Comparative characteristics of fuel types

First, about the price of energy resources. The table shows the cost of fuel at Moscow prices:

| Raw materials for pellets | Cost from 20 tons with shipment from warehouse | Price from 1 ton with shipment from warehouse |

| Sunflower husk pellets | From $50 (3300 rub.) per 1 ton | From $70 (4500 rub.) per 1 ton |

| Wood light pellets from 6 mm | From $100 (6500 rub.) per 1 ton | From $105 (6800 rub.) per 1 ton |

| Wood light pellets from 8 mm | From $95 (6000 rub.) per 1 ton | From $100 (6500 rub.) per 1 ton |

| Birch briquettes | From $90 (5800 rub.) per 1 ton | From $95 (6000 rub.) per 1 ton. |

Comparative characteristics of fuel costs:

The use of granular energy carriers is noticeably more profitable than the use of traditional types of raw materials. However, the costs of maintaining the equipment will be higher, but this figure is offset by savings when purchasing briquetted raw materials.

What are pellets and their types

Pellets or fuel granules are an environmentally friendly type of fuel that is used for heating private houses, cottages, and industrial enterprises.

Boilers operating on this fuel are very easy to install and operate. Thanks to automatic adjustment of the heating process, there is no need to constantly monitor the operation of the units.

Such boilers are divided into two types: with an external burner (used for heating industrial buildings), with an integrated burner (for private houses).

Pellets have gained the greatest popularity in Western Europe and North America. However, recently many Russian users also prefer this type of fuel.

Various materials can be used as raw materials for the production of pellets, therefore, based on this, the following types are distinguished:

- wood (most often used);

- coal;

- peat;

- made of straw;

- from corn waste;

- from peat;

- from husks;

- from chicken manure;

- from solid household waste, etc.

Sunflower husk pellets

Wood is considered the highest quality raw material. For example, high efficiency is observed in units operating on pine pellets. This fuel does not crumble into powder, which is very convenient for transportation.

For domestic boilers you should not choose: fuel pellets from other raw materials (except wood); granules that were created using chemical glue (during combustion, such fuel can release toxic gases); low-quality pellets with the addition of soil or sand (slag may remain on the walls of the combustion chamber). All of the above types of fuel pellets will reduce the performance and service life of boiler equipment.

White oak pellets

Another classification of pellets is based on their grade. According to this criterion, the following are distinguished:

- White pellets. Premium fuel: high-quality raw materials are used for its production. Compared to other types of varieties, the price of white granules is much higher. The raw materials are sawdust from beech, oak and other hardwood trees.

- Dark (industrial) pellets. The granules are dark in color due to the addition of tree bark. This type of fuel is characterized by high productivity and the release of large amounts of heat. However, such fuel pellets also have a drawback: the ash content is quite high - 0.7% and higher. The price is slightly lower than the previous ones.

- Agropellets (dark color). To produce such fuel, sunflower and buckwheat husks are used. Ash content - from 3% and above, low calorific value. Agropellets are inexpensive and act as fuel for industrial boilers.

Table of comparative characteristics of buckwheat and wood pellets.

| Type of fuel | Heat of combustion, kcal/kg | Average price, $/t |

| Buckwheat husk pellets | 4300 | 115 |

| Wood pellets | 4500-5000 | 150-180 |

Advantages and disadvantages of pellet boilers.

When choosing fuel pellets for the heating system of a private home, you need to pay attention to the following parameters:

- Before purchasing fuel, make sure that the product has a quality certificate. The most preferred pellets are those that meet the European standards EnPlus, DinPlus;

- calorific value is the second important indicator. It is recommended to choose pellets with calorific value from 4000 kcal/kg;

- ash content - it should not exceed 1%;

- humidity - this indicator should vary from 8 to 14%.

All these criteria have a direct impact on the performance and efficiency of the boiler.

The quality of pellets can be determined based on their appearance. Good fuel will be smooth, without cracks or damage. It should also be strong enough and not crumble under your hands. Color does not affect quality in any way.

Rules for selecting and determining the quality of granular energy carriers

The quality of the pellets affects the cost of pellets; on average, pine fuel is estimated at $90 (6,200 rubles) per 1 ton, peat briquetted pellets from $85 (5,700 rubles) per thousand kilograms. Also, the cost may depend on the prevalence and availability of a particular raw material, but on average the difference does not amount to more than 500 rubles.

Selecting quality raw materials is the main task of the owner. The better the granular fuel, the higher the functionality of the heating system and all equipment.

To distinguish good fuel from bad, you need to pay attention to some nuances:

- Presence of dust. If there is a lot of dust in a bag of pellets, the pellets are overdried, so they crumble and crumble - this is a minus. Chips, defects and dents on briquettes also indicate poor quality of the product.

- Uneven color. The shade should be uniform without obvious areas of lightening or darkening. If the granules have taken on a gray tint, are swollen or cracked, they have been lying around for a long time and have lost some of their beneficial properties.

- Size. European standard length 25 mm. Small deviations in the direction of increase and decrease are allowed; this does not affect the overall quality of combustion.

- Smell. The fuel must have the aroma of raw materials with a hint of sweetness, which appears during the drying and processing process. The smells of rot, burning, chemicals are a minus.

You can check the purity of the raw materials just by smell - sunflower pellets smell like oil, wood - sawdust, peat - smoke.

Classification of granular fuel

The technological map of classes divides energy carriers into the following types:

- White. They are made from high-quality dried wood, cleared of bark. High class fuel with low ash content (up to 0.5%) is used in any solid fuel boilers. Heat transfer averages 17.2 megajoules (MJ) per 1 kg of raw materials. Clean the ash pan chamber no more than once every 4-6 weeks.

- Industrial. The raw material mass may contain dust, grant, bark and other impurities. Increased ash content, heat production 7.2 MJ/1kg. The ash pan needs to be cleaned once every 3-5 days; exact data on boiler maintenance is prescribed in the accompanying technical documents for the fuel.

- Agropellets. Classified as standard, the raw materials are sunflower and buckwheat husks. Dark color, reduced thermal efficiency (up to 15 MJ/1 kg), high ash content - disadvantages. The fuel is inexpensive, so it is often used in boilers with automatic cleaning in industrial regions where pellets are more accessible. Fuel is also used for home systems, but the ash pan will have to be cleaned daily.

Advice! When choosing pellet heating, you need to pay attention to the availability of fuel. In regions with extensive agricultural land, agropellets are cheaper, and in areas with peat bogs it is more convenient to buy granulated peat raw materials.

Pros and cons of pellet heating

Heating with pellets has many advantages compared to other types of solid fuel, including:

- equipment independence from connection to standard energy sources (provides autonomous heating for a private home);

- environmentally friendly raw materials (the fuel contains no chemical additives, and a sufficient amount of carbon dioxide is released);

- availability of fuel for use (installation of pellet equipment can be quite expensive, but the pellets themselves have a low price, which will affect the reduction in the price of the heating season);

- high level of heat transfer (the efficiency of pellets can reach 94%, which significantly exceeds the rate of wood use);

- automatic fuel supply to the system;

- simplicity, both in transportation of raw materials and in their storage.

The only drawback of pellet heating is the high purchase price of the boiler . But over the years, this drawback will be covered by a significant reduction in the monetary costs of purchasing pellets.

Thus, this choice will be a good investment in the heating system of a private home.

Characteristics and features of pellets

Defining what pellets are, we can describe the product as waste from industrial processes of wood processing, processing of coal, peat, and agricultural crops. Briquettes are formed under pressure of more than 300 atmospheres at high temperatures.

The raw materials are mixed, processed, passed through molds, resulting in capsules or granules. Gluing particles does not require the use of artificial adhesives, natural lignin is sufficient, so heating a house with pellets is the cleanest and safest from an environmental point of view. The thickness of the granules can be 6-10 mm, length 20-30 mm. The peculiarity of using pellets is their increased thermal efficiency. Compared to other types of raw materials, 1000 kg of pellets will replace 500 kg of diesel, 480 m3 of gas, 1600 kg of firewood.

On a note! The property of 100% combustion and low ash content will help you make a choice in favor of pellets. The price of raw materials is higher than that of firewood, but when choosing sawn birch firewood, pellets turn out to be more profitable, even if you take wooden pallets for heating of the highest class of cleanliness.

Some manufacturers produce granules from solid waste. Granules are very cheap, do not differ in thermal efficiency, but are suitable as a reserve supply for heating a house during the off-season or late spring frosts.

Weather thermostat for heating boiler control

Comparison of pellets and coal

Having briefly familiarized yourself with the description and characteristics of the two types of solid fuel, you can move on to studying information that will allow you to answer the question - pellets or coal, which is better? One of the most important characteristics for any combustible energy source is its calorific value, which is where the comparison begins. For pellets and coal, this figure is almost the same and amounts to 4.8 kWh/kg. However, it is worth noting that we are talking about high-quality pellets made from hardwood and high-quality coal. In turn, the calorific value of pellets made from agricultural waste will be slightly worse.

Another important characteristic for any type of solid fuel is its cost - due to the high consumption during the heating season, any buyer pays close attention to it. In this review, we will not give prices for coal and pellets, as they often change and depend on the number of offers on the market. Regarding this issue, it is only worth noting that if previously fuel pellets were somewhat more expensive than coal, at the moment the situation has changed dramatically

Now a ton of high-quality wood pellets is equal in price and has even become cheaper than a ton of the same high-quality anthracite

Regarding this issue, it is only worth noting that if previously fuel pellets were somewhat more expensive than coal, at the moment the situation has changed dramatically. Now a ton of high-quality wood pellets has become equal in price and has even become cheaper than a ton of the same high-quality anthracite.

Next, we move on to comparing the performance characteristics of coal and pellets. The ease of use of both types of fuel differs significantly. Owners of coal boilers need to constantly add rock to their firebox, and also constantly clean the heat generators from accumulating ash. And its level in some types of black fuel can reach 50%. Also, coal dust tends to eat into the ceilings and walls of the room, so a boiler room of this type will always be very dirty. In addition, we should not forget about the harmful chemical compounds that will be constantly released into the atmosphere during the combustion of such fuel.

As for wood pellets, they are much more practical and easy to use. An extremely important fact is that pellet boilers are fully automated. Such heat generators are equipped with a special tank containing a supply of mini-briquettes, which are independently fed into the firebox. Since very little ash remains after the combustion of the pellets, this type of boiler will have to be cleaned very rarely - only a few times per season. And the resulting ash can be used as organic fertilizer. In addition, the operating efficiency of pellet heaters is higher than that of their coal counterparts. An additional advantage of the granules is their organic origin, due to which during the combustion process they do not emit substances hazardous to the environment.

Taking into account the above information, it becomes quite obvious the answer to the question - coal or pellets, which fuel is better? Good quality wood pellets are truly superior to charcoal in most respects as well as ease of use. The high efficiency and practicality of pellets is also confirmed by the fact that in some European countries about half of all households are heated with such fuel.

Pellet production

In order for the finished fuel to meet quality parameters, the raw material goes through several stages of processing:

- Splitting up. Grinding the waste helps to make the mass homogeneous, from which fine-grained granules no larger than 2x25x25 mm in size will then be made. This size is more convenient and dries faster.

- Drying. Residual humidity should be no more than 10%.

- Grinding. A hammer mill is used to crush the raw material into granules sized 4 mm.

- Hydration. To saturate the mass with moisture, a screw mixer is used.

- Pressing. The type of press used depends on the type of raw material. After pressing, the mass is passed through a sieve and then trimmed with a knife. The process is carried out at temperatures up to +100 C. An increase in temperature is unacceptable so that the pellets do not lose their combustible properties and burn well.

- Cooling down. Packing. These are the final stages of production, after which the fuel goes on sale.

Despite the lengthy processing process, the cost of pellets for heating remains low, which explains the popularity of the raw material.

Pellet boilers and fireplaces

Special equipment is produced for the combustion of granular briquettes; it is not recommended to burn fuel in conventional solid fuel boilers. Pellet boilers, like fireplaces, have their own characteristics and characteristics.

Fireplaces for burning pellets

They are used as an additional heating source for rooms with an area of no more than 25 m2.

The average power level is 6-15 kW, fireplaces differ:

- convection type, heating the air;

- supplemented with a DHW circuit, they heat the air and serve to distribute hot water;

- combined (universal) for heating water and air.

Advice! When choosing a combined fireplace, the owner can heat it not only with pellets, but also with wood, briquetted fuel of various types.

Solid fuel pellet boilers

These are pellet heating systems with a power of up to 100 kW, which can be installed in large houses equipped with water mains or underfloor heating circuits. Due to the high flammability of pellets, boilers are installed in a basement or a separate room - the boiler room must be equipped in accordance with safety requirements.

The thermal efficiency of boilers depends on the type of equipment; there are also devices on sale that can burn only granular fuel, firewood and briquettes, and universal units that burn any type of fuel.

Advice! All parameters of boilers are indicated in the technical data sheet of the device; universal types of equipment with a circuit for DHW distribution are more expensive, but are considered more economical and profitable.

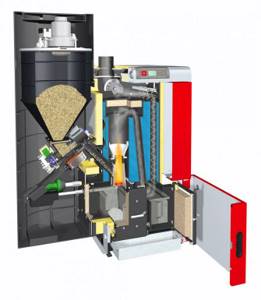

Operating principle and design of pellet combustion boilers

The difference between pellet boilers and standard solid fuel boilers is the small size of the combustion chamber. Reduced volumes are needed because all processes take place in the convection compartment of the equipment.

The principle of operation is standard - a special type of burner with increased efficiency ignites the fuel, during the combustion process heat is released, which warms up the water, the coolant is sent to heating appliances and pipes in the house, giving off energy to the air.

On a note! Pellet boilers last at least 20 years and are always equipped with an automatic control system that can completely eliminate human intervention. Boilers with a power of 20-100 kW are suitable for home systems; if you need less heat, it is more profitable to install a fireplace.

To calculate the boiler power rate, the formula is used for 10 m2 of area 1 kW of heat plus 15%. The additional reserve may be greater if the house is located in regions with a harsh climate, is not insufficiently insulated, or has large windows. Fireplaces with a power of 15 kW are used for heating houses up to 100 m2 only when the heating system circuit is connected. But most often, for houses from 25 m2, boilers are used, fireplaces are used for local heating of rooms or as an alternative heat source with the possibility of distributing hot water.

Types and production of pressed fuel briquettes from peat

The principle of operation of boilers for heating a house using pellets

Pellets are used as the main source of energy for heating devices of this design. This is pressed waste from the wood processing industry (chips, shavings, sawdust, etc.). They look like granules up to 7 cm long and up to 10 mm in diameter. As a result of burning 1 kg of pellets, 5.2 kW of thermal energy is released. The combustion reaction in boilers occurs using a burner.

Types of burners for pellet heating boilers

Today, two main types of burners for pellet heating devices enjoy consumer recognition:

- retort burners. They are a bowl (cast iron or steel, heat-resistant), on the surface of which the combustion reaction occurs. Fuel is supplied from the loading hopper using a screw device to the middle of the retort burner. This is where primary air is supplied. It supports the combustion reaction by blowing fuel from below, and prevents the burner itself from heating up to a critical temperature. Secondary air is supplied to the combustion chamber through special openings in the boiler structure. It regulates the intensity of pellet combustion. Retort burners can be movable (designed for burning high-ash and high-dust energy carriers) and stationary (designed for using prepared raw materials - fine coal, pellets);

- grate burners. In boilers with this type of burner, pellets are fed through a chute from the loading hopper under the influence of their own weight onto cast iron or steel grates. Primary air is supplied from the bottom of the grate, which supports the combustion reaction of the pellets and prevents the grate from overheating. Combustion products - ash - are removed through holes in the grate and collected in the bottom drawer of the boiler. Grate burners can be movable or fixed.

Advantages and disadvantages of pellet heating

The benefits include:

- lack of regular maintenance;

- there are no unpleasant odors during the combustion process;

- 100% combustion of raw materials;

- high efficiency;

- ease of transportation, ease of storage, storage of raw materials;

- the ability to connect a DHW circuit - this is available in almost all boilers;

- easy installation.

To find out the calorie content of pellets for heating, you need to look at the technical documentation. For wood pellets, heat transfer is considered to be the highest, for pellets from solid waste – the lowest. Bags or sacks of briquettes should be stored in a ventilated area protected from water.

Minuses:

- High price of boilers. The equipment costs much more than gas or solid fuel boilers.

- You need to clean it from ash, but it all depends on the type of boiler. Cleaning frequency – no more than 2 times a week.

- Gas equipment is cheaper, and you also need to take into account possible interruptions in the supply of pellets, especially if there are no raw material producers in the region.

Important! High-quality boilers from foreign manufacturers do not always withstand pressure surges and equipment operation at maximum speed. It is much more profitable to take domestic products adapted to the conditions of the regions.

How to make pellets with your own hands?

Pellet heating can be cheap if the farm has a lot of raw materials.

The owner will be able to make granules himself, having previously purchased special equipment:

- a crusher for sawdust, but not husks - this raw material is sold in already crushed form;

- drum dryer - it can be made from an old barrel;

- secondary crusher;

- granulator equipped with a flat or cylindrical matrix.

Important! If you buy a granulator with a flat matrix, then crushers are not needed. The entire crushing process will be carried out in the granulator.

You can make the device yourself; a video from professionals will help you understand the nuances.

To organize fuel production, raw materials must be properly prepared. The mass must be clean, sifted from impurities with a moisture content of no more than 12%. If the raw material does not contain resin or lignins, then the granules do not stick together well. A drum should be used to dry finished briquettes and pellets. And the process of making fuel depends on the type of feedstock.

Sawdust

Production stages:

- Dry the crushed mass thoroughly. The humidity indicator is no more than 12%.

- Sift through the sawdust, remove foreign particles and impurities.

- Grind the mass with a hammer mill, if after the raw material is released the moisture content is less than 8%, treat with wet steam.

- Pass the raw material through a granulator, form granules, and cool.

- To wrap up.

The fuel is ready. Store in a ventilated shed with a roof.

Straw

Straw burns well, produces a lot of heat, but also a lot of ash. But the raw material is considered the cheapest, which is why straw is often used as a main or additional component in the production of pellets. For crushing, you will need a large crusher into which you can load dried straw or chopped reeds. Additional equipment - as in the example with sawdust; The fuel is suitable for stoves and fireplaces.

Peat

The raw material must be dried under natural conditions, then the ground mass must be cleaned of impurities, plant roots and other components. Grind the raw materials, dry until the moisture content is within 12%, then grind again. Pass the finished substance through a press and be sure to douse it with hot steam. After this, the pellets are dried and stored.

Peat pellets can be used not only for heating a home, but also as a fertilizer or component for purifying water from oil residues and petroleum products.

What are pellets?

For centuries, only firewood was used as fuel, but nowadays a large number of different energy sources have appeared, but more and more people are returning to the roots and prefer to use biofuel, that is, fuel from plant or animal raw materials. Pellets are one of the types of environmentally friendly fuel. We will tell you more about what pellets are, where they are used, and how to make this miracle fuel yourself below.

Advantages of pellets, their application and production

Pellets are a type of biofuel that is compressed granules from peat, wood products or agricultural waste. With a diameter of 4 to 10 millimeters and a length of 2 to 5 centimeters, depending on the size, they can be in the form of cylinders or briquettes. The raw materials most often used are sawdust, shavings, bark, sunflower husks and more.

As a rule, processed products are used as raw materials, which are usually simply thrown away. Sawdust and other wood waste in landfills begin to rot over time and can spontaneously ignite. Using this waste to make fuel pellets not only allows for waste-free production, but also eliminates the need to cut down forests. Unlike natural gas or oil, the raw material for fuel pellets is renewable.

No additional chemical additives, thickeners or adhesives are used in production. The gluing of the granule is ensured by the substance contained in the initial raw material - lignin; it heats up during pressing and holds the granule together.

- If coarse raw materials such as peat or pulpwood are used, they are crushed to a particle size of 3-5 cm.

How to make pellets yourself at home

To make your own fuel pellets you will need:

Coarse crusher;

The use of sawdust as a raw material eliminates the need for crushers, since they have the required original size. You can make a drying chamber yourself from a metal barrel. A sieve is necessary to exclude from the raw materials all large and foreign impurities that will negatively affect the quality of the finished product.