The main technical characteristics of aluminum heating radiator models are information that it is advisable to know before choosing and purchasing them. Along with the appearance (design) of the heating device and its cost, technical data allows you to compare different models and choose the option that is optimal in terms of the main parameters.

There are quantitative and qualitative characteristics of aluminum radiators. Quantitative ones allow you to compare heating devices according to their weight and size parameters and heat flow power. In turn, quality characteristics take into account design features and manufacturing technology.

What influences the dimensions of aluminum heating radiators

One of the most important parameters is the gap between the axes of the radiators. Most often you can find aluminum devices on sale, in which the distance between two collectors - lower and upper - is 350 or 500 millimeters. True, there are products with values equal to 200, 400, 600, 700 and even 800 millimeters.

The dimensions of aluminum radiators in length have practically no restrictions. The longer the battery, the higher its power. To achieve the required power level, it is necessary to purchase a certain number of heating sections.

The total length of the device depends on the power needed to heat the room, the size of the heating radiators, sections and heat transfer.

To connect individual elements of an aluminum radiator to the pipelines of the heating structure, use an installation kit, which includes:

- special brackets for hanging the battery on the wall in the amount of 2-4 pieces;

- Mayevsky valve - a device for bleeding air trapped in the system;

- a key designed for a faucet;

- pass-through radiator plugs with a diameter of 3/4 or ½ of the right or left type;

- plugs for the heating device, they are also called blind plugs;

- sometimes there are also dowels included to secure the brackets.

Depending on the type of manufacture of the aluminum alloy radiator, the heating device can be cast or extruded:

- Thanks to casting, the battery becomes durable and reliable. In this case, the sections are made up of individual parts, cast entirely and then assembled into a single heating device. Its lower part is welded last;

- in the process of using extrusion equipment, a heated aluminum alloy is forced through a special metal plate with holes. This method allows you to make a long aluminum profile of the required shape. When it cools, it is divided into segments that correspond to the size of the device. Only then are the top and bottom of the battery welded. In this case, it is impossible to adjust the radiator in length, and sections cannot be added or subtracted from it. Extrusion devices are quite rare on sale.

What do you need to know about the sizes of heating batteries?

Heating radiators are produced in different sizes, which allows you to choose the optimal place in the room for their installation.

- Standard height.

- Low heating radiators.

- Tall heating radiators.

The length of the radiator depends on the number of sections.

Dimensions of cast iron heating radiators

- Standard dimensions of cast iron heating radiators: section length 93 mm, depth 140 mm, height 588 mm.

- Low heating radiators dimensions: height 388 mm, other parameters are the same.

- Tall cast iron radiators: height from 661 to 954 mm, section length 76 mm, depth - 203 mm.

Cast iron heating radiators can last up to 50 years without replacement

Dimensions of aluminum heating radiators

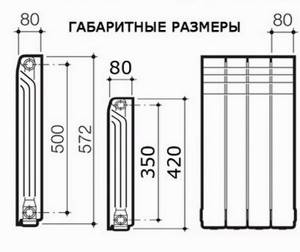

- Standard dimensions of aluminum heating radiators: height 575-585 mm, section length - 80 mm, depth - 80-100 mm.

- Low: height from 200 to 400 mm, section length from 40 mm, depth up to 180 mm.

- High: height 590 mm, depth 95 mm, section length 80 mm.

Aluminum radiators have good heat dissipation

Dimensions of bimetallic heating radiators

- Standard dimensions of bimetallic heating radiators: height 550 – 580 mm, section length 80-82 mm, depth 75-100 mm.

- Low: height 30 -500 mm, section length 80 mm, depth – 95 mm.

- High: height 880 mm, section length 80 mm, depth 95 mm.

Bimetallic radiators combine all the best qualities of steel and aluminum radiators

Dimensions of steel heating radiators

- Standard dimensions of sectional tubular radiators: height 600 mm, radiator length 400-3000 mm.

- Low: height 400-500 mm, radiator length 400-3000 mm

- High: height 700-900 mm, length the same.

Steel radiators are most often used in individual heating systems

Parameters and dimensions of aluminum radiators ROVALL

The company producing aluminum radiators TM ROVALL is one of the divisions of the Italian concern Sira Group. This company produces batteries from aluminum alloy with a distance between the two collectors of 200, 350 and 500 millimeters. The kit for their fastening, which is purchased separately, includes the following products: plugs, adapters, for connecting sections - nipples with gaskets and for wall mounting - brackets, as well as a Mayevsky tap. Main parameters of ROVALL aluminum radiators:

- permissible operating pressure is 20 bar, and when tested - 37.5 bar;

- maximum temperature – no more than 110 °C.

All Rovall devices of the Alux 200 models, according to official sources of the manufacturer, have a distance of 200 millimeters between the axes, a height of 245, and a depth of 100 millimeters. In this case, the minimum length is 80, and the maximum is 1280 millimeters. In turn, heat transfer can be a minimum of 92, and a maximum of 1472 watts. The number of sections varies from one to 16.

The Rovall Alux 350 radiator models, with a distance of 350 millimeters between the collectors, have a height of 395 and a depth of 100 millimeters. In this case, the minimum length of the devices is 80, and the maximum is 1280 millimeters. In turn, heat transfer can be from 138 to 2208 watts. The number of sections is from one to 16.

Models of Rovall Alux 500 devices, with an interaxial distance of 500 millimeters, have a height of 545 millimeters and a depth of 100 millimeters. At the same time, the minimum length of the devices is 80, and the maximum is 1280 millimeters. In turn, the power can be a minimum of 179, and a maximum of 2840 watts. The number of sections ranges from one to 16.

Conclusions from comparative characteristics

When purchasing radiators, you need to take into account the main performance characteristics: the ability to withstand significant pressure drops, resistance to corrosion processes, the strength of section connections and, ultimately, the durability of the product.

Aluminum ones can be installed in private households, where it is possible to control the quality of the coolant and the pressure in the system. They will serve well for many years. Home owners will receive good quality at an affordable price. However, you should not install such radiators in houses where antifreeze is supposed to be used as a coolant.

Bimetallic ones are ideal for apartment buildings where space heating is done centrally. They can withstand high pressure and are suitable for coolant of any composition.

How a battery differs from a radiator is its ability not only to release, but also to accumulate heat. In this regard, of course, cast iron models win. However, they are excessively heavy, expensive and are justified in houses where the heating system runs on solid fuel. In other cases, it is more convenient to install modern heating devices made of aluminum or bimetallic, which are convenient to install even yourself. The radiators are supplied with wall brackets, air vents and other elements necessary for installation.

Radiator volume parameters from Climatic Control Corporation LLP

This company from the UK produces aluminum heating devices BiLUX AL, which have an excellent degree of heat transfer and are manufactured taking into account the characteristics of autonomous heating systems.

The surface area of these batteries is significant, and the cross-section of a vertical pipe, when calculating aluminum heating radiators, was determined optimally. The plant where BiLUX AL M 300 and BiLUX AL M 500 radiators are manufactured is located in China. The distance between both axes of the collectors is 300 or 500 millimeters. During the manufacturing process, the injection-molded top parts of the instruments are connected to the bottom, which is manufactured using a specially developed welding technology.

When the products are ready, after assembly they are subjected to chemical and mechanical processing. Only after this, aluminum devices are tested and checked for strength and tightness. They are painted in several stages. In addition, they are exposed to an electrostatic field and at the same time enamel produced on the basis of epoxy resins is sprayed. Then, when heated to a high temperature, the surfaces of the radiators are polymerized.

The peculiarity of BiLUX AL devices is that their ends have a special design solution that allows the use of a special ring for gasketing.

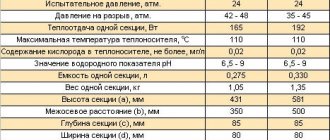

The material it is made of completely seals the joints. The nipples for them use cadmium, as a result, the likelihood of coolant leakage is reduced to zero. Main dimensions of BiLUX AL aluminum radiators:

- the permissible operating pressure is 16 bar, and when testing the device - 24 bar;

- the pressure that can rupture the device is 48 bar.

Single-section BiLUX AL M 500 batteries with a distance of 500 millimeters between the axes and a power of 180 watts have the following parameters (in millimeters):

- height – 570;

- depth – 75-80;

- length – 75.

Single-section BiLUX AL M 300 with a distance of 300 millimeters between the axes and a power of 128 watts have the following aluminum radiator section size (in millimeters):

- height – 370;

- depth – 75-80;

- length – 75.

Qualitative characteristics

Before purchasing a heating device, you should study the quality characteristics of various models, showing the design features and manufacturing technology.

Coolants

The technical data sheet for the product must indicate which coolants it can be used with. The permissible range of values of the hydrogen index (pH) of the coolant can also be indicated. If an aluminum radiator is supposed to operate with non-freezing liquids (antifreeze), special intersectional gaskets are used in its design.

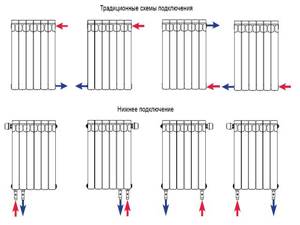

Connection diagrams for aluminum radiators.

Connection methods

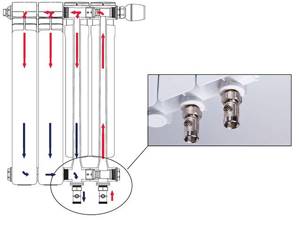

The standard aluminum radiator section has upper and lower manifolds, allowing for one of the known side connection methods. Some models of heating devices are equipped with a manifold with a lower connecting pipe, allowing for a convenient bottom connection when installing a manifold heating system.

Scheme of coolant flow with bottom connection.

Manufacturing method

Sections can be manufactured by injection molding or extrusion. Extrusion is a forming method that produces a high-density product. Radiators made by this method have higher strength, which allows them to withstand increased pressure.

Aluminum radiators of various sizes.

Aluminum sectional radiators have proven themselves well in individual heating systems, when the homeowner has the opportunity to independently choose the type of coolant and control its quality. Such devices are characterized by high thermal performance, outperforming bimetallic models due to their lower cost. The technical characteristics of aluminum heating radiators give the buyer the opportunity to choose the best model among a number of analogues.

Dimensions of aluminum radiators from Fondital

The Fondital company (Italy) produces Calidor Super aluminum batteries, adapted for the climatic conditions of Russia and the CIS countries (see photo).

When manufacturing them, European standards such as EN 442 and Russian ones are taken into account, in accordance with GOST R RU.9001.5.1.9009. The method of their manufacture is casting, performed under high pressure. Painting is carried out in two stages: initially, using anaphoresis, one layer of enamel is applied as protection, and then, using powder enamel, the product is given a decent appearance. The installation kit for the radiator will have to be purchased separately. It includes: adapters; brackets; blind plugs and Mayevsky tap.

The distance between the axles is:

- 350 millimeters for the S4 model, which has 4 side ribs and a section depth of 97 millimeters;

- 500 millimeters for models S4 and S3 (with 3 ribs and depth - 96 millimeters).

Main parameters of aluminum radiators Calidor S:

- permissible operating pressure - 16 bar, and when testing the device - 24 bar, maximum burst limit - 60 bar;

- maximum temperature – no more than 120 °C.

The Calidor Super 350 S4 radiator models, with a gap of 350 millimeters between the two axes, according to the manufacturer’s official sources, have a height of 428 millimeters and a depth of 96 millimeters. At the same time, the minimum length of the devices is 80, and the maximum is 1120 millimeters. In turn, the heat transfer can be a minimum of 145, and a maximum of 2036 watts. The number of sections is from one to 14.

The dimensions of aluminum heating radiators Calidor Super 500 S4 with a center distance of 500 millimeters are as follows: height 578 millimeters, section depth 96 millimeters. In this case, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be a minimum of 192, and a maximum of 2694 watts. The number of sections varies from one to 14.

All models of Calidor Super 500 S3 devices have a distance of 500 millimeters between the axes, a height of 578, and a depth of 100 millimeters. In this case, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the minimum power can be 178, and the maximum - 2478 watts. The number of sections varies from one to 14.

Dimensions of heating radiators by height and width, how to calculate

When arranging a heating structure in their own apartment or house, their owners need to decide on the purchase of batteries, taking into account the size of the heating radiators.

In this case, the following basic parameters should be taken into account:

- dimensions of heating radiators;

- degree of heat transfer of one section;

- the maximum operating pressure for which these devices are designed.

Among the products on the modern market, the spread of the main parameters of batteries is quite large, since they are presented in a wide range.

Characteristics of aluminum radiators from Faral SpA

This company exclusively for the Russian heating equipment market produces durable radiators FARAL Green HP (Italy), capable of withstanding a working pressure of 16 atmospheres.

In their production, the injection method is used. External and internal surfaces are covered with a zirconium protective layer that penetrates deeply and is not washed off during operation. As a result, when the device comes into contact with water, no gases are released. The possibility of electrochemical corrosion is excluded. The depth of Green HP batteries is 80 millimeters, and Trio HP is 95 millimeters. The distance between the axes can be 350 or 500 millimeters. A separately sold kit for installing the device contains: an air bleed valve; brackets; adapters with plugs; screws with plugs and silicone gaskets.

Main parameters of FARAL aluminum radiators:

- working pressure up to 16 bar is allowed, and when testing devices - 24 bar;

- maximum temperature – no more than 110 °C.

All models of FARAL Green HP 350 devices, according to information from the manufacturer’s official data, with a distance of 350 millimeters between the two collectors, a height of 430 and a depth of 80 millimeters. In this case, the length varies from 80 to a maximum of 1120 millimeters. The power can be a minimum of 134, and a maximum of 1904 watts. Number of sections from 1 to 14.

The FARAL Green HP 500 radiator models, with a distance of 500 millimeters between the axes, have a height of 580 millimeters and a depth of 80 millimeters. Moreover, the length of the devices is from 80 (minimum) to 1120 millimeters (maximum). In turn, the heat transfer can be a minimum of 180, and a maximum of 2520 watts. The number of sections is from one to 14.

FARAL radiators of the Trio HP 500 model range have a center-to-center distance of 500 millimeters, the height of the devices is 580 millimeters, and the depth is 95 millimeters.

In this case, the minimum length of the devices is 80, and the maximum is 1120 millimeters. As for heat transfer, its minimum value is 212 watts, and the maximum is 2968 watts.

The number of sections, depending on the power, can range from 1 to 14.

FARAL radiators of the Trio HP 350 model range have a center-to-center distance of 350 millimeters, the height of the devices is 430 millimeters, and the depth is 95 millimeters.

Moreover, the length of the devices ranges from 80 to a maximum of 1120 millimeters. As for heat transfer, its minimum value is 151 watts, and the maximum is 2114 watts. The number of sections can be from one to 14 depending on the power.

Common types

The most common and oldest models are cast iron. Today they are used less frequently, but there are a sufficient number of buildings that are heated with the help of such batteries. Previously, the size of heating radiators made of cast iron was impressive, they looked unaesthetic.

Today, manufacturers have improved them, and it is also possible to hide the device under a special screen, the design of which is selected to the taste of the homeowner. The advantages of such radiators are unpretentiousness to the chemical composition of the coolant, resistance to corrosion and high temperatures, durability, ease of operation, and no need for constant maintenance.

We advise you to study - Which vacuum cleaner is better to buy for the home - an overview of functionality and the best models

But batteries also have disadvantages. The most important of them is considered to be instability to sudden temperature changes, therefore, in the event of system failures in centralized heating, cracks and coolant leaks may appear. Installation is problematic because the structure is heavy.

Transportation of such radiators is also difficult, since careless handling results in defects that make the device unsuitable for use. A significant disadvantage is the inability to properly paint old models, as well as the need to regularly update the coating

Despite the shortcomings, the devices are used in apartments and private houses, as they are considered reliable and durable.

Aluminum heating radiator, how to add, twist sections, extend and unscrew the battery

Aluminum models

Aluminum radiators have become quite popular in the last few years. They have advantages that make the models the most preferable option for installation in a private home:

But there are also some disadvantages. The most important is the impossibility of installing such batteries in apartments, since the devices have a low operating pressure. If central heating is interrupted, local leaks may occur due to structural damage.

Aluminum is a brittle metal that is easily damaged during transportation or installation. Its peculiarity is the ability to interact with the chemical components of water in the system. As a result, corrosion areas form on the inner surface, which gradually lead to the complete destruction of the metal. The service life of such models is slightly lower than that of their cast iron counterparts, and ranges from 5 to 15 years. Some manufacturers have been able to extend this period to 20 years.

Bimetallic and steel

Steel and bimetallic models are considered the most modern and reliable, their service life reaches 25-30 years. The first is a stainless steel structure, which is made in different shapes.

The most affordable option would be a steel panel battery, made in a modern style and having a small size and attractive design. Tubular models are durable and are made in the form of small diameter tubes connected to each other. Their number depends on the area of the room.

Sectional models are also very reliable and durable. They are a structure of several sections connected to each other by spot welding. This method allows you to extend the life of the radiator and eliminate the possibility of leakage.

Bimetallic radiators are also available in several versions and are distinguished by their reliability and long service life. The outer frame of the battery is made of a special alloy of aluminum and silicon called silumin. Inside each section there is a steel pipe that prevents contact of silumin with water. This reduces the likelihood of corrosion areas forming.

Bimetallic and steel radiators are suitable for installation in a private house and apartment with a centralized heating system. The devices can withstand operating pressure differences and high coolant temperatures and are not subject to corrosion. A significant advantage is the unpretentiousness to the chemical composition of the coolant.

The disadvantage of the models is their high cost, which differs from the prices of aluminum analogues

It is also worth considering that these heating devices must be installed and connected to the system carefully, following all instructions

How to choose a bimetallic radiator?

Calculation of aluminum radiators from Global

Global radiators from the company of the same name (Italy) can be installed both in apartments of multi-storey buildings and in your own homes.

Their distinctive characteristics are an elegant and original appearance. The most popular models are ISEO and VOX with a center distance of 350 or 500 millimeters. The installation kit is standard and sold separately. Main parameters of Global aluminum radiators:

- the maximum operating pressure is 16 bar, and when testing the device - 24 bar; The maximum temperature of heated water is no more than 110 °C.

The Global VOX 350 device models, according to the manufacturer’s official sources, with a distance of 350 millimeters between the axes, have a height of 440 and a depth of 95 millimeters.

In this case, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be a minimum of 145, and a maximum of 2030 watts. The number of sections varies from one to 14. Global radiators of the VOX 500 model series have a center-to-center distance of 500 millimeters, the height of the devices is 590 millimeters, and the depth is 95 millimeters.

In this case, the minimum length of the devices is 80, and the maximum is 1120 millimeters. As for heat transfer, its minimum value is 193 watts, and the maximum is 2702 watts. The number of sections can be from one to 14 depending on the power.

Models of Global ISEO devices, according to official sources of the manufacturer, with a distance of 350 millimeters between the axes, have a height of 432 and a depth of 80 millimeters. In this case, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be a minimum of 134, and a maximum of 1976 watts. The number of sections varies from one to 14.

For Global radiators of the ISEO model range, with a center-to-center distance of 500 millimeters, the height of the devices is 582 millimeters and the depth is 80 millimeters.

In this case, the minimum length of the devices is 80, and the maximum is 1120 millimeters. As for heat transfer, its minimum value is 181 watts, and the maximum is 2534 watts. The number of sections can be from one to 14 depending on the power.

Which radiator is better to choose?

The choice of radiators depends on what goals you are pursuing. If the number one goal is to save money, then you can find an old Soviet cast-iron radiator in a landfill or scrap metal that will last another hundred years without the slightest breakdown.

If the buyer’s task is to effectively combine an inexpensive product and a good design, modern steel radiators are best suited - they perfectly combine high heat transfer, modern design, durability and maintainability.

If the goal is to achieve maximum thermal efficiency, you should pay attention to bimetallic products with a copper core. This technique provides maximum heat transfer, but the price will make you think.

Today, suppliers are ready to provide any desires of the buyer - from elite European goods to cheap and low-quality Chinese ones. In any case, when purchasing products for such an important thing as heating, you should consult a specialist.

Parameters of aluminum radiators from Torex

The Italian company of the same name offers aluminum sectional heating devices, which are manufactured using the casting method.

Their peculiarity lies in the presence of unusual light transitions on the front part. For models that have a center distance of 350 millimeters, the depth is 78 millimeters. But for batteries with a gap between the axes of 500 millimeters, the depth of the radiators can be 70 or 78 millimeters. They can have one or an even number of sections. The mounting kit must be purchased separately. Main parameters of Torex aluminum radiators:

- the permissible operating pressure is 16 bar, and when testing the device - 24 bar;

- maximum temperature – no more than 110°C;

- the required water pH is 7-8 (acceptable 6.5 - 8.5).

The Torex B 350 device models, according to the manufacturer’s official sources, with a distance of 350 millimeters between the axes, have a height of 420 and a depth of 78 millimeters.

In this case, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be a minimum of 130, and a maximum of 1820 watts. The number of sections ranges from one and then an even number to 14. Torex radiators of the B 500 model series have a center-to-center distance of 500 millimeters, the height of the devices is 570 millimeters, and the depth is 78 millimeters. In this case, the minimum length of the devices is 80, and the maximum is 1120 millimeters. As for heat transfer, its minimum value is 172 watts, and the maximum is 2408 watts. The number of sections can be from one and then an even number to 14.

Torex radiators of the C 500 model series have a center-to-center distance of 500 millimeters, the height of the devices is 570 millimeters, and the depth is 70 millimeters. In this case, the minimum length of the devices is 75, and the maximum is 1050 millimeters. As for heat transfer, its minimum value is 198 watts, and the maximum is 2772 watts. The number of sections can be from one and then an even number to 14.

What should the dimensions be?

In order for the heating radiator to give off maximum heat, the dimensions must be as follows:

- The length should be more than 70-75% of the width of the window opening.

- The height should be such that there is 8-12 cm between the floor and the battery, and 6-12 cm between the window sill and it.

If the recommendations are not followed, the operation of the aluminum convector will be accompanied by heat loss.

When the length is less than 70% of the width of the window opening, the battery will not be able to create a thermal curtain capable of blocking the movement of cold air entering through the window. Cold and warm zones will appear in the room. The windows will be constantly covered in steam.

If the window is 2 m wide, then the length of the battery should be at least 1.4 m.

Section dimensions of aluminum radiators from Rifar

The company produces aluminum batteries of BASE models with a distance between two axes of 200, 350, 500 millimeters.

ALP products have an improved design, increased heat dissipation and a center spacing of 500 millimeters. Alum models are specially designed devices that can be used both in standard heating systems and as an oil-fired electric heater. Flex's unique development allows you to give the device the desired radius of curvature. Main characteristics of Rifar aluminum radiators:

- permissible operating pressure is 20 atmospheres;

- maximum temperature – no more than 135°C;

- the required water pH is 7-8.5.

Types of heating radiators depending on the material of manufacture.

Aluminum radiators have good thermal conductivity and heat dissipation. Pleasant appearance, lightness, ability to withstand high working pressure - these are advantages. Minus: aluminum, when reacting with water, releases hydrogen, which accumulates in the radiator. At first, it is necessary to remove accumulated gas from the coolants every day, otherwise the heating system will not function.

Steel heating radiators are available in two types: panel, sectional and tubular. Panel radiators are inexpensive, unpretentious, and their design is simple. Tubular radiators have very high heat transfer and a long service life (up to 25 years). Designers work on their creation, which allows us to classify this type of steel radiators as premium. Sectional ones are a structure of several sections connected to each other using spot welding. This significantly increases the service life and allows you to withstand pressure changes.

Steel panel radiator

Read an interesting article on how to connect aluminum heating radiators here.

Aluminum radiator section volume

Knowing the volume of one section of an aluminum radiator is very important for autonomous heating systems.

To determine how much antifreeze is needed to fill the heating system, use calculation tables. To find out the volume of water in one section, use the information available in thematic reference books:

- in a standard device, the volume of the aluminum radiator section is 0.45 liters of coolant;

- a linear meter of a pipe with a diameter of 15 millimeters contains 0.177 liters, and a pipe with a diameter of 32 millimeters contains 0.8 liters.

Calculation of the number of sections

There is a simple option for calculating the number of sections.

To do this, you need to know the area of the room and the standard power, which is equal to:

- if the ceiling height is 2.5 - 2.7 meters, there is one external wall and one window - 100 watts;

- if the ceiling height does not exceed 2.7 meters, there are two external walls and one window - 120 watts;

- if the ceiling height is no more than 2.7 meters, there are two external walls and two windows - 130 watts.

Before calculating the number of aluminum radiators, you need to find out the power of one section in the device passport. Now you need to multiply the standard power by the area of the room and divide by the power of one section. The result must be rounded up (pro

Selection of radiators - power, dimensions, placement and mounting

When choosing radiators, from a practical point of view, first of all, the dimensions and mounting are of interest. Placing the radiator in a specific installation location. The section power of similar models is approximately the same. Moreover, it is similar for heating devices made from different materials.

In principle, we are not talking about working pressure, since for an ordinary house of up to 3 floors this figure needs to be from 6 atm. This is what all commercially available radiators satisfy. And for high-rise buildings with risers - from 16 atm.

The material used to make modern radiators also has little effect. You just need to avoid fakes and cheap products and take products from trusted, well-known manufacturers.

The appearance of modern batteries for most people is at least “pleasant”; it remains to discard those models that are “not the same” in design, but this is a personal choice.

But the sizes of the sections, their number depending on the required heating power, are very important when choosing. Let's take a closer look at what to pay attention to...

The height of the device is the main parameter for the installer

On sale you can find radiators of different heights. But among them, the vast majority are of three standard sizes, which is characterized by the distance between the centers of connection of the battery to the pipes (between the radiator connections).

- The center distance of the supply pipes is 500 mm - high standard devices.

- The same distance is 380 mm - models of reduced height, for example, under a low window sill, or near the door to the hallway, so as not to stand out.

- 200 mm - low products.

Most often there are radiators with a distance between connections of 500 mm. They can be cast iron or aluminum sectional, or steel panel.

For products of smaller height, the power of one section is also significantly reduced. Therefore, in order to match the heat transfer with high ones, they must be longer, i.e. consist of more sections.

When replacing radiators, pay attention to the location of the supply pipes, their height and the distance between them along the centers, which is usually 500 mm.

What are the dimensions (dimensions) of radiators

The dimensions of one radiator section can be found in the reference data. As an example, the dimensions of a typical “old model” cast iron radiator, model MC140, are given:

- distance at the centers of the eyeliner - 500 mm;

- section height - 588 mm;

- section length - 93 mm;

- section depth - 140 mm;

- The length of the assembled radiator of 10 sections, taking into account the thickness of the gaskets between the sections, is 940 mm. (there are several standard sizes, the data differs)

It should be taken into account that air vents and flushing taps are installed at the edges of the radiator. Devices that are connected only on one side are equipped with flushing taps on the opposite side.

Also read in more detail how to properly connect a water heating device to pipes

A typical rule for choosing a radiator location is that the center of the window coincides with the center of the radiator. Then the heating device fits into the design of the room

Common sizes of aluminum

— section width — 80 mm; — depth — 80 mm; — the width of the radiator of 10 sections is 810 mm. (depending on manufacturers and models, the characteristics vary slightly) The gap between the aluminum radiator and the wall on a standard mount is 30 mm. Therefore, the device will protrude 110 mm from the plane of the wall.

Power

With the power of radiators, not everything is as simple as it seems at first glance, since it can only be found out from the official technical specifications. At the same time, sellers' stories or advertising brochures usually do not reflect reality.

Among similar models, the buyer chooses the most powerful. Therefore, the buyer is simply deceived about the power.

This indicator depends mainly on the surface area of the radiators, i.e. on the type and number of ribs, their sizes. Where does the big difference in power come from between devices of the same type with the same dimensions? She is attributed.

The passport data usually indicates the heat transfer in watts of one section at a temperature difference between the ambient air and the coolant of 70 degrees. This means that at 20 degrees in the room, and 90 degrees of coolant, one section produces, for example, 170 W.

170 W of power per section is a typical heat transfer characteristic for aluminum, bimetallic and cast iron radiators of regular sizes with a distance between connections of 500 mm.

But the fact is that now the coolant is rarely heated to 90 degrees, more often it is +60 - +70 degrees. And in the rooms the air temperature is usually +22 - +24 degrees, not +20 degrees. Under such conditions, the heat transfer of the section is reduced to 120 - 130 W.

Those. an ordinary ten-section radiator is suitable in power for a room of 12 - 13 square meters. meters with one large window in a normally insulated building in which the coolant is not heated to dangerous temperatures.

Heat dissipation options

But recently, very economical condensing boilers have become increasingly popular. For them, the optimal supply coolant temperature is no more than +55 degrees. Read more about condensing boilers and the most economical low-temperature heating

And this requires an increase in the power of heating devices (surface area) by another 20 - 30 percent.

For low radiators, the heat transfer per section also decreases, which must be taken into account when selecting the width (number of sections).

Typically, for batteries with an interaxial distance of 380 mm, the rated power of the section is 100 - 110 W.

The power of the radiator is also affected by the speed of the coolant. The passport indicates the power at which the difference in coolant temperature at the input and output of the device is 20 degrees, i.e. at the inlet 90 degrees, at the outlet 70 degrees. If the coolant moves faster, the energy flow is greater and the temperature difference is smaller, and the heat transfer is greater.

Some nuances of choosing heating batteries

Above are the main parameters of the most common radiator models. But for sale you can find a variety of options and configurations. The center distance varies in 50 mm increments - it can be 200, 250, 300, 350, 400, 450, 550 mm, etc.

The section power varies from 40 to 200 W. There are high batteries with an output of 400 watts per section. Their use is only advisable in some recesses, under flights of stairs, when the upper floor needs to be heated. In principle, you can choose any device according to size and taste.

Nowadays steel non-removable panel batteries are also popular. They have a special design that many people like, while the unit price $/W is similar to aluminum.

The selection of power and dimensions can be made very accurately, since the standard sizes of each model vary significantly not only in height and width, but also in depth (thickness). Experts consider them more reliable, since there are no intersectional joints, which is especially useful with anti-freeze products that are aggressive.

For a gravity system, the hydraulic resistance of the radiator is also important. The lowest value is for old cast iron ones, type MC140, they are better suited for gravity flow. Also, aluminum ones have larger passage holes than bimetallic ones.

The radiator’s own heat capacity is also important, which affects temperature changes in the room. Old-style cast iron batteries have a heat capacity that is many times greater. They contain 4–5 times more liquid than aluminum ones, and their mass is ten times greater.

As a result, when the boiler is turned off by the temperature sensor, the batteries will continue to give off heat for a long time and the temperature in the room will rise. Then, when everything cools down, the boiler will turn on, but the temperature in the room will rise slowly, because at first the inertial radiators will warm up for a long time.

Modern heating devices with low heat capacity create smaller fluctuations in room temperature and greater comfort.

The speed of coolant movement in modern radiators is greater, so silting does not occur. Cast iron ones, as a rule, become clogged with deposits over time if the liquid in the heating system is changed (replenished). More information, recommendations for purchasing heating appliances

Easy installation and fastening

Watch the film on how to mount and connect a radiator to a pipeline with your own hands - simple and accessible. This video will help you decide on the choice of batteries for heating.