Description of raw materials

Pellets are pellets made from wood waste.

Pellets are wood pellets processed with a special material. Essentially they are wood processing waste. Pellets are environmentally friendly natural raw materials, which do not contain hazardous chemicals and compounds. They are non-toxic and safe for health and the environment.

The best raw materials for making pellets are sawdust, cuttings, shavings, slabs, wood flour and other waste. Depending on the type of wood, the granules can be white, black, or gray. Farmers can create pellets from hay, sunflower husks, reeds, rice husks and other agricultural waste. Their processing is not difficult and does not require special equipment. You can also produce pellets from peat. This is a more expensive process, as it requires special equipment and good resources.

The main parameters include:

- Ash content. The lower it is, the better for the boiler - it does not require frequent cleaning.

- Humidity. The amount of water in pellets is about 60.

- Total length of granules.

- Density.

- Bulk mass.

- Abrasion class.

Properties also depend on the rock from which the fuel is made.

What are fuel pellets?

One of the characteristics of fuel pellets is the amount of thermal energy released

Fuel pellets began to be produced in 1947. These were granules of a certain size, usually ranging from four to ten millimeters in diameter and one to five centimeters in length. They consist of waste from wood production, agriculture and as processing of independent plant raw materials. Industrial boilers and home heating systems are the main consumers of fuel pellets.

The raw materials for their production are environmentally friendly products, namely agricultural and woodworking waste. Due to the good flammable properties of these materials, and the constant need for their disposal, the industry received its main impetus for development.

Manufacturing technology

The main point of production is to dry and extract wood waste to a certain fraction under a pressure of 300 atmospheres. The use of glue and other fastening additives is prohibited.

The following equipment is required for production:

- Crushers. Allows you to grind raw materials to a certain fraction.

- Dryer. Reduces moisture level to a specified level.

- Hammer mills, flakers or disintegrators. Allows you to obtain fractions up to 4 mm in size.

- Screw mixers.

- Presses.

Production stages:

- Drying the rock to a certain percentage of moisture. The value is preset. High-quality fuel contains a minimum of liquid, making home heating more efficient.

- Grinding. The raw material is sent to a crusher, where it is crushed to a given fraction.

- Pressing. The pellets are sent to a granulator press, which collects them into granules. This process is also called pelletization. For pressing, special stamps and molds are used.

- Cooling.

- Packing and sending to the consumer.

Also, before pressing, additional grinding and water treatment can be carried out. It depends on the type and quality of raw materials.

When the cooling process is completed, small particles are sifted and sent for recycling. This makes production virtually waste-free.

On average, the production of one ton of pellets requires about three to five cubic meters of wood. Compaction occurs three times. To prepare one ton of fuel will require about 30-50 kWh of energy.

Benefits of pellets

The characteristics of the fuel make it possible to improve the heating process, making it more efficient.

The positive qualities of raw materials include:

- Environmentally friendly. Pellets are made from natural materials, so they are safe for the environment and human health.

- Price. Pellets are more expensive than firewood, but their price is lower than that of other types of fuel.

- Low ash content. During the season, the average ash formation is 20 kg.

- Possibility of recycling ash.

- Simplicity and ease of storage.

- High efficiency of a pellet-powered installation. High thermal conductivity.

- No combustion control required.

- Depending on the stove model, the fuel supply may be enough for the entire season.

The only disadvantage is the higher price than that of firewood. Equipment powered by this type of raw material requires more complex maintenance, which increases the cost of use.

Poor quality pellets

It is very rare when it is cheap, high quality and safe at the same time. Using pellets that were purchased at a low price compared to competitors and of poor quality can lead to dire consequences.

The consumption of poor quality wood pellets is much higher due to their low heat transfer and hardness. A product with a high ash content, after combustion, forms a lot of waste in the boiler in the form of sand and earth. Consequently, the boiler will need to be cleaned more often than usual, and it is possible that inexpensive fuel can quickly damage the device.

Difference from firewood

Both types of fuel are produced from the same materials. But their combustion process is different. This is due to the fact that the firewood is more humid, which is why some of the energy is spent on evaporation of moisture. Only after this does combustion occur. It also contains ash, which is non-combustible ash. Pellets consist of the same parts, but in different proportions. They contain about 5% water, so it will take less time to evaporate, all the energy will be spent on heating.

The density of pellet granules is higher than that of firewood. For this reason, fewer of them are required for heating. When burning 1600 kg of wood, the same amount of heat is released as when using 1000 kg of pellets.

Press lines for pellet production

There are a great many offers on the market of various lines and installations used for the production of pellets. From huge multi-ton lines to installations for personal use weighing a couple of tens of kilograms. Many of them are so simple that, using the technical solution included in the design, you can make a granulator for the production of pellets with your own hands with good characteristics.

The standard device of a powerful installation is a structure of two thick-walled steel drums mounted on a powerful steel frame. The drums have a common line of contact and rotate in different directions. On the surface of the working drums there are holes through which the granules themselves are squeezed out and formed.

In simpler and more affordable versions of the granulator, it is possible to use two roller runners rolling on the surface of a perforated disk. The runners are rotated by a geared motor and, using their weight and clamping force, force the raw material through holes in the disc, similar to making pasta.

A small design will allow you to produce from 30 to 100 kg of pellets per day, which will allow you to prepare sufficient quantities of fuel pellets with your own hands for the winter using cheap available raw materials. The characteristics of such fuel are somewhat worse than industrially produced pellets, but only in the strength of the granule. They burn no worse.

Fuel consumption

Raw materials are sold in bags with a specific volume. This allows you to simplify the calculations of the required number of pellets per 1 sq.m. and 1 kW of energy. It is possible to correctly calculate pellet heating in several steps, as a result of which the user will receive monthly fuel consumption for heating and will be able to find out the average cost.

First you need to find out how much heat is generated by 1 kg of granules. Part of the energy is sent into the chimney pipe. As a result, the heat of combustion of the particles is multiplied by the efficiency of the generator.

To generate 1 kW of energy, a certain amount of fuel is required. To do this, you need to divide 1 kW by the resulting amount of heat.

On average, to heat a house with an area of 100 sq.m. approximately 5 kW of energy per hour is required. The heat consumption per day is 5 kW * 24 hours = 120 kW. In a month you get 120 kW * 30 days = 3600 kW. This value is multiplied by the calorific value and the weight of pellets that will be used per month is obtained.

From these values you can find out the daily flow rate and other values for any area.

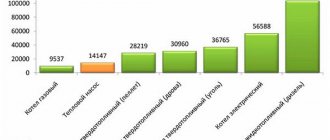

Characteristics of heating costs with pellets

The average daily consumption rate will be up to 60 kg; within 6 months you will spend about 10 tons of pellets, which, with an average ceiling price of 3,600 rubles per ton, will be at least 36 thousand. For comparison: heating with coal briquettes or coal will cost approximately 20-22 thousand rubles; when using gas, heating will increase in price by 15%. The calorific characteristics of pellets are clearly inferior.

In addition, for productive combustion and use of heat, a special pellet boiler is needed; with fittings and control systems, it will cost at least 1300-1400 dollars. In fact, this is the price of a two-year supply of pellets.

In the wake of popularity, many Western manufacturers decided to occupy the niche of boilers using fuel pellets and more advanced characteristics. Boiler-fireplaces are now becoming the most popular, allowing installation even in high-rise apartments.

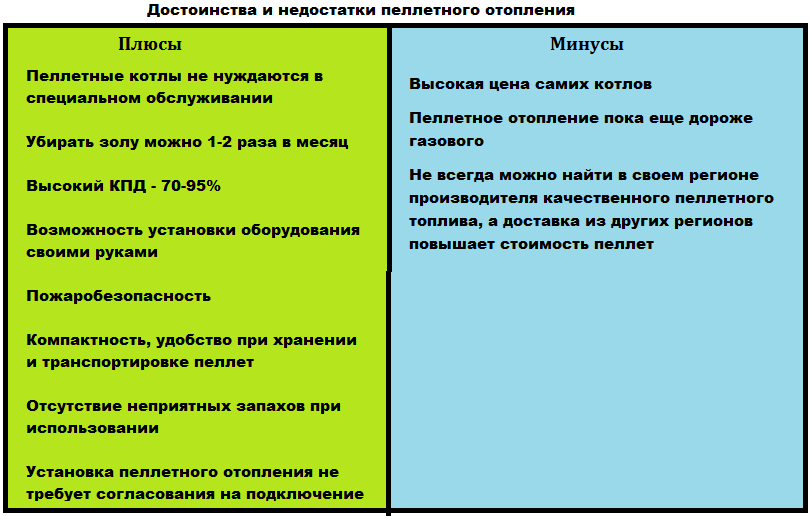

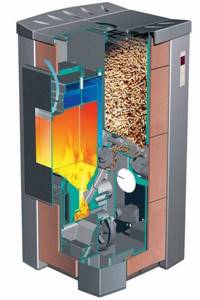

Features of pellet boilers

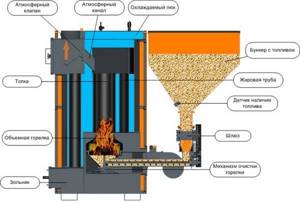

Boilers operating on pellets are characterized by increased efficiency and high cost. The design of such a device has the following components:

- Compartment. Pellets for heating are placed in it. There is built-in and external.

- Pellet feeding mechanism. Screw and pneumatic systems are used.

- Automatic ignition module. There are lambda probes, local line control systems, GSM, monitoring via the Internet.

- Burner. There are different types - torch, fireplace, volumetric combustion. They differ in the principle of action, shape and temperature conditions.

- Sensor control module. Sensors are responsible for maintaining temperature conditions.

Thanks to the presence of well-thought-out and high-quality automation, pellet boilers are popular. This allows them to be conveniently operated without the need for constant monitoring.

The operating features of the device directly depend on the quality of the granules. When buying cheap fuel, there is a risk of deterioration in the functioning of the boiler. Technology depends on electrical energy, failures of which also lead to difficulties in operation. The average service life is 20 years or more.

The main disadvantage of pellet boilers is the high cost of equipment and maintenance.

Recommendations from experts

If you want to purchase a pellet boiler, you should study the opinion of professionals. High-quality devices are ways to heat and provide hot water to an entire building.

Basic tips:

- The boiler requires periodic cleaning, otherwise its efficiency decreases. It is also important to add granules to the hopper in a timely manner and check the draft in the chimney pipe.

- Pellets are stored in a dry room in a house or outbuilding.

- When choosing fuel, you need to pay attention to the dimensions. The average length does not exceed 50 mm, diameter is about 6 mm. Elements must be smooth.

- When making your own fuel, you should find out in advance what equipment you can use to make it. Rice husk requires serious costs and effort due to the presence of silicon in the composition, which leads to rapid wear of equipment.

- A high-quality pellet boiler requires financial costs. Its price cannot be low due to the materials and manufacturing technology. It is important to buy equipment in a specialized store and choose equipment from well-known, trusted brands.

There are pellet fireplaces. This device uses fire-resistant safety glass, which prevents fire from escaping into the room. The selection criteria are the same as for the boiler, plus the style of the device itself.

Quality requirements

The main requirements for the quality of fuel pellets are:

- The granule should be even and smooth.

- No cracks in the granules, no warping or shedding.

- The granule should be tightly compressed.

- The finished product must have the correct percentage of moisture (it should not exceed 15%).

- It is desirable that the pellets be the same size (mainly manufacturers make fuel pellets from 5 mm to 70 mm in length, and from 6 mm to 10 mm in diameter) regardless of the type of fuel pellet.

- The absence or minimum content of impurities (dust, sand) in the finished product, which deteriorate the quality of pellets.

- Color. For wood fuel pellets, it should be light (lighter is higher quality), since the fewer dark or brown inclusions in the pellet, the less bark and impurities it contains. In peat and plant granules it is dark gray or black.

- There should be no fungus or mold on the pellets.

- There should be no chemicals.