Almost all modern household gas boilers are controlled electronically. The boiler control board is designed primarily to ensure its correct operation. If problems or malfunctions occur, the automation also informs the user of the cause of the failure in the form of an error on the screen. Error codes and probable causes of their occurrence are usually described in the gas boiler operating manual, and in this article we will look at the most common reasons for the appearance of error e01 on a baxi boiler

.

Attention! Before taking independent steps to troubleshoot your gas boiler, carefully study the operating instructions and manufacturer’s recommendations, or better yet, contact a specialist.

Error e01 is classified as critical, in which the boiler cannot continue to operate until the cause of the problem is eliminated, so it must be reset! Resetting the error in baxi boilers is done by pressing and holding the R button for 2-3 seconds. After resetting the error, the boiler should attempt to start in normal mode.

Boiler baxi mainfour 240f error e01 does not see flame

The baxi mainfour 240f baxi boiler is a single-circuit boiler with one fourth-generation bithermal heat exchanger from a well-known brand; it is usually distinguished from the similar baxi 24 by a white display panel. The letter F in the name means that the model is equipped with a fan for forced removal of combustion products. The principle and functional diagram of ignition of this boiler is no different from other boilers, and if the Baxi Main For 24 boiler produces error e01, you must follow the general recommendations that we describe in this article below or by watching the first two minutes of a video from one of the service organizations (exactly about the reasons errors e01 baxi mine for 24).

Additional Information

To prevent breakdowns and errors from appearing, you must follow certain rules . It is important to take the following into account:

- For the system to work well, you need 170-250 V. If the voltage is lower, the device will turn off, but if the voltage is higher, the varistor will burn out.

- Gas boilers are very sensitive to power surges. Experts strongly recommend purchasing additional devices to stabilize it.

- To connect you need to create a separate functionality.

- If a phase-dependent type of boiler is used, you need to ensure that the phase coincides with zero.

Baksi heating systems are excellent equipment for the home. When operating, it is very important to follow the instructions and follow the recommendations given by the manufacturer. In case of problems, problems should be resolved in a timely manner. In case of serious damage, there is no need to try to restore the operation of the unit with your own hands; it is best to contact a professional.

In this video you will learn how to repair boilers:

BAXI eco four 24 f error e01

Ecofor 24 is a series of double-circuit turbocharged boilers with a closed combustion chamber. They differ fundamentally from the Baxi Main For by the presence of a second plate heat exchanger for preparing hot water. One of the reasons for boiler ignition errors may be the electronic board, but for diagnostics it is advisable to contact specialists in order to exclude all other options for the occurrence of error e01 baxi eco four 24 f. This is due to the fact that the ignition module of these boilers is located directly on the board and the average user is unlikely to be able to figure it out on their own. It is also worth noting that the boards of the Main For and Eco For boilers themselves are interchangeable and are customized for a specific model by setting specific parameters in the configuration mode.

Reason eight. The boiler lights up and then immediately goes out

If, during startup of the tank, it instantly turns off, and the flame does not even have time to burn completely, the problem again lies in the flame control electrode. He does not see the flame due to poor contact with the control board and because of this he turns off the boiler. The exact reason for the shutdown in this situation can only be determined during diagnostics of this board itself, and, therefore, it is necessary to contact specialists.

Why does the Baxi boiler give error E01?

In most cases, this error indicates that the boiler burner has not ignited (the signal is supplied from the flame control sensor or also called the flame ionization sensor). The sensor is an electrode for determining the presence of a flame and blocks the operation of the gas boiler in the event of incomplete combustion of the main burner or gas supply interruptions.

- Insufficient pressure or lack of gas supply to the system (for example, gas valve malfunction)

- Incorrect connection of the boiler power supply for phase-dependent models

- Poor contact or no signal from the flame ionization sensor

- Malfunction of the flame control sensor (contamination, breakdown)

- Failure of the control board

- Lack of air for proper combustion (lack of draft, clogged inlet pipe)

The boiler is blocked after three unsuccessful attempts to start; to restore operation, you must hold the “R” button for at least 2 seconds (using the example of a BAXI boiler of the eco four or main four series).

Check some reasons for the baccy error e01

you can do it yourself, for example, the presence of contact with the sensor, the state of its contamination and air access, but if the error occurs again, it is better to contact a service organization or service center. Let's look at this issue in more detail.

What does low blood pressure mean and what needs to be done?

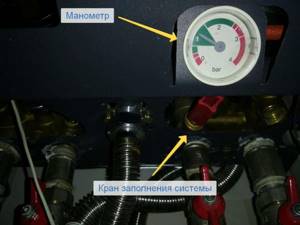

For normal operation of the heating system, so that the coolant can circulate normally and there is no overheating, the pressure must be normal. It is for this purpose that a special sensor controls it in the boiler. Also, the pressure in the heating system is controlled visually - with a mechanical pressure gauge (see photo). In most cases, this problem is encountered by users who have just started using the BAXI boiler. So what to do:

- Examine the readings of the mechanical pressure gauge. If the arrow is in the red zone, go to step 2

- We find the tap water make-up tap at the bottom of the boiler. Depending on the boiler model, it can be located in different places, but this place is definitely at the entrance to the boiler water pipe and probably next to the pressure gauge. The location of the system filling valve must be included in the instructions for the boiler! In BAXI boilers, the system filling valve can be red or black with a square cross-section (see photo BAXI EcoFour), blue or black with a round cross-section.

- Once the feed tap has been found, you need to fill the heating system to the required level. We open the tap (turn it counterclockwise), usually you will immediately hear the noise of water entering the boiler; as soon as you hear the sound of water, you don’t need to turn it further - we watch the pressure gauge needle. As soon as the pressure gauge needle has risen to the green zone - more than the 1 bar mark - close the tap by turning it clockwise (do not over-tighten it - just close it).

- As soon as the pressure in the boiler is raised to a normal level, error e10 should disappear and the boiler will automatically start working.

We remind you that a frequent loss of pressure in a closed heating system indicates a possible coolant leak. Frequent means more than once every 6-12 months. Constant replenishment of the boiler will negatively affect the service life of the main heat exchanger, and this is the most expensive part in the boiler (30-40% of the cost of a new boiler). This is due to the fact that tap water contains various impurities of salts and minerals, which at high temperatures will be deposited on the walls of the heat exchanger and reduce its permeability and efficiency.

Error E01. Incorrect boiler power supply connection

In BAXI boilers, according to the operating instructions, it is required to observe the polarity of the phase and zero connections, and if the boiler is connected incorrectly, the user will also receive an E01 error. This can be checked either at the corresponding connectors on the board, or simply by turning the connection plug over in the socket. The second is usually the easiest to do.

An important point is grounding the boiler. All metal parts of the boiler must be reliably grounded according to the PUE standards! Improper grounding is often the cause of problems with electronics.

Reason four. Problem with power supply to the boiler

All Baxi boilers are very dependent on the correct electrical connection. Simply turning the plug over to swap the zero and phase can solve the problem. But if this does not correct the situation, then you should check this same connection on the connectors of the boiler board, because no one has canceled the defects in production. A very important point in the operation of an electric boiler is also such a thing as grounding. If the tank is not grounded, this can also cause malfunctions of the heating elements and cause the Baxi boiler to issue error E01.

Flame control sensor fault (baxi e01)

In general, some manufacturers claim that the “igniter” is a consumable item. Personally, I have a baxi eco four boiler in my apartment and I have never changed it (the boiler is already six years old). But nevertheless, everything depends on the specific operating conditions, gas quality and air pollution. Therefore, you need to carry out an inspection, if necessary, clean the electrode with an alcohol solution and check its correct position and gap relative to the burner body according to the instructions (this may be different for different models). Case from practice: a client complains about the Baxi boiler error E01. We changed the board - the boiler worked for a day and again the same error. What did you do with the boiler before the error appeared? We bent the electrode and made a gap of 1 mm. On what basis? Somewhere someone told, showed...

In Baxi boilers, the ignition electrode also performs the function of flame control. Flame control is one of the most important functions of the boiler safety system. It is needed so that the boiler immediately shuts off the gas supply if the flame on the burner goes out for some reason. The gap must be set exactly as specified in the operating manual for the device!

The fact is that the principle of flame control is to register a small current that begins to flow through the electrode during combustion. And the flame structure has an air gap at the base, and if the gap is too small, the flame will not be registered and the boiler will fail when operating at certain power modes.

We do not recommend bending the electrode under any circumstances - it is very fragile and will most likely break off.

As an option, carefully bend the attachment point.

Troubleshooting instructions

If you purchased a Baxi boiler, error E10 may become a reality for you. Therefore, before starting to operate such equipment, it is necessary to understand the main types of problems. They are indicated by codes that can be divided into two groups, namely: the equipment goes into standby mode or completely blocks the operation of the device.

In the latter case, the problem can be solved by simply rebooting the unit. Such an error indicates that serious problems have arisen that can create dangerous situations for human life and health. That is why such a failure should be treated with special attention. Among them, the lack of traction, lack of fuel supply, and overheating of the device should be highlighted. If you purchased a Baxi boiler, error E10 can resolve itself. However, without human intervention such an outcome is unlikely. But if this happens, then it can be argued that the automation turned on the device on its own.

BAXI error e01. Control board fault

As a rule, if the above checks have been performed and do not reveal a problem, then diagnostics and repair of the boiler board will be required. In the case of Baxi boilers, the ignition unit and modules responsible for modulating the flame are located on the board itself, so their breakdown can lead to error E01. Diagnostics of the control board can only be carried out by a qualified specialist.

You can also watch a short video that shows in detail and clearly the checks discussed.

If you still think that the cause of error 01e

is a breakdown of the electronic board - contact us, we have everything you need to diagnose and repair the boards of BAXI gas boilers: specialist, experience, spare parts, equipment for professional installation. It is possible to deliver boards to other regions of Russia and organize repairs by agreement.

Instructions for many BAXI boiler models are also available for download on our website.

If you are interested, we have posted an article on our website with a complete list of error codes for Baxi boilers.

Description of error E10

The most common problem is error code E10, which you can see on the display under some circumstances. The reason may be caused by incorrect operation of the sensor, which monitors the circulation of coolant in the system and the functioning of the pumping equipment.

Automation can work in cases where the coolant pressure is reduced to a critical level. This can also be caused by a lack of contact between the pressure switch and the board. In some cases, consumers who use a Baxi boiler experience error E10 for this very reason. It can also be caused by a malfunction of the pressure switch or incorrect operation of the pumping equipment sensor. This code may also indicate a malfunction of the pump itself. Sometimes this problem is caused by a clogged heat exchanger or filter system located in the heating circuit.