Autonomous home heating is an attractive option for any owner.

If one device also provides hot water supply, then this option is optimal under any conditions.

There are a lot of installations that perform such functions and have high performance qualities.

A striking example of such heating devices is the Baxi Main 24 Fi double-circuit gas boiler, which has extensive capabilities and has been specialized for Russian technological and climatic conditions.

The unit is highly rated by users and deserves detailed consideration.

Description

The well-known Italian company Baxi, part of the BDR Thermea Group, has been working on the manufacture of heating equipment for more than half a century.

During this time, many technological methods have been developed that allow us to produce high-class products that meet all the requirements and standards accepted in Europe. Baxi Main 24 Fi is one of the models of double-circuit wall-mounted boilers using natural or liquefied gas as fuel .

Almost 70% of the company's products are intended for export, so manufacturers take into account the conditions of the upcoming work. The units undergo special training to comply with Russian conditions.

They tolerate changes in gas pressure and are able to compensate for a slight decrease in voltage in the electrical network.

Among Russian users, Baxi products are deservedly in high demand and preference.

Peculiarities

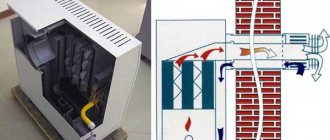

Baxi Main 24 Fi is a double-circuit boiler capable of simultaneously supplying hot water and heating the coolant for heating systems or underfloor heating. The numbers 24 indicate the boiler power (24 kW), and the letters Fi indicate the turbocharged combustion chamber.

It has a closed design that ensures tightness and cleanliness of the surrounding air . The combustion mode is maintained by a fan supplying air flow to the burner.

The main feature of Baxi Main 24 Fi boilers is a bithermic heat exchanger. Unlike other series, not two separate, but one combined version was used.

It is a design in which another tube is installed inside the tube, having a shape close to a rhombus.

The coolant flows along the outer side, and hot water flows along the inner, rhombic side. The OM flow receives thermal energy from the burner, and the DHW flow from the coolant. This design makes the boiler design simpler, more compact, and simplifies adjustment and configuration.

Accessories for temperature control

The latest self-diagnosis system, with errors displayed on the LCD display, allows for precise adjustment of the boiler’s thermal processes.

An electronic chip using primary sensors will analyze the condition of the boiler for compliance with the established temperature conditions and adjust the operation.

The electronic system is able to remember the latest failures. The temperature regime in the house and the heating level of the hot water supply can be set directly on the remote control unit.

Outdoor temperature sensor

When an outside temperature sensor is connected to the unit, the weather-compensating automation integrated into the electronic board of the device is activated.

The boiler will independently regulate the temperature in the supply pipe according to the specified control schedule. In this option, the internal thermal regime will correspond to maximum comfort and efficiency, since real atmospheric conditions will be taken into account.

The outdoor temperature sensor modifies the temperature regime of the supply coolant in the heating system in accordance with the outside air temperature outside. The device is designed to maintain a constant sanitary regime in the house.

The group use of external and internal air temperature sensors in the electronic control board implements self-adaptation of the equipment. In this way, the temperature relationship adjustment curve will be calculated automatically.

Room programmable thermostat

Such a thermostat is designed to guarantee a stable temperature in the house. It operates on the principle of turning off the equipment when the required ambient temperature is reached and turning on when it drops. Thus, a simple and safe means of regulating climatic conditions in the house is implemented.

The simplest adjustment system can save up to 15% of gas fuel used for heating needs. This is achieved by maintaining the temperature conditions more accurately and reducing the number of unit turns on/off.

The use of such devices is mandatory according to EU requirements and domestic standards for the operation of gas equipment.

What functions does it have?

Set of functions of the Baxi Main 24 Fi boiler:

- Heating of coolant and hot water.

- Organization of circulation of the heating agent along the heating circuit.

- Self-diagnosis system.

- Convenient controls.

- Automatic flame ignition.

- Thermometer and pressure gauge showing the pressure and temperature in the system.

- Power indicator.

NOTE! The functionality of Baxi boilers is almost the same for all models. There are only small features that do not represent a fundamental difference.

Technical characteristics of the boiler

For convenience and ease of consideration, we will provide the parameters of the Baxi Main 24 Fi boiler in the form of a table:

| Characteristics | Meaning |

| Power | 24 kW |

| Heated area | 240 m2 |

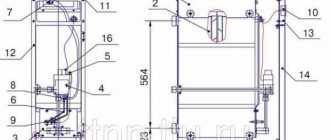

| Dimensions | 734 : 400 : 317 mm |

| Weight | 33.5 kg |

| Power consumption | 10.6 kW |

| Efficiency | 90,3 % |

| Gas consumption | 2.78 m3/h |

| Exhaust temperature | 35-80° |

| DHW temperature | 35-55° |

| Allowable pressure | 19.1 bar |

| Chimney | Coaxial 60/100 mm |

| Power supply | 230 V, 50 Hz |

Price range

The cost of Baxi boilers with a capacity of 24 kW ranges from 32 thousand rubles. up to 41 thousand rubles. depending on the specific model.

The price does not include installation and delivery. You will also have to spend money on a chimney, which is not included with the equipment.

The total cost will be approximately 10% higher, which should be taken into account and prepared in advance.

Advantages and disadvantages

The advantages of Baxi Main 24 Fi boilers are:

- European quality equipment, compliance with all certificates and regulations.

- Environmentally friendly equipment.

- Compact, attractive appearance.

- The ability to provide heating of the heating agent in parallel with the supply of domestic hot water.

- Low gas consumption.

- Ability to serve a fairly large area.

The disadvantages include:

- Difficulty in washing the bithermic heat exchanger.

- High cost of spare parts.

- Vulnerability to voltage surges.

- For maintenance or repair, you must invite a specialist.

IMPORTANT! Both the advantages and disadvantages of the Baxi Main 24 Fi boiler are due to design features. Most of them are common qualities of gas boilers.

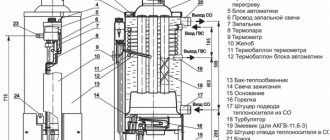

Construction of the Baxi Main 24 Fi gas boiler

The main elements of the boiler design are:

- Single bithermic heat exchanger.

- Closed type gas burner.

- Expansion tank.

- Turbocharger fan.

- Circulation pump.

- Three-way valve.

- A system of sensors connected to the control board.

- Connecting pipes, connecting pipelines.

The operation of the boiler is to heat the coolant using a heat exchanger and a gas burner. The outgoing OM is mixed with the colder return flow, obtaining the specified temperature parameters.

At the same time, hot water is heated in the heat exchanger, passing through the inner tube and receiving energy from the hot heating agent. The combustion mode and the removal of fuel combustion products are provided by a fan receiving fresh air from the external pipe of the coaxial chimney.

All processes are monitored by a system of sensors, which, when problems occur, signal to the control board and display one or another error code on the display.

Almost all processes occur automatically, user intervention is minimal and is aimed only at adjusting the operating mode.

General information 13. checks before installing the boiler, Additional pump, Important

Page 8

- Image

- Text

72

926.237.1 - RU

MANUAL FOR TECHNICAL STAFF

The boiler is designed to heat water no higher than the boiling point at atmospheric pressure. It connects to the system

heating and hot water preparation system in accordance with its characteristics and power.

Before installing the boiler you must:

a) Check that the boiler is configured to work with this type of gas. This information is provided on the packaging and on the factory

boiler nameplate.

b) Make sure that there is sufficient draft in the chimney, there are no narrowings, and there is no entry of foreign products

combustion, unless the chimney is specially designed to serve several

devices.

c) When connecting a smoke exhaust pipe to an existing chimney, check that the chimney is completely clean,

because When the boiler is operating, soot particles can come off the walls of the chimney and block the exit of combustion products, thereby creating

the most dangerous situation.

In addition, to maintain the product's warranty and to maintain its proper functioning, you must

apply the following precautions:

1. hot water system:

1.1.

if the water hardness is higher than 20º F (where 1º F = 10 mg CaCO3 per 1 liter of water), a polyphosphate filter should be installed

a dispenser or similar water softening system that complies with current regulations.

1.2.

The DHW system must be thoroughly flushed after installing the device and before using it.

2. heating system

2.1. new equipment:

Before installing the boiler, the heating equipment must be pre-cleaned to remove possible

deposits or contamination (pieces of sheathing, solders, etc.), using for this purpose substances available in free

sale. Substances used to clean equipment must not contain concentrated acid

or alkalis, which can corrode metal and damage plastic and rubber parts of equipment (e.g.

SENTINEL X300 or X400 and FERNOX Rigeneratore for heating equipment). When using cleansers

substances must strictly follow the instructions for their use.

The following instructions and notes are designed to assist a qualified person in carrying out

error-free installation and maintenance. Instructions regarding ignition of the boiler and its operation are given in the section

“User's Guide”.

Installation, maintenance and testing of the operation of household gas appliances should only be carried out by

by qualified personnel and in accordance with current regulations.

Note:

• this boiler can be connected to any type of radiators and heat exchangers, using single-pipe, double-pipe or

beam system. You can arrange the sections in the heating system in the usual way, taking into account the data from

section “Flow/pressure characteristics”.

• keep packaging parts (plastic bags, polystyrene foam, etc.) out of the reach of children, as they are a source of

potential danger

• the first start-up of the boiler must be carried out by a qualified specialist.

Warranty obligations are fulfilled by the organization that carried out the first start-up of the boiler. This organization should

have statutory licenses. The warranty period begins from the moment of first start-up. To implement

For the first start-up and subsequent maintenance of the boiler, we recommend that you contact authorized BAXI service centers

(“BAXI”). Ask your sales organization for addresses and phone numbers of service centers.

ADDITIONAL Pump

If an additional pump is used in the heating system, install it at the return to the boiler. This arrangement

pump contributes to the correct operation of the hydraulic pressure switch.

important

in case of connecting a double-circuit boiler to an installation with solar panels, the maximum temperature of domestic water

at the entrance to the boiler should not exceed 60 °C

.

12. GENERAL INFORMATION

13. CHECKS BEFORE INSTALLING THE BOILER

For which rooms is it best suited?

Baxi Main 24 Fi boilers are designed and designed for use in residential premises - houses or apartments of the appropriate size. They are often installed in office or public spaces.

Such units are not recommended for use in industrial workshops, since the specifics of the work will be too harsh and will cause rapid failure of the unit..

The declared area of the heating circuit is 240 m2, although in practice it is not recommended to use this model for rooms larger than 200-220 m2 due to the gradual decrease in the capabilities of the boiler, which occurs due to contamination, the appearance of scale and general wear and tear of the unit components.

Where is it better to use

The intended purpose of Baxi Main 24Fi boilers is to operate them in residential buildings, apartments, and sometimes they are installed in offices or public institutions.

At enterprises with industrial capacities, the installation of boilers is not recommended due to the aggressive nature of the work, which will lead to boiler failure. This model is theoretically designed to heat an area of 240 m2, but as practice shows, 200-220 m2 is the optimal area for work in order to reduce wear on boiler components and prevent the appearance of scale.

Startup instructions

After delivery, installation of the boiler in the designated place and connection of all communications, it is necessary to carry out the initial start-up of the boiler.

Procedure:

- Fill the boiler and system with water. It is necessary to set the pressure to about 0.7-1 mbar using the supply tap or drain. The circuit should be filled slowly so that the air has time to bleed out. The mode switch must be set to “0”.

- Turn on the power.

- Open the gas tap.

- Set the switch to “summer” or “winter” mode.

- Turn the burner regulator (turning it clockwise increases the temperature and counterclockwise decreases it). At the same time, the sound of water movement and the noise of the burner will become audible.

NOTE! The process may not start the first time due to the presence of air in the system. In such cases, the procedure is repeated until the boiler starts up normally.

Filling the system

Page 6

- Image

- Text

70

926.237.1 - RU

User Guide

To turn off the boiler, you must turn off the power supply to the device. When the mode switch is in position

“OFF” (see paragraph 5) the boiler does not work (OFF appears on the display), but the electrical circuit of the boiler remains

under voltage and the “frost protection” function remains active (paragraph 9).

7. BOILER TURN OFF

8. Converting the boiler to another type of gas

The boiler can operate on both natural and liquefied gas. Converting the boiler to another type of gas can only be done

qualified specialist.

attention

Turn off the power supply to the boiler using the bipolar switch.

important:

Check the pressure gauge regularly to ensure the pressure is between 0.7 and 1.5 bar when the system is cold

heating. If the pressure exceeds, open the drain valve. If the pressure is below normal, open the fill valve

(Fig. 2).

We recommend opening the tap very slowly to make it easier to bleed out the air.

6. FILLING THE SYSTEM

The boiler is equipped with a differential hydraulic pressure switch, which turns off the boiler in case of

pump blocking or lack of water.

Fig.2

note:

If the pressure drops frequently, have your boiler checked by a qualified professional.

24 F - 24

1.24 F - 1.24 - 1.14 F - 1.14

A - Drain valve

B - Filling valve for heating system

C - Cold water inlet to the DHW system - It is necessary to install a shut-off valve to fill the system

0812_1801/CG_2010

B

A

A

C

User manual

The boiler operates automatically, requiring virtually no user intervention. The owner is required to periodically perform maintenance using the services of an invited specialist from the service center.

To improve operating conditions and extend service life, it is recommended to install a voltage stabilizer and a water softening filter . It is especially important to improve water quality if the power comes from your own well and standard water treatment has not been carried out.

Before starting operation, you should carefully study the user manual in order to understand important points and avoid unacceptable actions.

Download instructions You can download instructions

here

.

Features of the Baxi Eco four 24 f model

The Baxi Eco four 24 f boiler model is quite popular and has excellent technical characteristics. This model is quite enough to provide heat and water to a room of more than two hundred square meters. The Baxi Eco four 24 f model is equipped with a liquid crystal display, thanks to which you will be able to control the operation of the unit, as well as receive all information about operating errors or failures.

The operating features of the Baxi Eco four 24 f model are as follows:

- the presence of continuous electronic fire modulation in DHW and heating modes;

- smooth electronic ignition;

- the Baxi Eco four 24 f boiler operates stably, even if the gas inlet pressure is reduced to 5 mbar;

- you can reconfigure the boiler to run on liquefied fuel;

- the copper primary heat exchanger is coated with a special substance that additionally protects the boiler from corrosion;

- flame dividers located on the burner are made of stainless steel;

- the secondary one is made of stainless steel;

- you can connect a storage water heater for hot water operating externally;

- the structure can also be connected to solar collectors;

- there are several temperature control ranges, including a mode for “warm” floors;

- the set temperature in the heating and hot water circuits can be adjusted and maintained automatically;

- it is possible to connect a room-type thermostat or a programmable timer;

- the presence of an electronic self-diagnosis system;

- the boiler blocking signal is output to the control panel;

- the presence of a pump blocking protection system and a three-way valve that operate automatically.

Basic faults and troubleshooting methods

All malfunctions that are possible during the operation of the boiler are immediately detected by the corresponding sensors and displayed on the display in the form of a corresponding code.

The main ones:

- E01 . No flame ignition. Check the sensor, the presence of gas or the condition of the burner.

- E02 . Thermostat overheating. There may be scale or problems with water passage.

- E03 . Fan malfunction. Check functionality or replace.

- E05 . Exhaust temperature sensor malfunction.

- E06 . DHW sensor failure.

- E10 . Excessively low coolant pressure. Usually caused by a leak in the circuit.

- E25-26 . The circulation pump stops or the corresponding sensor fails.

- E35 . False combustion signal (stray flame). There are several reasons, from water on the board to sparking of the sensor.

- E96 . Low power supply voltage.

The user's first reaction when an error occurs (if there is no visual confirmation of the problem) should be to reset the error by pressing the R button and holding it for 3 seconds. If the error occurs again, you need to call a technician.

Preparation for installation, Preparation for first start-up

Page 3

- Image

- Text

67

926.237.1 - RU

User Guide

The boiler is designed to heat water no higher than the boiling point at atmospheric pressure. It connects to the system

heating and hot water preparation system in accordance with its characteristics and power. The boiler must

installed by a qualified technician.

Before installing the boiler you must:

a) Check that the boiler is configured to work with this type of gas. This information is provided on the packaging and on the factory

boiler nameplate.

b) Make sure that there is sufficient draft in the chimney, there are no narrowings, and there is no entry of foreign products

combustion, unless the chimney is specially designed to serve several

devices.

c) When connecting a smoke exhaust pipe to an existing chimney, check that the chimney is completely clean,

because When the boiler is operating, soot particles can come off the walls of the chimney and block the exit of combustion products, thereby creating

the most dangerous situation.

d) In addition, in order to maintain the warranty on the device and to maintain its proper functioning,

The following precautions must be taken:

1. DHW circuit:

1.1.

if the water hardness is higher than 20º F (where 1º F = 10 mg CaCO3 per 1 liter of water), a polyphosphate filter should be installed

a dispenser or similar water softening system that complies with current regulations.

1.2.

Thoroughly rinse the equipment after installation and before use.

2. heating circuit

2.1. new equipment

Before installing the boiler, the heating equipment must be pre-cleaned to remove possible

deposits or contamination (pieces of sheathing, solders, etc.), using for this purpose substances available in free

sale. Substances used to clean equipment must not contain concentrated acid

or alkalis, which can corrode metal and damage plastic and rubber parts of equipment (e.g.

SENTINEL X300 or X400 and FERNOX Rigeneratore for heating equipment). When using cleansers

substances must strictly follow the instructions for their use.

2.2. Operated equipment:

Before installing the boiler, the heating equipment must first be cleaned of dirt and deposits,

using commercially available substances (see paragraph 2.1)

To protect equipment from scale, it is necessary to use inhibitor substances such as SENTINEL X100 and

FERNOX Protettivo for heating equipment. When using these substances, you must strictly follow

instructions for their use.

We remind you that the presence of deposits in heating equipment leads to problems in the operation of the boiler (overheating,

burner noise, etc.)

If these recommendations are not followed, the device will be removed from warranty service.

1. preparation for installation

The first start-up of the boiler must be carried out by a qualified specialist. You need to make sure the following:

a) The boiler parameters for power supply, water and gas correspond to the existing power, water and gas supply systems.

b) Installation was carried out in accordance with current regulations.

c) The device is correctly connected to power and ground.

If the above requirements are not met, the manufacturer's warranty becomes invalid. Before the first start

Remove the cellophane protective film from the boiler. To avoid damaging painted surfaces during washing and cleaning

surfaces, do not use hard tools or abrasive cleaners.

The device should not be used by children, people with physical or mental problems, or without sufficient

experience and knowledge, except when they use the services of a person responsible for their safety, do so

under supervision or according to the instructions intended for the device..

2. preparation for the first launch