Is it necessary, and in what cases?

Many owners of country real estate, and especially two-story houses, are interested in the question of installing an additional circulation pump in the heating system. They come to this conclusion after uneven heating of the radiators in the rooms, provided that the boiler has sufficient power. If the temperature difference between the boiler and the coolant in the pipelines exceeds 20 degrees, then it will be necessary to remove air plugs or set the existing pump to an increased speed.

Installation of additional pumping equipment is necessary in the following cases:

- When adding an additional circuit to the heating system, and especially when the pipe length exceeds 80 meters;

- For uniform movement of coolant in pipelines.

An additional pump in the heating system may not be needed if it is balanced using balancing and control valves, so before purchasing additional equipment, bleed the air from the radiators and add water to the system. If everything works fine, then there is no point in installing an additional pump.

Structure and types of systems with a natural type of circulation

Typically, a heating circuit without a pump includes a list of required components:

- heating device - a boiler or stove that can be heated with the type of fuel available in a particular region;

- expansion tank, which allows you to relieve excess pressure or add water to the heating circuit;

- pipes that form the circuit along which water will move in the system;

- batteries that allow you to heat the room more efficiently by increasing the area of the heat-transferring surface.

The diameter of heating pipes with natural circulation will be slightly larger than if a circulation pump is used.

Based on what kind of coolant will be used, heating systems with natural circulation can be water or steam.

Here are the distinctive features of each type of heating.

Hydraulic separator

If there is a need to install an additional pump, then another device must be included in such a heating system - a hydraulic separator. In the list of terms used, a hydraulic separator can also be called an anuloid or a hydraulic arrow.

Operating principle of hydraulic separator

Such devices are recommended for use in heating systems where the coolant is heated using long-burning boilers. The fact is that the heating devices in question can operate in several phases (fuel ignition, combustion process and attenuation), and for each of these phases it is necessary to maintain a certain combustion mode.

Installing a hydraulic needle in the heating system allows you to create a certain balance in the operation of heat and warming up the system. The anuloid itself is made in the form of a pipe with four outlet pipes. The main functions of such a device include:

- Automatic removal of accumulated air;

- Collecting sludge particles (works as a dirt trap).

Heating in a private house performs many functions that must be implemented regardless of coolant flow and possible pressure drops in the pipelines. It is quite difficult to achieve efficient operation of the system, because the liquid enters the pipeline circuits from one source of thermal energy - the boiler, which will ultimately lead to unbalanced heating. To prevent such situations, the hydraulic separator serves; it performs the function of decoupling.

How to choose a water pump for heating your home

A heating pump for a private home is selected according to several basic parameters:

- Productivity and pressure;

- Rotor type;

- Power consumption;

- Control type;

- Coolant temperature.

Let's look at how to choose water pumps for heating a private home.

Performance and pressure

Correctly made calculations will help you choose the unit that best suits your needs, which means it will help you save your family budget.

The performance of an electric water pump refers to its ability to move a certain amount of water per minute. The following formula is used for calculation – G=W/(∆t*C). Here C is the thermal capacity of the coolant, expressed in Wh/(kg*°C), ∆t is the temperature difference in the return and supply pipes, W is the required heating power for your home.

The recommended temperature difference when using radiators is 20 degrees. Since water is usually used as a coolant, its heat capacity is 1.16 W*h/(kg*°C). Thermal power is calculated for each household individually and expressed in kilowatts. Plug these values into the formula and get the results.

The pressure is calculated in accordance with the pressure loss in the system and is expressed in meters. Losses are calculated as follows - losses in pipes are considered (150 Pa/m), as well as in other elements (boiler, water purification filters, radiators). All this is added up and multiplied by a factor of 1.3 (provides a small margin of 30% for losses in fittings, bends, etc.). There is 9807 Pa in one meter, therefore, we divide the value obtained by summation by 9807 and obtain the required pressure.

Rotor type

Home heating uses wet rotor water pumps. They are characterized by a simple design, minimal noise levels and no need for maintenance. They are also characterized by small dimensions. Lubrication and cooling in them is carried out using a coolant.

As for dry-type water pumps, they are not used in home heating. They are bulky, have a high noise level, and require cooling and periodic lubrication. They also require periodic replacement of seals. But they have a large throughput capacity - for this reason they are used in heating systems of multi-storey buildings and large industrial, administrative and utility buildings.

Power consumption

The most modern water pumps with energy consumption class “A” have the lowest power consumption. Their disadvantage is their high cost, but it is better to invest once to get reasonable energy savings. In addition, expensive electric pumps have lower noise levels and a longer service life.

Control type

Through a special application you can get information about the operation of the device wherever you are.

Typically, the rotation speed, productivity and pressure are adjusted using a three-position switch. More advanced pumps are equipped with electronic control systems. They control the parameters of heating systems and allow you to save energy. The most advanced models are controlled wirelessly, directly from a smartphone.

Coolant temperature

Water pumps for heating a private home differ in their operating temperature range. Some models can withstand heating up to +130-140 degrees, these are the ones that should be preferred - they can cope with any thermal loads.

As practice shows, operation at the maximum temperature is possible only for a very short time, so having a solid reserve will be a plus.

Other characteristics

When choosing a water pump for heating, you need to pay attention to the maximum operating pressure for the selected model, installation length (130 or 180 mm), type of connection (flange or coupling), and the presence of an automatic air vent. Also pay attention to the brand - under no circumstances buy cheap models from little-known developers

The water pump is not a part you should skimp on.

Where to put

In the autonomous heating system of a private house, it is recommended to install circulation pumps with a wet rotor, which rotate without the use of special lubricants. The coolant and lubricating element here are the coolant. When installing such a device, the following rules must be taken into account:

- The pump shaft must be in a horizontal position relative to the floor surface;

- The movement of water flow in the system must coincide with the direction of the arrow on the device;

- To prevent liquid from entering the pump terminals, the box should be installed on the top or side of the equipment.

According to some users, it is better to install the pump on the return pipeline. Here the coolant temperature is minimal, which will increase the service life of the device, but not all experts agree with this statement. The fact is that the pump is designed for operation in a coolant environment whose temperature can reach 110 degrees.

With warm floor

When filling the system with coolant, it is not always possible to get rid of the air present here. Accumulated gases often block the movement of fluid, and not every manifold can be used as a relief valve. To solve this problem, the circulation pump has a special outlet valve made in the form of a disk.

To release accumulated gases, you need to turn this part with a screwdriver counterclockwise. After supplying water from the slot, the disk is tightened and the pump is started again. A similar procedure is repeated several times in a row.

Two pumps in a scheme with heated floors

Reference! If this technology is used, the pump must be mounted horizontally, always after the feed mixer. Some systems use several devices, one for each floor.

When filling the piping with coolant, it is not always possible to remove all the air. The latter blocks the path of the liquid, and the descent cannot be carried out through any collector. The solution to the problem is a valve built into the circulation pump. To release gases, simply turn it counterclockwise, apply water, then tighten the disk and turn on the device. If necessary, the procedure is repeated.

The need to install an additional circulation pump

The thought of installing a second device arises when the coolant is heated unevenly. This is due to insufficient boiler power.

To detect the problem, measure the temperature of the water in the boiler and pipes. If the difference is 20 °C or more , the system should be cleared of air pockets.

If the malfunction continues, install an additional circulation pump. The latter is also necessary if a second heating circuit is installed, especially in situations where the length of the piping is 80 meters or more.

Reference! Invite specialists to clarify the calculations. If they are incorrect, installing an additional device will result in poor performance. In rare cases, nothing will change, but the purchase and placement costs will be wasted.

A second pump is also not needed if the heating system is balanced with special valves. Clear the pipes of air, replenish the amount of water and carry out a test run. If the devices interact normally, then there is no need to install new equipment.

Hydraulic separator

Used when installation of an additional pump is required. The device is also called an anuloid .

Photo 1. Hydraulic separator model SHE156-OC, power 156 kW, Poland.

Such devices are used in heating if water is heated using long-burning boilers. The devices under consideration support several modes of heater operation, from ignition to fuel extinction. In each of them, it is advisable to maintain the required level, which is what the hydraulic gun does.

Installing a hydraulic separator in the piping creates a balance during the operation of the coolant. Anuloid is a tube with 4 outgoing elements . His main tasks:

- independent air removal from heating;

- catching part of the sludge to protect pipes;

- filtering dirt that gets into the harness.

Attention! You need to carefully select the characteristics. Choosing a quality device will help protect the system from problems. Because of this, installing a pump becomes mandatory.

Functionality

A connection with a circulation pump performs many tasks. They must be allowed regardless of the flow of working water and possible pressure surges in the pipes. Efficiency is difficult to achieve because the fluid is supplied internally from a common source.

Thus, the coolant leaving the boiler unbalances the system.

Because of this, a hydraulic separator is placed: its main purpose is to create a decoupling that will solve the problem described above.

The following functions are also important:

- contour matching , if several are used;

- support of the calculated flow rate in the primary piping, regardless of the secondary ones;

- constant operation of circulation pumps;

- facilitating the operation of branched systems;

- cleaning pipes from air;

- sludge fishing ;

- ease of installation when using modules.

Where to put the second device in the house

In autonomous heating, it is recommended to install a device with a wet rotor, which is self-lubricated with the working fluid. Therefore, consider the following points:

- the shaft is positioned horizontally , parallel to the floor;

- the water flow is directed in one direction with the arrow installed on the device;

- the box is placed on any side except the bottom , which protects the terminal from water ingress.

The device is mounted on the return line, where the coolant temperature is minimal.

This increases the service life, although some experts disagree with this phrase. The latter is related to the operating rules: the device must withstand heating of the working fluid to 100-110 °C.

Important! Placement is possible not only on the return pipe, but also on the straight pipe. The main thing is to install it between the boiler and radiators, since the opposite is prohibited. This also makes the device easier to maintain.

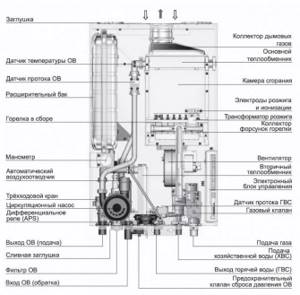

What is a circulation pump

One of the necessary elements in the hot water supply and heating system is the circulation pump. This device performs pumping and suction functions and promotes the active movement of liquid inside the heating system. The pump is mounted directly into the pipeline. Designed to operate in a closed loop.

The main elements of the device are:

- frame;

- impeller;

- rotor;

- motor shaft;

- terminal box;

- engine;

- air propeller.

As soon as electrical energy is supplied to the rotor, it begins to rotate, transmitting a signal to the impeller to move. This causes fluid to be sucked in from one side of the device and expelled from the other. To make the units easier to install and maintain, manufacturers produce different models in body shape and dimensions.

Prices for circulation pumps for heating boilers

circulation pumps for heating boilers

What is it used for?

Thanks to the circulation pump, the heating of the premises is carried out evenly and quickly, so the scope of application of such units is extensive.

Pumps are installed for the following purposes:

- Improving the quality of operation of a natural circulation system.

- Forced movement of coolant during geothermal heating. The heat pump operates according to the classic Carnot cycle: it takes in cold coolant deep below and in return receives a fluid flow heated to 50 degrees inside the heating system. In the summer, geothermal equipment transforms from a heater into a passive air conditioning device.

- Ensuring water circulation in hot and cold water supply systems in a private home.

- Increasing the efficiency of a warm water floor design.

- Use in air conditioning systems for cooling purposes.

Types of pumps

All electric pumps have a common operating principle, but differ in design and efficiency. To choose the right device, you need to know what types of equipment exist and how they differ.

There are two types of circulation units:

- With wet rotor. Such devices have a modular design, which simplifies their maintenance and repair. The rotor and impeller are in the working environment, only the electrical part remains dry. The devices have a low noise level. A step speed controller allows you to control the consumption of electrical energy. The advantage of the unit is its long service life if installed correctly. The disadvantage of the device is its sensitivity to the quality of the working fluid.

- With dry rotor. The pump differs in the type of design. The rotor is enclosed in a sealed housing, and the impeller is immersed in the coolant. The engine is protected from liquid penetration by sealing rings. The main advantage of the unit is its high efficiency and minimum requirements for the quality of the coolant. The device produces a high noise level.

Judging by the characteristics, we can conclude that devices with a wet rotor are more suitable for private houses and apartments.

Advantages of boilers with a pump

An electric boiler with a circulation pump, thanks to its unique design, can perform the functions of a whole complex of heating devices.

The increased demand for such equipment is due to its advantages:

- A large range of models makes it possible to choose a boiler for heating rooms of any size. The user does not need to select a pump separately.

- The device allows you to drive liquid through all circuits at optimal speed. This helps to heat the room evenly and quickly.

- The efficiency is 90% and above, which indicates the high efficiency of the models.

- Automation of the process ensures simple setup and high safety of boilers.

- The equipment is environmentally friendly, since no harmful substances are emitted during its operation.

- Simple installation of the heating system.

Manufacturers produce wall-mounted boilers that are suitable for small apartments, as well as floor-standing boilers that can provide heat to a large area.

Flaws

Boilers with built-in circulation pumps are not without drawbacks, familiarity with which will allow you to decide whether it is worth installing such equipment.

Main disadvantages:

- Electricity is more expensive than gas or solid fuel.

- The uninterrupted operation of the boiler directly depends on the voltage in the supply network.

- The need to install high-quality wiring in a heated room.

The disadvantages of using boilers are mainly related to the need to provide them with electrical energy. Before installation, it is necessary to calculate the current strength in order to select a cable of the required cross-section and a machine. To reduce the power of the boiler itself, a battery tank is installed on the output circuit of the heating system.

Is an additional pump needed for a double-circuit boiler?

After installing a double-circuit condensing boiler, many users consider installing an additional pump in the heating system of a country house. The need to use an additional pumping device is explained by the uneven heating of the living spaces of a two-story house with sufficient power of the boiler equipment.

Advice! If the temperature differences of the coolant in the supply and return pipelines exceed 20 degrees, it is necessary to switch the circulation pump to a higher speed or get rid of air pockets.

Installing another pump is necessary in the following cases:

- When installing heating in a private house with an additional circuit, or in cases where the length of the pipes is more than 80 meters.

- For uniform supply of coolant through the heating system.

There is no need to install an additional pump if the heating is balanced using special valves. Therefore, before purchasing pumping equipment, bleed the air from the heating radiators and add water, check the circuit for leaks using a manual pressure test pump. If after such procedures the autonomous heating of a private house works normally, then another pump will not be needed.

Circulation pump in a gas boiler

The circulation pump in the design of a gas boiler accelerates the coolant through the heating system, due to which the coolant cools in the system more slowly and returns to the boiler in a “heated” form. Since heating in the boiler occurs to a certain temperature, the next heating cycle of the coolant will be shorter. This results in lower gas consumption and faster water heating cycles (higher efficiency).

It is believed that hydraulic heating systems do not require the installation of circulation pumps, however, it will not interfere at all in old heating systems with large diameter pipes.

By purchasing a gas boiler with a circulation pump in the design, you no longer need to install a separate circulation pump in the heating system.

Why do you need a hydraulic arrow?

If several pumps are installed in the heating system of a summer house or cottage, a hydraulic separator or hydraulic arrow must be included in the circuit. This device can be used together with a single-circuit diesel boiler or solid fuel unit. In the latter case, the device regulates the supply of coolant in different phases (fuel ignition, combustion phase and attenuation). Installing a hydraulic arrow allows you to balance the operation of the heating system. The main tasks of the hydraulic separator are:

- Automatic removal of accumulated air;

- Catching dirt from coolant flows.

Important! The hydraulic arrow in heating allows you to balance the operation of the system, protects it from airing, and prevents the accumulation of dirt in the pipelines. Such a device must be installed without fail if there are several booster units.

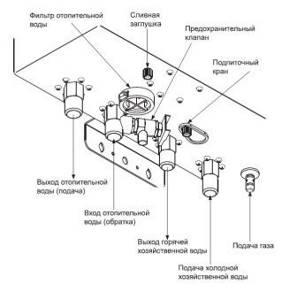

Installation nuances

When installing turnkey heating, a master plumber installs a circulation pump with a wet rotor. Such a device does not create much noise; its rotor rotates without lubrication. Coolant is used here as a coolant and lubricant. When installing pumping equipment, you need to take into account the following nuances:

- The shaft of the pressure-injecting device is positioned horizontally relative to the floor plane.

- Carry out installation in such a way that the direction of water coincides with the arrow on the device body.

- Install the device with the terminal box facing up, which will prevent water from entering the electronics.

Important! Experts recommend installing the pump on the return pipeline of the heating system of a single-story or multi-story residential building. Despite the fact that such equipment is designed to operate in hot water with temperatures up to 110 degrees, warmer liquid in the return pipeline will only extend its service life.

Installation of the unit is carried out only after draining the water from the system. If there is a power outage, the pump will not be able to pump the coolant, so it is connected through a bypass, and a mesh filter is installed in front of the inlet pipe to prevent scale and debris from getting onto the impeller. In addition, shut-off valves are provided at the input and output of the device for possible replacement and repair of the device.

As we can see, installing a circulation pump requires certain skills, so the installation of this equipment must be carried out by a professional. To order a service, you can leave a request on the website or call the number

Connection methods

Electrical connection using a plug and socket

. This method involves installing an electrical outlet in close proximity to the place where the circulation pump is mounted. Sometimes they can be supplied with a connected cable and plug included, as in the photo:

In this case, you can simply plug the device into the mains using an outlet located within reach of the cable. You just need to make sure there is a third, grounding contact in the outlet.

If there is no cord with a plug, they need to be purchased or removed from an unused electrical appliance.

You should pay attention to the cross-section of the cord conductors. It should be between 1.5 mm2 and 2.5 mm2. Wires must be stranded copper, ensuring resistance to repeated bending

The cord with a plug for connecting electrical appliances to the network is shown in the photo below:

The wires must be stranded copper, ensuring resistance to repeated bending. The cord with a plug for connecting electrical appliances to the network is shown in the photo below:

Before connecting the circulation pump, you need to find out which of the three wires of the cord is connected to the ground pin of the plug. This can be done using an ohmmeter, while at the same time checking the integrity of the remaining wires.

Open the terminal box cover. Inside the box there are three terminals designed to connect the device to the network, marked as in the picture:

We unscrew the clamp of the cable coupling (in the first photo it is a plastic nut into which the cable is inserted), put it on our cord, and insert the cord into the coupling. If there is a cable tie inside the box, thread the cord through it. We connect the ends of the cord wires, previously stripped of insulation, to the terminals.

The wires connected to the plugs of the plug should be connected to the L and N terminals (don’t be afraid to mix them up, this is not critical), the wire of the grounding contact of the plug should be connected to the PE terminal (but you can’t make a mistake here). The instructions supplied with the product prohibit its operation without protective grounding. Next, tighten the clamp (if any), tighten the cable sleeve clamp tightly, and close the terminal box cover. The pump is ready to be plugged into the mains.

Fixed connection.

The connection diagram for the circulation pump to the electrical network with grounding is provided below:

The requirements for the wire cross-section here are the same as in the previous version. The cable for this installation can be used either flexible or inflexible, copper, VVG brand, or aluminum, AVVG. If the cable is inflexible, the installation should ensure that it does not move. To do this, the cable along the entire route is secured with clamps.

In this option, a residual current device (differential circuit breaker) is used. Instead, you can use a regular single-pole circuit breaker, passing only the phase wire through it. If the machine is installed in a panel where there is a PE bus, then the cable from the pump to the machine must be three-core. If there is no such bus, the PE terminal should be connected to a grounding device. This connection can be made with a separate wire.

Separately, I would like to consider such an installation option as connecting the pump to the UPS. It is the most preferable and ensures the independence of the heating system from power outages. The connection diagram of the circulation pump to the uninterruptible power supply is provided below:

The power of the UPS should be selected based on the power of the pump motor. The capacity of the battery is determined by the estimated time of autonomous power supply of the circulation pump, that is, the time when the power supply is turned off. We talked about how to choose a UPS for a boiler in a separate article. Requirements for cable cross-section, as well as the presence of protective grounding, apply to all connection options.

Finally, we recommend watching video instructions for connecting various pump models to the electrical network:

So we looked at how to properly connect the circulation pump to the electrical network. The diagram and video examples helped to consolidate the material and clearly see the nuances of installation!

It will be useful to read:

- How to choose batteries for a UPS

- How to connect an electric heating boiler

- Connection diagram for differential machine

Additional pump in the heating system

The Vaillant boiler installed in the house has a built-in circulation pump. The heating circuits are quite extensive, and it seems that the power of this pump is not enough. Two-pipe system. The question is: is it possible to install an additional circulation pump that will work constantly. What’s confusing is that the built-in pump turns off during each operating cycle, although only for a very short time.

It is possible, but you need to install a hydraulic separator and turn on the pump from it. If you simply turn on the pump in series with the boiler, then when the water is heated, it will work “at a standstill,” which is harmful for it. Or, as an option, you can install a bypass valve. We implemented this solution once and it worked fine. But I like the hydraulic separator better, because I don’t need to configure anything.

Usually, in wall-mounted boilers, the pump can be switched to constant operation quite simply, this will also improve the hydraulics of the heating system. Just in case, check what speed the pump switch is set to. By what sensations did you determine that the pump power is not enough? If the temperature difference on the boiler is less than 20 or so and no circuit is being pressed through, it is necessary to balance the heating circuits. If the boiler cannot reach the temperature, there is not enough boiler power. Without a bypass valve and a hydraulic separator, an additional pump of increased power and pressure against the boiler can be installed as follows: between the supply and return of the boiler, install a full-bore jumper L = 300-400mm directly at the boiler (the smaller the better), install the additional pump on the supply line behind boiler and the jumper connection point at any distance from them. Those. you will get two circulation rings - a large one for the heating circuit and a small one for the boiler circuit, with minimal mutual influence of the pumps. This is how Pindos connect their hydronic boilers. politically incorrect, American-Canadians. It is clear that when the boiler is operating on DHW, circulation in the large circuit is maintained. As usual, a filter in front of the additional pump and taps.

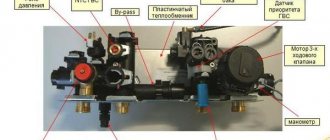

Navien Delux Coaxial device

The word Coaxial in the name of the boiler means the use of coaxial chimneys (pipe in pipe). This system is convenient in that only one pipe is used to supply air to the combustion chamber and remove exhaust gases, which can be led from the room to the street by the shortest route. In general, the boiler is not fundamentally different from products from other brands. You can note the convenient location of the expansion tank and the non-standard location of the fan - it is located below the burner.

It is noteworthy that Navien boilers do not have a built-in control panel. All adjustments are made using a separate control panel. The remote control is also equipped with a temperature sensor and displays various information about the operating status of the equipment and will report a malfunction with an error code. A special feature of Navien is also the presence of an air pressure sensor, which not only performs a draft check function, but also sends data to the control unit for portion control and determines the presence of reverse draft. If there is excess pressure in the chimney, for example due to wind blowing, the gas supply to the burner will be stopped and the boiler will stop.

At the bottom of the boiler there are inlets and outlets of the heating and hot water circuits, a make-up tap, a drain plug, a cleaning filter and a safety valve for relieving excess pressure.