Electric boiler repair

When purchasing any electrical equipment, we hope for its long-term operation, but it often happens that our hopes are not justified. And at the most inopportune moment, equipment breakdown occurs. It’s good if the warranty period of your purchase has not yet expired, then you can call a specialist and he will fix the problem for free. If the warranty period has expired, then we are faced with a choice - contact a service workshop, or try to fix the problem ourselves.

To determine the malfunction and carry out proper repair of electric boilers, you need to know their structure and differences. Also, to quickly identify a breakdown, it will be useful to know the most common types of faults.

Types of electric boilers and their fundamental differences

Electric boilers differ in the type of working heating elements and are:

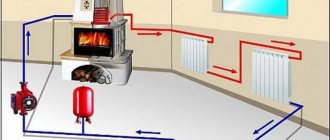

Electrode-type boilers for heating water use the property of water to conduct electric current, releasing heat. It is very simple to describe their basic structure: two electrodes are immersed in water and alternating current is passed through them.

Heating element boilers use a completely different principle. These electric boilers use special tubular electric heating elements (TEH) as a heating device.

Since these boilers have fundamental differences in the types of heating elements, the repair of electric boilers has significant differences.

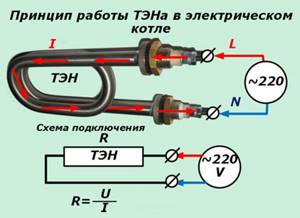

Connecting heating elements of an electric boiler

The first thing you need to pay attention to is the rated power of the heating element. By installing a device with low power, you will not receive enough thermal energy, while consuming a large amount of electricity. And by setting an unacceptably high power, there is a high probability of constant overheating of the device, and an explosion is possible.

As for its location, it must be completely immersed in water, otherwise it will overheat; as a rule, it is installed at the bottom of the radiator. This makes it possible to isolate it from places where air accumulates. In order for it to last longer and less plaque to accumulate on it, which leads to a significant loss of efficiency, as well as to corrosion, you need to use distilled liquid.

It is very important, when you insert a heating element or a block of heating elements into the heating system, to properly seal the end joints, because if liquid gets on the heating element (coil), there will be a threat to the residents of the house. Let's consider the option of connecting to electrical networks with different numbers of phases.

If you have one phase, often this option is most typical for cottages or old buildings, you need to install a fuse. It is characterized by the presence of two conductors: phase and zero. There are two connection methods - parallel or serial, the difference is in dividing the original voltage between the components.

More often, the connection is made in parallel to minimize the loss of useful energy. The sequential circuit is used extremely rarely, as it involves energy losses. For any of the selected circuits, it is necessary to choose a wire with a large cross-section, since it will carry a large load.

Connection to three phases - the first method is the so-called star, it involves feeding from a 220 V network with a neutral wire supplied from the panel. One jumper is used, connected to zero, and the remaining three free ends are connected to the phases.

Triangular connection, the incoming voltage in this case is 380 V. By connecting heating elements intended for use at 220 V here, you risk damaging them because they will burn out. The difference between a triangle and a star is the absence of a neutral conductor.

Most common faults

The most common malfunctions of electric boilers can be divided into two categories:

• Failure of heating elements.

• Failure of control and monitoring equipment.

When electric heating elements fail, it is necessary to replace the heating elements in the electric boiler in electric boilers of the heating element type, or to replace the electrodes in an electrode-type boiler. Below we will look at how to do this yourself.

If there is a problem with the control and monitoring system, you must first identify the faulty unit and either repair it or, if repair is impossible, replace it. If you do not have a special radio engineering education and the necessary circuit diagram, then it is better to contact a specialized workshop and entrust the repair to a specialist. Since without the necessary knowledge and skills it is impossible to make proper repairs and the consequences can be very disastrous.

Peculiarities

Today it is impossible to imagine a comfortable apartment or even a private house without hot water. Where it is not possible to use central heating, you have to install water heaters. If such a system is chosen correctly and installed properly, it will provide the household needs of a large family quite effectively. The decisive link in the heating equipment is the heating element, which is a copper or stainless steel element. Its tube contains a spiral inside, through which a strong current passes.

The heater for an Ariston and any other boiler differs from those similar devices that are mounted in electric kettles or in washing machines and dishwashers. Its total electrical power is noticeably greater, because it is necessary to heat a significant amount of liquid in a short time. The company produces both “wet”, made in an open circuit, and “dry”, hermetically sealed heating elements. Ariston Corporation uses an alloy of copper with chromium and nickel to make its heaters.

A specially designed brass flange allows the maximum amount of thermal energy to be released.

Power varies depending on the specific model. All the highest quality heating elements are equipped with a thermostat. This block stops the operation of the device as soon as its temperature becomes critical. On the other hand, the automatic system gives a command to start even when the temperature drops below a certain threshold. Therefore, when buying Ariston products, you don’t have to worry that any negative phenomena will arise or there will be a risk of fire.

Main types of electric boilers

Heating units are divided into several types based on the method of heating the coolant:

- Heating elements - heat transfer is due to the operation of special heating elements - heating elements.

- Electrode - based on the principle of heating water when exposed to electric current.

- Induction - the conversion of electrical energy into heat occurs due to the phenomenon of electromagnetic induction.

Design features

Regardless of the type, the design of electric boilers requires the following mandatory elements:

- circulation pump;

- copper heating unit;

- fuse in the form of a thermal switch;

- safety valves;

- air valve;

- pressure gauge;

- control panels;

- power control systems.

Typical problems

Among the most common problems that are typical for electric heating boilers are the breakdown of heating elements, equipment for monitoring and controlling the operation of the system.

If the heating elements fail, restoring the boiler's functionality involves replacing the heating elements or electrodes, depending on the type of equipment.

To prepare for the planned activities, you need to visit a specialized spare parts store. Here you can find the required electric heating element without any problems. You can find out the model of the spare part that will help perform repairs from the technical data sheet of a specific heating unit.

If the problem concerns control and monitoring systems, it is necessary to first take measures to identify the faulty units.

In cases where it is impossible to repair heating boilers by repairing a non-working element, it should be replaced.

Causes of failure

Common reasons for insufficient performance of electrical equipment and its complete failure are as follows:

Reasons for replacing the heating element

It is necessary to replace the heating element if the old element fails. But how can you determine that the heating device has actually burned out? To do this, you need to plug in the boiler and wait until it reacts.

If the device turns off immediately, then this is a clear sign of a problem. Well, in the case when the equipment continues to operate, there are no malfunctions and, accordingly, there is no need for repairs.

If the boiler constantly knocks out plugs in an apartment or house, then this is a good reason to start repairing it, namely replacing the heating element

To be completely convinced that a part is faulty, you need to “ring” it, so to speak. Simply put, evaluate the conductive characteristics.

To do this, the following procedure must be followed:

- unplug the equipment from the outlet;

- unscrew the protective cover;

- find the contacts of the heating element;

- check component resistance.

For testing, you can use an ohmmeter or multimeter. If the measuring device shows “infinity,” then the heating element has become unusable (burnt out) and needs to be replaced. Well, when the device shows zero or any exact number, then there are no problems.

Prevention

Compliance with operating rules, along with the implementation of timely preventive measures, largely affects the service life of the boiler. Some manufacturers include an annual service inspection of heating equipment in its cost. If this option is not provided, it is better to carry out preventative maintenance of the boiler in the summer.

Before the start of the new heating season, all unstable functioning elements should be replaced, malfunctions should be eliminated and the system should be checked for operability in advance.

Preventive measures can also include cosmetic repairs of the heating boiler. For example, cleaning air ducts and checking the reliability of connections will help to avoid major problems during operation. Timely, regular implementation of preventive measures along with high-quality installation and proper operation will allow heating equipment to operate trouble-free for decades.

Tips for use

When installing an electric boiler, it is important to pay attention to the nature of the water that is used as the working fluid. If the water is too hard, the heating elements become coated with scale rather quickly. The result is insufficiently efficient operation of the heating system, as well as an increase in the amount of energy consumed by electrical equipment.

To extend the service life of the heating unit, it is necessary to carry out regular maintenance of the boilers, in particular, cleaning the heating elements from scale. However, you can prevent the problem by pouring distilled or soft water into the heating system. A less effective option is to install devices for filtering the working fluid.

Types and design, as well as operation

Structurally, a heating element for heating a house is a metal tube with a wire spiral inside, made of a material with high electrical resistance. When energy is supplied from the network, the coil heats up and transfers heat to the shell of the heating element, which in turn heats the coolant in the radiator.

The heating element is installed in a specialized socket of the heating battery, be it aluminum, metal or cast iron. The heating element is also used as the main heating element in electric boilers.

Most tubes use stainless steel or carbon steel. If low-quality metal was used in production, the heating element can quickly “burn out”. The power of the spiral and the shape of the tubes are determined by the purpose of the device and in which radiator or boiler it will be used.

Models are available with fins and additional plates around the tube to increase heat transfer. The ribs significantly increase the dimensions of the product, so they cannot be used in all cases.

In addition to devices that heat water, space heating with an electric heating element can be carried out using an air device that heats air instead of water. But due to their low efficiency, they are little used.

The thermostat included in the heating element measures the temperature of the surrounding coolant in the radiator and, if necessary, supplies power to the coil. After reaching the specified temperature parameters, it breaks the circuit. And as the water cools, it reconnects the coil to the network and heats the water. The presence of a thermostat allows you to set temperature parameters that are most comfortable for those present in the room. In its absence, the heating element will operate at maximum power, constantly consuming electricity, which will sharply increase the bills for it.

Some models of electric heating elements for heating a home are equipped with additional functions: “turbo mode” (turns on the device at maximum power for a short time) and “anti-freeze” (prevents the coolant from freezing, maintaining its temperature at a minimum).

Installation of a new heating element block in the boiler

To do this, we will need a new heating element unit (in boilers produced by Pyramid Plus LLC, heating elements with a G2 ½ flange thread are installed), a paranitic gasket or an o-ring (made of oil- and petrol-resistant rubber).

Lubricate the connection points on the flask and on the heating element block with a thin layer of lithol.

We install the gasket on the heating element block and screw it into the flask clockwise. Before installing the block into the flask, it is important to check the connection points on the flask and on the heating element block against debris so that the connection is airtight during operation. Next, we return the flask to the housing and secure it to the wall.

What heating elements are there, how to service them, check their integrity, replace them

A heating element is an electric heater in the form of a curved tube with a terminal pad for connection to the power supply circuit. Inside the tube there is a wire in an insulator that is heated by electric current. If the tube breaks and water gets inside, the heating element will immediately burn out. Also, the wire can burn out “on its own” due to timing or manufacturing defects, but more often - from overheating... Which heating element is preferable, how to maintain it, check it and replace it if necessary....

Branded wet heating element together with a small anode on one platform

Choose dry or wet shade

- Wet heating elements - constantly in contact with water, have the usual appearance of a thin tube. Its surface directly transfers energy to water, and absorbs corrosive effects and precipitation.

- Dry heating elements can be of different designs, but the essence is the same - the heating element is closed on top by another flask body. This protective housing transfers energy to the water and absorbs environmental aggression, but the heater itself is better protected.

Repairers criticize dry heating elements because each major manufacturer makes them very individual, and finding a replacement for them is not easy. Wet heating elements are largely unified in size, power, and location of attachment, and branded products are counterfeited in the widest possible way by representatives of the Far and Near East and local aborigines.

Manufacturers claim an increased service life of dry ones, but their price is much higher.

Many believe that dry heaters do not live up to expectations, since cheap branded wet ones, provided they are properly maintained, do not break, work without problems, and even if they burn out, they are easy to replace for pennies.

Why heating elements burn and how to service them

Any heating element will probably burn out relatively quickly if it is not maintained. You don’t have to worry about servicing electric heaters and change the heater every time it burns out. But it’s better, cheaper and easier to sometimes open the devices and “look inside”. Then high-quality products do not fail until the device itself breaks down, resulting in a real service life of 10 years or more.

- If the magnesium anode in a water heating tank has completely crumbled and no longer performs its functions, then corrosion leaves the heating element only a few days of life.

- Over time, the heating element will be littered with a mountain of sediment and remnants of the magnesium anode; in this state, it cannot withstand prolonged overheating and burns out.

- The ten itself accumulates scale and deposits from water on its surface, which it is advisable to purify chemically (the simplest is a day in concentrated citric acid) once a year, in order to avoid the same overheating, but this depends on the composition of the water.

How to check if the heating element is burnt out

Opening and repairing 220 V devices can only be performed by qualified personnel who have an electrical safety certificate of the appropriate group. If there are simply tons of such certificates, read on...

To check whether the heating element is intact or has already burned out, you need to use an avometer to measure electrical resistance. Any combined instrument for electrical measurements can do this.

You need to disconnect the heater from the electrical network, open it, get to the place where the heating elements are connected, disconnect at least one 220 V conductor and measure the resistance of the heating element. Or, as experienced people say, “ring” an electrical circuit, in this case one heater.

If the wire inside is intact, then the device will show a resistance close to zero - unity; if it is burnt out - an infinitely large number or a short circuit with the housing is detected.

How to check the integrity of a tenk without a device

To check whether the heater is working or burned out, when there is nothing to measure the resistance of the electrical circuit, you need to replace this “nothing” with something.

- An electrical probe detects the phase among the connected conductors; one of them is connected to the TEN, on the other terminal it will appear on the probe if the device is intact.

- A 220 V light bulb is connected in series to Ten, if the heater is working properly, then it will manifest itself. But 220 V can be replaced with a battery with a small LED - a homemade electrical circuit integrity tester.

- The most desperate method, which is unacceptable, is to use a spark. Disconnect only one conductor, apply voltage and tap it on the connection terminal. When touched, a spark will break through if the heating element is working properly, since the current strength here is significant.... Let us recall that in most cases the power of the device for a 220 V network is in the range of 1.5 - 2.0 kW.

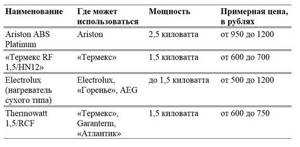

Replacement and selection of tena

Experts recommend not to mess with the gray market, since with “successful” purchases you can replace several heating elements per year, constantly disassembling and reassembling the electric water heater. Still, it’s better to try to pick up a branded product, and it’s not that expensive. To replace the heating element, first of all, you need to go not to the city market for cheap consumer goods, but to a service center, even if it’s not from the same company, since manufacturers often make according to standards. It is advisable to take the burnt one with you for a sample. Typically, prices for heating elements from well-known manufacturers used to fit in figures of up to 1000 rubles. The approximate cost of tens and the possibility of a unified replacement is shown in the figure below.

We recommend watching a visual guide from an expert on maintenance, disassembling the boiler and replacing the heating element

Heating element blocks (TENB) with star connection

This connection is intended for units with 220V heating elements, with the ability to connect to both 220V and 380V. Install the jumper as shown in the photo.

Then we install the neutral wire on the middle pin and stretch all the contacts well.

We install power wires (phase) on the contacts on the opposite side; the cross-section of the wires must also correspond to the power of the heating element unit.

This connection is made at 380V; to connect to 220V, it is enough to install the same jumper on the opposite side and connect the power (phase) wire in the center, or install a jumper on the terminal block of the electric boiler or control panel.

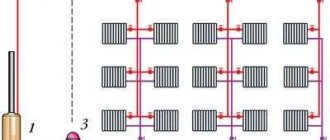

Two ways to connect heating elements to three phases.

“Three-phase” used to be something not very necessary and understandable for the common man, but in our time it has become a necessity for a private home. It is needed primarily for heating with electricity. Since an electric boiler has a high power (in most cases more than 6 kW), when using one phase you will need to install cables with a large cross-section of conductors. And this will be expensive, especially if the cable cores are made of copper. In a three-phase network, the cross-sections of the conductors will be noticeably smaller, for this reason most modern electric boilers are connected to a “three-phase” system. Now let's talk about the basic schemes for connecting heating elements to such a network.

Star.

This method is used if the heating element is designed for 220 V. In addition, the “star” requires that the neutral wire be connected from the panel. For clarification, consider the following figure:

In this case, instead of two jumpers there will be one. And it will be connected to zero, and the three remaining free ends will be connected to the corresponding phases. If you look at the block nut from above, it will all look like this:

Triangle.

This method is used to connect heating elements designed for 380 V. If you suddenly decide to install heating elements designed for 220 V in a “triangle”, they will simply burn out. Don't miss this important moment. The main difference between a “triangle” and a “star” is the absence of a neutral conductor. There are only 3 phases and nothing more. To better understand what we are talking about, look below:

In the picture everything looks simple and clear, but if you start connecting the contacts on the block nut, you will get the following:

It looks a little complicated, but in fact it is no different from the top picture. Colored lines and numbers here indicate the phases, and letters indicate the heating elements of the block.