How to connect a wilo circulation pump

The heart of any heating system is the circulation pump, which is responsible for the forced movement of water in the system.

To minimize energy costs and at the same time create comfortable temperature conditions in a living room, buy Wilo pumps. Ensuring their efficient and reliable operation and extending their service life occurs through compliance with operating rules and timely maintenance. If the owner ignores these requirements, equipment malfunctions will inevitably occur. Their elimination when the warranty period has expired is often done by hand.

Connecting the device

Heating efficiency and uniform distribution of heat throughout the rooms is ensured by a properly selected circulation pump . It is important to install it correctly; a lot also depends on this.

Self-installation does not require professional knowledge, but there are several important points.

Connection point

It can be installed on any section of the circuit, but professionals recommend choosing a return pipe.

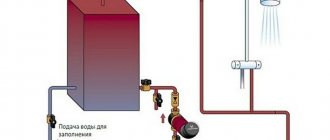

Photo 4. Diagram of the heating system. The circulation pump is installed on the return circuit.

Installation in a heating system

The water is shut off, the pipes are cut according to the installation length of the product. Before installation, check in which position, horizontal or vertical, the pump should operate. The joints are then sealed and tightened. They think about connecting to the power grid in advance.

Filters

It is recommended to install additional coarse filters ; this will protect the device from accidental ingress of particles and significantly reduce the likelihood of failure.

Separate pocket

Sometimes, for ease of maintenance and repair of the pump, installation is carried out in a separate pocket . For this, an additional branch of half a meter in length is created. Valves are installed at the ends, which allow you to disconnect the device from the general circuit at the right time. In this case, there is no need to shut down the system - the valves are closed, the pump is removed from its place and sent for repair, and the structure continues to operate.

Photo 5. Special pocket for the circulation pump. There are valves at the edges of the structure.

A circulation pump is a device that provides a given speed of movement of the coolant (water or oil) through the pipeline of the heating system. Thanks to it, the water circulating through the pipes returns to the boiler faster, without having time to cool, which leads to a reduction in energy costs for reheating and gas savings, which can reach 20-30%.

This article presents circulation pumps for heating systems from the company Wilo (Italy). We will review the most popular equipment models, and also give recommendations for their installation and repair.

To come in

Already registered? Sign in here.

There are currently 0 users on the page

There are no users viewing this page.

Modern circulation pumps require virtually no maintenance, and if a heating circulation pump needs to be repaired, it is better to entrust this task to a specialist from the service center. However, in order to prevent equipment breakdown, you can take some measures that will help prevent such an unpleasant event.

Operating the circulation pump

It is necessary to follow some rules when operating the pump, including the following:

- The pump should not operate if there is no water in the heating system.

- The pump must not be allowed to operate at zero flow.

- A certain range of permissible flow rates must be observed during pump operation. The pump may fail if the water supply is too low or too high.

- If the pump is idle for quite a long period of time, then to prevent it you will need to turn it on at least once a month for 10-15 minutes. If this is not done, some pump components may oxidize.

- For normal operation of the pump, the temperature of the coolant in the heating system should not be higher than +65 degrees. This is necessary in order to prevent the precipitation of hard salts.

- First, you need to make sure that there are no vibrations or noise from the heating pump.

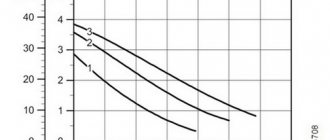

- Check how the circulation pump works, based on its pressure-flow characteristics.

- Check to see if the electric pump motor is overheating.

- Check visually if there is a ground connection on the pump housing.

- Check if there are any leaks in the places where the pump is attached to the pipeline. If there is a slight leak, you will need to replace the gaskets or tighten the connecting components.

- Check how well the electrical wires in the terminal block are connected to each other.

Tips for use

We can offer several key recommendations that will ensure long-term operation of this type of equipment.

- You can leave the device in constant operation mode without fear.

- Experts advise sometimes turning on the equipment for 10-20 minutes after the heating season has ended.

- You can turn on the equipment only if the heating system is filled with media.

- Models that have a wet rotor in their structure use a coolant for lubrication. When turned on, if there is no lubricant, the bearings can burn out very quickly.

You can learn how to connect a circulation pump to a heating system from the following video.

Heating circulation pump

Purpose

Before us is a unit from the leading German manufacturer Wilo.

There are two types of organization of coolant movement in heating systems:

- natural;

- and forced circulation.

Natural circulation is possible in small, simple wiring diagrams, but long and branched pipelines require forced fluid movement.

Previously, private home heating was used without a pump, since units were in short supply and were quite expensive. In addition, not all populated areas have been electrified, and the pump motor operates using electrical energy.

Types of coolant movement.

However, now they are trying to make even small systems with forced circulation, since this increases the efficiency of heat transfer, increases the efficiency of heating, and the gas consumption for heating the coolant, accordingly, decreases. Fuel savings in forced circulation schemes can be up to 30% compared to the natural movement of water due to the convection movement of layers of different temperatures.

Important! A circulation pump is necessary to organize the forced movement of the coolant due to the operation of the pump with an electric motor.

Nowadays private houses are heated according to a forced principle.

In multi-circuit schemes with collector-beam wiring, buildings with several floors and large heating areas, normal natural circulation in the heating system is impossible due to the high hydraulic resistance that occurs in the pipeline. To overcome this resistance, a circulation pump is needed.

Device and principle of operation

Another representative of German mechanical engineering, the high price of which corresponds to the quality.

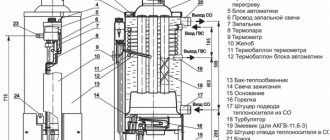

Let's figure out how a home heating pump works. For clarity, we will use a diagram of the main parts of the device:

The pump is disassembled.

So, the unit includes the following components:

- Pump body made of cast iron or stainless steel. Here the water flow is captured by a rotating impeller and pumped in a given direction;

- Motor housing with stator windings. A rotating magnetic field is induced in the windings, which causes the rotor to move;

- Motor rotor with a short-circuited squirrel-cage winding, in which the stator field induces a current that interacts with the rotating armature field (asynchronous operating principle);

- Motor shaft with ceramic bearings, which transmits torque to the impeller;

- An impeller that rotates on a shaft and captures liquid, pumping it;

- Between the impeller and the rotor there is a protective sleeve that does not allow water to penetrate inside the motor;

- Terminal box with control unit, speed switch or frequency converter;

- Air screw to remove excess air.

Rotor structure of an asynchronous electric machine.

The principle of operation of such a machine is as follows: alternating current is supplied to the stator winding and creates a pulsating (rotating) magnetic field in it with a rotation speed of 3600 rpm with one pair of windings. The field lines cross the stationary rotor and induce a current in its winding, which creates a rotor field.

The rotating field of the stator grabs (attracts) the rotor and causes it to rotate with it. The shaft is rigidly connected to the rotor, and therefore also rotates, transmitting force to the impeller located on it, which pumps the liquid located in the pump body and creates circulation in the system.

Important! For normal operation of the unit, the pump must be filled with water, otherwise liquid capture will not occur and the impeller will rotate at idle speed.

Electrical circuit for powering the stator windings.

The control unit allows you to regulate the shaft rotation speed by switching the terminals (adding or reducing the number of pairs of armature windings) or by converting the frequency of the AC supply.

Maintenance of circulation pumps

Pump malfunctions and ways to eliminate them

The design of a circulation pump with a “wet” type rotor is based on a modular principle. Modules can be configured in different configurations. It all depends on the power and size of the pump.

Any repair work can only be carried out if the power is completely turned off and the area has been drained.

Malfunctions of the heating circulation pump:

- The pump turns on, sounds are heard, but the shaft does not rotate. Why is the heating pump noisy and why do other “symptoms” appear? The reason may be oxidation of the shaft after a long period of inactivity of the device. If the pump is blocked, the device must not be left on. It is necessary to drain the water and all the screws that connect the pump housing with the electric motor must be unscrewed. Next, we remove the engine itself, and its impeller is turned manually. If the pump is of low power, the shaft can be unlocked by turning it with a screwdriver. For this purpose, there is a special notch at the end of the shaft.

- A foreign object has blocked the wheel. How to disassemble a heating circulation pump? We dismantle the pump motor using the above method. To prevent blocking from happening again, a mesh type filter must be installed in front of the pump.

Star-RS Series

This range of pumps has a low power and is suitable for use in houses whose area is in the range of 200 - 750 m².

Peculiarities

The main advantage of this series is the wet type rotor. It is continuously immersed in the pumped energy carrier, which prevents the graphite bearings from drying out. Another advantage of Star-RS is that a technical polymer is used to produce the rotor wheel.

This material is resistant to high temperatures typical of heating systems and is not afraid of sudden changes.

Housing and fasteners

The Vilo circulation pump is connected to the pipeline using a thread, the diameter of which may vary depending on the model. The unit has a cast iron body and a stainless steel shaft.

A comfortable working environment for such a device is water or a water-glycol composition. Star-RS pumps for forced heating systems are almost silent. They quickly pump coolant and consume little electricity.

Advantages

German equipment of this series has gained great popularity due to the following advantages:

- the body is coated with an anti-corrosion cataphoresis compound;

- speed is regulated using a three-stage mechanical switch;

- durable metal-graphite bearings do not wear out in aggressive temperatures;

- low cost.

Operating and installation conditions

Devices for heating systems of the Star-RS series can operate in a temperature range of +10 +110 °C at a pressure of up to 10 bar, and this makes it possible to use them in air conditioning.

When installing Vilo Star-RS, the manufacturer’s instructions must be strictly followed, which states that:

- insertion is possible after installation and cleaning of pipes from chips;

- the terminal box and motor must be reliably protected from moisture;

- The pump axis must be positioned strictly horizontally.

Electrical connection of pumps

Water pumps operate from a 220 or 380 Volt power supply. Power is needed to operate the pump motor.

The pumps are connected to the power supply through the factory connection terminals, observing a safe connection for wet environments.

Related articles: Concrete trays for communications, what are they?

The pump power cable is selected according to the electrical power of the pump motor and the method of its installation. Submersible pumps have a fairly long factory pump connection cable.

Electrical repair

The electrical part of the pump includes the following components:

- inductor;

- starting capacitor;

- connecting wires;

- control terminal.

If the stator winding breaks down, the pump becomes unrepairable; all other components can be repaired or replaced. To analyze the condition of electrical parts, you will need an ohmmeter.

Photo of the circulation pump Wilo MTSL 15/5 HE – 2.

Main symptoms of malfunction

If the boiler display shows an error code corresponding to a water circulation problem, and it is not reset, the problem may be hidden in the electronic part of the device.

Circulation pump with cover removed.

To identify the problem you must:

- Turn off the heating mode in the boiler, and after stopping all components, turn off the power (soft stop).

- Open the front panel of the case.

- If the pump is covered with a large layer of dust, clean its surface.

- Using the information in the diagram, remove the control terminals and remove the terminal with the capacitor.

- Visually examine the condition of the pump contacts and terminals; they should be free of oxides, burnouts and mechanical damage.

- Using a tester in diode testing mode, determine the integrity of the connecting wires that go from the control board to the pump.

- Use an ohmmeter to determine the resistance of the inductors. On a working device, the instrument readings on the contacts will correspond to the following values:

- No. 1, 4 – 150 – 160 Ohm;

- No. 1, 6 – 290 – 300 Ohm;

- No. 2, 3 - 0 (contacts connected together);

- No. 3, 5 – 220 -230 Ohm;

- No. 4, 6 – 150 – 160 Ohm.

- The device will be considered faulty if the ohmmeter reading on any of the above pair of marks is 1 (winding wire break) or 0 (short circuit, except for contacts 2,3).

- Check the condition of the starting capacitor. To do this, switch the tester regulator to the 20 microfarad capacity test mode. Connect the probes of the device to the terminals of the capacitor and determine its capacitance. It should match the nominal ± 10%. Loss of capacity leads to a decrease in pump performance; it will emit an uncharacteristic hum.

Electrical diagram of the pump Wilo MTSL 15/5 HE – 2.

Measuring the resistance of the circulation pump windings.

Heating models

| Wilo model | Connection, inch | Length, mm | Power, W | Price, rub |

| Star-RS 15/2 | 1 | 130 | 20 | 6450 |

| Star-RS 15/4-130 | 1 | 130 | 20 | 6900 |

| Star-RS 15/6 | 1 | 130 | 24 | 8250 |

| Star-RS 25/4-130 | 1 1.2 | 130 | 20 | 7120 |

| Star-RS 25/6-130 | 1 1.2 | 130 | 40 | 8500 |

| Star-RS 25/2 | 1 1.2 | 180 | 20 | 5550 |

| Star-RS 25/4 | 1 1.2 | 180 | 20 | 5550 |

| Star-RS 25/6 | 1 1.2 | 180 | 24 | 7000 |

| Star-RS 25/7 | 1 1.2 | 180 | 40 | 9570 |

| Star-RS 25/8 | 1 1.2 | 180 | 20 | 10290 |

| Stratos PICO 15/1-4 | 1 | 130 | 20 | 15000 |

| Stratos PICO 15/1-6 | 1 | 130 | 20 | 16900 |

| Stratos PICO 25/1-4 | 1 1.2 | 130 | 24 | 11000 |

| Stratos PICO 25/1-4-130 | 1 1.2 | 130 | 20 | 13800 |

| Stratos PICO 25/1-6 | 1 1.2 | 130 | 40 | 12200 |

| Stratos PICO 25/1-6-130 | 1 1.2 | 130 | 20 | 15100 |

Not all models are shown in the table, please contact us with your request.

Mechanical repair

All other parts that are not listed in the section: “Electrical repair” refer to mechanical components. If vibration or noise occurs in a running pump, to determine the source of its occurrence it is necessary:

- Stop the boiler smoothly.

- Remove the front panel of the housing and lower the control unit.

- Close the cold water, supply and return taps.

- Drain water from the boiler system through the drain valve.

- Unscrew the pump air vent lock to completely drain the water from the system. After all the fluid has been drained, tighten the lock until it stops.

- Remove the terminal with the starting capacitor.

- Unscrew the fastening screws and remove the motor-turbine unit.

- Inspect the bearings, impeller, and pump cavity for oxidation, contamination, foreign objects, and damage. If there is wear on the bearings or the motor shaft rotates with force, then they need to be replaced with others, for example, fluoroplastic ones. All dirt from the turbine, internal compartments of the housing, and sealing rubber should be removed.

- Place the repaired mechanism in place and secure it.

- Insert the terminal with the capacitor.

- Open the return, supply and cold water taps.

- Using the make-up tap, check the pump for leaks; if it does not leak, then add coolant to the system up to 1.2 bar.

- Start the pump in circulation mode and check its condition.

- If the results are positive, set the heating circuit temperature control knob to the required position.

The service life of the Wilo circulation pump and other boiler components can be extended if full maintenance is carried out before each heating season.

Related articles:

Possible causes and methods of eliminating coolant overheating in double-circuit, automatic and semi-automatic gas heating boilers are described.

The article describes five practical methods for eliminating icing on a coaxial air duct.

The principle of operation is considered, the main signs and causes of the malfunction are shown, methods for diagnosing and repairing the fan (smoke exhauster) of a gas boiler.

The main reasons for changes in pressure in a closed heating system are listed, and effective ways to stabilize the coolant pressure are given.

Let's look at what to do if a gas water heater with a semi-automatic ignition system does not light up, the principle of operation of the ignition system, the reasons.

The efficient functioning of the heating system in a cottage or country house is impossible without a circulation pump. Its uninterrupted operation guarantees that residents will be comfortable indoors during the cold season.

Circulation pump in the heating system

A heating circulation pump is considered reliable equipment that is easy to maintain. By following operating rules and performing timely preventive maintenance, you can minimize the likelihood of malfunctions. If malfunctions do occur, most of them do not pose a problem even for a technician with little experience. Repairing a heating circulation pump with your own hands is not difficult; it is enough to have general knowledge about the design of such equipment.

Areas of application

The Wilo brand produces pumps designed for different purposes and therefore having different characteristics.

With the help of such a pump, you can water the beds directly from a well, borehole or the nearest body of water.

The scope of their application is wide and varied:

- Wilo devices are used in heating systems in closed circuits.

- They are used in the water supply of private houses and in wells for water extraction.

- Such pumps are also suitable for pumping out groundwater when creating basements and cellars.

- They are also used on construction sites when working with contaminated water.

- Owners of private suburban areas have found good use for them, in particular those who grow plants on their plots.

You can connect the device yourself without any problems. For this purpose, it is equipped with special spring terminals. It does not have a fan, so there is virtually no noise during operation.

Installing a circulation pump (connection): how to install?

Contents Circulation pumps are a necessary component of heating systems that use natural or forced circulation. They are necessary in order to increase heat transfer and regulate the temperature in the room.

Installing the unit is not very difficult; you can do it yourself if you have a minimum of skills. Let's look at how to do this correctly.

Where should it be installed?

It is recommended to install the circulation pump after the boiler, before the first branch, and it makes no difference whether it is on the supply or return pipeline. Modern equipment is made from materials that can withstand temperatures up to 100-115°C. Heating systems rarely use hotter coolant, so the concept of a more “comfortable” temperature is not important.

Circulation pump on bypass

The unit can be installed on both the supply and return lines. For hydraulics, the installation location of the circulation pump also does not matter. The main thing is that the unit is correctly installed in terms of piping and the correct orientation of the rotor. The rest doesn't matter.

It is necessary to emphasize one important feature of the installation. If there are two separate heating branches, a separate unit is installed on each branch, and not one common one after the boiler. But on each branch it is necessary to follow the installation rule: after the boiler, before the first branch in a given heating circuit. This allows you to provide the necessary thermal conditions in a separate part of the house, and in 2-story houses to save on heating. This can be done due to the fact that it is colder on the ground floor and more heat is needed there.

If you install two pumps in the branch going upward and set the speed of the coolant to much lower, then you can burn less fuel while maintaining the necessary comfort.

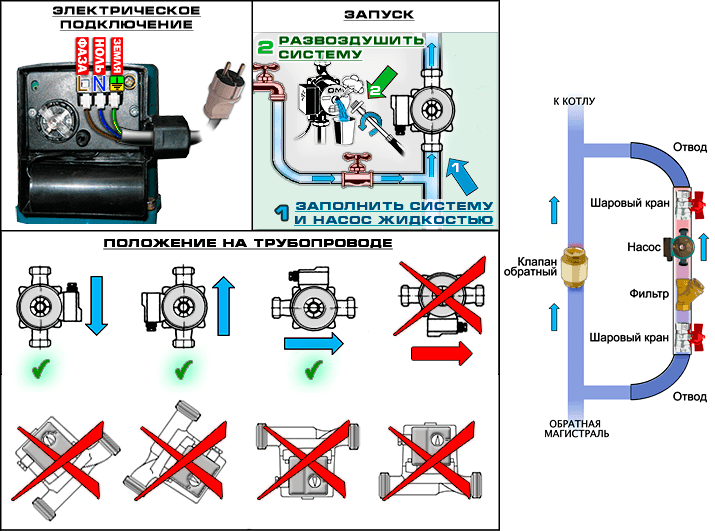

Basic installation rules

The design of any household circulation pump provides for its installation on pipelines or shut-off valves using union nuts (American). This makes it possible to quickly dismantle it if necessary, for example, for repair or replacement. Installation of pumping equipment requires compliance with the following recommendations:

- The device can be installed in any position - horizontally, vertically or obliquely, but observing the following rule: the rotor axis is placed horizontally. That is, you cannot mount it “head down” or up.

- It is necessary to ensure that the plastic box containing the electrical contacts is located on top of the case so that it does not become flooded with water in the event of an accident. Yes, and servicing the unit will be difficult. This is easy to achieve: you need to unscrew the screws that secure the casing and turn it to the required angle.

- Remember the direction of flow, which is indicated by the arrow on the housing.

- To remove equipment without emptying the system, it is necessary to install shut-off valves before and after it.

Circulation pump on the distribution comb of the heated floor

Stages of work

To correctly install the circulation pump, you must follow several rules and strictly follow the installation sequence.

- Drain the liquid, thus cleaning the heating system. If it has been in use for a long time, then it is necessary to rinse it several times, running water and draining it.

- It is necessary to cut in bypass sections to connect the equipment. Between the taps, a bypass is installed on the pipeline, which is equipped with a check valve or ball valve. This will prevent the plastic inserts of the ball valves from overheating when welding.

- Shut-off equipment is installed on the bypass pipeline.

- Install the coarse filter.

- The upper part of the bypass is equipped with a Mayevsky valve or an automatic air valve.

- The insertion of the hot water circulation pump is carried out in a special place according to the principle of co-direction of the energy carrier. The rotor of a “wet” pump must be installed horizontally, paying attention to the fact that the contacts in the terminal box are directed upwards.

- The unit is connected to the network through a separately connected socket with grounding.

Functionality check

- After installing the equipment, it must be filled with coolant.

- We check the functionality of the heating system. If malfunctions are identified, they must be eliminated.

- Using the central screw, remove air from the system. If water comes out, then you were able to understand how to install the pump correctly.

- After the pump is filled with water, it is turned on. Connecting the pump to the electrical network requires the use of an automatic fuse with a special flag, which additionally plays the role of a switch.

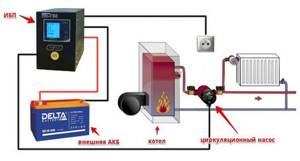

Connection diagram for a circulation pump via a UPS

- If an additional pump is installed in the system, it will turn on only after a signal from the heat sensor.

- To synchronize the operation of two pumps, it is necessary to connect the second pump to the sensor or use an alternative parallel connection.

At first glance, it does not require much effort to correctly install the circulation pump into the system. This is true if you have experience in installation work. If you have no experience, it is recommended to carefully study the documents that are supplied with the unit by the manufacturer, and then you will be able to correctly decide where and how to connect the pumping equipment.

How to install a GRUNDFOS circulation pump in a heating system? (video)

Home page » Pumps byreniepro.ru

Installation

The installation of a Wilo unit in a heating system must be carried out in full compliance with the existing operating instructions provided by the manufacturer. There are several important rules to follow during installation.

- Only vertical installation of units from this company is allowed. Horizontal placement of Wilo pumps into the system is strictly prohibited. The only exceptions will be those models that are specifically designed for horizontal connection. The installation position of a specific pump can be found in the detailed instructions.

- Connecting a heated floor system - the device is installed in a special unit. The correct placement of the Wilo heating product will be indicated by arrows located on the body of the unit itself and on the hydraulic wiring.

- Connection to a radiator-type heating system - installation is carried out in the heating return, directly in front of the boiler. In order to prevent a complete stop of coolant circulation, a bypass is also installed here.

The rules for installing Wilo devices allow you to select equipment for heating systems with both natural circulation and forced circulation.

- Installation and maintenance - the pump is mounted vertically in compliance with the direction of the coolant, which will be indicated by arrows on the body and assembly. Installation should only be performed by qualified technicians.

- Methods for installing the device will depend on the selected model; as a rule, they are described in some detail in the instructions. If connected correctly, the Wilo pump will not require any special maintenance.

- You need to place a coarse filter on the bypass frame immediately in front of the pump. Only an experienced specialist can take into account all the specifics of installing a Wilo heating pump, disassemble and reassemble it, and carry out repairs. Installation of the device is completed in just 2-3 hours.

If you also install a bypass, it will take 4-6 hours.

Connection steps:

- the pump is assembled, the connection location on the circuit is selected;

- the water is turned off, a connection to the heating system occurs;

- the device is mounted, the main thing is to install it in the correct position;

- connections are tightened and sealed;

- the product is connected to electricity;

- the liquid is supplied to the circuit and the device starts;

- tested in operating mode.

An extraneous hum when the device is operating will indicate a number of possible malfunctions. The air vent may become clogged, resulting in air not being removed from the system. Another common malfunction will be an incorrectly selected operating mode.

Reducing the speed of the device with your own hands usually leads to the disappearance of the hum. If this does not happen, the pump needs to be serviced.

Dry and wet rotors

Units in which the rotor does not come into contact with the liquid during operation are usually called “dry”. They are able to withstand high loads. The main problem with models with this design is that their O-rings quickly become unusable. Although these parts are designed to operate for 3 years, they quite often fail long before the specified time.

The reason for rapid destruction is usually impurities, which are always present in one quantity or another in the coolant. Particles contained in the air around the boiler can also have a negative impact.

If the tightness of the device is broken, this will inevitably lead to a short circuit. Electrical elements fail, and repairing the circulation pump with your own hands in the event of such breakdowns is already extremely difficult, if not impossible.

Heating circulation pump: device

Owners of private houses usually give preference to economical, low-power pumps with a “wet” type rotor.

The operating principle of this unit is simple: the impeller, rigidly fixed to the electric motor shaft, rotates and draws in the coolant coming from the inlet pipe. Then, under pressure, it pushes it into the discharge pipe, thus ensuring circulation.

If we disassemble the pump with our own hands, we must have a good understanding of its structure.

Diagram of a circulation pump with a “wet” rotor

Important! It must be taken into account that in “dry” type models, the rotor and drive motor are separated into a separate unit, and the rotation is transmitted to the impeller using a clutch.

Wilo heating pumps

If the pressure in water supply systems can be maintained using gravity spill methods (from top to bottom), then in heating systems it is very difficult to “force” the coolant fluid to circulate through the system without a circulation pump.

This is especially true for closed heating systems of private houses, including water heated floor systems.

A circulation pump installed in a heating system not only ensures the circulation of coolant in the system, but also increases its speed.

Increasing the coolant velocity increases the heat transfer coefficient and, as a result, increases the efficiency of the heating system.

In addition, forced circulation of coolant in a closed system allows the use of pipes of smaller diameter, which not only saves on installation costs, but also reduces water consumption by the system.

To purchase a circulation pump you need to know:

Pumps are available with a “dry” and “wet” rotor. Glandless rotor pumps have low power, but are virtually silent and maintenance-free.

Related articles: Combined panels: configuration options and advantages of equipment

The moving parts of such a pump (rotor, shaft, bearing system) are assembled into a single unit (cartouche), which operates immersed in liquid.

The Wilo brand is represented by the following series of wet rotor circulation pumps.

Forced circulation equipment

Wilo circulation pumps will help ensure high-quality movement of hot water through pipes and radiators. They do their job well in large houses with complex heating systems. A review of Vilo models and instructions from the manufacturer will help you make the right choice of a modern and compact device that will show effective operation.

All German-made units are distinguished by their reliability, ease of installation and the ability to reduce the diameter of the pipes, which allows reducing the cost of heating installation.

For complete heating of private houses, two series of Wilo pumps were specially developed, which differ slightly in technical characteristics.

How to disassemble a circulation pump

Disassembling the circulation pump is carried out only after the device is disconnected from the network. The taps mounted at the inlet and outlet are closed to prevent water from entering the device. In some cases, it is removed from the pipeline by shutting off the bypass and connecting a backup pump. The heating system continues to function normally, and the technician can deal with the breakdown without haste.

Let's look at how to disassemble a water pump using the example of repairing a Wilo circulation pump.

First, remove the terminal box cover. To do this, unscrew the screw on which it is attached.

Inspect the contents of the box. How to check if the starting capacitors are working? They are called using a tester.

The performance of starting capacitors is checked using a tester

At the next stage, the “snail” is removed. Unscrew two screws located diagonally and separate the element from the electrical part of the pump (rotor and stator).

The internal surface of the dismantled device is inspected for the presence of deposits that form due to poor water quality. The rotor cartridge is picked up with a screwdriver and pulled out of the housing.

Disassembly of the pump is completed, access to all parts located inside the pump is provided. Now the parts of the device can be carefully inspected and cleaned. The modular design allows you to reduce repairs to replacing a failed unit.

Connection methods

Connection to the electrical network using a plug and socket . This method involves installing an electrical outlet in close proximity to the place where the circulation pump is mounted. Sometimes they can be supplied with a connected cable and plug included, as in the photo:

In this case, you can simply plug the device into the mains using an outlet located within reach of the cable. You just need to make sure there is a third, grounding contact in the outlet.

If there is no cord with a plug, they need to be purchased or removed from an unused electrical appliance. You should pay attention to the cross-section of the cord conductors. It should be in the range from 1.5 mm 2 to 2.5 mm 2. The wires must be stranded copper, ensuring resistance to repeated bending. The cord with a plug for connecting electrical appliances to the network is shown in the photo below:

Before connecting the circulation pump, you need to find out which of the three wires of the cord is connected to the ground pin of the plug. This can be done using an ohmmeter, while at the same time checking the integrity of the remaining wires.

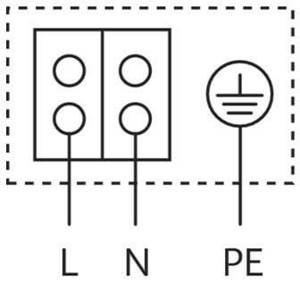

Open the terminal box cover. Inside the box there are three terminals designed to connect the device to the network, marked as in the picture:

We unscrew the clamp of the cable coupling (in the first photo it is a plastic nut into which the cable is inserted), put it on our cord, and insert the cord into the coupling. If there is a cable tie inside the box, thread the cord through it. We connect the ends of the cord wires, previously stripped of insulation, to the terminals.

The wires connected to the plugs of the plug should be connected to the L and N terminals (don’t be afraid to mix them up, this is not critical), the wire of the grounding contact of the plug should be connected to the PE terminal (but you can’t make a mistake here). The instructions supplied with the product prohibit its operation without protective grounding. Next, tighten the clamp (if any), tighten the cable sleeve clamp tightly, and close the terminal box cover. The pump is ready to be plugged into the mains.

Fixed connection. The connection diagram for the circulation pump to the electrical network with grounding is provided below:

The requirements for the wire cross-section here are the same as in the previous version. The cable for this installation can be used either flexible or inflexible, copper, VVG brand, or aluminum, AVVG. If the cable is inflexible, the installation should ensure that it does not move. To do this, the cable along the entire route is secured with clamps.

In this option, a residual current device (differential circuit breaker) is used. Instead, you can use a regular single-pole circuit breaker, passing only the phase wire through it. If the machine is installed in a panel where there is a PE bus, then the cable from the pump to the machine must be three-core. If there is no such bus, the PE terminal should be connected to a grounding device. This connection can be made with a separate wire.

Separately, I would like to consider such an installation option as connecting the pump to the UPS. It is the most preferable and ensures the independence of the heating system from power outages. The connection diagram of the circulation pump to the uninterruptible power supply is provided below:

The power of the UPS should be selected based on the power of the pump motor. The capacity of the battery is determined by the estimated time of autonomous power supply of the circulation pump, that is, the time when the power supply is turned off. We talked about how to choose a UPS for a boiler in a separate article. Requirements for cable cross-section, as well as the presence of protective grounding, apply to all connection options.

Finally, we recommend watching video instructions for connecting various pump models to the electrical network:

So we looked at how to properly connect the circulation pump to the electrical network. The diagram and video examples helped to consolidate the material and clearly see the nuances of installation!

It will be useful to read:

Circulation pumps are installed in heating systems with forced or natural circulation. It is needed to increase heat transfer and to be able to regulate the temperature in the room. Installing a circulation pump is not the most difficult task; if you have a minimum of skills, you can do it yourself, with your own hands.

Causes of circulation pump malfunctions

There are many reasons why the circulation pump may not work. For example, the presence of a large amount of suspended matter in the coolant can lead to malfunctions of circulation pumps. Small particles are deposited on the surface of the rotor, reducing the distance between it and the glass. Because of this, jamming occurs, leading to overheating and short circuit of the windings.

Wear and tear of the unit, operation in an unacceptable mode and a number of other factors lead to the need to replace some piece of equipment.

In cases of typical breakdowns, it is not difficult to repair the heating pump yourself. You can identify such problems by knowing their characteristic signs. This does not even always require disassembling the pump.

Product advantages

Circulation pumps from the German company Wilo successfully compete with similar devices due to the fact that they are made from anti-corrosion materials and can work with various coolants.

They are durable and easy to use, and also consume electricity economically. Another important factor that affects demand is the compact dimensions of the units with their multi-stage protection.

Common problems

For what reason might the circulation pump not work? Owners of electric heating pumps most often encounter the following problems:

- the shaft does not rotate;

- the device vibrates too much;

- pump operation is accompanied by uncharacteristic sounds or excessive noise;

- the equipment heats up;

- coolant pressure is below the standard value;

- The unit suddenly switches off.

Let's look at each of these situations in more detail.

Shaft blocking is determined by the following signs: after switching on, the pump hums, but the impeller remains motionless. This usually happens after a long period of equipment downtime due to oxidation of the shaft surface.

Inner surface of the circulation pump housing

Vibration of the device in most cases is caused by the fact that the bearing that ensures the rotation of the impeller blades has worn out. The noise may be caused by a clogged filter. Sounds uncharacteristic of pump operation are also a sign that there is air in the system.

A discrepancy between the coolant pressure and the standard value can be caused by a number of factors: violation of instructions when connecting a three-phase device; clogged filter on the suction line; increased viscosity of the coolant.

Heating occurs in cases where the pump operates in an unusual mode with a significant excess of the permissible load.

The pump in the heating system turns off some time after it starts working due to scale and deposits that accumulate on the inner surface of the stator. Incorrectly connected wires and oxidized fuse contacts can also cause malfunctions.

Basic problems and methods for resolving them

In cases where vibration appears during operation of the device, extraneous noise occurs, or the pressure in the system changes, you should determine the cause and, if possible, troubleshoot the problem yourself.

When turned on, the pump hums, but the shaft does not rotate:

- The shaft jammed due to prolonged downtime. Remove the protective cap on the motor housing and rotate the shaft using a flat-head screwdriver;

- if foreign objects get in, disassemble the pump and clean the impeller, after which replacing the cleaning filter, which is installed in front of the device;

- problems with power supply (insufficient voltage in the network).

When turned on, the device does not work:

- there is no voltage in the network. Electrical wiring and protective automation are checked;

- The fuse has blown. Replaced with a new one.

Automatic shutdown of the device after a short period of operation:

accumulation of limescale in the stator cup. The glass and rotor of the electric motor are cleaned.

The pump makes a lot of noise when running:

- dry operation with air in the system. Release the air and make sure the pump shell is filled with liquid;

- cavitation. The pressure in the fluid supply line must be increased.

Excessive pump vibration:

critical condition of support bearings due to severe wear. The bearings should be replaced.

Reduced head and flow compared to manufacturer's specifications:

- power supply failure or phase change, which leads to a drop in power or reverse rotation of the impeller. Checking the phases (three-phase motors) and replacing the capacitor (for single-phase power supply);

- the pipeline has great resistance to fluid movement (hydraulic resistance). Clean (replace) the filters, check the shut-off valves, and increase the diameter of the pipes if necessary.

Automatic pump shutdown by external protection system:

malfunction of the electrical components of the device. Check connection terminals (oxidation, short circuit), capacitor (replacement), control unit.

Vilo circulation pumps

One of the most important parameters of any heating and plumbing system is the pressure of the working system. Maintaining the standard pressure of working fluids in water supply and heating systems is a guarantee of their reliable operation.

Circulation pumps are used to increase and maintain pressure in heating and plumbing systems. They are installed directly on system pipelines and ensure the movement of coolant in heating systems and maintaining pressure in water supply systems.

Vilo circulation pumps are distinguished by the high quality of the German brand, universal use in hot and cold water supply systems, as well as in liquid heating systems.

Design features

Products from German manufacturers can work for a very long time without maintenance. And all because durable and reliable materials are used in its production. For example, the body of the product is made of durable gray cast iron. Inside it is a stainless steel shaft. It is secured using bearings made of graphite. The fluid supply speed has three-stage adjustment. In this case, the maximum possible coolant temperature parameters can reach +110 degrees Celsius. In industrial models, this ceiling may increase.

Note! The described pump is also designed for very high operating pressure. Standard products used in everyday life can withstand a pressure of 10 bar

Industrial designs in special designs can withstand pressures of 16 bar.

Troubleshooting Methods

The ability to avoid going to a workshop to repair the circulation pump will save money and time. But only if the owner of the device is able to determine the cause of the breakdown himself and knows how to disassemble the pump and replace the faulty part.

Our recommendations are designed to resolve simple problems. Attempts to repair the pump with your own hands in the event of a serious breakdown that requires qualified intervention can permanently damage the equipment.

Attention! The engine can only be dismantled after turning off the power supply and draining the water from the unit.

Shaft blocked

Dismantle the engine and inspect the shaft surface. If it has oxidized, then the shaft should be turned by pressing the screwdriver against the special notch of the rotor.

The body vibrates

To stop strong vibration, replace the bearings. The worn part is removed, and a new bearing is carefully driven into the seat using a wooden hammer. The size of the spare part can be clarified in the technical documentation supplied with the device.

The pump is noisy

The metal mesh mounted at the inlet of the pump is pulled out and thoroughly washed under running water. Then, without turning on the device, open the taps. Find a nut on the body designed to bleed air and unscrew it. After the excess air has been bled off and water has flowed out, the nut is tightened.

Attention! For uninterrupted operation of the system, it is necessary that air is removed in a timely manner in each area. It is recommended to install air vents that will perform this task automatically.

Removing air from the circulation pump

Weak pressure

In a three-phase pump, the first thing to check is whether the phases are connected correctly. If the rotation of the blades is performed in the desired direction, then pay attention to the cleanliness of the filter. The clogged filter is pulled out and washed.

Pump casing heating

The problem can be eliminated if you follow the operating rules of the device and do not exceed the maximum load specified in the documentation.

Switching off the unit after starting

Lime deposits that impede the movement of the shaft are removed. If the surface is clean, then check whether the phase wires are connected correctly. Oxidized contacts are cleaned.

Prevention of circulation pump breakdowns

The equipment must be prepared in advance for intensive use during the cold season. Emergency repair of a heating circulation pump can cause a lot of inconvenience and lead to unplanned expenses. Prevention, to some extent, is a guarantee that the system will not fail at the most inopportune moment.

The pump in the heating system circulates the coolant

Careful owners perform the following activities before the onset of cold weather:

- check whether the device is installed correctly;

- renew the lubricant on the pipes and gaskets of the pump;

- clean the filter of the suction pipe;

- check how tight the connecting nodes are;

- Using a tester, they evaluate whether the device is correctly connected to the electrical network.

It is also necessary to conduct a test run to ensure that the equipment is working properly.

Owners of a house with autonomous heating need basic knowledge about the design and operating principle of circulation pumps. Any signs that the device is operating abnormally should not be ignored. After all, breakdowns in most cases are caused by improper operation. In order for the pump to function without failures, it is enough to regularly monitor the system throughout the heating season and carry out the necessary preventive maintenance.

Choosing a circulation pump

It is also not advisable to purchase a pump that is too powerful. Also, an overly powerful pump will only create noise interference. There are also schemes where two pumps operate in the heating system.

To calculate a pump for a room that has overly complex architectural features, you will need to call a specialist in the field of heating engineering.

For an ordinary private home, using a simple formula will be sufficient. Let's consider what is the scheme for installing a heating pump.

Source