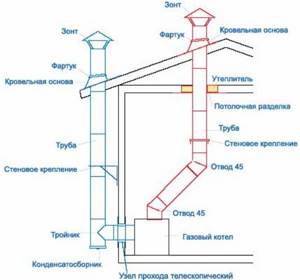

Chimneys and material options for their installation

Current heating equipment powered by gas is characterized by a fairly high efficiency index and low temperatures of combustion products, which implies increased requirements for the materials from which chimneys are constructed. In the construction market, there is a gradual replacement of brick, steel, asbestos pipes, and galvanization with more modern ones. Increasingly, special protective sleeves are used, as well as stainless steel and Hungarian furanflex. Let's take a closer look at the parameters of each of these materials.

Galvanized pipes

Steel pipes are quickly exposed to corrosion, which makes the operation of a galvanized chimney quite short (about 3 years). The use of a specially designed protective coating can extend the service life up to 5 years.

Asbestos cement pipes

This material was widely used in organizing the removal of combustion products, despite the maximum temperature of 300 degrees Celsius. This option has an acceptable cost, but has a number of nuances that would have to be dealt with (for example, installing a chimney on a gas boiler is quite difficult in the vertical plane, insufficient tightness of the joints, the likelihood of rupture or splitting of pipes when they overheat, as well as the ability of asbestos cement to absorb moisture and condensate).

Brick chimney

Brick is far from the best material for creating a chimney, since condensation quickly destroys the integrity of this material. Quite often, in houses equipped with a brick chimney, the ceilings and walls are “decorated” with damp spots, which are formed due to the absorption of moisture and condensation by the brick.

Protective sleeve

The smoke exhaust device, which has equal perimeters of the ventilation duct and the protective sleeve, is a composite multilayer shell. The main function of this design is to protect smoke channels from the adverse effects of thermal gas flows. Special hoses can be used to seal ventilation channels; their use can minimize the effect of combustion products on the chimney, as well as improve draft and increase the operating time of the entire structure.

Furanflex

It is a new option that is used for chimney installations. It is made from reinforced plastic reinforced with special fibers. A distinctive feature of this material is its resistance to interaction with the acidic environment of condensate, low thermal conductivity and efficiency when operating at temperatures less than 200 degrees Celsius.

Stainless steel

This material is characterized by high levels of tightness and fire safety, quickly overcoming the threshold of condensation. Thanks to its round cross-section and smooth surface, stainless steel promotes maximum traction

When purchasing pipes of this type, you should pay attention to their marking data, since they can significantly affect the quality of welded joints, as well as options for connecting disparate elements into a single structure

Parapet heating systems

One of the types of gas chimney boilers is parapet. The design resembles the design of condensing equipment. The main difference from the latter is the presence of a closed combustion chamber. During operation, air, which is inevitably consumed during combustion, enters the firebox not from the room itself, but from the street, therefore, overheating does not occur and the oxygen concentration does not decrease. As a result of this method of operation, the efficiency, environmental friendliness and efficiency of equipment increase

It is important to remember that some types of equipment, in addition to the traditional heat exchanger, have a convection casing in their design, which allows you to heat the room, consuming less gas, that is, with greater efficiency. There are mounted types of parapet equipment, which are mostly energy-dependent and also require additional power from electrical networks

At the same time, floor-standing units are completely energy independent.

How to make a chimney for a flueless boiler

The advantages and disadvantages of chimneyless boilers have been discussed more than once in various construction forums. In Europe, the units enjoy a well-deserved reputation as economical and reliable equipment with low installation requirements. Under domestic operating conditions, boilers' efficiency and productivity are somewhat reduced.

Several aspects can be highlighted as advantages:

- There is no need to coordinate with the gas service when installing a turbo boiler, provided that licensed and certified equipment is purchased.

- It is allowed to install the boiler in rooms with limited space, in apartment buildings and private houses. There is no need for forced ventilation of the room.

- Performance – chimneyless units use the temperature of heated flue gases to generate additional thermal energy, which increases the efficiency and efficiency of the devices.

What malfunctions often occur with chimneyless boilers?

Most malfunctions occur due to improper operation or installation of equipment. The specialist will try to find out the reasons why the chimneyless boiler goes out and eliminate them. There are several factors leading to this:

- Poor traction - non-compliance with the requirements for installing a coaxial pipe: exceeding the permissible vertical and horizontal sections leads to shutdown of the equipment.

- Voltage failures - in most cases, sensitive automation is installed in chimneyless units. If there is a voltage failure, the processor gives a signal to shut down.

- Malfunctions in the operation of automation - the design provides a large number of monitoring sensors: draft, heating of hot water and coolant, etc. Failure of any sensor leads to a shutdown.

If you follow the rules for installing chimneyless wall-mounted heating boilers and carry out regular maintenance, the devices will operate without complaints or difficulties throughout their entire service life.

How to deal with blowing out of a chimneyless turbo boiler?

One of the main problems that owners of chimneyless heating equipment face is shutdown due to poor draft or blowing out of the boiler. The danger of chimney backdraft for a boiler with a closed combustion chamber lies in the likelihood of carbon dioxide entering the room, as well as failure of individual components.

There are several ways to troubleshoot the problem:

- Improve the draft in the boiler by installing a deflector that increases the draft by approximately 1.5 times.

- Install wind protection - a block mounted on the head of the pipe reliably protects against wind.

- If the situation is not corrected, the coaxial chimney is redone, taking into account the technical requirements for the location of the chimney, when installing a turbocharged boiler with a closed combustion chamber in a private house.

In Europe, it is mandatory to install a gas detector when operating any gas equipment. In our country, this is a desirable measure that has already saved dozens of lives.

Which boiler is better - chimney or flueless, expert opinion

When answering this question, it should be taken into account that condensing / chimneyless boilers were created for operating conditions in low-temperature coolant heating mode. The 95% efficiency declared by the manufacturer is only possible if the return temperature is no more than 40°C. In the harsh Russian winter, it is quite difficult to fulfill this condition.

Installing a boiler with a closed combustion chamber in a regular chimney when replacing old equipment with new equipment is prohibited. You will have to redo the smoke exhaust system, which is quite expensive. Chimneyless units are optimally suited for well-insulated buildings located in temperate climates.

Main malfunctions of chimneyless boilers

As a result of incorrect operation, the most frequent, most recurring problems of chimneyless boilers arise. These include: deteriorated traction, breakdowns in the automatic control unit, voltage failures.

To ensure the supply of electricity in the presence of constant voltage failures, it is necessary to attend to the issue of purchasing a stabilizer. Checking the correct installation of the coaxial pipe will help to identify its incorrect installation, which leads to deterioration of traction in the unit.

Features of the design, operation and installation of floor-standing chimneyless gas boilers

If it is impossible to install a classic vertical chimney, flueless gas boilers are used for heating. For such heating equipment, a separate ventilated room for natural draft is not equipped.

Despite the name “flueless”, such boilers do have a chimney. Its role is played by a compact coaxial pipe, which provides draft and removal of smoke masses from the combustion chamber.

External outlet of coaxial chimney

Design and principle of operation of chimneyless boiler equipment.

Chimneyless boilers, like classic gas boilers, operate in heating mode - single-circuit, and also as water heaters (DHW) - double-circuit.

A distinctive feature of the design is a closed combustion chamber. The burner, through which the gas heats the water in the system, is located in a sealed chamber. Thus, carbon monoxide, soot and smoke from fuel combustion do not penetrate into the room, and the boiler’s operating efficiency increases.

Oxygen-saturated combustion air enters the closed chamber through the external chimney block. The air heated by the burner element heats the copper circuit through which the coolant flows. Then the “exhaust” air, together with the products of fuel combustion, exits through the internal block of the coaxial pipe.

Scheme of operation of a floor-standing coaxial boiler

The coaxial chimney is simple to implement. These are two coaxial pipes of different diameters, fastened together. In this way, the heated gas waste is cooled by the air entering the chamber, making the boiler fireproof and environmentally friendly for the residents of the house. By cooling the combustion products, the air enters the combustion chamber already heated, which saves energy resources.

To prevent insufficient draft, high-power gas boilers are equipped with deflectors that increase the air flow by one and a half times. If there is a possibility of wind blowing, a special wind protection block is installed at the pipe outlet.

Features of installation of gas boilers with a coaxial chimney.

Floor-standing chimneyless boilers for autonomous heating systems are installed in small buildings and in multi-apartment buildings or industrial premises.

Chimneyless gas boilers are installed on a special stand. If the boiler is controlled by an electronic board, it is connected to electricity according to the rules for installing electric and gas equipment by specialists.

They are included in the heating system and gas mains in the same way as chimney gas boilers. The difference is the installation of a coaxial chimney.

Installation diagram of a horizontal coaxial chimney

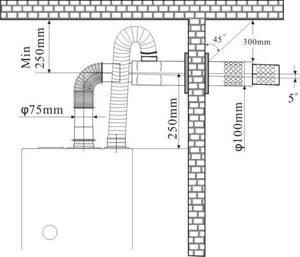

Requirements for installing a coaxial pipe as a chimney:

- The chimney outlet to the street runs horizontally through the wall. The length of this pipe section is no more than 1 meter.

- The chimney is horizontal, but if horizontal exhaust is not possible, a vertical chimney is used. The length of the vertical part of such a chimney is about 3 meters.

- The outer part of the pipe is located no lower than 2 meters from the ground.

- The distance from the pipe to window or door openings is at least half a meter.

- Do not place the pipe outlet under a window.

- To prevent the accumulation of condensation liquid, it is installed at an angle of 3-5 degrees.

- Observe the diameters of the coaxial chimney pipes and their ratio for fire safety.

- The hole drilled in the wall for the pipe is lined with insulation made of non-flammable material.

Compliance with these requirements will ensure the boiler operates safely and efficiently.

Chimneyless boilers - their pros and cons of operation.

The advantage of floor heaters equipped with a coaxial pipe is installation in a living room. To fit the boilers into the interior, the finishing of the walls and the junction of the chimney with the wall is selected.

More details about coaxial chimneys and their use for gas boilers can be found in the video below.

Coaxial boiler in the interior of the apartment

Besides this, other advantages:

- simplicity and low cost of installation;

- there is no need to install supply and exhaust ventilation;

- high power of units of such a design that they heat large areas;

- some gas models are equipped with convection holes, which makes it possible to heat a room without a radiator;

- long service life.

The disadvantages of coaxial boilers are the smoke exhaust system. The length of the smoke exhaust pipe is no more than 5 meters. During frosts, chimneyless boilers operate at high power, which causes more condensation to form in the coaxial pipe, which freezes and blocks the air supply and smoke removal. Blowing out of the chimney occurs if it is not equipped with a wind protection.

The principle of operation of a boiler without a chimney

This type of gas boiler works on the principle of removing smoke through smoke vents located in the wall (without any openings or openings), and not through a smoke duct leading to the roof. This type of gas exchange is called “pipe in pipe”. The outer pipe contains an inner one, but of a smaller diameter. Through it, smoke waste is removed, as well as water, carbon dioxide or carbon monoxide - combustion products.

Air from the street enters through an external pipe with a large diameter. Moving through the pipe, it is warmed up with the help of combustion products, filling the boiler chamber. There, the air mixes with fuel, which has the state of aggregation as a gas. Due to the high air temperature, the fuel burns out completely, creating significant savings.

The system is equipped with special fans that control the flow and draft of air, while in classic chimney boilers such measures are carried out independently.

What we pay attention to

Heating devices with a closed combustion chamber include a coaxial chimney for a gas boiler.

It is designed to ensure smooth operation of the device. And serious requirements are placed on it, because combustion products are released through it, which are very harmful to human health. Therefore, it is recommended to install it through a wall in which there are no window or ventilation openings.

In all other parameters, the criteria for choosing a gas flueless boiler do not differ from others

When purchasing it, you should also pay attention to:

- power

- compactness

- design

- ignition options

The brand of the manufacturer is also an important factor, and since each of them has a wide range of products, it is worth evaluating several different samples to decide which one is best suited for the room.

Flueless boilers are divided into:

Let's start our consideration with floor-standing boilers from the Slovak manufacturer Proterm. They are non-volatile and have an efficiency of 90%, are reliably protected from overheating and are supplied assembled. Floor-standing boilers have high power ratings and can be used for heating large rooms, and also have other remarkable characteristics:

- reliability

- ease of use

- relatively low price

- possibility of changing fuel

When choosing these devices, even the brand is not so important. It can be:

All of them are well adapted for use in the Russian climate and have high quality indicators, a large number of safety sensors and are very easy to operate.

German chimneyless boilers are undeniable in their reliability and quality. Not only are they designed for a long service life, but they also have a lot of advantages, not the least of which is environmental friendliness.

The brand plays a significant role when choosing, but you should not lose sight of other parameters:

They are also important and must be taken into account when purchasing.

How to choose the right chimneyless boiler for a residential premises

First of all, when choosing, you need to decide on the installation location of the gas flueless boiler in the room itself. Among the models of many manufacturers there are both parapet and wall models. To install a parapet model, it is necessary to take into account the location of the windows - the chimney should not be at the same level or below the level of the windows.

It is recommended to install a wall-mounted gas flueless boiler on an external wall of the room. As an exception, installation on internal walls is allowed, but the length of the coaxial chimney should not be more than 5 meters.

The boiler power is selected depending on the area of the heated room. As for a specific brand, professionals advise paying attention to how long this brand is represented on the market, and whether this brand has a network of service centers. This is an important point, since servicing this equipment requires not only trained specialists, but also the availability of branded spare parts. Thus, most domestic brands, as well as global brands of climate control equipment manufacturers, advise diagnostics and maintenance of chimneyless boilers at least once a year, before the start of the heating season.

A chimneyless gas boiler allows you to solve the problems of installing individual heating in almost any house and apartment, providing warmth and comfort in the most severe frosts.

SNiP standards

The manufacture and installation of any chimney structures must comply with all requirements of SNiP 2.04.05-91 and DBN V.2.5-20-2001. Such adherence to standards guarantees the safe operation of the heating system. Violation of the conditions listed in the documents can lead to problematic situations, the solution of which will require the participation of the gas industry.

Abstracts from the main regulatory documents:

- The structure of the condensate collector should solve the problem of moisture accumulation on the walls of the chimney;

- Good traction is a must;

- The head of the chimney must be free and do not allow the presence of deflectors or fungi on it that inhibit the removal of combustion products;

- A careful fit of all structural elements at their connection points is mandatory;

- Tight sealing at joints and all kinds of connections is required.

Chimney boilers general information

When choosing chimney boilers powered by natural gas, you need to know what types of this equipment are on sale today. Popular types are:

- Parapet boilers;

- Mounted;

- Floor-standing.

When choosing heating equipment, you should pay special attention to the following indicators and parameters:

- Possibility of additional power supply from electricity in case of emergency shutdown;

- The presence or absence of a circuit and/or built-in boiler;

- Performance.

Despite the fact that the equipment produced in our country does not have a wide range of capabilities and the functionality is much more modest than that of analogues from Western countries and Japan, the reliability and durability of all elements allow it to be used for heating rooms of various sizes without loss in performance

It is important that all gas boilers are completely safe, since they undergo preliminary quality control before entering the market

Boiler application:

Gas boilers are often used for heating apartments. This option is by far the most profitable and has a number of advantages over the centralized system. It is easy to install, does not require additional costs for chimney equipment, has compact dimensions and a modern design, and also allows you to turn on the heating during the off-season. These advantages and the presence of a coaxial pipe made the chimneyless boiler very popular and in demand in the Russian climate.

Gas boiler in the apartment