Heat-resistant fire glass for fireplaces Schott Robax®

By purchasing heat-resistant, fire-resistant glass for a fireplace from us, you will receive high-quality products at the most favorable prices both at retail and wholesale.

brings to your attention glass for fireplaces | fireproof protective screens | heat-resistant glass from Schott Robax® For fireplace protection screens and inspection panels, it is best to use special heat-resistant glass. They are also actively used for glazing braziers, ovens, ovens and barbecues.

German-made glass ceramics Schott Robax® has not only a beautiful and aesthetic appearance, but also the highest technical and consumer characteristics:

- ability to withstand high thermal loads;

- optimal sheet thickness;

- high level of strength;

- temperature coefficient of expansion close to zero.

The main quality criterion when choosing glass for fireplaces is fire resistance. After all, its main function is to prevent sparks from entering the room, withstanding high temperatures. Protective glass for a fireplace from is German quality and the lowest prices to date

. Delivery throughout Russia, Moscow and the Moscow region.

Fireproof glass for stoves and fireplaces (glass ceramics)

You can buy glass for your fireplace from us. We deliver throughout Russia to your apartment or the nearest location. Delivery is made upon presentation of a passport.

To select glass for a fireplace or stove - above, in the search module, enter the length and width in mm. If arched is required, check the box next to the “Arch” parameter and enter the distance to the beginning of the rounding. Please note that the data is entered in millimeters. Click the “go to product” button and you will be taken to the desired page.

We recommend that you purchase a fire-resistant cord; it is used when attaching glass to the door of a fireplace or stove. It is chosen equal to the perimeter of the glass (the sum of the four sides). For example, for glass 400 mm by 350 mm, 1.5 meters will be required.

We also recommend purchasing a sponge for dry cleaning of fireplace glass. It is made using technology that allows you to completely remove soot and deposits without leaving scratches. Glass for fireplaces – manufactured in Europe. Operating temperature - 760°C. Used for installation in fireplace doors.

We provide specialist advice on proper installation. The call is free. ROBAX fireplace glass confidently bears such names as heat-resistant, fire-resistant, heat-resistant, fire-resistant, heat-resistant. Used in door construction. The unique properties of these products have been successfully used for decades. The material from which it is made has another important quality – strength. Freely withstands heat up to 760°C and instant temperature changes up to 450°C. It is Robox glass that is used in fireplace and stove systems, which indicates consumer appreciation for this brand. The service life of fireplace glass is up to two decades. Choose glass ceramics at the best price from us. Place the selected item in the cart on the website and pay. If you have any unspecified questions, call us and we will advise you. If you need to make glass according to individual parameters, please contact us. We will complete your order as soon as possible and send it to you.

With respect to your customers, Naletu.ru.

The quality of our work has already been appreciated in Moscow St. Petersburg Novosibirsk Yekaterinburg Nizhny Novgorod Kazan Chelyabinsk Omsk Samara Rostov-on-Don Ufa Krasnoyarsk Voronezh Perm Volgograd Saratov Tyumen Togliatti Izhevsk Barnaul Ulyanovsk Irkutsk Khabarovsk Yaroslavl Vladivostok Makhachkala Tomsk Oren burg Kemerovo Novokuznetsk Ryazan Astrakhan Naberezhnye Chelny Penza Kirov Lipetsk Cheboksary Balashikha Kaliningrad Tula Kursk Sevastopol Sochi Stavropol Ulan-Ude Tver Magnitogorsk Bryansk Belgorod Surgut Vladimir Tagil Chita Arkhangelsk Simferopol Kaluga Smolensk Volzhsk Yakutsk Saransk Cherepovets Kurgan Vologda Orel Vladikavkaz Podolsk Grozny Murmansk Tambov Petrozavodsk Ster litamak Nizhnevartovsk Kostroma Novorossiysk Yoshkar-Ola Khimki

Online store Nalety.ru.

Prices

| Name | Price |

| Fireproof glass for fireplace 4mm | wholesale price 10,500 rub./sq.m. |

| Fireproof glass for fireplace 5mm | wholesale price 11,500 rub./sq.m. |

| Fireproof glass ceramic 4 mm | wholesale price 10,000 rub./sq.m. sale of glass sheets |

| Round fireproof glass of any diameter. Thickness 4 mm Fireproof glass of various diameters | 450 rub/piece |

Tempered glass firebox sheet

| 5,000 rub./sq.m. |

Protective screen for fireplace

| 6,500 rub. for 1 piece |

Manufacturing and processing

In the manufacture of heat-resistant glass, the principle of uniform heat distribution over the entire surface is used to reduce the temperature load at each point.

There are several technological processing methods that allow you to achieve the desired result:

- The glass is coated with a special heat-resistant compound, which blocks the access of heat to the material itself.

- Several glasses are connected to each other using a special polymer or glue, which helps to evenly distribute thermal energy.

- The source material is subjected to a special hardening method and processing.

All of the above methods give the same result in terms of efficiency - durable heat-resistant glass is obtained.

Glass is classified by grade, depending on the degree of heat resistance, melting time and further purpose.

Quartz glass is considered to be one of the most resistant to high temperatures. And borosilicate ones have increased inertness to aggressive environments.

Characteristics

| Manufacturer | Schott |

| Manufacturer country | Germany |

| Type of glass | Tinted, heat-resistant glass ceramic |

| Glass thickness | 4.0 or 5.0 mm |

| Glass width | 1100.0 mm |

| Glass length | 1954.0 mm |

About glass for fireplaces, protective screens for fireplaces

The combustion chamber of a fireplace poses a certain threat to the room due to the large number of sparks, embers emitted by cracking wood and hot ash. It is inconvenient to close the opening with a steel or cast iron damper; in addition, all the beauty of the flame disappears and heat transfer decreases.

Therefore, modern fireboxes use glass for the fireplace, which is strong enough not to shatter when closed, and heat-resistant to withstand the heat of the flame.

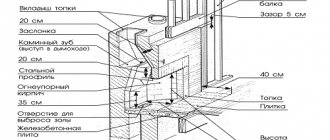

FIREPLACE GLASS DOOR CONSTRUCTION

The idea of using glass as a fireplace surround has been around for a couple of hundred years. In those days, quartz glass was used for fireplaces in the form of individual mosaic fragments on a bronze or copper fireplace screen. The glass had to be changed periodically, since the screen moved too close to the fireplace became hot and the mosaic cracked.

There is currently no alternative to using glass valves:

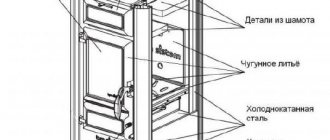

- Doors for fireplaces made of heat-resistant glass do not expand or deform from heat, like cast iron or steel, thanks to this it is possible to obtain minimal gaps and a high quality seal between the frame and the edge of the door;

- Fireproof glass for fireplaces does not burn or oxidize and retains its original appearance throughout its entire service life;

- The main thing is that a fireplace door with glass allows you not only to enjoy the play of fire, it is the only possible way to control the combustion process so that the flame does not turn into smoldering with the formation of carbon monoxide.

Today, it is rare that any fireplace insert is made with a black metal door; most often these are high-temperature fireplaces designed to use universal types of fuel, including those with a high content of tar and resin. But even in such designs, the manufacturer tries to use fireproof glass for the fireplace, since it is easier to see with your own eyes what is happening in the firebox than to guess by sound or thermometer readings. True, owners have to regularly look for a means and a way to clean the glass of the fireplace from soot.

For a small country house or cottage, a cast iron fireplace with glass is most often chosen. In addition to the beautiful appearance, this choice has a purely practical advantage - heat-resistant glass for the fireplace ensures faster and more uniform heating of the room. The champion in terms of heating efficiency is a round fireplace with glass, which is capable of heating and simultaneously lighting the room.

For glass fireplaces

If you have a great desire to turn an ordinary fireplace into a glass one, then we assure you that this is possible. But we should not forget that the firewood used to operate the fireplace forms a deposit, so the glass structure requires timely maintenance. Thus, there are currently two types of glass heating structures on sale - gas structures and hearths powered by bioethanol.

In gas glass fireplaces, fake firewood is placed inside the firebox, which is covered with a layer of “ash” for greater authenticity.

The illusion of combustion is almost perfect. The fuel tank (natural gas or propane-butane) is hidden inside the structure. A remote control is provided as a heating device. The biofireplace operates on a special type of fuel, which is made from plant extracts. The fuel is based on environmentally friendly alcohol. It is important that during operation there is no release of toxic substances and solid combustion products that contaminate the glass. In order to be able to extinguish the flame in time, a regulator is installed inside the burner.

The production of fireplaces is carried out from reliable fireproof glass, which is effectively combined with natural and artificial finishing materials. Heating devices of this type have all the necessary documents, so they undergo strength tests and are certified for fire resistance. The products are environmentally friendly and have high characteristics, so the fireplace does not harm either humans or the environment.

Glass fireplace care

There are no special instructions regarding the care of glass heating structures, since the fuel does not leave marks on the surface of the material. The only condition is to wipe off any dust that may accumulate on the installation.

If the fireplace runs on natural gas or wood, you should carefully consider the fireplace when choosing; if installed correctly, there should be no traces of contamination. However, unpleasant moments often happen in practice.

The appearance of soot in gas structures is explained by an incorrect balance of air and fuel. Contamination can be avoided by keeping the burner in proper condition.

You should also pay attention to the quality of the fuel. Often the use of poor quality gas leads to clogging and plaque formation.

Advantages and characteristics

Depending on the class and brand, heat-resistant glass has many advantages and physical characteristics:

- High temperature resistance.

- Low expansion coefficient.

- Particular strength. Even with prolonged exposure to thermal energy, thermal glass does not crumble or collapse, but is simply slightly deformed.

- Some brands are particularly resistant to open fire.

- High fracture resistance. The material is difficult to drill and cut.

- Infusibility.

- Durability.

Heat-resistant glasses can be decorated to suit every taste; they can be polished or embossed, tinted or colored, depending on the application.

Scope of application

The use of heat-resistant glass is widespread - from industrial needs to everyday life.

Most of all, their use is associated with the arrangement of human life. Heat-resistant dishes and various kitchen utensils are made from this material.

Glassware is convenient and environmentally friendly, and its heat resistance allows it to be used in cooking in microwaves and ovens. The use of heat-resistant glass in the construction of fireplaces is also very popular.

Main areas of use:

- cookware;

- hobs;

- fireplace windows and doors;

- microwave and conventional ovens;

- laboratory glassware for experiments;

- saunas and steam rooms;

- glazing of premises with increased fire hazard.