Heating systems on two wings

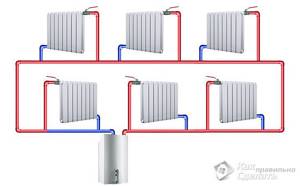

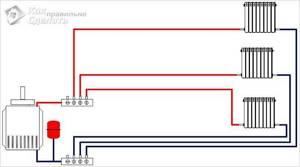

And yet, more often they use a system with a dead-end circuit.

And all because the return line is longer and it is more difficult to assemble. If your heating circuit is not very large, it is quite possible to adjust the heat transfer on each radiator and with a dead-end connection. If the circuit turns out to be large, and you don’t want to make a Tichelman loop, you can divide one large heating circuit into two smaller wings. There is a condition - for this there must be a technical possibility of such a network construction. In this case, in each circuit after separation it is necessary to install valves that will regulate the intensity of the coolant flow in each of the circuits. Without such valves, balancing the system is either very difficult or impossible. Different types of coolant circulation are demonstrated in the video; it also provides useful tips on installation and selection of equipment for heating systems.

Self-installation of two-pipe heating of a private house

To carry it out safely, it is better to follow the sequence:

- Decide on the wiring diagram.

- Make a careful distribution of elements: valves, radiators, as well as pipe connections.

- Assembling the network begins with the boiler. If we are talking about solid or liquid fuel, then it is necessary to provide a separate room for it and, without fail, construct a concrete platform as a base. Electric and gas units can be installed in a residential area, but you need to take care of a separate hood by installing a coaxial pipe, not forgetting about the expander.

- The pump for forced circulation operation is mounted in a line that is responsible for supplying water to the boiler. This action is necessary to protect against hot liquid.

Radiators are installed according to the following standards:

- placement should be planned under the windows, this will help protect against the cold air flow that is directed through the window opening. The top part should be about 5 cm from the edge of the window sill and at least 6 cm from the bottom to the floor;

- The ribs must be positioned in a horizontal plane at the same level.

For two-pipe heating of a two-story private house, the scheme is selected according to the individual structure and characteristics of the building, as well as the personal advantages of the owners. It can be with hidden installation of pipes and with distribution along the walls.

The arrangement of a two-pipe system should be carried out in compliance with certain principles:

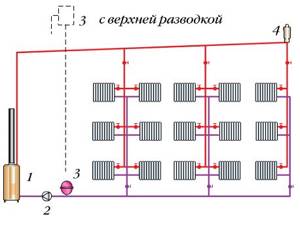

- The presence of two pipelines: the upper one with the coolant and the lower one with the cold one.

- The pipes are installed at an angle.

- Highways are laid symmetrically and maintaining parallelism;

- For ease of maintenance and repair, technological units, radiators, as well as a bypass with a pump are equipped with taps.

- The distribution tank in a system with overhead wiring is located in an insulated attic area.

- The pipeline is installed without right angles where air pockets can form.

You should end up with a two-pipe closed network that maintains the temperature in the house. To control the consumption of thermal energy, thermostats should be installed. Their new generation is able to control the operation of the boiler at an automatic level, turning on or off the additional heater if necessary, thereby economically consuming fuel and energy.

Advantages and disadvantages

Despite its cheapness and simplicity, the single-pipe design is becoming increasingly less common over time due to the advantages of the two-pipe circuit:

- uniform temperature distribution around the perimeter;

- when carrying out repairs, the required area is easily covered;

- possibility of use in large areas and in multi-storey buildings;

The disadvantage of a two-pipe system is the large number of pipes and connections.

Nuances of installing heating systems

Having selected the required number of radiators, the boiler and the connection option, you can directly assemble all the elements into a single harmonious system. First of all, you need to choose the right place for the boiler

For efficient operation it is important to place the unit as low as possible

Radiator installation

At the next stage of implementing the heating scheme, radiators are installed with your own hands. As you can see in the photo above, it is more convenient to use batteries with valves at the inlet and return. First of all, they are installed under the windows. This is done for a reason, but because warm air blowing through the window allows you to move the dew point back.

The instructions for attaching the batteries are very simple:

- the installation location is determined based on the following dimensions - at least 5 cm from the wall, at least 5-10 cm from the floor and at least 5-10 cm to the edge of the window sill;

- brackets are selected and installed based on the weight and size of the radiator; brackets for cast iron options are installed especially securely and deeply;

- the wall behind the radiator is finished if possible, since after installing the system, it will not be possible to remove the batteries;

- valves are installed to bleed air if they are not included in the kit.

If you doubt your abilities, you should not do the installation at random. There are tutorials and video tips. As a last resort, you can always turn to professionals in your field.

After choosing a place for the boiler and its installation, marking and installing radiators, we install a circulation pump, if it is included in the diagram

It is important to install a coarse filter in front of the pump to prevent mechanical particles from entering the system. On both sides you need to install two valves or taps to be able to remove the pump without draining the water from the system

Expansion tank and its replacement

In the case of installing a heating system with natural circulation, an expansion tank is installed at the highest point. Most often it is placed in the attic and insulated in the winter season.

There are also heating installation schemes without an expansion tank. Instead, a safety unit and a hydraulic storage tank are used. The tank is installed on the return heating main near the boiler. The safety unit is placed where the expansion tank should be. Air is released through the air valve of the unit at the right time.

Pipe installation

After installing all the elements of the system, they are connected into a common structure using pipes.

The tool used for installation will depend on the selected pipe material, and there are three main ones:

- metal;

- metal-plastic;

- PVC, polypropylene or cross-linked polyethylene.

Each material has its pros and cons, and, of course, the price-quality ratio.

Wiring methods

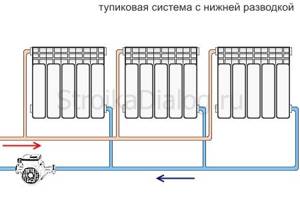

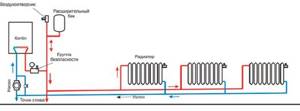

The circuit of a dead-end heating system can be organized with an upper or lower coolant supply. The upper wiring is used most often with natural circulation, the lower wiring is possible only if there is a circulation pump in the circuit.

In the first case, pipelines are installed with mandatory slopes for more efficient coolant movement. An open type expansion tank is installed at the top point of the system.

The most suitable way to connect radiators in a two-pipe dead-end heating system with natural circulation is diagonal. A Mayevsky valve or an air vent of another design must be installed on each battery.

Bottom wiring involves laying supply and discharge pipelines above the floor surface. In this case, the pipes are placed one above the other - supply from above. A circulation pump and a closed expansion tank of the membrane type are implanted into the return pipe at a short distance from the inlet pipe of the boiler, if it is single-circuit. In double-circuit boilers, the pump and tank are located inside the housing and are elements of heating equipment.

A dead-end heating system with bottom wiring is good because the main pipelines can be recessed into the floor structure or covered with a small box behind a wide baseboard. Its biggest drawback is its dependence on electricity. However, the problem can be solved by purchasing a small generator, which will help out during a lack of electricity. Radiators can be connected using any method: bottom, diagonal or side.

There is also a shoulder dead-end heating system. One of the varieties with side connection of radiators is shown in the diagram for a two-story house:

The coolant can serve the entire network simultaneously, while at the same time each arm of the system can work independently. In addition, taps are installed at the inlet and outlet of each radiator. This is convenient for adjusting the heating temperature in each room.

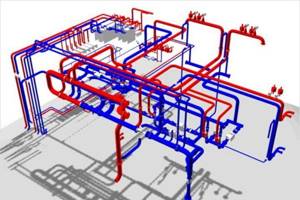

Features of the scheme of primary-secondary rings

This scheme provides for the organization of a primary ring through which the coolant must constantly circulate. Heating boilers and heating circuits are connected to this ring. Each circuit and each boiler is a secondary ring.

Another feature of this scheme is the presence of a circulation pump in each ring. The operation of a separate pump creates a certain pressure in the ring in which it is installed. The assembly also has a certain effect on the pressure in the primary ring. So, when it turns on, water comes out of the water supply pipe, entering the primary circle and changing the hydraulic resistance in it. As a result, a kind of barrier appears on the path of coolant movement.

Since the return pipe is connected to the circle first, and after it the supply pipe, the coolant, having received considerable resistance at the supply pipe, begins to flow into the return pipe. If the pump is turned off, the hydraulic resistance in the primary ring becomes very small and the coolant cannot float into the boiler heat exchanger. The piping continues to work as if the disconnected unit did not exist at all.

For this reason, there is no need to use one complex automation system to turn off the boiler. The only thing that is needed is to install a check valve between the pump and the water return pipe. The situation is similar with heating circuits. Only the supply and return lines are connected to the primary circuit in the opposite order: first the first, then the second.

Universal combined scheme

This system has the following harness:

- Two common collectors or hydraulic collectors. The first one is connected to the boiler supply lines. To the second - return lines. There are shut-off valves on all lines. There are circulation pumps on the coolant return pipes.

- The membrane tank is connected to a large return manifold.

- The indirect heating boiler is the link between two collectors. On the pipe that connects the boiler to the supply manifold there is a circulation pump and a shut-off valve. The pipe connecting the boiler to the return manifold also has a valve.

- The safety group is installed on the coolant supply manifold.

- The make-up pipe is connected to the manifold, which is located on the hot water supply line. To prevent leakage of hot coolant through this pipe, a check valve is installed on it.

- A certain number of small hydraulic collectors (there may be two, three or more). Each of them is connected to the above-mentioned common manifolds. These hydraulic reservoirs and large reservoirs form the primary rings. The number of such rings is equal to the number of small hydraulic collectors.

- The heating circuits depart from small hydrocollectors. Each circuit has a miniature mixer and circulation pump.

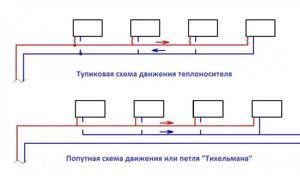

Dead-end and associated two-pipe systems

A dead-end system is a system in which the coolant supply and return flows are multidirectional. There is a system with passing traffic. It is also called the Tichelman loop/scheme. The latter option is easier to balance and configure, especially with long networks. If a system with a parallel flow of coolant has radiators with the same number of sections, it is automatically balanced, while in a dead-end circuit it will be necessary to install a thermostatic valve or needle valve on each radiator.

Two schemes of coolant movement in two-pipe systems: associated and dead-end

Even if radiators and valves/valves of different numbers of sections are installed with the Tichelman scheme, the chance of balancing such a scheme is much higher than a dead-end one, especially if it is quite extensive.

To balance a two-pipe system with multidirectional coolant movement, the valve on the first radiator must be screwed on very tightly. And a situation may arise in which it needs to be closed so much that the coolant will not flow there. It turns out then you need to choose: the first battery in the network will not heat, or the last one, because in this case it will not be possible to equalize the heat transfer.

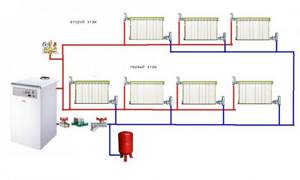

Two-pipe system for a two-story house

Two-pipe heating of a two-story house is perfect for a country house in which it is necessary to heat not one, but several floors. It is enough to supplement the system with several devices (circulation pump, expansion tank, heating control valves) so that it helps create the most cozy, comfortable atmosphere in the house. In addition, creating this system is a fairly easy process that does not require the involvement of outside specialists. A do-it-yourself two-pipe heating system is a great way to save quite a large amount.

The two-pipe heating system of a multi-storey building has an important advantage - a large number of auxiliary elements can be connected to it. Most often, a “warm floor” system and heated towel rails are connected to it.

The important thing is that these elements can be connected either directly during installation of the entire system, or later - after it has been operating for a certain time

Most often, a “warm floor” system and heated towel rails are connected to it.

The important thing is that these elements can be connected either directly during installation of the entire system, or later - after it has been operating for a certain time

It should be understood that the most appropriate moment for installing a heating system is the period of construction of the house. That is, during the construction of a building, it is necessary to create a plan for the most efficient heating system and immediately implement double-circuit heating of a private house.

A two-pipe heating system is a proven and effective way to heat a private home. This system allows you to regulate the heating of any room without changing the temperature in the rest of the house. A two-pipe heating system can be used in houses of any number of floors. The main feature of a two-pipe system is the separation of the forward and return coolant circuits. Heated water from the boiler enters the system through the so-called supply pipe, from which the coolant is disassembled into radiators, coils, and a heated floor system. After passing through them, the cooled liquid is discharged using another pipe - the return pipe.

Two-pipe heating system for a private house

The two-pipe system has a number of advantages:

- Ease of regulating the flow of coolant into any of the radiators;

- Possibility of use in a house of any number of floors;

- Possibility of installation of systems of considerable length.

Among the disadvantages, it is worth noting the doubled number of pipes compared to a single-pipe system. which increases the cost of installing the system and reduces its aesthetics - direct water flow pipes should be located above the level of radiators; they are usually laid under the ceiling or at the window sill level.

Operating principle of closed CO

A closed (otherwise known as closed) heating system is a network of pipelines and heating devices in which the coolant is completely isolated from the atmosphere and moves forcibly - from a circulation pump. Any SSO necessarily includes the following elements:

- heating unit - gas, solid fuel or electric boiler;

- safety group consisting of a pressure gauge, safety and air valve;

- heating devices - radiators or underfloor heating circuits;

- connecting pipelines;

- a pump that pumps water or non-freezing liquid through pipes and batteries;

- coarse mesh filter (dirt collector);

- closed expansion tank equipped with a membrane (rubber “bulb”);

- shut-off valves, balancing valves.

Typical diagram of a closed heating network for a two-story house

The operating algorithm of a closed type system with forced circulation looks like this:

- After assembly and pressure testing, the pipeline network is filled with water until the pressure gauge shows a minimum pressure of 1 bar.

- The automatic air vent of the safety group releases air from the system during the filling process. He also removes gases that accumulate in pipes during operation.

- The next step is to turn on the pump, start the boiler and warm up the coolant.

- As a result of heating, the pressure inside the ZSO increases to 1.5-2 Bar.

- The increase in the volume of hot water is compensated by a membrane expansion tank.

- If the pressure rises above the critical point (usually 3 Bar), the safety valve will release excess liquid.

- Once every 1-2 years, the system must undergo an emptying and flushing procedure.

The principle of operation of an apartment building's SSS is absolutely identical - the movement of coolant through pipes and radiators is ensured by network pumps located in an industrial boiler room. There are also expansion tanks there; the temperature is regulated by a mixing or elevator unit.

How a closed heating system functions is explained in the video:

Watch this video on YouTube

Two main heating system schemes

Heating schemes for buildings can be divided into:

In addition, each system is divided into components according to the physical layout. For example, a single-pipe heating system can be star-shaped, radial or collector.

The single-pipe heating system (radiator connections) is classic. Almost all multi-storey buildings, except those built in recent years, have exactly this design. It can be found both in Khrushchev and in new buildings.

The main advantages of this construction:

- easier installation than other heating options;

- natural coolant circulation;

- saving material and pipes.

To increase the efficiency of such a system, a circulation pump is often installed. By increasing the coolant flow rate, it is possible to use smaller pipes.

Unfortunately, the previously popular single-pipe system has a number of disadvantages:

- use of large diameter pipes;

- consumption of large amounts of fuel;

- there is no possibility of adjusting radiators;

- electricity costs if forced circulation of coolant is used.

A more efficient option can be implemented using a two-pipe scheme. In this case, the coolant passes in parallel through each battery and along a straight heating main. This increases the number of pipes used, but significantly increases the overall efficiency of the system.

Let's consider the main advantages of two-pipe schemes:

- versatility of use in both single-story and multi-story buildings;

- uniform heating of all radiators in the system;

- small diameter pipes for heating lines;

- precise adjustment of the heat transfer of each radiator.

How does it work

The design of such a heating system is quite simple. At the heart of everything is any boiler. It heats the coolant supplied through a pipe coming from the boiler. Why is this scheme called one-pipe? Because one pipe is laid along the entire perimeter, which comes from the boiler and enters it. Radiators are installed on the brackets in the right places and connected to the pipe. The coolant (most often water) moves from the boiler, filling the first radiator in the unit, then the second, and so on. At the end, the water returns to the starting point and the cycle repeats. A continuous circulation process occurs.

It should be noted that having assembled such a scheme, you may encounter one difficulty. Since the rate of movement of the coolant may be small, temperature losses are possible. Why? If we talk about a two-pipe system, then the principle of its operation is as follows: through one pipe water enters the battery, through the other it leaves it. In this case, its movement passes through all the radiators at once, and no heat loss occurs.

In a single-pipe system, the coolant enters all batteries gradually and, passing through them, loses temperature. So, if when leaving the boiler the temperature of the medium was 60˚ C, after passing through all the pipes and radiators, it can drop to 50˚ C. What to do in this case? To overcome such fluctuations, you can increase the heat capacity of the batteries at the end of the chain, increasing their heat transfer, or increase the temperature in the boiler itself. But all this will lead to additional costs, which are unprofitable and make the cost of heating more expensive.

To get rid of this problem without high costs, you need to increase the speed of coolant movement through the pipes. There are 2 ways to do this:

Technology for installing a pump in a heating system

Install a circulation pump. This way you can significantly increase the speed of water movement in the system. In this case, heat loss at the outlet will be significantly reduced. The maximum loss can be several degrees. These pumps are powered by electricity. It should be noted that for country houses where electricity is often cut off, this option will not be ideal.

Installation of the collector directly behind the boiler

Install the accelerating manifold. This is a tall, straight pipe, thanks to which the water passing through it gains high speed. Then the coolant in a system with natural circulation makes a full circle faster, which also solves the problem of heat loss. It is especially good to use this method in a multi-story building, since in a one-story building with low ceilings the work will be ineffective. For normal operation of the collector, its height must be more than 2.2 m. You should know that the higher the accelerating collector is, the faster, more efficient and quieter the movement in the pipeline will be.

In such a system there must be an expansion tank, which is best installed at the top point. It acts as a stabilizer, controlling the increase in coolant volume. How does he work? When heated, the volume of water increases. This excess flows into the tank, preventing excess pressure from occurring. When the temperature drops, the volume decreases and flows from the expansion tank back into the heating network.

This is the whole principle of operation of a single-pipe heating system. This is a closed circuit that includes a boiler, main pipes, radiators, an expansion tank and elements that ensure water circulation. There are forced circulation, when all the work is done by the pump, and natural circulation, in which an accelerating manifold is mounted. The difference between this design is that it does not have a return pipe through which the coolant returns to the boiler. The second half of such wiring is called return.

Connecting heating radiators with a two-pipe system

In a two-pipe system, any of the methods of connecting radiators is implemented: diagonal (cross), one-sided and bottom. The best option is a diagonal connection. In this case, the heat transfer from the heating device can be in the region of 95-98% of the rated thermal power of the device.

Diagrams for connecting radiators to a two-pipe system

Despite the different values of heat loss for each type of connection, they are all used, just in different situations. The bottom connection, although the most unproductive, is more common if the pipes are laid under the floor. In this case it is easiest to implement. When laying hidden, you can connect radiators using other schemes, but then either large sections of pipes remain visible, or they will need to be hidden in the wall.

Lateral connection is practiced if necessary when the number of sections is no more than 15. In this case, there is almost no heat loss, but when the number of radiator sections is more than 15, a diagonal connection is required, otherwise circulation and heat transfer will be insufficient.

Despite the fact that more materials are used to organize two-pipe circuits, they are becoming more popular due to the more reliable circuit. In addition, such a system is easier to compensate.

Battery connection diagram

In two-pipe heating, one of three options for connecting batteries is used: diagonal, one-sided or bottom. The best way is considered to be a diagonal connection. This way you can achieve maximum heat transfer from heating equipment (up to 98% of the nominal value).

Radiator connection diagram

Despite all the differences between different types of radiator connections, they are all used in practice, but with different tasks. For example, the bottom connection is not very efficient, but it is a good option if the pipeline needs to be located under the floor.

Disguised laying of pipes can also be used in a diagonal and one-sided scheme, however, in these cases, significant sections of pipes will remain on the surface, which can only be hidden under the wall decoration.

Connecting side-type radiators is used when the number of sections is limited to 15 units - there are practically no heat losses in this case. If there are more than 15 sections, a diagonal connection will be needed, since only this method will ensure normal coolant circulation and heat transfer.

The most efficient heating system is one in which the coolant becomes hot due to the operation of two or three boilers. However, they can be the same in power and type. This rationality is explained by the fact that one heat generator operates at full capacity only for a few weeks a year. At other times, you need to reduce its productivity. And this leads to a drop in its efficiency and an increase in heating costs.

Several boilers combined into one heating system allow you to more flexibly control the operation of the piping without loss of efficiency, since it is enough to turn off one or two devices. In addition, if one of them breaks down, the system continues to raise the temperature in the house.

Vertical and horizontal system diagrams

Two-pipe heat supply structures come in two types:

- Vertical

. It is usually used in multi-story buildings. A two-pipe vertical heating system requires the use of a large number of pipe products, but connecting radiators on each floor can be easily done. Its main advantage is the automatic removal of air - it rushes to the top and there, through a drain valve or expansion tank, it comes out. - Horizontal

. This system has found application in one-story, maximum two-story buildings. To bleed air from it, so-called Mayevsky taps are mounted on the batteries.

Variety of residential heating schemes

All standard heating schemes involve time-tested options. These include the familiar one-pipe and two-pipe designs, collector or beam, as well as the well-known “Leningrad”.

The radial system is characterized by installing a pair of pipes for each radiator. Very convenient to install and maintain. For effective heat removal it requires preliminary balancing.

Leningradka is known for its solution of independent adjustment of each radiator in a single-pipe circuit. This is achieved by shunting each battery with a bypass pipe, as well as using valves on the radiators.

The heating scheme for two wings is interesting. It is convenient for use in a multi-storey building. Can be used with either one or two circulation pumps. As in the case of the beam scheme, it requires adjustment and balancing of the “wings”.

Symbols in heating diagrams are not particularly complex. Most often, these are rectangles - a boiler and radiators, connected by straight lines - heating pipes. The valves are indicated in the form of an hourglass. Modern diagrams are more like pictures, where each element is represented by its own picture. Therefore, symbols on heating diagrams are drawn in simple language.

Planning and calculation

When choosing the most optimal type of heating system for a private home or cottage, it is imperative to take into account the area of the house

This is important, since, for example, a single-pipe scheme with natural circulation shows itself excellently only in houses with an area not exceeding 100 m2. But in a house with a significantly larger square footage, it will not be able to work due to the rather large inertia. It follows that the initial calculation of pressure in the heating system and the design of the heating system are needed in order to find out and design a system, the use of which in the house will be more rational

At the stage of preliminary drawing up of the plan, one must try to take into account all the specifics of the architecture of the building. For example, if the house is quite large and, accordingly, the area of the rooms that need to be heated is also large, the most rational would be to introduce a heating system with a pump that will circulate the coolant

It follows that the initial calculation of pressure in the heating system and the design of the heating system are needed in order to find out and design a system, the use of which in the house will be more rational. At the stage of preliminary drawing up of the plan, one must try to take into account all the specifics of the architecture of the building. For example, if the house is quite large and, accordingly, the area of the rooms that need to be heated is also large, the most rational would be to introduce a heating system with a pump that will circulate the coolant.

In this case, there are certain characteristics that the circulation pump must meet:

- long service period;

- low level of electricity consumption;

- high power;

- sustainability;

- ease of use;

- absence of mechanical vibrations and noiselessness during operation.

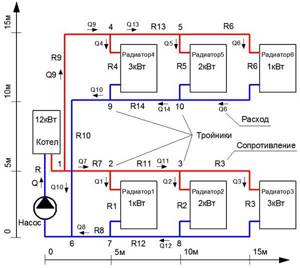

When planning a heating system, be it a private or multi-storey building, the most difficult and critical phase is the hydraulic calculation, in which it is necessary to establish the resistance of the heating system.

Calculations are made according to a heating diagram created in advance, on which all the components present in the system are marked. Implement hydraulic calculations of a two-pipe heating system using axonometric projections and formulas. The design object is taken to be the busiest ring of the pipeline, divided into segments. As a result, an acceptable cross-sectional area of the pipeline, the required surface area of the radiators, and the hydraulic resistance in the heating circuit are established.

Calculations of hydraulic characteristics are carried out using various methods.

The most common:

- calculations using the method of specific linear pressure losses, providing for equivalent changes in coolant temperature in all components of the wiring;

- calculations based on resistance parameters and conductivity parameters, providing for variable temperature fluctuations.

The result of the first method is a clear physical picture with a specific distribution of all observed resistances in the heating circuit. The second calculation method makes it possible to obtain clear information about water consumption and temperature values in each element of the heating system.

Classification of 2 pipe systems

Heating systems of any type are divided into open and closed. In closed ones, a membrane-type expansion tank is installed, which makes it possible for the system to operate at increased pressure. Such a system makes it possible to use not only water as a coolant, but also ethylene glycol-based compounds, which have a low freezing point (up to -40 o C) and are also called antifreeze. For normal operation of equipment in heating systems, special compounds developed for these purposes must be used, and not for general purpose, and especially not for automobiles. The same applies to the additives and additives used: only specialized ones. It is especially strict to adhere to this rule when using expensive modern boilers with automatic control - repairs in case of malfunctions will not be guaranteed, even if the breakdown is not directly related to the coolant.

The installation location of the expansion tank depends on its type

In an open system, an open type expansion tank is built in at the top point. A pipe is usually connected to it to remove air from the system, and a pipeline is also installed to drain excess water in the system. Sometimes warm water can be taken from the expansion tank for household needs, but in this case the system needs to be recharged automatically, and additives should not be used.

From a safety point of view, closed systems are more promising and most modern boilers are designed for them. Read more about closed heating systems here.

Equipment classification

A two-pipe heating system for a private house can be open or closed. The latter provides for the presence of a membrane expansion tank, which allows the system to operate at high pressure.

The heat carrier can be not only water, but also ethylene glycol compounds that can operate at low temperatures (up to 40 degrees below zero). Compositions based on ethylene glycol are called antifreeze.

It should be noted that proper operation of the equipment is ensured only when using specialized compounds designed specifically for heating purposes. Automotive antifreeze will not work. The same applies to additives and additives: only those specially adapted for heating can be used.

It is especially important to follow this recommendation when operating expensive boiler models that are controlled automatically. In the event of a boiler breakdown, manufacturers usually decline responsibility and do not carry out warranty repairs unless the malfunction is directly caused by the thermal fluid.

One highway pros and cons

A single-pipe heating system for a two-story house - the Leningradka scheme - consists of one main line laid horizontally along the perimeter of the building, above the floor of each floor. Heating devices are connected to the main line at 2 ends, alternately. This type of heating network is well suited for houses where two floors occupy a small area (up to 80 m² each). There are reasons for this:

- The coolant entering each subsequent radiator has an increasingly lower temperature due to the mixing of cooled water from previous radiators. Therefore, the length of the ring is limited to 4-5 heating devices.

- In order to properly heat the second floor and the rooms where the last radiators are located, their heat output should be increased by adding sections.

- The horizontal network of a two-story house with natural circulation should be made with a large slope (up to 1 cm per 1 m running pipe). The boiler is placed in a recess, and in the attic there is an expansion tank communicating with the atmosphere.

The Leningrad heating distribution of a two-story house with forced supply of coolant works much more stable and efficiently than by gravity. For natural circulation in a private house, it is better to make vertical risers that penetrate the ceilings and distribute heat to radiators near the windows. Water is supplied to the risers from a horizontal collector laid in the attic, and returned to the boiler through the same line running above the floor of the 1st floor.

As in the first case, an open expansion tank is placed in the attic of a 2-story cottage, and the mains are laid with a slope. If the heating system is closed, then minimal slopes are required (3 mm per linear meter of pipe), and the membrane tank is placed in the boiler room.

Single-pipe heating distribution for a two-story house, although inexpensive to install, is complex in calculation and execution.

And not every owner will like it when large-diameter pipelines run through some of the premises; they have to be hidden under boxes.

Which heating network layout to choose?

Depending on the location of the supply pipeline, two-pipe heating is classified into two types - with upper and lower wiring.

The diagram of a two-pipe heating system with top wiring involves installing an expansion tank and a distribution line at the highest point of the heating circuit, above the radiators. This installation cannot be done in a one-story building with a flat roof, since to accommodate communications you will need an insulated attic or a specially designated room on the second floor of a two-story building.

Bottom wiring system

A two-pipe heating system with bottom wiring differs from the top one in that the distribution pipeline in it is located in the basement or in an underground niche, under the radiators. The outermost heating circuit is the return pipe, which is installed 20-30 cm lower than the supply line.

This is a more complex configuration, requiring the connection of an upper air pipe, through which excess air will be removed from the radiators. If there is no basement, additional problems may arise due to the need to install the boiler below the level of the radiators.

Top wiring system

Both the lower and upper circuits of a two-pipe heating system can be made in a horizontal or vertical configuration. However, vertical networks, as a rule, are made with bottom wiring. With this installation, there is no need to install a powerful pump for forced circulation, since due to the difference between the temperatures in the return and supply pipes, a strong pressure drop is created, increasing the speed of movement of the coolant. If, due to the specific layout of the building, such installation cannot be done, a main line with overhead routing is installed.

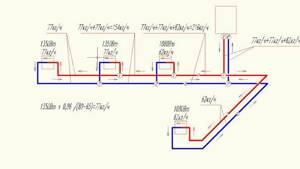

Selecting pipe diameters and rules for installing a two-pipe network

When installing two-pipe heating, it is extremely important to choose the correct pipe diameter, otherwise you may get uneven heating of radiators located far from the boiler. Most boilers for domestic use have a diameter of the supply and return pipes of 25 or 32 mm, which is suitable for a two-pipe configuration

If you have a boiler with 20 mm pipes, it is better to opt for a single-pipe heating system.

The size chart of polymer pipes on the market consists of diameters of 16, 20, 25 and 32 mm. To install the system yourself, you need to take into account the key rule: the first section of the distribution pipe must correspond to the diameter of the boiler pipes, and each subsequent section of the pipe after the branch tee to the radiator must be one size smaller.

Diagram of pipe diameters in a double-circuit system

In practice, it looks like this: a diameter of 32 mm comes out of the boiler, a radiator is connected to it through a tee with a 16 mm pipe, then after the tee the diameter of the supply line is reduced to 25 mm, at the next branch to the radiator line 16 mm after the tee the diameter is reduced to 20 mm and so on. If the number of radiators is greater than the standard sizes of pipes, it is necessary to divide the supply line into two arms.

When installing the system yourself, adhere to the following recommendations:

- the supply and return lines must be parallel to each other;

- each outlet to the radiator must be equipped with a shut-off valve;

- the distribution tank, if installed in the attic when installing a network with overhead wiring, must be insulated;

- pipe fastenings on the walls should be placed in increments of no more than 60 cm.

When setting up a system with forced circulation, it is important to correctly select the power of the circulation pump. The specific choice is made based on the size of the building:

- for houses with an area of up to 250 m2, a pump with a capacity of 3.5 m3/hour and a pressure of 0.4 MPa is sufficient;

- 250-350 m2 – power from 4.5 m3/hour, pressure 0.6 MPa;

- over 350 m2 – power from 11 m3/hour, pressure from 0.8 MPa.

Despite the fact that it is more difficult to install two-pipe heating with your own hands than a one-pipe network, such a system, due to its high reliability and efficiency, fully justifies itself during operation.

Basic elements of the heating system

Having determined the heat loss of the home, we select the indicators of the main element of the heating system - the boiler. To understand the power of this device, you should consider:

- maximum heating of the boiler in winter frosts;

- material of the walls of the building in which the heating network is being designed;

- number of heating batteries;

- heating structure.

The next step is the choice of fuel, and therefore the boiler itself. There are not many options:

- firewood;

- peat, brackets, sawdust or coal;

- gas.

Very rare, but there are liquid fuel options.

The second important element or elements of the thermal structure of the house are heating radiators. The market for modern radiators is quite full.

By type of material there are:

You can also conditionally subdivide water radiators by price range. These include budget cast-iron radiators, and individual devices, right up to batteries with artistic casting. The average price range is represented by aluminum and bimetallic options.

Cast iron batteries are the cheapest, but also the most inert in terms of heat transfer. They take a long time to warm up, but cool down slowly. They have a relatively short service life. In general, heating radiators are selected based on heat output, service life, price and appearance.

Which fuel is more convenient?

If gas is used as fuel, then heating with natural circulation is based on the principle of taking air from the room into an open burner and discharging the combustion product into the ventilation ducts. In this case, the boiler will need a room of 4 m2 with good ventilation (windows and doors).

Therefore, this scheme is not very convenient. Much more often, a closed or open water heating system with natural circulation is used, which you can do with your own hands.

In multi-story buildings, a single-pipe system is often used. Basically, a scheme with closing sections is used, when part of the water from the riser goes up, part of it goes down, thanks to the closing section, which ensures a balance of temperatures between the lower and upper floors. The system works thanks to the difference in diameter of the connection pipes and the pipes of the closing section (one size smaller). A two-pipe system, compared to a single-pipe system, is less compact and easier to install.

Advantages and disadvantages

The main disadvantage of this method of organizing heating follows from the method of organizing the circulation of the coolant: double the number of pipes compared to the main competitor - a single-pipe system. Despite this situation, the costs of purchasing materials are slightly higher, and all due to the fact that with a 2-pipe system, smaller diameters of pipes and, accordingly, fittings are used, and they cost much less. So the resulting material costs are higher, but not significantly. What there really is is more work, and accordingly it takes twice as much time.

Distinctive features of the heating system

The biggest advantage is electrical independence, and the disadvantage is the pipes, which have a large diameter and are routed at an angle.

Compared to the two-pipe option, there are quite a few advantages:

- pipes can be diverted to the “warm floor” system or heating radiators can be connected;

- it can be carried out regardless of the layout of the room;

- it covers the entire perimeter with a closed ring;

- it is less material-intensive and has a lower cost.

During use, difficulties may sometimes arise with circulation through the pipes, but this is easily solved by installing pump equipment. It produces proper circulation of coolant through the pipes.

A vertical single-pipe circuit is a popular example of wiring in apartment buildings.

Single-pipe heating system with pump.

But horizontal is used mainly for heating large rooms and is used very rarely in private buildings (mainly in small one-story houses). Here the supply pipe bypasses the heating devices, which are on the same level. The water in each radiator cools down and, approaching the last heating devices, becomes significantly cooled. This scheme will help reduce installation and piping costs, but has two disadvantages.

Firstly, this is a problem with heat regulation in any heating device. You cannot increase heat transfer, reduce it, or turn off the radiator. In installation practice, there is a jumper - a bypass, which allows you to turn off the radiator without turning off the system. Heating of the room is carried out indirectly through a riser or supply pipes. Another disadvantage is that you need to use radiators of various sizes. In order for the heat transfer to be the same, the first heating device must be very small, and the last one must be large. A horizontal single-pipe heating circuit is also used.

Single-pipe vertical

How else can you heat two-story households with a single-pipe system? There really is an alternative - this is a single-pipe vertical heating system, which is used by many people who are looking for a suitable steam heating scheme in a private home. There are no difficulties in such a scheme; you just need to bring the supply pipe with the coolant to the second floor and connect the batteries located there, and then make branches down to the first floor.

Advantages and disadvantages of a single-pipe vertical scheme

As usual, let's start with the positive features:

In single-pipe vertical heating systems, the coolant flows from the radiator on the top floor to the lower floors.

- greater savings on materials;

- relatively equal air temperature on the first and second floors;

- ease of implementation.

The list of disadvantages is the same as the previous scheme. It included heat losses on the last radiators. And since our coolant is supplied through the upper floor, it can be cooler on the first floor than on the second.

The savings on materials are more than substantial. We only have one pipe going upstairs, from which the coolant is distributed to all the radiators on the second floor (not sequentially). From each upper radiator, pipes go down to the radiators on the ground floor, after which they end up in one common return pipe. Thus, this scheme involves minimal use of materials.

Features of installation of a single-pipe vertical system

When installing a vertical single-pipe system, you will receive as many chains as there are radiators on each floor.

In the previous gas heating scheme in a private house, the pipes sequentially bypassed the radiators on the first and second floors. That is, we got two parallel chains, each of which included several radiators. In the current scheme we also have chains, but they are vertical. For example, if there are four radiators on each floor, then we get four chains connected in parallel.

This scheme assumes one solid supply pipe passing along the top floor. Branches are made from it to each radiator. After passing through the upper radiators, the coolant flows to the lower radiators, and only after that into the return pipe passing along the first floor.

If in the first case the greatest heat losses were observed in the distant radiators of the first and second floors, then in this scheme it will be cooler on the first floor, since part of the heat will be consumed on the second floor.

A single-pipe vertical heating scheme for a private house with a gas boiler can be implemented without forced circulation of the coolant. The thing is that the temperature of the coolant supplied to the radiators on the second floor is the same. A drop in temperature is observed only on the first floor. But if we supplement the radiators with bypass jumpers, then the temperature change will be minimal - it can be neglected.

Thus, this circuit, supplemented by bypass jumpers, will become the most economical and inexpensive among any other circuits. Instead of a gas boiler, any other boiler can be used. The electric heating circuit of a private house is no different from gas heating (except in the type of boiler).

Related Posts

- Leningrad heating system for a private house

- How to make steam heating

- Hydroarrow: principle of operation, purpose and calculations

- At what temperature of the coolant is the heating system turned off and turned on in an apartment building according to GOST

- Tichelmann loop

- Water supply collector

- Heating system of a one-story private house

- A supply of hot water that is always at hand: how does an electric water heater for heating work?

- Cheap and efficient heating option

- Heating distribution manifold

- Which pipe to choose for heating

- Autonomous heating in an apartment in a multi-storey building

- Optimal heating distribution in a private house: comparison of all typical schemes

- What to do if the bottom of the battery is cold and the top is hot?

- Connection diagrams for bimetallic radiators

- Connection diagram for double-circuit gas boilers to the heating system

- Subtleties of crimping a heating system

- How to choose and install an air valve for heating

- Thermal accumulators for autonomous heating systems

- Installation and connection of the expansion tank

- We make a water heated floor from a gas boiler

- Comparison of heating radiators by heat transfer

- Operating principle of an open heating system with a circulation pump

- Heating scheme with forced circulation of a two-story house

- Major heating repairs in an apartment building

Read with this

- Leningrad heating system for a private house

- How to make steam heating

- Hydroarrow: principle of operation, purpose and calculations

- At what temperature of the coolant is the heating system turned off and turned on in an apartment building according to GOST

- Tichelmann loop

- Water supply collector

- Heating system of a one-story private house

- A supply of hot water that is always at hand: how does an electric water heater for heating work?

- Cheap and efficient heating option

- Heating distribution manifold

Conclusion

We examined the main elements and components, analyzed the heating circuit of a typical version, and learned the differences in connecting boilers and radiators. We determined that there is nothing difficult about installing a heating system with your own hands. Having time, means and desire, you can complete the most difficult work at first glance.

Heating, water supply and sewerage are the three pillars on which the comfort of a home rests. The correct choice of wiring for the heating system in the house will allow you to create a cost-effective and efficient heat supply. The design of the heat supply scheme and the construction of the building are carried out simultaneously, since in this case possible nuances are taken into account.