The main differences between cast iron stoves and steel ones

Initially, the parents of both cast iron and steel were iron ore, coke and high temperature.

In a blast furnace, through complex redox reactions, these components produce cast iron, the main product of blast furnace production. Cast iron has a high carbon content in the total mass, relatively large, since it is more than 2% of the total mass. Steel is born a little differently; to obtain it, cast iron is placed in an open-hearth furnace, where, under the influence of high temperatures, carbon is burned out and an alloy is obtained, which contains less than 2% carbon. The resulting material is steel. This difference of a few tenths of a percent of carbon content determines the properties of the material. Cast iron with a high carbon content easily tolerates high temperatures, but cracks when there is a sharp change in temperature. Steel, on the contrary, easily tolerates temperature changes and cooling of a separate zone of the sheet, but often deforms when heated at high temperatures. Cast iron easily withstands high pressure, it is massive and durable, but with a sharp impact it can collapse. Steel, on the contrary, has plasticity at high pressure, but is absolutely not afraid of impacts.

Another difference between these materials is the method of connecting structural parts - steel is welded using gas or electric welding. And cast iron parts are obtained either by casting or by joining with steel ties.

And of course, the qualities that are important for a sauna stove are manifested in cast iron and steel:

- Steel heats up quickly and cools down just as quickly;

- Cast iron, on the contrary, has a relatively long heating period, but its heat capacity is such that it gives off heat for a long time, thus maintaining a comfortable temperature in the steam room;

- A stove with steel walls quickly burns out, while cast iron sauna stoves retain their integrity for a long time;

- The weight of a cast iron stove of the same size is greater, since the minimum thickness of the device wall is 10 mm, while a steel device has a wall thickness of 3-4 mm.

The best material for a sauna stove

The material from which the sauna stove is made is very important.

If you plan to install a metal stove, then the choice is mainly between two types of metal - steel or cast iron. You can, of course, opt for a brick oven. However, such a stove requires special knowledge in care, and this option is not cheap at all. In addition, it is not easy to find a really good craftsman who will install a stove today. Professionals are often busy, and you don’t want to turn to untested specialists. The market for metal sauna stoves today is quite diverse, but the main choice is between steel and cast iron stoves.

Both steel and cast iron are alloys. The only difference is the carbon concentration in these alloys. In addition to iron, cast iron usually contains up to 4% carbon, and steel - up to 2%. At first glance, it may seem that the difference between the materials is not significant. However, in practice this is not at all the case. In steel, the determining element that affects quality is the number of alloying elements. In cast iron, the main thing is the molecular structure and production technology. It is these factors that determine the thermophysical characteristics of the future furnace and its strength.

One of the main characteristics that you should rely on when choosing the metal from which a sauna stove is made is reliability, its maintainability and price. Having examined each of the two options for metal furnaces in more detail, the following conclusions can be drawn.

The principle of heating cast iron and steel stoves

Both steel and cast iron sauna stoves have similar heating principles. The main fuel for them is wood. True, more modern models can use wood briquettes and pellets for heating. And models with a large firebox and a large ash pan can theoretically be heated even with coal. But still, the main fuel is firewood.

Depending on the design, stoves come with conventional and remote fireboxes. The first ones are installed and heated in the steam room itself, while the second ones have the firebox taken out to another room, from where fuel is loaded through the door.

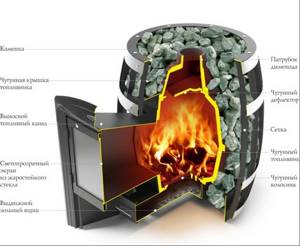

The design of cast iron sauna stoves is extremely conservative - the properties of the material do not allow sudden cooling of the metal surface, so the body is lined with a thick layer of stone, since the metal conducts heat well and contributes to long-term heating of the heater. Most stoves have a simple design - there is a firebox in the lower part of the ash pan and in the upper part. Smoke is removed through a chimney pipe. Additional equipment in the form of a heating water tank and a basket for stones are made of steel and are put on the body after installing the stove.

The lighting of both types of stoves is carried out traditionally - paper, small splinters and wood chips are placed in the firebox, and a layer of small logs is laid out on top of them. Air is supplied through the blower door or through a special damper. But the chimney usually does not provide dampers; this is still a bathhouse, and not a house with a chimney system.

There is also no big difference in the heating procedure - the main thing is that at the lowest point of the steam room the temperature quickly reaches 40-45 degrees. Depending on the height of the room and its volume, the temperature at the top point will thus have a heating range from 80 to 110 degrees, depending on the wishes of the visitors. But a cast iron stove still has a slight advantage - it holds heat longer, and therefore a small amount of firewood is enough to maintain the desired temperature in the steam room within the desired range.

Which company should you choose?

In Russia there are a number of companies specializing in the production of cast iron and steel heating devices not only for residential or industrial premises, but also for baths and saunas.

Among them, experts highlight the following:

- Teplodar is a company with original patented technologies and its own development of materials that ensure the reliability and durability of furnaces, resistance to temperature changes and damage. A high-quality production process control system reduces the risk of burnout or damage to walls and parts to almost zero;

- Vesuvius - unusual stoves with original design. The brand offers a wide range of models in various styles: from classic to avant-garde. The second advantage of their furnaces is their affordable price, ease of installation (with rare exceptions) and high efficiency rates due to the design features of the walls;

- ETNA are productive and highly thought-out stoves with precise calculations of the thermal load on all elements. This approach allowed the manufacturer to reduce the wall thickness without loss of efficiency, and accordingly reduce weight, metal costs and product costs;

- Termofor - the main feature of their products is the smooth heating of the room and soft steam, which is achieved due to the special shape of the elements, which, in turn, provide the necessary density and power of heat flows. The models are easy to install and affordable; there are options of different power for different areas.

The difference between cast iron stoves and other sauna units

First of all, it is worth focusing on the duration of operation. If the bathhouse is heated on weekends and the temperature in it does not drop below 0 degrees, that is, it simply does not have time to freeze, the service life of cast iron can be safely counted on for half a century. Potbelly stoves, for example, cast back in the days of the cult of personality still do an excellent job of heating garages today. But if the room does freeze, then cast iron has an undeniable advantage - it rusts 2 times slower than steel. Compared to brickwork or lining, cast iron does not absorb water and is not prone to cracking when heated.

Despite the apparent massiveness, cast iron has a small mass, therefore, for installation, cast iron sauna stoves do not require large and massive foundations, such as for brick buildings. On the other hand, it has a large mass, which is 40-60 kg; on such a base you can easily install a basket for 50-70 kg of stones and a water tank with a capacity of 80-100 liters. This design, when properly balanced, is not afraid of tipping over.

Compared to steel devices, which have one bottleneck - a weld, cast iron stoves, assembled from individual elements, the cavities between the parts are necessarily filled with a high-temperature adhesive. This composition can easily withstand heating to temperatures of 1500-1700 degrees.

And of course, it is worth paying attention to the fact that cast iron, unlike brickwork and steel stamping, has a special charm when it comes to artistic design. Stoves with openwork casting have a more interesting appearance and look very stylish.

Correct installation of the stove in the bathhouse

Installation will require several hours of free time. Consider the location of the equipment. It is most convenient to place it in a separate room between the relaxation room and the steam room. If you want to install it directly in the steam room, then place it so that the stove does not interfere with free movement in space. But keep it away from wooden walls and other flammable objects and surfaces. It is a good idea to equip the room with special heat-insulating screens that will prevent the room from overheating.

For the stove, you will need to lay any non-combustible material on the floor, for example, a sheet of metal and smooth slate. You can also lay out a special base for the stove made of brick or masonry. If you have purchased a model that is far from your ideas about the ideal design for a bathhouse, you can cover it with brickwork. But these costs need to be taken into account in advance.

A cast iron stove is very heavy, because on average its weight is 200 kg, and therefore you need to prepare a good foundation for it. For this purpose, it is recommended to make a concrete screed at its future location. When the floor preparation is completed, move the dismountable structure into the room and begin assembling it according to the instructions provided with the product. Apply sealant to all joints, which is usually added to the kit.

Once the main elements of the cast iron stove have been assembled, proceed with the installation of the chimney. Install the insulation into the prepared hole in the bathhouse ceiling. Place one end of the smoke channel into the outlet of the stove, and insert the other into the ceiling hole. Carefully fill all gaps between the pipe and other surfaces with heat-resistant sealant and tighten with clamps. When all the work is completed, you need to try to ignite the unit to check the quality of the installation. Before further regular use, the stove must be heated 3-4 times to remove foreign odors from the primer materials.

During the first kindling, first check the tightness of all joints and determine the presence of draft.

Bring a lit candle or match to the firebox vent and watch the behavior of the flame - if it rushes into the stove, it means the draft is normal. Place small wood chips, paper and small logs in the combustion chamber and set them on fire. If after the fire burns out there are no signs of soot on the external connecting seams, then the smoke channel is connected hermetically. Otherwise, you will have to wait until the oven cools down and re-insulate all joints.

Cast iron stoves pros and cons

At the same time, it is worth remembering what the pros and cons of cast iron sauna stoves are. This is especially true when choosing a stove for a specific bathhouse project; here it is worth considering not only the general characteristics of the material, but also the parameters of a specific model. Although when choosing, most people pay attention to the general advantages of cast iron stoves:

- High thermal conductivity and efficiency. For cast iron models it reaches 80-82%;

- High strength and durability;

- They are well preserved even in conditions of high humidity;

- They do not require special care and maintenance;

- Light weight compared to brick buildings;

- They have a large number of accessories, such as glass doors or special linings;

- This is one of the safest types of stoves.

As for the downsides, there are really few of them:

- High and sometimes exorbitant price of the product;

- Not everywhere it is possible to purchase a stove right away; most often, such accessories are supplied to order upon prior request.

What is the difference between steel and cast iron

Without going into subtleties and details, they differ in the amount of carbon. Steel contains from 1.5% to 2% carbon, cast iron contains more than 2%. This seemingly not very significant difference actually has a strong impact on the characteristics: steel is denser and stronger, it is forged, cut and welded. Cast iron has a looser structure, but at the same time has a greater heat capacity. It can only be cast. Cast iron cannot be processed in any other way and therefore cast iron stoves are practically not subject to repair. You can only order a burst element from the manufacturer and, after disassembling the stove, replace it (these units have a modular structure).

Metal wood-burning stoves for saunas. View - for every taste and can heat any room

Based on these characteristics, it follows that it is easier and faster to manufacture steel products: we made blanks, welded them and received the product. Corrections are needed - changes have been made. It's simple. Cast iron products can only be cast. In short, the process is this: the product was divided into parts, a method for connecting them was developed, mock-ups were made, a mold was made from them, then cast iron was poured into the mold, the parts were obtained, and assembled. Any change made and the process repeats again. Such production is too complex and cumbersome. That is why there are so few cast iron products on the market and their range is so small. It's a pity. After all, our ancestors made truly amazing things from cast iron. Here are just some photos of old cast iron stoves (see more at the end of the article).

Antique cast iron stoves are a miracle

But production difficulties are not the whole story. If we talk specifically about sauna stoves, cast iron has one bad property: it bursts when the temperature changes. True, we are talking about thin sheet cast iron, but stoves are made specifically from sheet cast iron. And in a bathhouse, where there is always a danger that water will get on the hot stove, there is a very high probability that the cast iron stove will crack. And there is no way to weld/solder the crack: cast iron is only cast and not repaired in any way.

The disadvantages and advantages of cast iron and steel as materials are clear. Now about the advantages and disadvantages of sauna stoves made of each material.

How to choose the right cast iron stove for a sauna - expert advice

First tip

In the first case, it is recommended to choose a device that corresponds to the parameters of the steam room specified in the project or to choose a device a little more powerful than the recommended power. The fact is that a device designed for a smaller area simply cannot cope with heating a large steam room. Even if it is heated with the best oak wood, it will not make the steam room warmer. Therefore, it is better to take a device a little more powerful.

Second tip

The second point is the quality of the product. A sauna stove is not an electric kettle or a vacuum cleaner. Poor assembly, incorrectly molded parts or a door that simply cannot be adjusted due to the quality of the casting will spoil the mood much more. The fact is that famous manufacturers highly value their name and really know a lot about a real bathhouse. Therefore, the products are sold with a 25-year warranty and a bunch of certificates and instructions. The same cannot be said about the products of small factories and artisan workshops. In fact, branded products are a unique creation, the biography of which can be checked using a unique code on the company’s website literally from the moment of casting to the place where it was sold.

Inspection of structural elements

And of course, experts advise you to carefully examine the following structural elements:

- Case – the inlaid case has a surface of the same texture, the metal has a slight roughness, the ends of branded models are carefully processed and polished;

- All parts of the body are tightly fitted to each other, the glue between the plates is neatly trimmed, it does not protrude and does not leak;

- The openwork casting is carefully processed, the surfaces have clear outlines;

- The doors fit tightly to the body, the handles and locking devices have no backlash and firmly fix the doors;

- A non-flammable seal is installed between the body and the door;

- If glass is inserted into the door, it has a neat frame and reliable fixation;

- Inside the firebox, the metal has the same texture, there are no sagging, craters or traces of processing;

- The outer coating is made of heat-resistant paint and has a quality certificate.

Features of operation

When operating cast iron products that are subject to strong, constant heat, it is necessary to remember fire safety rules and carefully follow them. This will help not only avoid fire, but also extend the life of the stove.

The main disadvantage of cast iron is that it is susceptible to corrosion. Therefore, the installation of the product is carried out in a room devoid of sources of moisture. If damage has been caused or there are cracks on the product, they must be repaired in a timely manner to avoid damage to the unit.

You should also use the correct fuel for your stove. In Russia, summer residents most often lay firewood. There is no point in buying peat or pellets, since firewood is the most affordable type of fuel.

The type of logs must also be taken into account. Firewood should not protrude beyond the firebox, as this can lead to fire and untimely damage to the stove.

It is imperative to monitor the level of ash and clean the unit from it as often as possible. This extends the life of the cast iron stove and helps keep it looking beautiful and presentable. A cast-iron wood-burning sauna stove with a water tank requires careful treatment and it is highly not recommended to clog it with ash, dirt and debris.

The cast iron sauna stove is very easy to install and is ready for use immediately after installation. It significantly outperforms its brick and steel counterparts due to its strength, quick heating and independence from the season, which is ideal for use in our conditions.

Homemade stove made of cast iron pipe

One of the alternatives to branded cast iron sauna stoves is a homemade stove made from a cast iron pipe. The availability of the material allows us to talk about the possibility of creating such a device. For this, pipes with a diameter of at least 50 cm are usually used. The wall thickness of such pipes should be 10-12 mm. For construction, you will need a section 80-100 cm long. Since cast iron is difficult to weld at home, the blower can be made of brick or the section can be installed on a steel platform. The grate is welded from reinforcement with a thickness of 14-16 mm. The top cover is made of steel sheet 8-10 mm thick. The only difficult element of the design is the door, but even here you can get out of the situation by attaching the door hinges to the bolts.

Maintainability

As for maintainability, it is better to repair a stove made of steel. Repairs are made using conventional welding. However, a seam made by an unprofessional welder will most likely not bring the desired benefit, but rather the opposite. Loss of the firebox geometry will lead to the need to completely replace the sauna stove. Repairing a cast iron stove by welding will not work at all.

Cast iron is generally difficult to repair. However, if the cast iron stove initially has a prefabricated structure, then the part in need of repair can simply be replaced with a new one, if this is provided by the manufacturer.

Another advantage of cast iron is its resistance to corrosion. He is practically not exposed to it. An oxide film simply forms on the surface of cast iron, protecting it from the spread of corrosion. Destruction does not go deep into the metal. This wonderful effect is also known as passivation. Steel can also resist corrosion, but thanks to alloying. The final price of the furnace directly depends on the number of alloying elements in the composition.

Is the quality of cast iron the same among different manufacturers?

Even outwardly identical stoves can show themselves from different sides during use.

It's all about the composition and quality of materials.

The cast iron alloy does not have a clearly defined “recipe”; components in different proportions and additional additives can be added to it.

Quality is also affected by compliance with production technology (hardening, tempering).

Most sauna stoves are made from gray cast iron (GC). It differs in brands SCh-10, Sch-15, Sch-20, etc. These differences relate to tensile strength and tensile strength, but have nothing to do with heat resistance. Thermal conductivity depends more on the structure than on the constituent components.

True alloyed heat-resistant cast iron contains graphite and responds better to temperatures. Nickel (up to 19%) and chromium (up to 3%) are two more important components of a good alloy.

Price

Another criterion that concerns future stove owners is its cost.

The cheapest option is a steel stove. Not only does it cost a little, but it also does not require additional steps on the part of the installer. They can be located on the floors of the first floor, which makes such stoves very cheap. However, in bathhouses the iron stove is often lined with bricks. This is done to increase its heat capacity. Such heating devices can retain heat longer than their “naked” counterparts. Thanks to the uniform distribution of thermal energy, the stoves will not be very aggressive to careless touches, but even a stove lined with brickwork is not recommended to be touched.

The average price is a cast iron stove; a high-quality model is several times more expensive than the steel version. Such structures require additional arrangement of the site to evenly distribute the load over the base.

Stone stoves for the home will cost the largest amount. This is due to the skill of the stove maker. It has been very difficult to find real professionals in their field lately; they are usually called on the advice of friends. Only when working with a trusted person can you hope for his conscientious work.

Key points when choosing

So, how to choose a wood-burning stove for a sauna, and specifically a cast iron one? What nuances should you focus on when purchasing? Let's start in order.

- We determine the cubic capacity (volume) of the steam room. Based on this, we select the required power and model of the stove. Each manufacturer indicates on their product the volume of the room for which this stove is designed. It would be reasonable to add 20-30 percent to this power. Let there be a small reserve of heat. But purchasing a stove with a “large power reserve” is not advisable.

- We decide on the type of firebox. As already mentioned, the extended remote combustion channel is much more practical than the conventional option. But cast iron stoves with non-removable fireboxes are perfect for small spaces. And the owners of the country mini-sauna will be very pleased.

Cast iron stove

Cast iron stove with stone casing

Cast iron sauna stove

- We decide on the location of the hot water tank. It can be hinged and located on the side, on top or along the perimeter of the stove. The best option is a remote tank that can be located outside the steam room. The water is heated by a coil in the firebox, and if it boils, it will not cause discomfort during steam procedures.

- We decide on the design of the stove. They can be either with an open (ventilated) or with a closed heater. In the closed version, the resulting steam is softer and more moist. This temperature and humidity regime is more suitable for a Russian bath. And for a Finnish sauna, open stones are the best option.

- The price issue is also a very important parameter. Some people do not install cast iron sauna stoves for this very reason. Quite often, good stoves are reputable. It’s unlikely that an ordinary worker is ready to shell out such a sum.

In conclusion, I would like to say a few words in support of the domestic manufacturer. Such world-famous brands as Harvia, Edilkamin, Guca and others will charge you money for their name. Our Kalita, Firebird, Karelia, Sudarushka and others also do an excellent job with their intended purpose. But ultimately, the choice, as always, is yours. Happy purchasing!

Wisdom Quote: Conversations are invented to stop people from thinking.

Cast iron

The manufacture of cast iron stoves requires casting, so only steelworkers at the factory can make it themselves. Such installations must be purchased from trusted companies with good reviews.

But after purchasing, you can connect this heat source yourself. To do this, it is enough just to place the stove in its permanent place and ensure that combustion products exit into the street. The walls closest to the installation must be finished with non-combustible material. Basalt fabric is used as it. You can mount metal sheets, it will be much cheaper, but the metal near the furnace will certainly heat up and pose a threat to careless people passing by.

Steel

Installing a steel stove is the simplest. To do this, you don’t even have to ask the movers to deliver it to the place. Steel models weigh little and therefore can be installed without outside help. As is the case with cast iron installations, steel ones require a chimney device and protection made of non-combustible material.

The choice of stove depends on the requirements of the home owners. steel options are chosen by lovers of summer holidays in the country. The equipment can be installed independently, it does not require maintenance and, if necessary, heats the room very quickly.

Cast iron stoves can be used year-round, are durable, and appeal to weekend getaways year-round.

A stone stove is an ideal option for people who permanently live outside the city or come to their dacha with enviable regularity.