The room in which the fireplace is installed is an object that is at risk of various types of emergency situations. A live flame in a room poses a potential danger due to the fact that the products of incomplete combustion of fuel are water, carbon dioxide and carbon monoxide. Carbon monoxide is toxic and deadly to humans, so ensuring normal chimney draft is included in the list of priority tasks when installing a fireplace.

Unfortunately, the pitfalls don't end there. As a result of the release of a large amount of energy, some elements of the building become quite hot, which can lead to a fire. Frequent causes of fire are cases of hot fuel particles falling out of the firebox onto the floor, and even if a fire can be avoided, no one is safe from damaged floor coverings.

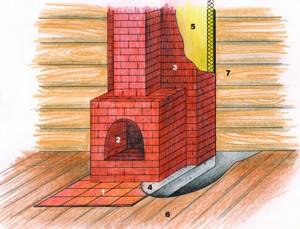

When building a fireplace, one of the stages will be insulating the floor covering. This is a set of measures that must be taken to minimize the risk of fire. Even brick structures that have their own foundation must be framed with a thermal insulation plate around the perimeter. The requirements of the fire safety rules state that a 0.5 x 0.7 m plate should be installed in front of the façade to prevent the fire of floor coverings. But in order to increase safety, many craftsmen increase the area so that the side walls are also insulated.

English style fireplace

Lighter models that do not require a foundation can simply be placed on a special platform, ensuring a level base and fire safety. Depending on external conditions, the solvency of the owner of the room, and design preferences, there are several different options for preparing the floor for installing a fireplace.

Using floor tiles

Ceramic tiles have a number of qualities that are necessary to ensure the fire safety of a fireplace, especially in a wooden house or in a brick building with wooden floors. It is known that laying tiles requires skill and experience, so weigh your options before undertaking the work. But if you decide to finish the floor in front of the fireplace yourself, then you should carry out some preparation of the surface.

Using ceramics on the floor

- To avoid differences in the horizontal plane, an analysis of the plank surface should be carried out. Detected irregularities should be processed with a plane.

- The tiles laid in front of the fireplace must have an ideal base, otherwise chips may occur in uneven areas. As such a base, you need to install a substrate made of plasterboard or plywood. The backing sheets are cut along the prepared contour and attached to the floor with self-tapping screws.

- At the next stage, the formed surface is treated with a primer. It is enough to apply it in one layer with a brush. The primer will promote better adhesion of the tiles and protect the substrate from delamination. You can continue work only when the soil is completely dry. According to preliminary estimates, this can take about a day.

- Using a spatula, apply special tile adhesive to the prepared surface. If a brick wood-burning fireplace is installed in the house, then the tiles should not only protect the floor from accidental ingress of hot particles from the firebox, but also prevent the harmful effects of high temperatures on the wood. This means that laying tiles is best done using heat-resistant adhesive. Its layer should be uniform. Despite the apparent pliability of the consistency, it will be impossible to level the tiles if they are unevenly applied.

Red tiles in the living room

The complexity of the work lies in the fact that the laid tiles under the fireplace on the floor reveal all the inaccuracies of the masonry, so you should constantly check not only the horizontal level, but also the width of the joints, which, in the absence of experience, is recommended to be increased slightly.

How to finish the wooden floor and walls around the fireplace?

Everyone knows that wood does not tolerate heat well - it warps, cracks and darkens. Restoring it is difficult and often simply impossible. This means that wooden walls and floors need to be insulated from the heat source

The method of protecting wood from heat directly depends on what exactly is emitting it. The most difficult situation is with a brick fireplace. Both he and his chimney get quite hot and can cause irreparable damage to the walls of the house. How to solve this problem? If the location of the fireplace is determined at the project development stage, an opening is created in the wooden wall higher and wider than the future hearth by 5 cm on all sides and filled with solid, non-combustible masonry material (usually brick).

It is important that the insulating insert rests on the foundation of the fireplace . Otherwise, during seasonal movements of the house, both structures will “walk” independently of each other. This, in turn, entails the risk of cracking of the brickwork. There is no need to say how dangerous damage to the firebox or chimney is.

A masonry fireplace becomes very hot during combustion. Not only contact, but even its proximity to a wooden surface is categorically unacceptable

In the case when a fireplace is being erected in an already finished house, the leaning wall is protected using a screen made of brick, stone or tongue-and-groove concrete blocks . As in the case described above, it should be at least 5 cm wider than the fireplace on both sides and be integral with the foundation. To prevent this heavy structure from collapsing, it is given an L- or U-shaped profile. An important nuance: since brick accumulates heat, it is necessary to lay a layer of durable non-flammable insulation at least 5 cm thick between the masonry and wooden walls, securing it with ceramic dowels. Metal ones may not withstand constant heat.

Construction of a brick leaning wall

If the house is heated by a fireplace with a metal firebox, which heats up much less than a masonry fireplace, it is enough to cover the leaning wall with something hard and non-flammable. For example, asbestos. It does an excellent job of protecting wood from heat, and is inexpensive, but its environmental safety is questionable. Disputes about whether asbestos poses a threat to human health have been going on for many years, and experts have not come to a clear conclusion. Most professionals agree that the dust that rises into the air when cutting slab material is harmful. If the asbestos is covered with cladding, the risk is minimal.

A safe (albeit more expensive) alternative to asbestos is vermiculite, a durable and environmentally neutral material that can withstand heat up to 1100°C. It is produced in slabs of different thicknesses, but a layer of 5.5 mm is enough to insulate a fireplace.

To attach heat-insulating boards to a wooden wall, it is best to use heat-resistant ceramic dowels

Finally, you can use mineral wool. To protect a wooden wall, a reinforced one is best suited. Unlike the usual one, which can “slip”, this one will not settle over time. Since the material does not look very presentable, it is usually covered with sheets of plasterboard and covered with tiles. A less labor-intensive finishing option is plastering over a grid followed by painting.

Do not forget that in addition to the walls, you also need to protect the floor from heat. And not only because expensive parquet may suffer. A coal flying out of the firebox can (and often does) lead to a fire if the floor in front of the fireplace is covered with flammable material.

In the case of an open brick fireplace, it is necessary to create a pre-furnace area in front of the firebox - a section of the floor covered with ceramic, porcelain stoneware or stone tiles. Its length must be at least 50 cm, and its width must be 50 cm larger than the fireplace itself (25 cm on each side). By observing these geometric parameters, you can not be afraid that sparks and embers flying from the firebox will fall on the floorboards.

The base for the firebox must be solid and durable. The best option is a reinforced concrete slab

It is not difficult to make a pre-furnace platform in a room with a cement-sand screed. But what if it’s not there? Then, in front of the fireplace vent, a concrete slab about 5 cm thick, reinforced with pins or mesh, is cast over the formwork and left until completely hardened (that is, for 28 days). You can stop there, but a gray monolith on the floor will hardly decorate the room, so it is usually covered with facing tiles. And it is important to lay it so that it is on the same level with the finishing floor covering, so as not to stumble at the junction.

If the room is heated by a compact metal fireplace with a closed firebox, it is much easier to protect the wooden floor. It is enough to place a metal or glass screen on it. By the way, many manufacturers of heating devices offer such accessories.

Fireproof glass

Typically, materials that provide various types of protection are subject to the most severe tests from external factors. Their high technical performance inversely affects the aesthetic appearance. But modern technologies make it possible to achieve a level at which the use of heavy-duty materials is possible not only in technical terms, but also as decorative elements.

Heat-resistant floor glasses have the described characteristics; they are not subject to damage in the form of scratches and retain their integrity when subjected to impact. The maximum permissible pressure is tens of times higher than real conditions. Therefore, they place such glass under the fireplace, directly on a prepared, flat floor surface. It not only supports the weight of the fireplace, but is also resistant to damage from firewood temporarily placed next to the fireplace.

Simple high-tech style

The variety of designs allows you to choose the right glass size for wall-mounted or corner fireplace models. The glass platforms are only 6 mm thick. Thanks to this, there is no need to finish the level transition from the stand to the floor.

Preparation method

Fireplace screens can be manufactured in various ways, which also determines their classification and influences the user’s choice.

There are three main options:

- Welding allows wire or rods, bent in accordance with the sketch, to be turned into a high-quality, reliable fireplace grate. The component elements are intertwined and welded at the points of contact. This method is often chosen for self-production.

- Casting usually involves the use of cast iron. This process is more complex than the previous one, but can be easily implemented at home. Finished products are not very expensive, although practicality and reliability are at a high level.

- Forging is the most difficult method; such products are more expensive. Forging can be hot or cold. The first option is selected for creating bulk orders. The cold method is better for custom orders. It provides more freedom for the master.

Construction of the podium

The idea of insulating the floor from the thermal effects of the firebox can be realized by installing a podium. This is a kind of insert between the floor covering and the fireplace hearth, which is made of brick or a metal profile covered with plasterboard.

Initially, the podium in modern fireplaces was built to imitate an English-style portal. But later it was noted that moving the firebox away from the floor reduces the risk of the floor covering catching fire. And if a closed firebox is used, then we can talk about ensuring the safety of the fireplace. However, open fireboxes still pose a risk of sparks falling beyond the designated limits.

Massive structure in the living room

This protection provided by the podium is somewhat arbitrary, since there are no standards for the height of the structure or the temperature gradient from top to bottom.

Functional

The right fireplace screen is a multifunctional design.

It must perform the following functions:

- Safety is the most important point that should be considered first. An open fire can cause a lot of harm and put the safety of the premises and people’s lives at risk. Moreover, the fireplace is of great interest to children and pets. Any careless action can cause irreversible consequences. A protective fireplace screen serves as a barrier to flames and sparks that come from different directions. The likelihood of a dangerous situation occurring in this case is significantly reduced or even reduced to zero.

- The efficiency of thermal energy use increases significantly. This is facilitated by heating the metal/cast iron of the screen and the further transfer of this heat into the room. This state of affairs turns the protective element into an effective heater.

- Aesthetic beauty is an integral function of fireplace screens. Nowadays they are made from a huge range of materials, decorated in various ways and presented in the most unusual forms. The varieties of these structures will be discussed later in the article. Often it is the screen that is the determining factor for choosing the design and shape of the entire fireplace composition.

Screen decoration

Fireplace screens perform several functions simultaneously. The first and main thing is protection , because even a wood-burning fireplace built according to all the rules carries danger.

The second and no less important function is to increase efficiency. Metal elements heat up during the combustion process and give off heat well, so such dampers are often used in the winter, since they can provide additional heat while spending the same amount of fuel or electricity. This is interesting: the combustion temperature of different types of wood in a stove is in Celsius.

The third function is an aesthetic appearance, because fireplace screens can decorate even the simplest and most unprepossessing design.

The most attractive are glass products that are made in the form of stained glass. They give the interior a vintage look, mystery and magic, and also create beautiful optical effects.

Interesting options for finishing fireplaces (photo)

All the methods described above can be combined to create finishes in different styles. Sometimes it turns out very beautiful. We post some already implemented ideas below.

Very interesting fireplace design

This option will fit into modern styles

Decorating a fireplace with mosaics is especially good on round shapes, where it is very problematic to use other materials.

Combinations of different types of artificial stone with wood fragments

Flagstone finishing of the fireplace portal and exhaust pipe

Combination of plaster and tiles

There are two options to achieve this effect - paint the existing brick fireplace or veneer it with clinker tiles

This is polished porcelain stoneware

This is unpolished porcelain tile, small format. As you can see, it fits well into round shapes. Horizontal surfaces and columns are also porcelain tiles of a similar texture, but in the form of slabs

Designer version of the cap and trim

Cladding a fireplace with stone can also be done outdoors

Terracotta in combination with a wooden shelf that follows the tile relief

Smooth clinker tiles - strictly and functional

This is a Czech stove tile. Mounted on special racks

Majolica looks very decorative

Non-standard design option

Combination of plaster and tiles

Tile inserts - beauty

Connection

A water fireplace can also be made of brick ─ the walls should be double (inner made of metal, outer made of brick), with a coil between the walls. This version of the fireplace requires precise adherence to dimensions and high qualifications; it is difficult to redo such work, so it is risky for a home craftsman to take on the masonry without such experience. It’s easier to buy a metal fireplace and other components of the heating system and use the installation instructions.

Step-by-step instructions for connecting a fireplace:

- Level the floor where the stove is installed and line it with reflective stainless steel underfloor sheets.

- Place the stove on the platform, twisting the legs, and adjust it to the level.

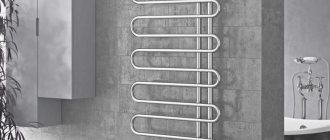

- Install a water heating system with a circulation pump. In some fireplace models, the circulation pump is already built-in. But it is also possible to install it in an open heating system without a circulation pump.

- According to the chosen scheme, a heat exchanger is connected to the heating system.

- Fill the system with water, check its tightness and normal operation of the circulation pump.

- Mount the chimney, connect it to the smoke duct of the fireplace, treat all joints with heat-resistant sealant, duplicate all penetrations with non-combustible materials.

- Test fire the fireplace. At the first attempt, an unpleasant odor may appear due to caking of the paint. Subsequently it will not exist.

- Check the heating of water in the system, adjusting the circulation speed, balance the system with valves on the radiators.

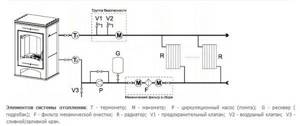

Connection diagram

Insulation options

There are many non-combustible materials that can be used in this case. The easiest way to protect all surfaces from heat is to place a protective box around a red brick heat source. It is able to protect structures from heat and easily tolerates thermal effects. However, this decoration of the wall around the stove in the house looks a little unaesthetic and you can choose other materials:

- Porcelain tiles and tiles.

- Fiber cement boards.

- Factory-made protective screens.

- Metal sheets.

- Artificial or natural stone.

The easiest way to work is with a ready-made protective screen - you just need to select it according to size and install it on site. This option is also good because such finishing of walls near the stove or fireplace is done in the shortest possible time and without “dirty” or “wet” finishing work. The remaining options are more labor-intensive and have some nuances. Therefore, they need to be considered in more detail.

Material selection

Protective partitions can be made of various materials. But most often for their production they use:

- superizol;

- metal;

- mesh;

- glass;

- heat-resistant tiles.

Metal devices can be bronze, copper and iron. Forged products are made in various shapes and sizes, while the screen can be made either as a single piece or have several parts. The products are made in the form of a large or fine mesh, with fire-resistant glass additionally inserted into them.

Glass fireplace screens are the most popular. They are reliable and transparent, which allows you to observe the combustion process. Such structures are made of heat-resistant ceramics or tempered glass. The ceramic material can withstand temperatures up to 750°C, but is not impact resistant. But the hardened version, on the contrary, perfectly withstands blows of any force, but can only withstand 300°C. That is why such material is installed at some distance from the firebox.

Glass fireplace screens are especially popular because they combine protection and beauty.

The grating is often made of superisol and calcium silicate. These products have fairly low thermal conductivity, which is why they are often used in smelting furnaces. Before purchasing, you should check the country of origin. The Germans and Belgians have good, high-quality material, but you shouldn’t take Chinese, because it contains components that, when heated, emit substances hazardous to health. And the material itself has not been fully studied.

Super-insulated elements are very durable. They lend themselves well to painting with fire-resistant paint, so they can always be repainted. In addition, a screen from this material can be easily made independently, and no special tools are required.

Advantages and disadvantages

- easily integrated into an existing heating system, and can also, if necessary, become a full replacement for it;

- multifunctional : used in heating and hot water supply systems, and also, due to its aesthetic appeal, serves as an excellent decoration in the house;

- can be used to heat houses with an area of about 250 m² ;

- due to constant heat removal, the metal of the firebox does not overheat, therefore the thermal fireplace is durable ;

- due to the closed type of firebox, it is a fireproof fireplace , which allows it to be installed anywhere at home;

- the open system does not require electricity connection, therefore it is very economical;

- fuel for thermal fireplaces is affordable and environmentally friendly;

- Some models have cooking capabilities.

- complete lack of automation : lighting the fireplace and adding fuel to it is only possible manually;

- rather low efficiency , which does not allow houses in regions with very low temperatures to be well heated in winter without an additional heating system.

When summing up the results of some economic calculations, it follows that the installation of fireplaces with a water circuit in comparison, for example, with the installation of an electric boiler of the same power, is quite expensive. Such a difference in cost will pay off in the best case within five years, and then only under the condition of permanent residence in the house.

Typically, houses that are built for periodic living in them have small areas and often only the first floor is heated. Installing water fireplaces in such houses is absolutely impractical. Thus, the choice of a water fireplace is justified when installing it as a backup source of heating for large houses and when the electric power is limited to 3 kW.

Parallel use of a thermal fireplace with the main electric or gas boiler will protect you from a complete shutdown of heating in the event of any malfunction with one or another heating device, and will also save more than 35% of fuel.

No. 7. Wood fireplace cladding

Probably, this method of cladding may seem impossible to many, because it is no secret that wood is very afraid of fire. However, if you follow certain rules, you can decorate your home with warm and cozy wood - such a fireplace will look great in living rooms designed in a classic style. Wood is an aesthetic, durable and natural material that has a special aroma. To enjoy these benefits, you will have to meet a number of conditions:

- It is necessary to choose rocks that are as resistant to high temperatures as possible and are not very susceptible to deformation due to constant temperature changes. It is clear that all types of wood, without exception, burn, but those that have a denser structure ignite much later. Oak, hornbeam, maple, and cherry are suitable for finishing a fireplace . Larch has average density, but pine, cedar and linden are not worth considering at all;

- impregnation is required to prevent fire. These are fire retardant-based products that penetrate well into the wood structure;

- It is better to place the tree as far as possible from the hearth . Therefore, consider partially finishing the wood or create a niche for installing the cladding 5-10 cm larger than the brick frame. Then the wood will heat up within acceptable limits;

- In any case, it’s better to cover the firebox protective screento prevent sparks from hitting the wood.

What is a fireplace with a water heating circuit?

A fireplace is a type of heating equipment where heat is generated through the combustion of primary fuel. It can be firewood, coal, pellets. There are gas fireplaces for heating.

Fireplace equipment can be:

- with open and closed fireboxes;

- water and air heating circuits;

- natural and forced air flow;

- built-in and free-standing.

The main distinctive feature of the heating device is the open combustion chamber.

The area of heat generation and the fuel oxidation zone (technological process zone) are combined here, which reduces the percentage of heating of the environment as a result of natural air convection. Most indoor temperatures are raised by radiant energy (IR waves).

The main disadvantage of the above-described heat exchange scheme between the fireplace and the environment is the significant heat loss from the energy combustion products leaving the combustion chamber through a brick chimney. The efficiency of the heating equipment was increased by the built-in water circuit, which is integrated into the wiring of the home heating system. That is, a fireplace with a water heating circuit heats the room both due to the formation of IR waves, and according to the principle of a conventional boiler, heating the coolant in the radiators.

Which is better: a fireplace with a water circuit or with air ducts?

This question cannot be answered unequivocally. The advantages and disadvantages of both systems are based on the characteristics of the heated room and the desired temperature conditions in the rooms.

Heating fireplaces with a water circuit have the following advantages:

- efficiency;

- low cost;

- the fireplace circuit is easily integrated into the existing heating system of the house;

- possibility of preparing hot water;

- low cost of equipment;

- low energy price.

A heating fireplace with a water circuit has disadvantages:

- low efficiency;

- the need for constant energy loading;

- manual mechanism for adjusting the intensity of work.

If we compare fireplaces with open and closed combustion chambers, the efficiency of the first is 20%, and the second is 70%.

An air-heated fireplace is the easiest to make with your own hands, because the equipment is not complicated. The layout of the air channels itself is also easy to organize. The room reaches the desired temperature within a few minutes.

Disadvantages of a fireplace heating system with air ducts:

- constant circulation of dust in the house due to the operation of fans (in the case of forced air circulation);

- increased noise level due to air movement through air ducts;

- the temperature in the room drops just as quickly as it rose after the fireplace went out;

- low efficiency;

- the need for manual control of the combustion reaction;

- the need for constant loading of energy into the firebox.

Heating a house with a fireplace with a water circuit and air ducts can be an excellent alternative source of heat, but not the main one. Such heating elements operate on inexpensive energy. But fireplaces can be afforded by those people who are not too lazy to constantly throw firewood into the firebox, control the intensity of their combustion and periodically clean the chimneys.

What should the fireplace lining be like?

Since there are many options for making a fireplace, it is difficult to name the ideal finishing material . It all depends on a lot of factors :

- fireplace type . The material for a wood-burning fireplace should be selected as carefully as possible, taking into account the constantly exposed high temperature. If you decide to go with an imitation fireplace with candles or an electric version, then the finishing requirements will not be so strict;

- fuel type The combustion temperature of different types of fuel is different, which must be taken into account when analyzing the parameters of finishing materials. For example, if you are going to use firewood, then it is important that the lining can withstand temperatures of about 9000C, but if we are talking about coal, then it is better to take a material that can withstand temperatures of about 11000C;

- installation location . If you are going to install a fireplace on the terrace, then it is important that the material has excellent frost resistance. If used in a heated room, such a requirement is not made. If the fireplace is located in a house where people visit only occasionally, then pay attention to such a parameter as moisture resistance;

- material weight . Material that is too heavy (for example, natural stone) may require strengthening the foundation, which is only possible in a private house and when installed on the ground floor. If it comes to an apartment or the upper floors of a private house, then you should definitely take into account what load the floors can withstand;

- appearance. The purpose of cladding is to decorate the fireplace, so when choosing a material you should take into account its appearance and compliance with the chosen interior style and color scheme.

No. 3. Brick fireplace decoration

This is not even finishing in the traditional sense of the word. In this case, there is no question of installing some kind of facing material on top of the fireplace. The brick from which the fireplace is constructed is finished accordingly. This is both the simplicity and complexity of the method.

If you initially planned not to use any additional facing materials, then when laying the fireplace, the mortar must be laid so that 5-7 mm remains to the outer edge of the brick. Later this void will be filled with decorative grout. If the fireplace has already been built, then you can grout the joints in order to subsequently use grout of a certain color. The brick can be left untouched, but can be sanded or chamfered. Such work should be performed by an experienced specialist. Not every stove maker is ready to take on this, so it’s better not to do this type of cladding yourself . Brick can be treated with hydrochloric acid solution - this will give the material a more saturated color.

There is a more standard way. This is finishing with ceramic facing bricks . The material can withstand high temperatures, looks great and expands the possibilities of decoration. The masonry is not much different from the laying of ordinary bricks. True, you will have to ensure that the seams are even (as is the case with tiles), and then seal them with heat-resistant mastic.

How to connect a fireplace with a water circuit

The schematic diagram for connecting a fireplace with a water circuit includes:

- The fireplace itself, which can be installed both in the basement and on the upper floors of the house.

- A container with water (hydraulic accumulator, heat accumulator), which is installed in the technical room.

- The hydraulic accumulator also has a coil into which the heated coolant enters.

- Radiators and a hot water supply system, which receives water heated in a hydraulic accumulator.

However, depending on the location and type of expansion tank, the installation diagram may differ slightly and be:

In an open system, the expansion tank is located at the highest point of the house, which means that water enters the heat exchanger due to gravitational forces. Excess expanded heated water flows back into the tank, which prevents some emergency situations. The coolant is heated in a coil, which is located in the open boiler head of the firebox. This installation system is very simple and does not require the installation of additional electrical appliances for its operation, however, it will not be able to heat a large area for a number of reasons:

- loss of specific gravity by heated water;

- high hydraulic resistance of pipes

Much more often than an open system, a closed system is used, in which the coolant from a membrane-type expansion tank enters a heat exchanger located in a closed boiler part. heated to 80-90 degrees moves directly through the operation of the circulation pump into the storage boiler, and then directly into the heating system. If heat transfer stops, water may boil, which will stop the power supply and, therefore, the operation of the circulation pumps.

Thus, the pressure in the fireplace system will greatly increase, which can lead to its failure. In order to prevent water overheating, an additional coil is installed in the rear part of the firebox, into which cold water is supplied if necessary. Also, a thermal protection sensor is placed in the water jacket of the firebox, which is triggered when the permissible temperature is exceeded, including draining water into the sewer.

Is it effective to use fireplaces in the home?

Any fireplace is, first of all, a decorative element of the interior, which, thanks to modern developments, can effectively participate in heating rooms. Thus, heating a house with a fireplace with an air duct has a simple structure and an equally simple operating principle, and therefore is inexpensive. However, the low efficiency of the circuit sometimes calls into question the entire feasibility of erecting such a structure.

The operating principle of a fireplace with a water circuit, as well as the structure of the heating element itself, is more complex than the previous version, which explains the high cost of both equipment and installation work. However, the efficiency of 70% of fireplaces with a water circuit makes this equipment an excellent alternative source of heat in the house when the main heating element (boiler) is turned off. This video will help you figure out how to properly install a fireplace with a water circuit:

SUBSCRIBE to OUR YouTube channel Ekonet.ru, which allows you to watch online, download free videos from YouTube about human health and rejuvenation. Love for others and for yourself, as a feeling of high vibrations, is an important factor in healing – econet.ru.

Please LIKE and share with your FRIENDS!

Did you like the article? Then support us, click

:

A fireplace in a home is a symbol of coziness and spiritual comfort, but an ordinary fireplace is not enough to fully heat a room. For this purpose, a water fireplace works perfectly, with which it is convenient and safe to heat the room, while maintaining all the advantages of a traditional fireplace for the interior of the house.

A fireplace stove with a water circuit is a reliable way to combine safety, warmth and aesthetic parameters of your home. According to the technical structure, a water fireplace is a boiler that runs on solid fuel, and advantageously combines the beauty of a traditional fireplace and the possibility of combined heating of the room, both with an open flame and with the heat that previously went into the chimney.