Circulation pump in a gas boiler

The circulation pump in the design of a gas boiler accelerates the coolant through the heating system, due to which the coolant cools in the system more slowly and returns to the boiler in a “heated” form. Since heating in the boiler occurs to a certain temperature, the next heating cycle of the coolant will be shorter. This results in lower gas consumption and faster water heating cycles (higher efficiency).

It is believed that hydraulic heating systems do not require the installation of circulation pumps, however, it will not interfere at all in old heating systems with large diameter pipes.

By purchasing a gas boiler with a circulation pump in the design, you no longer need to install a separate circulation pump in the heating system.

Power connection

The circulation pumps operate from a 220 V network. The connection is standard; a separate power supply line with a circuit breaker is desirable. The connection requires three wires - phase, neutral and ground.

Circulation pump electrical connection diagram

The connection to the network itself can be organized using a three-pin socket and plug. This connection method is used if the pump comes with a connected power wire. It can also be connected via a terminal block or directly with a cable to the terminals.

The terminals are located under a plastic cover. We remove it by unscrewing several bolts and find three connectors. They are usually labeled (the pictograms are N - neutral wire, L - phase, and “ground” has an international designation), so it’s hard to make a mistake.

Where to connect the power cable

Since the entire system depends on the performance of the circulation pump, it makes sense to make a backup power supply - install a stabilizer with connected batteries. With such a power supply system, everything will work for several days, since the pump itself and the boiler automation “pulls” electricity to a maximum of 250-300 W. But when organizing, you need to calculate everything and select the battery capacity. The disadvantage of such a system is the need to ensure that the batteries do not discharge.

How to connect a circulator to electricity through a stabilizer

Hello. My situation, a 25 x 60 pump is located immediately after a 6 kW electric boiler, then the line from a 40 mm pipe goes to the bathhouse (there are three steel radiators) and returns to the boiler; after the pump, a branch goes up, then 4 m, down, rings a house of 50 sq. m. m. through the kitchen, then through the bedroom, where it doubles, then the hall, where it triples and flows into the boiler return; in the bathhouse there is a branch 40 mm up, it leaves the bathhouse and enters the 2nd floor of a house of 40 sq. m. m. (there are two cast-iron radiators) and returns to the bathhouse in the return line; there was no heat on the second floor; the idea of installing a second pump in the bathhouse for supply after the branch; the total length of the pipeline is 125 m. How correct is the solution?

The idea is correct - the route is too long for one pump.

Types of pumps

To ensure that the energy carrier circulates efficiently, dry and wet pumps are used.

Dry

In equipment of the first type, contact of the rotor with the coolant is not provided. The seal used in such a device hermetically separates the pump itself from the motor. The efficiency of this equipment is 80%, so it is advisable to use it when constantly pumping large amounts of liquid.

The area of application of dry pumps is shopping centers, factories, factories. In private homes, such structures are not used due to the high level of noise generation.

Wet

The rotor of wet pumps is located in the coolant, which they pump. Water cools the engine. The stator included in the design serves to supply electricity. Pumps with a “wet” rotor have a lot of advantages: long service life, rare maintenance, low noise generation, small size, ease of replacing blocks.

Disadvantages - low efficiency (about 30-50%), limited scope of application (private houses and city apartments), inability to use pumps for drinking water and for anything related to food.

How to install an additional pump in a heating system - theory and practice

Content:

Arranging and operating the heating system of a private home can sometimes be problematic. So, the following problem often arises - the coolant moves unevenly through the pipeline, which is why heating the house is not effective enough.

An additional circulation pump built into the heating system will help solve the problem. Such a device can be connected to structures operating on any type of fuel. This article will discuss how to install an additional pump in the heating system.

Advantages of circulation pumps

An additional pump in the home heating system allows for a number of advantages, including:

- Significant increase in heating efficiency;

- Increasing the rate of heating of rooms and increasing the heated area;

- The temperature regime in the heating circuit becomes more uniform;

- The pipes do not become airy;

- Energy consumption for heating is reduced;

- It becomes possible to connect various dryers and thermostats to the system;

- The size of the pipes used for heating can be reduced.

In addition to the qualities described above, circulation pumps can boast a relatively low cost, so their installation will not require any special expenses. An additional pump in the heating system will increase heating efficiency without making significant changes to the design of the system.

Pump characteristics

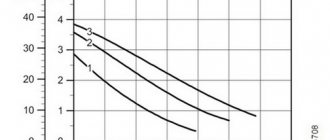

All circulation pumps have two main parameters:

- N – pressure value, i.e. the height to which the pump can lift liquid (measured in meters);

- Q is the fluid consumption over a certain time period (measured in cubic meters), which is directly dependent on the power of the heating boiler and the diameter of the pipes used.

Device Specifications

Knowledge of the characteristics of the circulation pump will help you find a suitable option for home or apartment heating. When purchasing, the following parameters are taken into account:

- pressure – a technical parameter that determines the rise of water to a certain level;

- consumption and performance indicator - the amount of coolant supplied over a certain time;

- installation dimensions - the size of the device, allowing you to determine the possibility of insertion into the pipeline.

On the front of the case there are digital and numeric markers:

- variety - circulation blowers are designated as UP;

- speed adjustment – models with single-speed mode are not indexed, S means step switching, E – smooth frequency switching;

- diameter of the internal pipe in mm;

- pressure - depending on the manufacturer, it is marked in meters or decimeters.

Based on the information on the front panel, you can determine the type of case. N indicates that stainless steel was used, cast iron is not indexed, A – the presence of a fitting for the bleeder, K – the possibility of use for systems with cold water, KU – for cold water, but with foam filler for the stator and terminal box.

Step-by-step instructions for assembling and installing the pump

After purchasing the device and choosing the location for its installation, it is necessary to carry out assembly and installation. It is first necessary to install ball valves on both sides of the pump, and install a mud trap in front of the unit to retain scale, dirt, and abrasive particles. The upper part of the bypass must be equipped with an air valve.

Assembling and connecting the pump to the heating boiler is carried out in the following sequence:

- Before installation, drain the liquid from the system. For complete cleaning, you need to fill it with coolant and drain it, then repeat this procedure a couple more times.

- Install the pump into the system.

- After installation, all connections must be carefully sealed.

- Fill the system with liquid. Remove excess air.

- Connect the device to the electrical network.

The number of circulation devices required in the system depends on the length of the pipeline.

Frequently asked questions from consumers

- Will the pipes make noise when the pump is running? The pipes may make noise if the pump is selected incorrectly or if air has accumulated.

- Is it permissible to use a high pressure pump in a water supply system? This type of pump cannot be used. The pumps are similar in appearance, but in a water supply system, pumps are used only to maintain a small pressure if there is not enough pressure.

- What are pumps made of? Many pump parts are made from ceramics, which ensures low noise operation and increases service life.

- Are there hot water pumps? Such pumps are commercially available. Their use will increase water consumption, as well as electrical energy consumption.

- How much electricity do pumps use? Many circulation pumps are economical devices. They consume energy like a simple light bulb. Pump manufacturers have adopted a convention to give pumps labels that show their electricity consumption, just like household appliances. There is a special classification.

- How often do circulation pumps need to be replaced? If the pump is of high quality, it will work for many years. But this depends on the manufacturer. In order for the pump to work longer, you need to follow the recommendations of specialists: select and install the pump correctly, prevent air from entering the system, use clean water.

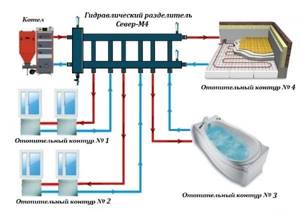

Hydraulic separator

If there is a need to install an additional pump, then another device must be included in such a heating system - a hydraulic separator. In the list of terms used, a hydraulic separator can also be called an anuloid or a hydraulic arrow.

Operating principle of hydraulic separator

Such devices are recommended for use in heating systems where the coolant is heated using long-burning boilers. The fact is that the heating devices in question can operate in several phases (fuel ignition, combustion process and attenuation), and for each of these phases it is necessary to maintain a certain combustion mode.

Installing a hydraulic needle in the heating system allows you to create a certain balance in the operation of heat and warming up the system. The anuloid itself is made in the form of a pipe with four outlet pipes. The main functions of such a device include:

- Automatic removal of accumulated air;

- Collecting sludge particles (works as a dirt trap).

Note! From these characteristics it can be understood that the hydraulic separator is considered an important device in the heating system, so it must be installed without fail if there is a pump.

Hydraulic separator in the heating system

Heating in a private house performs many functions that must be implemented regardless of coolant flow and possible pressure drops in the pipelines. It is quite difficult to achieve efficient operation of the system, because the liquid enters the pipeline circuits from one source of thermal energy - the boiler, which will ultimately lead to unbalanced heating. To prevent such situations, the hydraulic separator serves; it performs the function of decoupling.

Selection of a pump for a private house according to technical characteristics

The correct selection of pumping equipment is carried out based on calculations based on several criteria.

Pressure

You will need to know the total length of the pipeline for pumping water. For every 10 m of pipe length you will need 0.6 m of pressure. That is, a private household with a heating circuit of 70 m provides a supercharger with a pressure of 4.2 m.

Power

You can make a power calculation based on SNiP 2.04.07-86:

- for houses with a height of 2 floors - from 173 to 177 W/m2;

- for buildings with 3-4 floors - from 97 to 101 W/m2.

To select devices taking into account thermal insulation and wear and tear of buildings, use the table.

| power, kWt | Room volume in new buildings, m3 | Room volume in old buildings |

| 5 | 70-150 | 60-110 |

| 10 | 150-320 | 130-220 |

| 20 | 320-600 | 240-440 |

| 30 | 650-1000 | 460-650 |

| 40 | 1050-1300 | 650-890 |

| 50 | 1350-1600 | 900-1100 |

Performance

To calculate productivity, you need to apply the formula Q = 0.86R/TF–TR, where:

- Q – coolant consumption per hour in cubic meters;

- R – thermal power spent on heating;

- TF – temperature indicator of inlet water;

- TR – return temperature indicator.

Thermal power coefficient depends on the climatic conditions of the area. A private house in a European climate zone with a small area requires the cost of 100 kW to warm up 1 square. In apartment buildings, 70 kW is spent per square meter.

Options

When calculating the external parameters of the pump, you will need to take into account the features of communications:

- models 18 cm in length are installed on pipelines, mixers and floor-mounted bypasses;

- blowers 13 cm in length are placed inside heat generators or a small pipeline;

- the diameter of the nozzles depends on the cross-section of the main pipe; the dimensions can be increased;

- For primary rings and boiler circuits, gravity mains, options with pipes with a diameter of 32 mm are suitable.

In stores there are mainly bypasses for standard pumps 18 cm in length.

Installation diagram

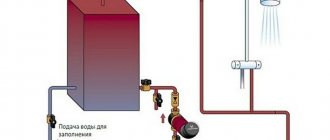

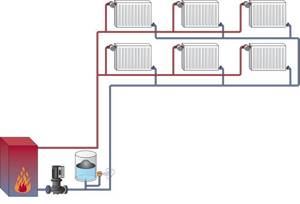

In practice, two schemes for installing a circulation pump are used in a single-pipe and two-pipe heating system. Before carrying out installation work, you must carefully study the attached instructions. At the preparatory stage of work, water is drained from the system and the pipes are cleaned of contamination by additional pumping of liquid. The pump is installed according to the attached diagram, then coolant is poured into the circuit and the unit is turned on.

As we have already said, it is best to install the pump on the return side using a tap or, as it is also called, a bypass. Such a device is necessary to shut off the water and replace the pump in case of breakdown. The diameter of the outlet pipe should be smaller than that of the central pipeline.

Installation diagram of an additional pump in the heating system

At each edge of the bypass, before entering and after exiting the pump, taps are installed for emergency shut-off of the coolant. Another valve is installed on the central line to direct the flow of liquid through the pump. Before entering the pumping equipment, a special filter is attached that will accumulate harmful particles in the water.

Principles for installing units with any rotor

In order for the circulation equipment to work efficiently, it is better to invite specialists to install it. But if you want to install the pump yourself, then follow these rules:

- The unit is installed on the return side of the boiler. That is, where the water, having passed through the entire closed loop of the system, returns back again. But this rule applies to premises whose area does not exceed 150-200 m2.

- It is important to follow the location of the arrow on the pump body when installing it. The arrow should point in the direction of the movement of warm water through the system.

- All flange and threaded joints must be treated with sealant to avoid possible leaks.

- If you are dealing with a reverse circulation heating system, then it would be useful to install a bypass - a piece of pipe that, in case of repair of the unit, can close the heating circuit after removing the pump.

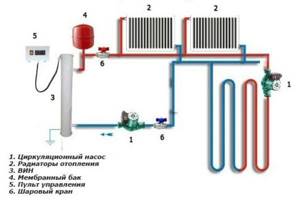

With warm floor

Note! In the “Warm Floor” system, the circulation pump is installed in a horizontal position after the mixing unit in the supply pipeline section. In some wiring schemes, several such devices are installed, each of which will pump liquid within one floor.

Installation diagram of the pump in the “Warm Floor” system

Video description

You can see the installation of supply or return pumps in the video:

Important! Installing a pump between radiators or in front of the expansion tank creates vortex flows that disrupt the direction of movement, creating temperature differences in different parts of the system. It is therefore very important that the pump is located between the boiler and:

- radiator system;

- collector;

- expansion tank.

In a double-circuit system, with the connection of “warm floors”, a separate pump is installed for each circuit.

Each heating circuit has its own pump. Source obzortop.com

Cost of different types of pumps

There are many companies on the market specializing in the production of circulation units. Consumers are advised to buy models from reputable European manufacturers. The products of some Russian enterprises are also in demand.

| Model | Manufacturer country | price, rub. |

| Prima UPS 25/60 180 | Russia | 1570 |

| Wester WCP 25-40G | Russia | 2127 |

| LRP 32-50/180 | China | 2598 |

| Hoffmann UPC 25-40 180 | Germany | 5256 |

| Yonos PICO 15/1-4 | Germany | 6051 |

| A 56/180 XM | Italy | 10953 |

You can find both budget and expensive models on sale. Which pump to buy for a heating boiler is an individual decision for the home owner. When choosing, some are guided by the level of popularity of the manufacturer, others - by cost, and still others - by the availability of the service. Learn how to choose a heating radiator by following the link.

The feasibility of using automatic and manual switching between two boilers

Let's consider the following five options with various units in conjunction with an electric boiler, which is in reserve and must turn on at the right time:

- Gas + Electric

- Firewood + Electric

- Liquefied gas + Electro

- Solar + Electro

- Pellet (granular) + Electro

Pellet and electric boiler

The combination of connecting two boilers - a pellet and an electric boiler - is best suited for automatic switching on and manual switching is also allowed.

A pellet boiler may stop because it has run out of fuel pellets. It got dirty and wasn't cleaned. The electric one must be ready to turn on to replace the stopped boiler. This is only possible with automatic connection. Manual connection in this option is only suitable when you permanently live in a house where such a heating system is installed.

Diesel boilers fuel and electricity

If you live in a house with such a system for connecting two heating boilers, a manual connection is quite suitable for you. The electric boiler will operate as an emergency boiler in case the boilers fail for some reason. They didn’t just stop, they broke down and require repairs. Automatic switching is also possible as a function of time. An electric boiler can operate in tandem with liquefied gas and a solar boiler at a night rate. Due to the fact that the night tariff is cheaper per 1 kW/hour than 1 liter of diesel fuel.

Combination of electric boiler and wood boiler

This combination of connecting two boilers is more suitable for automatic connection and less suitable for manual connection. A wood boiler is used as the main one. It heats the room during the day, and turns on the electricity to add heat at night. Or if you are not living in the house for a long time, an electric boiler maintains the temperature so as not to freeze the house. Manual operation is also possible to save electricity. The electric boiler will turn on manually when you leave and turn off when you return and start heating the house using a wood-fired boiler.

Combination of gas and electric boilers

In this combination of connecting two boilers, the electric boiler can act as both a backup and a main one. In this situation, a manual connection scheme is more suitable compared to an automatic one. The gas boiler is a proven and reliable unit that can operate for a long time without breakdowns. At the same time, connecting an electric boiler to the system for backup in automatic mode is impractical. If the gas boiler fails, you can always manually turn on the second unit.