One of the effective ways to solve the heating problem in a private home is to build a stove. It is located in the wall area between the kitchen and living room. Design features ensure high operating efficiency with rapid heating and heat transfer to the adjacent room. This is how the ideas of Swedish stoves with a stove bench, fireplace or hob were born.

Furnace design

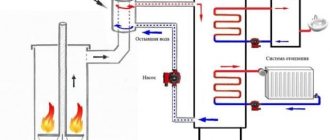

During operation of the heating system, heat exchange occurs in the bell part of the furnace, which is located on top of the firebox and drying chamber. In this case, gases from the firebox enter the pipe through a duct-type chimney.

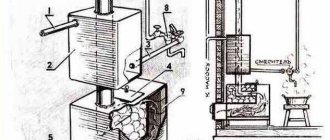

Structurally, the following features are distinguished:

The large oven is made of cast iron. Its role is to accelerate heating, which begins immediately after lighting the stove. Since the oven is located below the firebox or at its level, a lot of thermal energy is released as a result of reburning the wood. This leads to hot air entering the room, coming from bottom to top.

The upper niche is heated by primary and secondary heat. The temperature in this zone is constant. Here you can conveniently dry several sets of clothes.

The recess above the surface of the hob plays the role of a thermos.

Thanks to the view, which must be closed immediately after the end of the combustion process, the heat is retained for a long time.

The back surface, as can be seen in the photo of the Swedish stove, acts as a wall leading into the room. A couch or fireplace is installed here.

What guided scientists when developing the Swedish stove?

A Swedish oven is a combined structure made of brick. In the process of its development, a rather specific climate was mainly taken into account, living in which had to be made more comfortable.

The Siberian frosts of Sweden, combined with high air humidity, and the proximity of the Baltic and Atlantic with the Gulf Stream influenced the decision to create an improved version of the stove. As mentioned earlier, the shortage of free territory and fuel also contributed significantly to this decision. In addition, it is known that Sweden had a significant supply of high quality fireclay clay, a heat-resistant material with excellent characteristics, which is the basis for the production of fireclay. The fireclay clay of Sweden is the finest aluminosilicate deposits, in the place of which there was a glacier for a long time. In the manufacturing process of furnaces, other types of fireclay (zircon, corundum material) are also used, which are particularly durable and have increased heat resistance, which is reflected in their cost.

The lifestyle of ordinary people was of great importance. There was little arable land, swamps and boulders all around, and harsh climatic conditions. To survive until spring, we had to work hard every day. In winter, the Swedes could not afford to sit idle. Since Denmark and Norway took over the fishing grounds, and the Baltic Sea froze, all that remained was to engage in logging, mining, and hunting. There are a lot of valuable materials in Fennoscandia, which helped the Swedes a lot. Even now, opals are often discovered in the tundras of Finnish Lapland.

As a result of such difficult work, the owner and his sons came home tired and wet to the skin; it was important to warm up so as not to get sick, and to dry things that needed to be put on again in the morning and go to work. Since it was not possible to light the stove in advance due to the high probability of being left without fuel until the end of winter, the academics created a stove that heats up quickly and provides sufficient heat.

Advantages and disadvantages

Before deciding how to properly lay a brick wall, you need to evaluate all its advantages and problem areas.

Experts highlight the following advantages:

- compactness – base area up to 1 sq. m and height no more than 2 m;

- possibility of use both for heating and for cooking, relaxing, and drying things;

- excellent performance indicators - high efficiency and heat transfer;

- simplicity of design;

- decorative function of room decoration;

- the ability to regulate heating modes;

- efficiency of heating;

- ease of maintenance and infrequent fuel stowage.

Effective use of the Swedish stove is only possible with regular combustion processes. If the room is not heated too often, then it is necessary to dry it.

The optimal area for a heated room is considered to be 40 square meters. m. When laying a stove, you must use high-quality raw materials, and the door of the combustion chamber must be cast.

Firebox door

When operating a stove, the combustion door often suffers due to high heat loads. If you take a door made of cheap material of poor quality, it quickly becomes loose and sometimes even falls out. It is desirable that the door be cast, with a mustache that is walled into the masonry. You can make these whiskers yourself; just weld pre-annealed steel wire (length from 50 to 70 mm, diameter 3 or 4 mm) to the edges of the product. Homemade mustaches are directed in different directions so that their location corresponds to the letter V, and the distance is 40-50 mm, after which they are walled up. To obtain a reliable door, you must additionally use a steel strip or corner.

Varieties

It is important to understand what types of Swedish stoves there are, since the layout and location in the house will depend on this. The following models are popular:

- with a fireplace, when the stove for cooking is turned towards the kitchen, and the fireplace is directed towards the living room;

- Swedish stove with stove and oven - used for heating the entire room;

- with a couch for a comfortable rest while simultaneously heating the house.

Regardless of the chosen type of structure, it is necessary to correctly determine the pipe cross-section parameter. To do this you need to know:

- dimensions of the combustion chamber by multiplying the length of the firebox by its width and height;

- specific calorific value of fuel - tabular data is used.

When calculating heat transfer, the calorific value in specific units is multiplied by the volumetric characteristics of the firebox. The resulting value is multiplied by:

- Efficiency – 40%;

- combustion level – 80%;

- fuel load level – 63%.

Application of metal

The less iron is used in the construction of the furnace, the more reliable the structure is. But since Swedish scientists had the goal of creating an economical version of the stove, they made a cheaper design, which included iron corners and strips, and reduced its height. In villages, houses have low ceilings, which is why the Swedish stove was made small.

Structures containing iron in their construction have been time-tested and proven effective in heating houses. When using iron, you should follow the rule that exists for fireclay - do not place the material on bare brick, do not place it closely. A layer of mortar 6 mm thick is created on all sides of the iron, with the exception of the outer side. The slab is also laid using mortar, having prepared quarters in the bricks.

Foundation arrangement

The depth of the bookmark may vary. It is determined by the nature of soil freezing in winter and averages 80-100 cm. The width of the foundation should be 10-15 cm greater than the size of the stove itself.

- Bolt cutters and rebar shears

- Long-burning boilers: review of the best models of 2021 + instructions for beginners

Hydraulic rescue tool - how not to make a mistake when choosing

A 15-20 cm layer of sand is placed at the bottom of the dug trench, which will level the surface, provide drainage functions and redistribute pressure on the ground. Coarse crushed stone, fragments of brick or natural stone are poured on top and cement mortar is poured for strength.

To secure the concrete and regulate temperature, a reinforcing mesh is laid 10-15 cm before the start of the screed layer. Instructions on how to make a Swedish oven suggest the need to waterproof the foundation.

To do this, after the concrete has been leveled and hardened, roofing material is laid out in 2-3 layers. You can also use roofing felt or synthetic materials with foil.

At the last stage, it is necessary to make a hole for the masonry, and then increase the covering in the area adjacent to the base of the stove. Skirting boards are installed here. Timber logs can be attached to the floorboards with self-tapping screws.

Construction

Compliance with the required proportions and sizes

Academicians spent a lot of time choosing the right dimensions, determining the proportions of the fuel part, and performing various calculations. All these calculations are important to obtain a quality stove.

Requires 28" x 16" slab.

The dimensions of the firebox should be as follows:

- height - from 11 inches, but not more than 13;

- width - from 12 inches, maximum 14;

- depth - ranging from 16 inches to 20.

The following dimensions are available for the oven:

- height - about 11 inches (no more than 12);

- width - on average 14 inches (not less than 13, but not more than 15);

- depth - up to 20 inches (not less than 18)

The oven must have walls corresponding to a certain thickness - from 1/6 inch to 1/4, required approx. is 4-6 mm.

The grate should be positioned 0.75 to 1 foot from the oven wall, which is equal to a certain amount of brick - 0.75 to 1 brick.

It is very important to make an oven with normal wall thickness. You should not use roofing iron of small thickness, since the oven will quickly burn out, but it is also not recommended to choose too massive a material due to rapid heat removal and slow heating of the premises, the consequences of which are underburning, low efficiency, and the deposition of a large amount of soot. The same goes for stoves, special steel, cast iron - ideal materials because they conduct heat poorly. The burners should heat up, not the stove itself.

Sizes and proportions are important and should be observed. For example, if during the construction process the minimum dimensions of the firebox are used as a basis, then other parts of the stove must also comply with the minimum dimensions. If the depth of the firebox is too small, the efficiency decreases, and if it is very large, there are underburning and other consequences.

Heat is generated not only on the sides of the oven, but also behind it, which means that a gap (at least a quarter of a brick) must be left between the walls of this part and the firebox. The firebox and oven can be moved as much as possible if the wall of the oven, which is closest to the firebox, is protected from the effects of fire using asbestos or a layer of vermiculite.

Photos of Swedish stoves

Classic version

Let's consider a variant of the furnace that is closest to the structure, the drawing of which was made by Konstendt and Werd. The only external difference is the presence of a shelf instead of a niche.

In modern conditions, a niche is not as necessary as it once was; now it is more convenient for people to use a shelf.

To create such a Swede, the least amount of materials is required. You need to prepare:

- 30 and 540 pcs. fireclay and red brick M200, respectively;

- one sheet of galvanized steel 0.6 mm thick;

- 1.35 meters of metal strip measuring 50x5;

- 5.25 meters of steel angle measuring 40x40.

The accessories required are an oven with dimensions of 500×330×280 mm and three cleaning doors, otherwise the set is standard, as in the previous version, and includes one position of each element.

The stove does not have a summer operation, so it is created as simply as possible. The structure turns out to be economical and efficient; it is built mainly from whole bricks. In addition, the process eliminates the need to trim anything when doing masonry. In the summer, cooking in villages is usually carried out in summer kitchens; a Swede is not particularly needed during this period.

The thermal power of the structure is 5 kW, if two fireboxes are fired every day, the heat output corresponds to 3500 kcal/hour, which is quite enough for an area larger than 50 square meters. m. Such a Swedish stove can withstand overheating up to 30 or even 40% of the thermal power, which allows the house to be supplied with hot water.

Tools

A set of tools for laying a Swedish stove with your own hands, for both an experienced and a novice stove maker, should consist of:

- trowel (trowel) - the main tool used to take the masonry mixture from the container and apply it to the surface of the brick, as well as clean the rows of masonry from excess mortar that has protruded between the seams;

- hammer (pick) - the narrow nose of this hammer is used to trim and split bricks for laying corners and curved elements;

- jointing - used to design horizontal and vertical seams;

- plumb line - control the verticality of certain parts;

- rules - check the quality of fresh masonry and level the surface of the foundation;

- square - to check the right angles of the structure;

- cord - mooring or building level - to check the evenness of each row:

- rulers, tape measures;

- shovel;

- containers - for preparing masonry mortar;

To fill a monolithic support, you will need a tamper - it is compacted with concrete, as well as another container, a shovel, a probe and a metal sieve for sifting non-metallic materials: sand, crushed stone and clay.

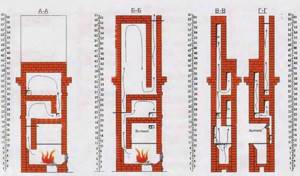

Hob

Any Swedish stove is a heating and cooking stove. This means that the firebox is covered by a cast iron stove with burners on which you can cook. A standard size stove is used; naturally, the device is adapted to our two-burner product 410 X 710 mm. For culinary manipulations, two modes are used - winter and summer. The summer direct passage opens when the main smoke circulation is cut off using valves, this allows you not to overheat the kitchen in the warm season. To ensure that the surface heats up well, the firebox is made relatively small in height - from 280 mm to 330 mm. Its width is up to 350 mm, and its length is up to 505 mm.

Important! For any changes in the size of the firebox, it is necessary to change all its other dimensional parameters in order to maintain the optimal proportion. Otherwise, there may be significant loss of device performance.

Arranging a small Swedish oven

Construction Materials

To build a Swedish stove with your own hands, not counting the construction of the pipe, you will need materials and stove fittings in the following quantities:

| No. | Name of materials and fittings | Unit measurements | Quantity |

| 1 | Red kiln brick | Thousand PC. | 0,92 |

| 2 | Fireclay brick | PC. | 215 |

| 3 | Sand | kg | 200 |

| 4 | Oily clay | kg | 250 |

| 5 | Fireclay mortar | kg | 160 |

| 4 | Blower door 14x25 cm | PC. | 1 |

| 6 | Fire door 21x25 cm | PC. | 1 |

| 7 | Cleaning door 7x13 cm | PC. | 3 |

| 8 | Valve for smoke duct 13x26 cm | PC. | 2 |

| 9 | Cooking plate 31x61 cm | PC. | 1 |

| 10 | Grate 25x40 cm | PC. | 1 |

| 11 | Steel strip 50x5 mm | m | 5 |

| 12 | Angle steel 60x60x5 mm | m | 0,8 |

| 13 | Sheet steel 50x70 cm | m² | 0,35 |

Characteristics

The base of the oven is 3x4.5 bricks. The dimensions of the bed are 2.5x7 bricks. The heat output of this design approaches 3500 W. This is quite enough for a room of 35 sq. meters it was always warm. Therefore, there is no need to provide heating to the room.

"Swedish" can operate in two modes:

- Summer;

- Winter.

To increase the reliability of the product, the firebox, together with the adjacent channels, is equipped with a lining for the construction of which fire-resistant bricks were used.

Historical reference

This type of stove came to us from Sweden, a country with a rather harsh climate and without large reserves of fuel. In addition, most Swedish dwellings are of a fairly small area, in which the construction of massive and large stove structures was not possible. In addition, Sweden is famous for its deposits of fireclay clay, which is used to make such structures. Therefore, it is not at all surprising that it was in this country that the first models of such a stove appeared when heating of small houses and cooking were required.

Swedish stove in country style

Equipping the stove with a hob and the compactness of the entire structure ensured heating the room in a fairly short time and preparing food for the whole family, while consuming fuel economically.

Swedish brick oven

Tips for use

Before the start of the heating season you should:

- inspect the stove for cracked seams and broken bricks. If defects are found, then the seams must be filled with clay-sand mixture and the masonry elements must be replaced;

- clean soot from all cameras and channels to which you have access. Cleaning hard-to-reach passages can be done the old way - by heating the stove with aspen wood and potato peelings, or using modern means, of which there are plenty on sale.

Firewood must be prepared in advance so that it is dry and stored in a well-ventilated area or under a canopy.

Why is it profitable to make heated floors?

The main advantage of heated floors over all other types of heating is that they are hidden from view and are ideal for families with small children. In addition to the fact that babies can crawl safely, they will not get burned on heat sources that are securely hidden under the finishing coating. There are no drafts in the room where heated floors are installed.

Warm floors reduce heating costs in houses with very high ceilings, where it is difficult to rationally organize heating of the entire volume of the room. In apartments located on the ground floor, above damp, cold basements, heated floors will provide a comfortable microclimate.

In addition, they do not dry out the air, which is especially appreciated by sensitive people prone to allergies. When heated floors are an autonomous type of heating, they will help out on cold days in the off-season. Ceramic tiles, even with the best heating system, remain cold, and here the use of warm floors will help out.

Thus, the decision to install heated floors is for the benefit of the health of family members

It is important to choose which system is best to use

Which brick is more suitable for masonry

Brick for laying a furnace must meet a number of requirements and standards. Not only the durability of the structure, but the safety and life of those living in the house will depend on the correct choice of material. Modern manufacturers offer us a lot of varieties of special bricks. Their common distinguishing features are fire resistance and resistance to high temperatures. Bricks for stove masonry are conventionally divided into two large groups: fireclay and solid. The former have high fire resistance, so they are used for laying out fireboxes where the fire source is located. They are intended for those furnaces that use coal or gas as fuel - during their combustion the highest temperatures are generated

If the stove is intended exclusively for heating with wood, then the use of this material is not so important

Solid bricks are made from clay and fired using a special technology. They are moisture and heat resistant, as well as fireproof.

When choosing building materials, it is very important to purchase high-quality products and not forget about the aesthetic appearance. By using special shaped materials - corner brick or round brick - the fireplace stove can be given a solid, elegant appearance without additional external finishing, which will allow significant savings