Borehole pumps produced by modern industry are characterized by the widest distribution. These devices have a large number of different functional characteristics.

Among the large number of numerous models of pumping equipment, the most popular are grundfos well pumps.

Specifications

The main technical characteristics for such units are:

- There is a distinction between total pump power and useful power. The total shows how much the equipment consumed, and the useful one shows how much was spent on pumping liquid

Pressure or lift height ( H , m) is a value showing how much the pressure increases. It is measured in meters. To convert to pressure units there is a formula: 10m=1bar.

- Flow (Q, m3/h) – indicates the maximum amount of liquid that can be pumped per unit of time. This value depends on the pressure.

- Voltage (U, V) – shows the rated voltage in the network that is necessary for the operation of the unit. Basically it is either 220V or 380V.

- Useful power (N, kW) – distinguishes between the total power of the pump and the useful power. The total shows how much the equipment consumed, and the useful one shows how much was spent on pumping liquid.

- TO . P.D.( η) – a value showing the relationship between the total power and the useful one. The higher this value, the better.

- Shaft rotation frequency (ω, rpm) – shows the number of revolutions of the working shaft per unit time.

- Rated current (I, A) – normal current consumption by the pump. May increase or decrease as equipment operating conditions change.

- Type of pumped medium - depending on the application, it can be: process water, drinking water, waste or sewer liquid.

- Medium temperature (0C) – shows the permissible temperature range of the liquid that the equipment is capable of pumping.

Well pump Grundfos

Devices from the Danish company Grundfos, despite the substantial price, are quite widespread among summer residents in the Moscow region. Let's see what models you can buy and their differences from each other:

The Grundfos SQ deep-well pump is the classic and most popular pump. The pump designation contains 2 numerical values, for example Grundfos SQ 2-70. The first number 2 indicates the nominal capacity (2 m 3 /hour), and the second number 70 is the nominal head (70 meters) at which a capacity of 2 m 3 /hour is ensured.

These pumps are protected against dry running, overloads, voltage surges, and also have a soft start. With a diameter of 3 inches (74 mm), Grundfos SQ is used in those wells where a classic 4-inch pump will not fit. As an example, we can give a well with 133 casing pipe and 110 or 117 mm plastic. Characteristics of Grundfos: Nominal pressure - 15-155 meters (depending on the model). Maximum pressure - up to 235 m. Maximum productivity - up to 7.5 m 3 / hour. Power - 700-1850 W. Weight - 4.7-6.7 kg. Diameter: 74 mm (3 inches).

The cost of the most affordable Grundfos SQ 1-35 starts at 35,000 rubles, while the most expensive 3-105 starts at 60,000 and above. The most popular model Grundfos SQ 2-70 can be bought for 40,000 rubles. and more.

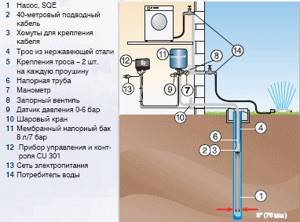

The Grundfos SQE submersible centrifugal pump is the same SQ, but with a variable speed motor, which makes it possible, together with the SQE kit, to maintain stable pressure in the system. The SQE kit includes a pressure sensor with a pressure gauge and plug, an automation unit and a membrane tank. Otherwise, the characteristics of the Grundfos SQE pump are similar to the standard SQ.

The most affordable model from this line is Grundfos SQE 3-30 and 5-15, the price starts from 38,000 rubles. The most expensive SQE 1-155 and 7-40 are estimated at 74,000 rubles or more. The most widely used are Grundfos SQE 3-105 and 5-70, the price of such models starts from 70,000 rubles.

Grundfos SP pump is a powerful multi-stage version of the SQ. It differs from the latter in its larger diameter (4 inches or 101 mm), three-phase design (there are several single-phase models) and impressive technical characteristics that allow it to be used in any domestic well.

The pump modification is indicated by two numerical values, for example Grundfos SP 3A-18, the first number 3 is the productivity in m 3 / hour, the second number 18 is the number of stages. Characteristics: Maximum pressure up to 540 meters (depending on model). Maximum productivity - up to 18.7 m 3 /hour. Power - 370-7500 W. Weight - 9-92 kg. Diameter: 101 mm (4 inches).

The most affordable model Grundfos SP 2A-6 is estimated at 35,000 rubles or more, the most productive SP 5A-85 can be bought for more than 450,000 rubles. The price of the popular Grundfos SP 5A-33 and 5A-25 starts at 80,000 rubles. and 60,000 rub. respectively.

There is no doubt about the reliability of Grundfos pumps; these are premium products and the quality is at the highest level. The disadvantages include the high price; it differs significantly from all other well-known brands. This is what makes us look for alternatives.

But, despite the high reliability of the design itself, Grundfos SQ had one unpleasant drawback - it does not hold the check valve. This problem arose after the transfer of pump production from Denmark to Mexico. Almost every second Mexican model suffered from this problem. To correct the situation, you need to buy a check valve separately. This is exactly what we began to do several years ago. Having gotten caught in this several times in a row and having lost a lot of time disassembling and assembling the water supply system, we began installing a check valve on all models without exception. This problem may have been resolved today. If you have time to disassemble and reassemble the water supply system, then you can check. Otherwise, buy a check valve, it costs about 1000 rubles.

Grundfos pump life

The potential service life of Grundfos pumps is more than 15 years. Everything is done there at a really high level and you don’t have to worry about it. But you should worry about the scheduled maintenance of the pressure automatics. After all, after a while it may become upset and the pump will turn on more often than it should. This leads to excessive loads and premature wear. For this reason, even really high-quality devices (like Grundfos) fail ahead of schedule. Drillers recommend periodic maintenance of the automation to keep the system in working order. It is with this approach that the service life of Grundfos pumps can exceed 15 years.

Features and benefits of pumps

The main advantages of Grundfos pumps are:

- The optimum ratio of price and quality,

- high energy efficiency of equipment,

- a huge selection that can satisfy any need.

- quite long service life,

- good technical support.

When choosing pumping equipment, the following technical parameters must be taken into account:

- At Grundfos, the designers have thought through in advance almost all possible problems that may arise in a particular area of operation, therefore, when choosing equipment from this manufacturer, you get a unit that takes into account many years of experience

First you need to decide what type is needed. In total, there are three large groups: for wells, for heating, for drainage or sewerage. At Grundfos, designers have thought through in advance almost all possible problems that may arise in a particular area of operation. Therefore, when choosing equipment from this manufacturer, you get a unit that takes into account many years of experience.

- Before ordering equipment, you need to decide what type of voltage will be used: single-phase or three-phase. For household pumps, single-phase pumps are mainly used; in industry, three-phase pumps are more commonly used.

- The main characteristic when choosing a pump is the graph of pressure versus flow. This graph shows how much water the pump will pump depending on the required pressure. The higher the pressure that needs to be maintained, the less water the pump can pump. When choosing equipment, the required operating point must be under its curve. It is also necessary to provide a margin of 20% for the supply.

- Power is also an important parameter. It depends on the current and voltage. This parameter is taken into account when selecting pump protection, as well as when calculating the required cross-section of power supply cables. The higher the power, the greater the productivity.

- When choosing pumps, it is also necessary to take into account geometric parameters and connection dimensions. Before placing an order, you must make sure that the selected equipment is suitable both in weight and dimensions.

- Depending on the operating conditions, it is necessary to pay attention to the minimum and maximum permissible temperature of the pumped medium. There are cases when the wrong choice of range led to equipment failure.

- Also, when choosing from equivalent pumps, you need to choose the one with a higher efficiency rating. In the long term, such equipment will provide significant energy savings.

In order for the unit to work for a long time and without interruptions, it must be installed correctly. Installation of any equipment must be carried out strictly according to the attached installation instructions. Also, do not forget about installing automated control systems for pumps.

Such a system will protect your unit from power surges, from engine overheating, from the possibility of working without water, from water getting inside, etc., and will also allow you to control the process automatically, without human intervention.

Another condition for durability is proper operation. It is also stated in the instructions. It is important to understand that if a pump unit protection system is installed, then you need to be alert when it is triggered. It is best to carry out a full cycle of equipment inspection.

Grundfos UPS pump. Review

We will begin our journey into the world of Grundfos pumps with an introduction to the household series of circulation pumps.

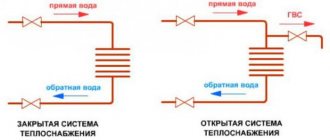

Back in 1959, the company introduced its first circulation pump for heating with the same name Grundfos. All models in the series are successfully used in the forced heating system of private houses. A special place in the series is occupied by time-tested UPS pumps. Each Grundfos UPS pump is equipped with a three-speed switch, allowing it to be more accurately matched to the hydraulic parameters of the system. The pump is manufactured in two versions with different frequencies: 50 Hz for Russia and 60 Hz for European consumers. The series is used in both open and closed heating systems.

Structurally, UPS pumps are manufactured using “wet-rotor” technology; in a word, the hydraulic part of the pump and the engine form a single whole. In this design, the rotor is completely sealed. This solution eliminates the need for a mechanical seal; instead, only a pair of seals are used. In addition, the pump does not have an impeller for cooling the engine, and the pumped liquid protects it from overheating; it also acts as a lubricating element for the bearings.

The Grundfos UPS pump circulates coolant in heating and air conditioning systems. Special production of pumps made of bronze and even stainless steel solves the problem of using them in hot water supply.

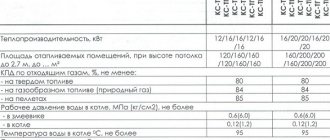

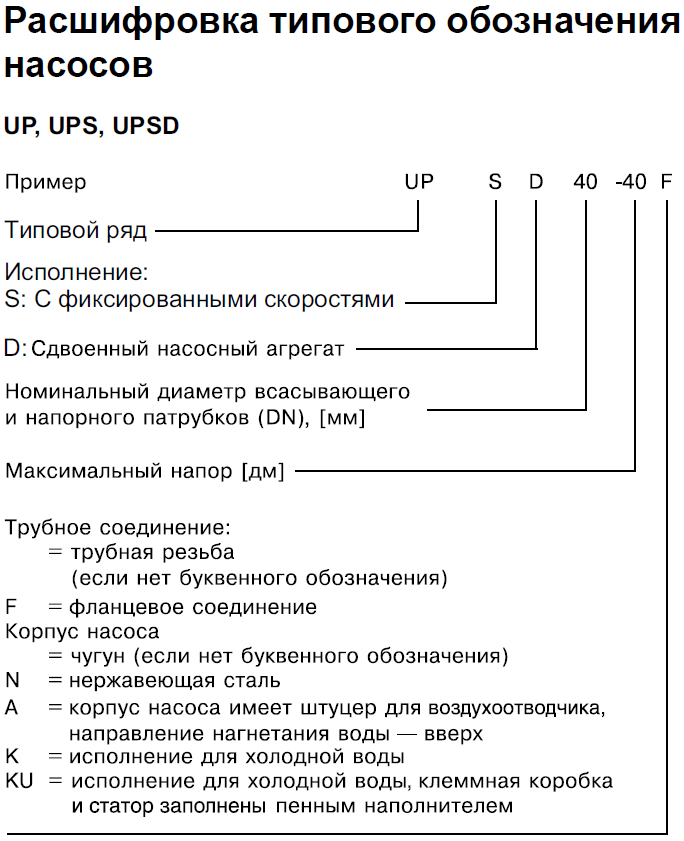

The Grundfos UPS pump currently has 28 products. This diversity is explained by the need for more accurate pump selection in modern heating systems. Despite the abundance of names, all models are easy to remember; you just need to remember the markings.

Grundfos UPS pump marking:

Let's look at the circulation pump GrundfosUPS25–40 as an example:

- Up – designation of equipment such as a circulation pump;

- S – pump equipment with speed switch;

- 25 – pipe diameter, mm. (there are pumps of 25, 32, and 40 mm);

- 40 – the highest pressure indicator, dm (40 dm = 4 m) – at the third speed.

Additionally, you can remember that there are pumps with the index “F”, for example the Grundfos UPS 40-100 F pump, this index “F” indicates a flanged connection of the pump to the pipe.

In addition, there are pumps with an installation length of 130 mm, then the designation contains the following marking UPS 25-40 130. Pumps with a length of 130 mm are most often used in limited space, for example in wall-mounted boilers.

Equipment with a flange connection, due to the small size of the pump, is used in isolated cases on a 40 mm pipe. In general, standard pumps with an installation length of 180 mm and with connecting nuts for a pipe of 25 mm are used. – one and a half inch nuts G1 1/2″, for a 32 mm pipe. nuts two inches G2″.

It is worth noting that the manufacturer supplies UPS pumps with nuts, which largely frees the buyer from possible misunderstandings, such as purchasing nuts of the wrong size. Recently, additions have been made to the Grundfos pump housing - “noises” have appeared, which are convenient for holding the pump with a wrench.

Grundfos UPS pump with letter “A”

A special model is the Grundfos UPS pump with the letter “A”, which is essentially a hybrid of a circulation pump combined with an air separator. The model allows you to successfully separate the air contained in the water and remove it using an air vent.

The pump is installed in the direction of the water flow from bottom to top. Please note that the air vent itself is not included in the delivery package of the pumps and is sold as an auxiliary accessory. The air vent is installed by screwing in; for this purpose, the housing is equipped with an internal thread Rp 3/8“.

A little about the company and products

Grundfos is a Danish company that manufactures and sells pumping equipment for various purposes. The company's main office is located in Bjerringbro in Denmark. The main range of equipment produced by the company is circulating, marked UP, submersible, marked SP, and centrifugal, marked CR.

Downhole models make up about 50% of all models presented on the world market. In addition to these products, the company supplies consumers with electric motors for pumping equipment and various components for this equipment.

Watch a video about the company:

The production of Grundfos borehole pumps was founded in 1945 by Paul Du Jensen. The company was originally called “Bjerringbro Pressestoberi og Maskinfabrik”, and the company received its current name “Grundfos” in 1967. The company produces a large number of equipment models, which can be reduced to several varieties, the main of which are the following:

The sq well pump is intended for the intake of clean water, which has mechanical inclusions in concentrations of no more than 50 grams per cubic meter.

Type designation

Grundfos sq well pumps allow operation in both vertical and horizontal positions. Models of this type of pumping equipment have special protection and a soft start system, which protects the device from power surges, overloads and overheating. Equipment of this type, produced by the company, has a capacity of 1.5 to 6.9 cubic meters per hour and a pressure height of 60 to 100 meters.

Pumping equipment marked SP is used in wells with an internal diameter of more than 110 mm. Equipment of this type is capable of lifting water from a depth of 440 meters with high productivity. The Grundfos sp series deep well pump has a built-in cooling system, temperature control based on the operation of an electronic sensor and a reliable strainer. All these innovations allow the sp series pumps to have a very high level of efficiency.

Various equipment modifications

The deep-well pump is capable of operating in both vertical and horizontal positions. produces a large number of models of equipment intended for use in wells, for pumping dirty drainage and fecal waters, for use in fire extinguishing systems, and produces equipment designs that have household purposes.

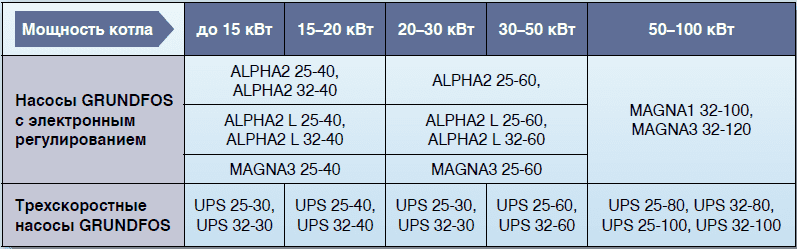

Grundfos UPS pump, selection. Selection table.

If we want to choose the right Grundfos UPS circulation pump, first we need to determine such characteristics as pressure = H in

meters, and consumption = Q in cubic meters. Then you need to calculate how much heat will be needed to heat your area.

To do this, a boiler with power is initially selected based on the parameters of the house. The calculation is not easy, you will need the dimensions of the area, you will have to take into account the number of radiators in the system, take into account the insulation of the house, decide on the installation of windows, ceiling heights, and so on and so forth. We advise that it is better to leave the calculations to specialists and experienced installers.

As a result of the calculations, we will obtain the required values; using them, based on the graphs of the hydraulic curves, we select the pump. But for simplicity, you can use the table for selecting pumps depending on the area of the house. In addition, as we know, the Grundfos UPS pump has three speeds, with which we will adjust the pump to our system.

| Heated area (m2) | Productivity (m3/hour) | Brands Grundfos UPS |

| 80 – 240 | From 0.5 to 2.5 | UPS 25 – 40 |

| 100 – 265 | From 0.5 to 2.5 | UPS 32 – 40 |

| 140 – 270 | From 0.5 to 2.7 | UPS 25 – 60 |

| 165 – 310 | From 0.5 to 2.7 | UPS 32 – 60 |

As can be seen from the table above, the owner of a two-story house with an area of 100-265 m2 is recommended to use a Grundfos UPS 32/40 or UPS 32/60 heating pump if he has water-heated floors. The decision to consult with your heating system installers is welcome; they know your system more accurately and, based on experience, will suggest the best size of Grundfos pump. You can also select a UPS pump based on the known boiler power according to the table below:

In this matter, the rule does not work - the more powerful the better, since an oversized pump in terms of hydraulic parameters, firstly, consumes more electricity, which leads to low energy efficiency. Secondly, the pipeline system may make noise, causing significant discomfort to your household. In the video, the legendary Grundfos UPS 25-40 180 pump.

ALPHA2 AND ALPHA3

Now these pumps are completely identical in functionality. This happened after ALPHA2 had the opportunity to independently carry out hydraulic balancing of the heating system, which was previously only present in ALPHA3. This is a very convenient solution that has earned the informal nickname “Cure for the Cold.”

For hydraulic balancing you will need an ALPHA Reader, which is installed on the electronic unit. It must be purchased separately and is not included in the package. APLHA Reader transmits information from the pump to a smartphone or iPad. You will also need the free GRUNDFOS Go Balance application, which must be installed on your gadget. The further procedure is carried out under the guidance of the application, which will provide detailed instructions for each stage of hydraulic balancing of the entire system. The ALPHA2 and ALPHA3 pumps allow you to measure the coolant flow in any heating system (warm floor, two or single pipe systems, dead-end, radiator network without thermal heads or with a constant flow) on all radiators and underfloor heating circuits in real time. This allows you to reduce to zero possible errors, which cannot be avoided even with the most careful theoretical calculations.

However, ALPHA2 and ALPHA3 are interesting not only because of their ability to self-balance. These are modern multifunctional units that perform excellent work in different conditions. They have three fixed speed modes, three constant pressure drop modes and three proportional control modes - such a wide choice opens up the possibility of fine-tuning the system, the pump becomes universal. There are two more important additional functions: “night saving mode” and “summer mode”. In Denmark, where these pumps were developed, they are in great demand. Firstly, heating rooms that are unoccupied at night is simply irrational. Secondly, there is a question of compatibility. The pumps are suitable for use with modern boilers where a similar mode is present. Pragmatic Danes know a lot about saving; heating is generally an expensive pleasure for them. Therefore, burning gas, wood or coal in vain is an unaffordable luxury.

As for the “summer mode”, this is a seasonal function. It allows you to start heating in the fall without unnecessary problems. For example, souring of the pump shaft during a long period of inactivity. In fact, starting the system yourself several times during the summer is a real hassle. “Summer mode” will maintain the system’s functionality independently.

GRUNDFOS ALPHA2 was the first pump to feature the AUTOADAPT mode - naturally, ALPHA3 also “inherited” it. This is a new product from the company’s engineers, who pay great attention, first of all, to ease of use, and of course, energy efficiency. The function became a real breakthrough and a kind of standard for subsequent generations of circulation pumps. The AUTOADAPT mode makes it possible to automatically change equipment settings when the needs of people living in the house change, or, for example. Changes of seasons. Using complex software algorithms, the equipment electronics constantly analyzes the processes and, depending on the indicators, selects the optimal pressure. This significantly saves heating system resources and consumer money.

Now more than 3 million ALPHA series pumps are successfully operating around the world. GRUNDFOS has released an updated model, which has an even higher energy efficiency class and meets the high requirements of the European EuP standard. The average energy efficiency index (EEI) for ALPHA2 pumps is 0.15. At the moment this is the best indicator. ALPHA2 and ALPHA3 consume only 3 W in constant speed mode and 4 W in AUTOADAPT mode. This means that the pump requires 87% less energy than most analogues on the world market. They have a built-in electronic flow meter to simplify balancing and diagnostics of the heating system. They are also capable of operating at temperatures from 2 to 40 °C and even in environments that form condensation.

By purchasing GRUNDFOS pumps, the consumer receives a very high-quality device made to the highest European quality standards. That is why the manufacturer provides a warranty of 2 to 5 years for various equipment models.

Separately, it is worth mentioning the engines. Do you know many manufacturers of pumps in which the rotor shaft and bearing are made of ceramics? Most likely not, since in most models from GRUNDFOS competitors the shaft is made of steel and the bearing is made of graphite. It is common knowledge that hot water heats up iron and expands it. Over time, such a bearing wears out and scale and other debris get into the gap formed between the shaft and the bearing. Sooner or later this leads to breakdown. In the case of ceramics this is almost impossible.

In addition, the ALPHA series pumps use a four-pole permanent magnet synchronous motor with a frequency converter. Permanent magnet rotors provide greater efficiency over a wide range of loads. The GRUNDFOS company values its customers and is ready to provide any assistance at any time. The “Service in 24 hours” program is presented in all cities of Russia where the company has representative offices. The user of GRUNDFOS pumping equipment can always call the hotline and get an answer to any question that may arise or call specialists to resolve

Types of devices for heating systems

Grundfos pumps designed to operate as circulation pumps are divided into two main groups , the difference of which lies in the operating conditions of the drive motor rotor.

If only the pump impeller comes into contact with the pumped liquid, then this design is called “dry rotor”.

If the transported liquid contains both the impeller and the motor rotor, it is a pump with wet rotor characteristics.

Both types of construction have their own characteristics and areas of application.

Dry

The dry rotor is good high efficiency and high power. Pumps of this type are also little sensitive to the quality of the coolant and can easily tolerate contamination from suspended matter and fine abrasives. Operates at temperatures significantly higher than the permissible operating values of glandless rotor pumps.

Photo 1. Disassembled Grundfos circulation pump for a heating system, equipped with a dry rotor.

The disadvantages are a shorter service life, comparatively high cost, slightly larger size, the need for regular maintenance (lubrication), and high noise. For this reason, models with a dry rotor are best installed in a separate room. But at the same time, they are able to “pump up” large cottages or even apartment buildings.

Wet

The wet rotor is more compact, almost silent, and extremely durable when installed correctly. Does not require maintenance during operation, but is less productive, with a relatively low efficiency - no more than 50%.

With overall low power consumption (on average 6–100 W depending on power, mode and load), this characteristic is not decisive.

This type of pumping equipment is extremely sensitive to the quality of the pumped liquid, since it is both a lubricant and antifreeze for the rotor. Therefore, such devices cannot operate at temperatures above 115 degrees and require the installation of a mesh dirt filter in front of the pump.

Photo 2. Grundfos compact circulation pump with a wet rotor, sensitive to the quality of the pumped liquid.

Wet-type devices are widely used in individual heating and water supply systems as additional circulation pumps for the make-up line.

Device and purpose

Depending on the purpose and design, the operating principles of pumping equipment differ.

Connection diagram

Deep models provide water extraction from wells of various diameters. The operation of these pumps is based on the influence of centrifugal force on water. Most often, products are placed in oblong-shaped cases.

Operation of the device is possible only if there is complete immersion in an aquatic environment while simultaneously filling the housing with water. An electric motor installed in the structure provides rotational movement of the pump impeller.

As a result of their movement, the impeller blades capture water and push it into the outlet pipe of the unit with great force and speed. Due to the decrease in pressure in the area where the impeller is located, the valve opens under the influence of external water pressure and liquid flows to the impeller from the outside. The operation is controlled by using a control unit and adjusting the operating parameters; as a rule, such units operate in automatic mode.

Selection options

If the Grundfos pump is considered as a supply pump (to replenish coolant losses and fill the system), then its main parameter is considered to be performance. Usually it is taken at the rate of 0.5% of the volume of the entire system.

But if the water device will work as a full-fledged circulation pump, then the choice should be stricter.

Power

This parameter shows how much volume the device pumps per unit of time. The choice depends on the heating power. It is better to take a pump with a small power reserve (but without fanaticism - a 10% capacity is enough), since at modes close to the maximum, the noise level may be exceeded. As a rule, the factory settings correspond to the lowest noise level.

Pressure

The pressure depends on the resistance of the system to dynamic pressure and the number of floors of the heated room. The more turns and control valves, the higher the performance should be.

The maximum pressure depends on the characteristics of the system. Static pressure in open systems is determined by the height of the expansion tank, in closed systems - by the pressure membrane.

Speed and noise

In addition to these parameters, you can pay attention to the additional options of the latest models of the concern.

For example, a pump with a three-position speed switch allows you to adapt the operation to the needs of the system and save on energy consumption (when compared with single-speed models).

But modern developments with electronic regulators are able to adapt so clearly to the conditions and needs of the heating system that they reduce energy consumption by 2–5 times. Not to mention reducing noise.

You need to know the following about noise: models with a dry rotor are noticeably noisier. Pumps with a wet rotor are practically inaudible during operation. But if their power exceeds the needs of the system or they work at the limit, the noise increases. Noise also

Reference! The latest Grundfos models are an excellent alternative to outdated pumps from other brands - they consume less energy and are noticeably quieter.

How to install a Grundfos pump correctly

Detailed recommendations for installation and installation are contained in the technical documentation included in the basic equipment package. But as practice shows, the instructions are often turned to in the very last place, when a breakdown has already occurred.

Things to remember when installing a circulation pump in a heating system:

- The pump is placed on the return line, usually immediately after the expansion tank.

- It is prohibited to start the electric motor until the heating system is filled with coolant.

- The correct installation position of the pump is vertical. Only in this position does the coolant completely lubricate all rubbing parts: bearings, rotor. When turned on with a dry rotor, the pump quickly fails. The service life is reduced if the internal volume of the housing is not completely filled with coolant, as happens with horizontal installation.

- Correct installation of the Grundfos circulation pump in the heating system takes into account the operating features. So, in case of frequent power outages, they are connected to a UPS and also installed in a bypass.

- The procedure for installing the pump is as follows: install the water circuit. Afterwards, using “Americans” (included in the kit) or couplings, the pump is connected. The heating system is filling up. Now you need to remove air from the pump. To do this, use a screwdriver to unscrew a special bolt on the top cover covering the engine.

- Selecting the operating mode - the pump works best at minimum speed. In quiet mode, bearings and other mechanisms that are subject to load during operation wear out less. But, as a rule, the minimum speed is not enough. The device has three stages of pump rotation speed. It is worth choosing the mode in which the heating system is evenly heated. Models with an electronic control unit independently select the required circulation speed.

How to choose a pump

In order to select a pump you need to know the answers to the following questions:

- How much liquid needs to be pumped per unit of time (flow rate) Can be measured in m³/h, l/min, l/sec, gpm... 1m³/h ≈ 16.67 l/min ≈ 0.28 l/sec ≈ 3.67gpm

- What pressure should the pump develop at the specified flow rate (pressure) Can be measured in m, kgf/cm², bar, psi... 10m = 1kgf/cm² ≈ 0.98bar ≈ 14.22psi

- What will the pump pump (purpose)

- Where the pump will be installed (design) More information about the purpose and design of pumps can be found in the articles describing the pump sections.

Centrifugal pump for well Aquarius

The most popular and frequently used deep well pump is the Aquarius. This device is produced in Kharkov, has a very attractive price and good quality, but first things first.

The Aquarius series of submersible pumps includes the following models:

1. Aquarius BCPE 0.32. 2. Aquarius BCPEU 0.32. 3. Aquarius BCPE 0.5. 4. Aquarius BCPEU 0.5. 5. Aquarius BCPE 1.2. 6. Aquarius BCPE 1.6.

1. Deep pump Aquarius BTsPE 0.32 - the simplest option, with a capacity of 0.32 l/sec. The second numerical value in the marking indicates the pressure at which the declared performance is ensured. With less pressure, productivity will be higher and vice versa.

Characteristics of Aquarius BCPE 0.32:

Nominal productivity - 1.2 m 3 / hour. Maximum pressure - up to 200 m (second digital designation in the name). Pump diameter is 105 mm (4 inches). Weight - 8.3-41 kg. Power - 440-2500 W. You can buy an Aquarius well pump at a price of 7,500 rubles for the simplest model BTsPE 0.32-25U, and from 21,500 rubles for the most productive model BCPE 0.32-140U. The popular model Aquarius BTsPE 0.32-63U is estimated at 11,500 rubles or more.

2. Submersible pump Aquarius BTsPEU 0.32 is an analogue of BTsPE 0.32, the main difference is the reduced diameter to 95 mm and the maximum pressure of this model reaches 63 m. Prices for Aquarius BTsPEU 0.32 range from 7500 rubles, for BTsPEU 0.32-25U, and from 11,500 rubles, for the top BCPEU 0.32-63U.

3. Deep centrifugal pump Aquarius BTsPE 0.5 - a model with a capacity of 0.5 l/sec at the pressure indicated in the pump designation.

Characteristics of Aquarius BCPE 0.5:

Nominal productivity - 1.8 m 3 / hour. Maximum pressure - up to 150 m. Pump diameter - 105 mm (4 inches). Weight - 7.3-26.3 kg. Power - 400-2050 W. You can buy an Aquarius BTsPE 0.5 pump for quite reasonable money, prices range from 6,500 rubles for BCPE 0.5-16U, and from 15,000 rubles for BCPE 0.5-100U. The widely used BTsPE 0.5-40U and BTsPE 0.5-50U cost at least 9,000 and 10,000 rubles, respectively.

4. Pump Aquarius BTsPEU 0.5 - a similar model to BTsPE 0.5, but with a diameter reduced to 95 mm. The maximum head of the BCPEU is 90 m. The price of the centrifugal pump Aquarius BCPEU 0.5 starts at 6,600 rubles, for the BCPEU 0.5-16U and reaches 12,000 rubles. and more, for the BCPEU 0.5-63U model.

What is needed for selection?

The main characteristics required when choosing any water pump include:

- operating flow , that is, the amount of water pumped per unit of time;

- the amount of pressure required , which is the pressure at the outlet of the pump.

The operating point is determined from the flow and pressure values in the program. To do this, select the most suitable operating schedule for the desired family of pumps, which has a point with the closest parameters.

Characteristics of circulation pumps for heating Vilo

Vilo circulation devices , especially in cases where the area of the house is large enough, and there is also a second floor or a pipeline with a large branching system. In order to heat houses, only two Vilo series have been developed - they have their own characteristics and advantages.

Wilo advantages

The equipment of the Vilo line has many advantages, for example, relatively low power, that is, not so much electricity will be spent . These devices are designed to heat houses with an area of approximately 200 to 750 m2. Another plus is the material from which the wheel is made - it is made of technical polymer, which is resistant to prolonged exposure to both low and high temperatures.

Advantages of Vilo equipment:

- Three-stage speed control thanks to a manual switch.

- Anti-corrosion coating of the pump housing.

- Bearings made of wear-resistant metal-graphite material never deform.

- Affordable price.

What parameters may be needed?

When selecting pumps for water supply, sewerage and other needs, it is necessary to take into account the specific operating features of units for various purposes.

Pump type Parameters

| Heating circulation pump | Heating system parameters - coolant temperature, total heat load, pipeline diameters |

| Downhole units | The size of the well and its flow rate (the amount of water that can be pumped out per unit of time) |

| Submersible and drainage pumps | Presence and nature of solid particles. This determines the need to use cutting mechanisms |

| Booster pumps | Pressure to pump |

| Fire station pumps | Type of fire extinguishing system (sprinkler, deluge), pressure in the system, total flow rate of sprinklers |

What is a circulation pump?

This is a small unit that is installed directly into the pipeline and ensures the movement of coolant through the pipeline. For heating systems of private houses, pumps with a so-called “wet rotor” are usually used, for example, GRUNDFOS type UPS . A special feature of this design is that the cooling and lubrication of the moving parts is carried out by flowing liquid, making the operation of the unit silent and reliable. Features of modern circulation pumps (CP) are efficiency, durability, small dimensions and noiselessness.

What determines the cost of a pump?

The choice of any equipment represents a compromise between its cost and functionality, so the consumer should take into account factors that influence the rise in cost of the order. Among them are:

- The nature of the working environment For example, its increased aggressiveness requires the use of particularly resistant materials; contamination places certain demands on the working parts of pumps

- The value of the maximum operating pressure The material of the housing parts of high-pressure pumps must have increased strength, requires a different manufacturing technology and an increase in metal consumption

- Operating temperature Operation at elevated temperatures requires the use of appropriate materials, this also applies to the design of sliding seals

- Equipping pumping units with a frequency-controlled drive. A frequency converter allows you to save up to 30-40% of electricity during periods of off-peak water consumption, but at the same time increases the final cost of the pump.

- Pump material , which can be brass, various grades of cast iron or stainless steel, significantly affects the total cost of the order.

Who makes Grundfos pumps

Grundfos household circulation pumps are manufactured in the company's own factories, whose activities date back to 1945. The word Grundfos literally translates as “spring” was not chosen by chance. Grundfos produces pumping equipment for wells, heating systems, etc.

About 16 million units of equipment are produced annually, which corresponds to approximately 50% of all pumping equipment produced in the world. Grundfos models are used for private and industrial purposes, installed in mines and mines, and used for the extraction of mineral and thermal waters. Pumping equipment is operated in extremely unfavorable conditions.

One of the company's latest trends has been the widespread introduction of energy-saving technologies, which can significantly reduce energy consumption while maintaining the performance and reliability of equipment.

Rules for installing Grundfos water equipment

First you need to decide on the installation location. In theory, the device is placed in any break in the main line. But in practice it is better to do this on the return pipe - as close to the boiler as possible. Between the boiler and the pressure (expansion) tank. This arrangement will reduce the thermal load on the pump structure and its working blades.

Important! When installed on the outlet line, the coolant may boil on the impeller blades, which will ultimately lead to rapid wear.

The best option would be to choose a horizontal pipe section. Although it is possible to install the pump on a vertical section.

True, it is important here that the flow in this place goes from bottom to top, and not vice versa - in order to avoid airing.

When installing the pump, you need to make sure that its rotor is horizontal - when tilted, air may accumulate and quickly wear out due to insufficient lubrication (in pumps with a wet rotor).

pump terminal box is placed on top to prevent water from entering if the line loses its seal.

Attention! It is important to ensure that the equipment is not installed close to a heating radiator, which may cause the internal thermostat to malfunction .

The pump is connected through a bypass - bypass branch. At a selected point in the line, a gap is made into which a ball valve is placed for automatic adjustment, or a ball valve is placed for manual mode switching, which is throttled with a bypass jumper.

with two shut-off ball valves at the inlet and outlet (to be removed if necessary). A dirt filter and a valve (when there is no built-in one) must be placed in front of it to remove air.

Guided by the instructions for the maximum power consumption (indicated on the case and in the technical data sheet), select an automatic fuse for the power supply. It is also possible to connect the device through an automation system: thermostat or timer.

Installation of a circulation pump

In order for the heating system to work efficiently, it is important not only to choose the right pump, but also to perform its proper installation .

In this case, you can avoid the need for its repair. It is best to entrust this work to professionals. But if the owner of the home has knowledge and has certain skills, then he can perform the installation work on his own. It is easiest to install grundfos pumping equipment together with the heating system. However, in some cases it is necessary to install the unit into a functioning system.

The installation process includes a certain set of works that must be performed in the following order:

- The first step is to drain the water from the heating system pipes and radiators. At the installation site there must be threaded connections, which in diameter must coincide with the holes of the installed pump. To install the pump correctly, you must pay attention to the arrow on the housing. It shows the direction of movement of the coolant. The unit should be installed in accordance with its direction;

- a water purification filter is installed in front of the unit. Its use allows you to extend the life of the pump. In addition, thanks to the filter, its efficiency significantly increases. If you refuse to install a filter, the device will fail ahead of schedule due to sand or debris getting into it;

- shut-off valves - taps must be installed in front of the device’s nozzles, which will make it possible to service the equipment and, if necessary, repair it. The pump must be located in a horizontal position. In this case, damage to the rotor will be avoided during its operation;

- when the equipment installation is completed, the system is filled with coolant . It is optimal if it is supplied through the lower part of the heating pipes. In this case, the air in them will rise into the storage tank and come out. In this case, airing of the system will be excluded. Therefore, automatic air vents must be installed in the system. The installed pumping equipment must receive power through an automatic circuit breaker.

Pump replacement

Replacing a pump that has exhausted its service life sometimes causes problems, since the same pump may well have been discontinued during its operation, and the replacement recommended by the manufacturer may differ significantly in connection dimensions. And even if there are no such problems, in any case it is advisable to consider other replacement options. The development of pumping equipment does not stand still, new manufacturers are entering the market, competition is forcing manufacturers to optimize pumping equipment. As a result, to replace a pump that has exhausted its service life, another one may appear, more suitable for specific technical conditions and significantly cheaper.

As an example of the feasibility of such a replacement, I usually cite the possibility of replacing flanged circulation pumps with a wet rotor with the same characteristics, only with a dry rotor. The price gain can be more than double. At the same time, pumps with a dry rotor have advantages in the form of higher efficiency and maintainability. The disadvantages of such a replacement include the need to rework the pipeline, because in most cases the connecting dimensions will be different and the need to install vibration-damping inserts if the heating system is implemented with steel pipes and the distance to living quarters does not compensate for the vibration that occurs during operation. However, the cost of solving these problems often does not compare to the price difference.

Another typical option for replacing an old pump with a new one is to replace a flanged cantilever pump on a slab with a flanged close-coupled pump. Old Soviet-made cantilever pumps did not have such high efficiency as modern ones; in addition, they were designed and installed with a significant margin, and correct replacement of such a pump will lead to significant energy savings.

Modern well pumps are more flow optimized than older ones. And where pumps with a diameter of 6-8 inches were previously used, it is now quite possible to use pumps with a diameter of 4-6 inches, which are cheaper.

A reasonable approach to replacing a pump that has reached the end of its service life, in most cases, leads to cost savings, reduced operating costs and an increase in the time until the next replacement.

JP (Grundfos)

VA 50, VA 60 (DAB) CA (Calpeda) DG Blue, DG BluePRO (Zenit) TCR (Lowara) EURO, EUROINOX, EUROCOM (DAB)

Let's consider how long submersible pumps for wells last

In order of increasing service life.

1) Screw and screw pumps for wells. These include such brands and models as: Caliber NTsPS, Unipump Eco Screw, Belamos 3sp 60/1.8, Whirlwind SN 90 and a lot of electric pumps of similar design. These models have a rubber screw as a working part, and not a polymer impeller like centrifugal pumps.

Screw pumps operate from 5 minutes to 1.5 years according to our statistics. On average 7 months - 1 year. However, there is still a possibility that a screw electric pump can last 5 years. It's just extremely small. The price of these well units ranges from 4 to 9 thousand approximately.

The following problems can occur with screw pumps (to watch the video, click on the image below):

Here is a video about the operation of a 4-inch screw pump:

2) Centrifugal pumps in the budget price segment. From 8 thousand for pumps for shallow wells to 30 thousand for pumps for wells over 100 - 150 meters 150 meters.

These are Chinese pumps Belamos, Aquatek SP, Gilex Vodomet Prof, Whirlwind SN, Unipump, etc., Ukrainian Aquarius BCPE.

Three-inch Chinese work for an average of 2.5 years. Aquarius can safely be given primacy; he often lives for more than 5 years and up to 10-12. Four-inch Chinese pumping equipment lasts longer, but Aquarius BCPE, in our practice, and in reviews from the forums, is the clear leader here.

From time to time, the problem of non-working Chinese pumps can be eliminated quickly and inexpensively, we talk about this in the video below:

4) Pumps of the middle price segment of the Italian brands Pedrollo, Aquario ASP. The service life of Pedrollo ranges from 5 to 15 years - a lot depends on the operating conditions. Often, when owners forget to monitor the pressure in the hydraulic tank, the pump begins to turn on and off frequently. So, under such conditions, Chinese submersible centrifugal electric pumps burn out, while Pedrollo (and Grundfos) simply damage the downhole underwater motor power cable, the motor itself remains intact.

With constant proper maintenance, the service life of such well pumps can be 6-8 years. And in some cases more.

4) Expensive pumps. The service life of Grundfos SQ submersible electric pumps can vary significantly. In our practice, in poor conditions (highly ferrous water, salt water, problems with electricity), pumps operate for 5-6 years. If the conditions are good, they can work for more than 10 years. Also, the statistics on Grundfos SQ pumps need to be adjusted, since for the last 5 years Grundfos pumps produced in Mexico have been supplied to Russia, and not Denmark, as was the case before. There are still some complaints about this brand and the need to diagnose problems after 1-3 years of operation, but in the vast majority of cases we can say that Grundfos SQ is the electric pump that you set and forget. One of the tested pumps.

There are, of course, cases when Grundfos work for 2-7 years:

Pump energy efficiency

Well-known European manufacturers of pumping equipment have made great strides in optimizing energy consumption, introducing several wet rotor models to the market. This was achieved through the use of modern DC electric motors controlled by a controller. Such models belong to class “A” equipment, which is considered the most effective in terms of minimizing energy losses - their consumption does not exceed 0.09-1.3 kW).

Grundfos specialists have developed a whole series of energy-saving pumps under the names ALPHA2 and MAGNA3. The former are distinguished by simple functionality and are intended for use in heating and hot water systems of private houses. Models of the second type have the AUTOAdapt function, which allows you to automatically set the optimal power consumption mode. Their capabilities meet modern requirements for the efficiency and performance of equipment in this class. They are designed for use in heating systems of private homes and industrial enterprises.

Types and purpose of circulation pumps

In heating systems, pumps are used mainly to provide a certain coolant pressure. It is due to this that the efficiency of coolant movement through pipes and heating radiators is achieved. This is a necessary condition for ensuring uniform heating of all parts of the system and creating a temperature regime in the interior of houses that is comfortable for living.

Design

If we talk in more detail about the design of the circulation pump, we note its similarity with a conventional electric motor. The pump design contains the following elements:

- stator - it is located in a stationary position on the frame. There are windings installed inside it, which are used to pass electric current;

- The rotor is a moving mechanism that is located inside the stator. It has blades that are rigidly fixed and are used mainly to circulate water through the pipes and radiators of the heating system.

Varieties

The listed mechanisms can be divided into two types according to such a criterion as the method of placement:

In a “dry” rotor, only part of the blades are in the water. Such a device usually includes large heating systems used in industrial enterprises. They have one drawback. It consists in the high noise of these installations during their operation.

Pumps used in autonomous heating systems incorporate a “wet” rotor. It is completely immersed in coolant. This is the reason why there is no noise during its operation. In addition, in terms of price, these devices differ from other units.

A characteristic feature of modern circulation pumps is their high reliability. The average service life of this equipment can be up to 20 years. To ensure efficient rotation of the rotors, the manufacturers of this equipment use high quality bearings . For their manufacture, special high-strength steel and various types of lubricants are used.

Currently, a wide range of mechanisms is available to consumers on the market for this equipment. Among imported pumping equipment, grundfos products are in demand. The pumps it produces have certain advantages. The main ones should be:

- high productivity;

- reliability during operation.

If you decide to purchase grundfos pumps for your heating system, you should know that the cost of this equipment is much higher compared to analogues from domestic manufacturers.

One of its features is that the pumps from this manufacturer can operate in several modes. And this is beneficial for the consumer, as it provides the opportunity to reduce energy costs. This also makes it possible to increase the service life of the equipment. When the task is to create a comfortable temperature in a production room in a short time, then in this case the maximum rotor rotation speed is turned on.

Operating modes

A modern recirculation pump for heating is a multifunctional device. Various samples of this equipment are capable of operating in the modes indicated in the passport, including “fixed speed”. All of them are equipped with a synchronous motor, the operation of which is controlled by a built-in processor. During operation of the unit, the control unit records the following main parameters:

- current strength;

- rotor speed;

- temperature in the working area and others.

Its presence allows you to adapt to a specific heating network with optimal energy consumption.

Do-it-yourself pump disassembly

If repairs are necessary, the equipment must be taken to a service center if the device is under warranty.

Any user who has thoroughly studied the design can disassemble a purchased sample of pumping equipment if desired. The need for this often arises when it is necessary to repair or overhaul it with the replacement of worn parts. After complete disassembly, the main working components of the mechanism are inspected and then checked for wear.

The main attention is paid to examining the condition of the “wet” rotor. It should be removed and replaced with a new part in the presence of a repair specialist who can supervise this difficult operation.

Rating of popular models

Most often, this model is counterfeited by scammers, since it sells better.

The pump rating is based on a comparison of the technical indicators and operational capabilities of three models. In first place is the Grundfos UPS 25-60 (N) 180 product, which is a circulation unit with a cast iron body (this option is used only for heating). Its modification for hot water supply has a stainless steel body. All samples are equipped with a single-phase asynchronous motor, a speed switch and a special sleeve separating the rotor and stator.

The advantages include:

- permissibility of use in any type of circuits (closed and open);

- wear resistance and efficiency (consumption no more than 60 W);

- low noise level (up to 43 dB);

- compactness, low weight and overheating protection;

- ease of installation and maintenance;

- long service life.

The disadvantages of these products are the obsolescence of individual models and their high cost.

The second position is occupied by a Grundfos ALPHA2 25-40 180 , equipped with a built-in permanent magnet electric motor. The power consumed by this device from the network is 0.022 kW, and the productivity is 2.4 m3/hour. At an operating temperature of the coolant from +2 to +110 °C, the pressure created in the circuits is 4.0 meters.

The Alpha model is made of cast iron and has an increased service life

This product has a pure cast iron body and is equipped with an efficient wet rotor motor and ALPHA plug. Vertical or horizontal installation of the unit is allowed, which, after startup, is controlled via built-in electronics. All information about the possible operating modes of the device, its energy consumption and typical breakdowns is displayed on the display located on the front panel.

The positive aspects of this model include:

- Low power consumption (only 22 watts).

- Small dimensions (10x15x18 cm) and light weight (2.1 kg).

- Low noise level during operation (no more than 43 dB).

- Protection from corrosion (the body is made of stainless steel).

- The presence of the AUTOADAPT function, as well as the ability to select night or summer mode.

- Low level of heat loss (the housing is insulated with a protective casing).

- Possibility of setting fixed operating modes.

- Long-term warranty (up to 5 years).

The disadvantages of this product are the frequent malfunctions of the electronics, as well as the lack of special protection against dry running.

The third place is confidently occupied by the Grundfos UPA 15-90 (N) - a modern monoblock type unit, which has characteristics slightly worse than the previous model.

TOP 5 best Grundfos well pumps

Grundfos SQ 1-50 (1020 W)

A powerful and productive submersible well pump has compact dimensions, a small diameter and built-in protection against overheating and dry running..

Ease of use is also enhanced by smooth engine start and automatic control of water level.

The model is characterized by increased wear resistance due to the body made of high-quality stainless steel with a good degree of corrosion protection.

The diameter of the pump is only 74 mm and the weight is 4.8 kg, making it convenient to position in both vertical and horizontal planes.

The device is capable of raising water to a height of up to 71 meters with a throughput of 1.5 cubic meters. m/hour.

Specifications:

- Max. head: 71 m;

- capacity: 1.5 cubic meters m/hour;

- liquid temperature: up to 35°C;

- functionality: protection against overheating, against dry running, smooth engine start, automatic control of water level;

- weight: 4.8 kg.

pros

- powerful pressure;

- small dimensions and weight;

- smooth engine start;

- build quality.

Minuses

- price.

Grundfos SQ 2-55 (700 W)

A submersible borehole pump is designed to pump clean water without foreign impurities to provide water supply to private homes, water pumping stations and irrigation systems.

The maximum pressure of the device is 68 meters, and the throughput is 3 cubic meters per hour. The body is made of stainless steel and fiberglass is included in the hydraulic elements.

The model is equipped with a fuse against overheating and dry running, as well as a smooth engine start mechanism.

The pump can be installed in both horizontal and vertical positions. It is lightweight and can be operated at ambient temperatures up to 35 degrees.

Specifications:

- Max. head: 68 m;

- capacity: 3 cubic meters m/hour;

- liquid temperature: up to 35°C;

- functionality: protection against overheating, against dry running, smooth engine start, automatic control of water level;

- weight: 4.8 kg.

pros

- ergonomics;

- built-in check valve;

- powerful pressure;

- protection against voltage surges;

- smooth engine start.

Minuses

- short power cord;

- price.

Grundfos SQE 2-85 (1650 W)

A submersible well pump with the highest pressure power of 109 meters and an electronic type of regulation is used for pumping clean groundwater with temperatures up to 35 degrees.

The device has small dimensions and weight: its diameter is only 74 mm. The body is made of stainless steel and equipped with an exit hole with a thread diameter of 1¼".

The pump can be installed in both horizontal and vertical planes.

The safety system consists of a thermal overload fuse, a dry-running protection mechanism, automatic water level control and a soft motor start..

The throughput is 2 cubic meters per hour.

Specifications:

- Max. head: 109 m;

- capacity: 2 cubic meters m/hour;

- liquid temperature: up to 35°C;

- functionality: protection against overheating, against dry running, smooth engine start, automatic control of water level;

- weight: 6.2 kg.

pros

- powerful pressure;

- small dimensions and weight;

- ease of installation;

- electronic adjustment;

- full set;

- smooth engine start.

Minuses

- short power cord;

- price.

Grundfos SQ 3-105 (2540 W)

Powerful, reliable, highly efficient and productive submersible well pump is distinguished by build quality, good technical parameters and ergonomic characteristics.

The pump can be installed horizontally or vertically and provides pumping of water with a temperature of up to 35 degrees without impurities and fibers.

The maximum pressure is 147 meters, thanks to which the device provides complete water supply in private homes and summer cottages.

The throughput of the unit reaches 4.2 cubic meters. m/hour. Its body is made of stainless steel, and the hydraulic elements are made with the addition of fiberglass, which increases the service life of the device.

Protective functions include shutdown in case of overheating and lack of water, soft start of the engine and automatic control of the water level.

Specifications:

- Max. head: 147 m;

- capacity: 4.2 cubic meters m/hour;

- liquid temperature: up to 35°C;

- functionality: protection against overheating, against dry running, smooth engine start, automatic control of water level;

- weight: 6.5 kg.

pros

- powerful pressure;

- good throughput;

- ergonomics;

- low noise level;

- smooth engine start.

Minuses

- short power cord;

- price.

Grundfos SQ 1-65 (1020 W)

The compact and powerful submersible pump with a stainless steel body is characterized by performance, good pressure and low weight, making it easy to install to obtain the required volume of clean water.

The maximum head of the model is 94 m, the throughput is 1.5 cubic meters. m/hour. The body is made of stainless steel and has an outlet with a diameter of 1¼".

The weight of the structure is only 4.9 kg, which allows you to quickly install it in a horizontal or vertical plane without the help of outsiders.

The motor has a smooth start, protection against overheating and dry running. Also among the protective functions is automatic control of the water level.

Specifications:

- Max. head: 94 m;

- capacity: 1.5 cubic meters m/hour;

- liquid temperature: up to 35°C;

- functionality: protection against overheating, against dry running, smooth engine start, automatic control of water level;

- weight: 4.9 kg.

pros

- powerful pressure;

- build quality;

- ease of installation;

- price;

- low weight and diameter.

Minuses

- short power cord.