Aluminum heating radiators are ubiquitous in modern interiors. And it’s not surprising, the problem of heating their own homes has been worrying people for a long time. First there were fires, then stoves and fireplaces. In the 19th century, the concept of “water heating” appeared. The first radiators were installed in St. Petersburg and were made of cast iron. At that time it was the most common material.

Cast iron radiators are still used today. But they have their drawbacks. They weigh a lot, so there are difficulties in installing them. After the start of operation, leaks may occur in the area of sectional gaskets. With prolonged use in cast iron radiators, scale forms inside the batteries, causing heat transfer to decrease. After a certain period of time, cast iron radiators can become covered with rusty stains at the junctions of sections, and therefore require regular painting.

In the middle of the 20th century, aluminum production began and buyers began to pay more and more attention to aluminum heating radiators, which do not have all these disadvantages. Their design is still being improved by inventors. Aluminum heating radiators are lighter, their weight is significantly less than cast iron, so installing such radiators is not much of a hassle.

They have good heat transfer, which is constant throughout the entire service life. This allows you to maintain a comfortable indoor climate, even if the coolant temperature decreases. The internal surface of such radiators is protected from corrosion and destruction by a special coating. Aluminum heating radiators have an attractive appearance and do not require regular painting. These radiators fit harmoniously into a modern interior.

And in order for us to choose the right aluminum heating radiators, we need to know the main parameters of any radiator:

- heat output;

- strength;

- Coolant volume in the section;

- Life time.

Now, let's see if aluminum radiators have these properties?

Aluminum heating radiators and negative aspects

But, despite their advantages, aluminum radiators have characteristics that limit their scope of application. If the water quality is unsatisfactory (high acidity, sand, abrasives), this can damage the internal protective layer of the radiator. It should also be taken into account that before the start of the heating season, air accumulates in the radiators.

To remove air pockets in aluminum heating radiators, it is necessary to install special equipment - air ducts. It must be remembered that radiators of this type do not tolerate pressure surges of the coolant in the system.

Aluminum radiators area of application

Aluminum heating radiators, taking into account all their features, have found application in private housing construction. In your own house with an autonomous heating system, unlike houses with centralized heating, it is possible to ensure the necessary quality of water in the pipes, which increases the service life of aluminum radiators and protects them from corrosion.

You can regulate the coolant supply and its pressure, which is optimal for such radiators. These radiators are light in weight and easy to install. They are not expensive compared to other types of radiators. Therefore, when building your own home yourself, choosing aluminum radiators is a smart choice that will save your budget.

To create warmth and comfort in your home, you should carefully choose heating devices. Today, the best option is to use aluminum radiators for heating. Thanks to their lightness and beautiful appearance, such devices fit perfectly into any interior.

Advantages of aluminum radiators.

Considering the advantages of aluminum heating devices, the following should be highlighted:

1. They are light in weight compared to analogues made from other metals. 2. Due to its light weight and simple design, it is very easy to install. 3. Fits well into the design of the room. If necessary, they can be easily disguised with various decorative boxes and screens.

What to focus on when choosing aluminum and bimetallic radiators?

When choosing any type of radiator, you should always listen to the advice of experienced experts. So, there are several points that you need to pay attention to.

- Coolant acidity . If you still plan to take a risk and install aluminum batteries in the apartment, then it is worth considering one more factor - the acidity of the coolant in a particular heating system. This indicator is usually abbreviated pH.

For Russian heating systems, the acidity standard is set at 6.5 to 9 pH. The ideal indicator of this parameter is 7 - an almost neutral environment. Everything below 7 is an acid, and everything above is an alkali. If the batteries are silumin, that is, they are an alloy of aluminum and silicon, then they can last long enough only if other parameters are met - temperature and pressure conditions. So, before purchasing batteries, it is worth clarifying what these indicators are for the coolant used in the heating system. Then, these indicators need to be compared with the characteristics indicated in the passport of the selected product. The permissible acidity level for aluminum radiators is 6.5÷9 pH, and for bimetallic batteries 6÷10.5 pH.

- Section weight . The thick walls of the aluminum radiator indicate the reliability of the device, as the risk of leaks in the event of water hammer is reduced. According to the laws of physics, thick and wide section petals provide greater heat transfer than thin ones. From this it should be concluded that a high-quality radiator cannot be excessively light, therefore this quality cannot in any way be attributed to the advantages of the heating device. A manufacturer who tries to save on the thickness of its walls or heat transfer fins by reducing the weight of the battery significantly reduces both heat transfer and overall reliability.

- Quality of threaded connections. It is very important to pay attention to the end of the thread of the outer sections - the turns should not be filled with paint. If this is discovered, it is recommended to refuse to purchase such products. Clean threaded pairs will provide a more reliable connection of the radiator with other elements of the heating system circuit. If the thread is filled with paint, then it will have to be cleaned before installation, which cannot be done perfectly. In addition, such a sign indicates an insufficient technical culture of production, which also leads to far-reaching conclusions.

Be sure to check the quality of threaded connections of sections

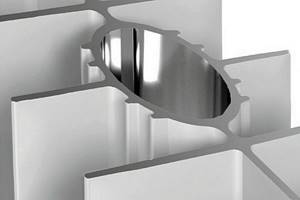

- Vertical channel. When choosing a radiator, you must definitely check with your sales consultant what design the vertical channel has. The wider it is, the thicker its walls and the heat exchange fins adjacent to it, the higher the heat transfer, and the lower the likelihood of blockages.

- Surface painting . When purchasing a radiator, you need to remove it from the packaging and conduct a thorough inspection of the outer covering. It is unacceptable for the surface to have roughness (shagreen), sagging enamel, ingrained grains of sand or burrs. In addition, the paint layer should not be too thick to the touch, as it significantly reduces heat transfer, and over time, it may begin to peel off. In addition, mechanical damage to sections can be masked under it. All these surface imperfections indicate low quality products and dishonesty of the manufacturer, so it is better to discard such products immediately.

- Documentation. To purchase quality products, it is recommended to purchase radiators from a well-known manufacturer, who has been working in this field for a long time and values its reputation, and its products have passed the full test of time. In the store, you should definitely read the quality certificate, and also find out who you can contact in case of problems with the radiator, what the warranty conditions are, and how service is established in the region.

In addition, you should ask whether the product is insured, as this is an indicator of its quality and the responsibility of the manufacturing company.

You might be interested in information on how to paint a battery

What about the thermal power of the battery?

The list of evaluation criteria did not mention the required thermal power of the radiator. This was done intentionally, since this calculation has received a lot of attention in other publications on our portal. In particular, a convenient universal calculator for calculating the power of a heating battery for a specific room, taking into account all its features, is given in the article on vertical radiators for an apartment .

The choice of any elements of the heating system must be approached with full responsibility. You cannot purchase heating devices for operating conditions that are clearly unsuitable for them, which can quickly damage the batteries. Moreover, having seemingly saved on inexpensive radiators, you can be left with a very large expense - in the event of a very likely emergency, you will have to shell out a larger sum, especially if, in addition to your own apartment, the one located on the floor below will also be flooded. Therefore, when buying heating radiators, you must immediately calculate all possible negative consequences and make the right choice. Fortunately, there are opportunities for this.

As another useful hint, here is a video comparing aluminum and bimetallic radiators. Study long-burning cast iron boilers at the link.

Disadvantages of aluminum radiators.

Like all types of radiators, aluminum also has certain disadvantages:

1. Aluminum heating devices begin to react with the coolant during operation. As a result, corrosion begins to form and gases arise. To remove gases from the system, special valves are provided in the design. 2. Increased susceptibility to water hammer and pressure drops, especially at the joints between sections. Because of this feature, it is not recommended to install aluminum models in central highways. 3. If the installation conditions are violated, the uniform distribution of water in each section may be disrupted.

Due to the disadvantages listed above, it is better to connect aluminum products to autonomous heating systems of private houses. If installed in an apartment building with central main heating, you should choose anodized aluminum appliances.

Antifreeze in an autonomous heating system

To extend the service life of aluminum batteries, you can use antifreeze. While water in batteries can freeze and rupture them, special liquids remain fluid even at temperatures of minus 60 degrees. They do not harm aluminum, but they heat up slightly longer than water and have a high level of thermal conductivity.

Negative properties:

- viscosity - to promote them in the heating system, a sufficiently powerful boiler is required;

- toxicity - precautions must be taken when using;

- Violation of the integrity of the elements of the joints of the heat pipeline is unacceptable.

For autonomous heating in aluminum radiators, antifreeze is preferable to water, as it increases their service life. The durability of the coolant is 10 years, during which the metal does not change at all.

Types of antifreeze

Coolants consist of distilled water and a certain additive:

- Antifreeze with ethylene glycol. Cheap, if accidentally ingested, it is extremely toxic. Long service life. Suitable for use in a single-circuit boiler due to high toxicity.

- Glycerol. The supplement is highly soluble, non-toxic, and does not precipitate.

- Propylene glycol. The best additive is non-toxic and does not create sediment, but is a bit expensive.

When using antifreeze for heating, batteries with a large number of sections will be required, since its heat capacity is lower than that of water. When heated, it expands greatly, so the radiator capacity should be 50% larger. Rubber is used as gaskets in the network, and sealant is used for all joints and connections.

Extruded aluminum heating radiators.

During the production of extrusion products, a molding extruder is used. The principle of its operation is that it extrudes the desired profile on finished metal blanks. The disadvantage of this method is the production of individual parts, which will later be joined by pressing. As a result, the seams can become a weak point in the radiator during water hammer and pressure fluctuations. This type of aluminum radiators is the most budget option among aluminum devices. Their feature is a more minimal outer surface, which leads to reduced heat transfer. Also, in extrusion models, corrosion begins faster, due to the fact that in their manufacture they use secondary aluminum containing impurities that are susceptible to rapid oxidation.

Advantages and disadvantages of bimetallic batteries

The use of a steel core makes it possible to protect aluminum from high operating pressure and interaction with the coolant, which eliminates its corrosion. The advantages of the products are as follows:

- high strength - pressure of 100 atm can destroy them;

- durability;

- high level of heat transfer;

- modern design.

The only drawback is the highest price among all batteries.

Cast aluminum radiators.

The next type of aluminum models are products made by casting. They have more enhanced positive characteristics during operation. Cast devices are more durable and have increased resistance to aggressive environments. But as a result, they are more expensive. During production, 88% aluminum and up to 12% alloys with silicon are used as feedstock. The manufacturing process occurs as follows: molten aluminum enters special molds, where it hardens. The resulting products are cooled and processed. They are also tested for leaks and coated with special compounds that protect the finished product from corrosion. It is worth noting that radiator manufacturers are constantly experimenting with this technology and, as a result, are producing more and more new types of cast aluminum radiators. In addition to regular cast batteries, there are anodized models. Their surface is covered with an oxide film, which serves as protection against exposure to aggressive environments. It also performs a decoration function.

Classification of batteries by manufacturing technology

For the production of heating radiators, it is not aluminum in its pure form that is used, but its alloys with silicon. Separate sections and whole products are obtained from blanks. The main methods of metal processing are extrusion and casting.

Type #1 – extrusion

On production lines, the main tool for the manufacture of extrusion devices is a molding extruder, which literally extrudes the required profile onto metal blanks.

The disadvantage of the technology is the production of separate parts, which are subsequently connected by pressing. Of course, the seams on the structure make it vulnerable to pressure changes and unclean coolant.

Sections and manifolds are made using extrusion. After the parts undergo pressing processing, it is not possible to change their size, therefore, during installation, the length of the finished products cannot be changed

Extrusion models are the most inexpensive among aluminum ones. They are characterized by a smaller working surface area, which reduces the heat transfer of devices. The seams obtained as a result of pressing are gradually destroyed by contact with low-quality coolant.

The corrosion process is also more active because secondary aluminum is used as a raw material for extrusion, a characteristic feature of which is the presence of rapidly oxidizing impurities.

Type #2 – cast

Radiators produced by casting technology have higher performance indicators. They are safer, stronger and more resistant to aggressive environments than their extrusion counterparts, and therefore more expensive. For manufacturing, aluminum (from 88%) and alloys with the introduction of silicon (up to 12%) are used.

Production occurs as follows. The molten metal enters the casting molds, where it acquires a given profile. The parts that have received the design configuration are cooled, processed and checked for leaks. The walls of the workpieces are treated on all sides with an anti-corrosion compound.

After further cooling and drying, the almost finished sections are painted with protective polymer enamel with the addition of epoxy resins. Final stage – assembly and testing

Various manufacturers are experimenting with casting technology, resulting in new types of radiators. Let's say the Faral Trio company has released a line of two-channel radiators that have not lost strength and cope well with burst pressure of more than 55 atm.

And Italian Raden radiators have vertical fins of 6 rows, due to which there is an increase in heat transfer.

If you want your heating system to be equipped with truly reliable and protected devices, pay attention to anodized batteries. These are radiators made of aluminum coated with a durable oxide film, which has two purposes - protection and decoration.

The oxidation process several times increases the metal’s resistance to corrosion and other negative changes or reactions to the poor quality of the liquid circulating through the channels of the devices.

Characteristics of aluminum heating radiators.

Before purchasing aluminum radiators, you should carefully read their technical characteristics. It is worth knowing that models with pressure from 6 to 10 atmospheres are suitable for private houses. When used in apartments with central main heating, it is worth taking models of 10 - 16 atmospheres. The maximum coolant temperature is also indicated on the product. Usually it is about +110 degrees, although the actual values are lower (about 60-70 degrees).

Which is better - aluminum or bimetallic?

When choosing between an aluminum and bimetallic radiator, it is worth knowing the features of each. Bimetallic radiators are practically no different in use from aluminum ones. That is why they are used in high-rise apartments and offices, as well as in enterprises. They are also often installed in private houses and cottages, but if we talk about feasibility, closed heating systems create up to 2 atmospheres, and therefore the use of aluminum analogues is considered more justified.

Aluminum appliances are imported mainly from Italy, and bimetallic appliances enter the market from China. Therefore, one can only guess about the quality of not only welding, but also materials. But it’s worth understanding each type of device in more detail to decide which radiator is better in your case – aluminum or bimetallic.

Cladding the basement of a house - which material is better?

How to choose and install a wireless video peephole

Installation of aluminum heating radiators.

If you have experience in plumbing work, you can install the radiator yourself.

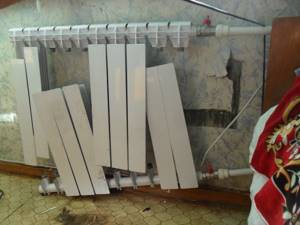

- Installation requirements. When installing the heating device, the following conditions must be observed:

1. The distance from the bottom of the radiator to the floor must be at least 4 cm. 2. The distance from the top of the radiator to the window sill is about 5 cm. 3. The distance from the rear wall of the radiator to the wall is about 2.5 cm.

Despite the given dimensions, exceptions may exist. The radiator can be located flush with the window sill (if the window is too low), but in this case the lower edge of the radiator must be at least 3 cm from the floor. To install an aluminum heating device, special brackets for radiators in the form of shelves and studs are used. If installed on the floor, there are special stands. There must be at least 3 brackets per battery. When installing a radiator in an apartment building, you should agree in advance to disconnect the circuit from the heating system (house management). - Tools and fittings used. To carry out installation work, you will need the following set of tools: pliers with wire cutters, a set of keys, sandpaper, a brush and grease, a pipe cutter, and a chamfer. You may also need a drill for the holes for the brackets and the corresponding dowels. In addition to the above tools, you may need the following parts:

1. Shut-off and control valve 2. Nuts and washers for fasteners 3. Stainless steel connection tubes 4. Mayevsky valve 5. Manifold adapters with seals.

- Installation procedure:

— Preparation of holes on the batteries in those places where the connection to the pipes occurs. They need to be cleaned with a brush and wiped with cleaner. - Then the tubes are prepared in the same way. — If necessary, install brackets. — The final step will be connecting and installing the radiator. After this, you can paint it (if necessary) and decorate it.

If the battery heats up quickly and equally in all sections, then its installation is done correctly.

Is it worth buying Chinese radiators?

Do you want to buy aluminum heating radiators, but can’t make the right choice in favor of one of the manufacturers? Are you looking at products from Chinese brands because they have a more affordable price? In this case, special care must be taken. Here are just the main reasons:

When buying Chinese heating radiators, you risk running into a low-quality fake that will let you down at the most inopportune moment.

- the Chinese like to save on materials - this leads to a deterioration in the technical characteristics of radiators;

- batches of batteries can vary greatly in quality - some batteries last for years, while others fail within the first month of operation;

- Chinese manufacturers often change product characteristics, forgetting to indicate new data on packaging and technical data sheets.

Thus, buying Chinese radiators is a big risk . Here you cannot rely on sellers in matters of choice, since they themselves may not know about the features of a particular batch. If you decide to purchase Chinese aluminum batteries, take a specialist with you so that he can inspect the radiators and evaluate their quality.

If you want to create a reliable and durable heating system that will not flood the floors and neighbors below, take a closer look at radiators from well-known European and Russian brands - among them you can easily find inexpensive but high-quality models.

As for the choice of radiators based on other parameters, you can read about this in the following sections of our review - we will tell you about the technical characteristics and teach you how to calculate the required number of sections.